1. What is a Recloser?

A recloser is an automated high-voltage electrical switch. Similar to a circuit breaker in household electrical systems, it interrupts power when a fault—such as a short circuit—occurs. However, unlike a household circuit breaker that requires manual reset, a recloser automatically monitors the line and determines whether the fault has cleared. If the fault is temporary, the recloser will automatically reclose and restore power.

Reclosers are widely used throughout distribution systems—from substations to utility poles in residential areas. They come in various types, including compact single-phase reclosers for single-phase lines and larger three-phase reclosers for substations and high-voltage distribution lines up to 38 kV.

Recloser design and performance are governed by international standards such as ANSI/IEEE C37.60 and IEC 62271-111.

2. Why Use Reclosers?

Automatic circuit reclosers are regarded by electric utilities worldwide as essential devices for achieving their core objective: delivering the most continuous and reliable power supply to customers in a simple and cost-effective manner.

Reclosers can detect and interrupt fault currents, then automatically restore power once a temporary fault has cleared. Essentially, a recloser is a self-contained intelligent device capable of sensing overcurrent, timing, interrupting fault current, and automatically reclosing to re-energize the line.

If the fault is permanent, the recloser will lock out after a preset number of operations—typically three to four attempts—thereby isolating the faulty section from the rest of the system. This capability saves utilities significant time and operational costs, as power is often restored after only one or two brief voltage flickers, without any need for field intervention.

In cases where crew dispatch is unavoidable, reclosers help minimize the outage footprint and assist maintenance personnel in quickly locating the fault and restoring service. Residential, commercial, industrial, and institutional customers all benefit from reduced disruption and associated costs. Without this high level of supply reliability, many critical modern loads—such as computers, water pumps, and automated production lines—would struggle to operate reliably.

3. How Does a Recloser Operate?

When a fault occurs on the line, the recloser detects it and automatically trips to interrupt power. After a very short interval—often so brief it only causes a momentary light flicker—the recloser attempts to reclose and restore power. If the fault persists, it trips again.

After typically three unsuccessful attempts, the recloser classifies the fault as permanent and remains open (locked out). At this point, utility crews must visit the site to repair the damaged infrastructure and manually reset the recloser to restore power.

Typical permanent faults include:

Lightning damage to conductors or equipment

Tree limbs falling onto and damaging lines

Vehicle collisions with poles or hardware

4. What Are Temporary Faults?

The majority of faults on overhead distribution lines are temporary. Examples include lightning strikes, wind-blown conductors, or momentary contact caused by birds or small animals. These faults typically self-clear once power is interrupted and cause no lasting damage to the line.

Common types of temporary faults:

Wind-induced clashing of conductors

Flashover along insulator surfaces due to lightning-induced overvoltage

Momentary bridging between live conductors and grounded parts by birds, rodents, or other animals

Tree branches briefly contacting energized lines

Switching surges causing insulator flashover

Long-term operational data and field experience clearly demonstrate the importance of the “trip-and-reclose” function. If the line is de-energized momentarily, the fault source often disappears—making successful reclosing highly probable. Thus, automatic circuit reclosers virtually eliminate prolonged outages caused by temporary faults or transient overcurrents in distribution systems.

5. Recloser Types

5.1 Single-phase reclosers

Single-phase reclosers are used to protect single-phase circuits, such as branch lines or tap-offs from a three-phase feeder. They can also be deployed on three-phase circuits where the majority of the load is single-phase.

In the event of a permanent phase-to-ground fault, only the affected phase is locked out, while the remaining two-thirds of the system continues to supply power—enhancing overall service continuity.

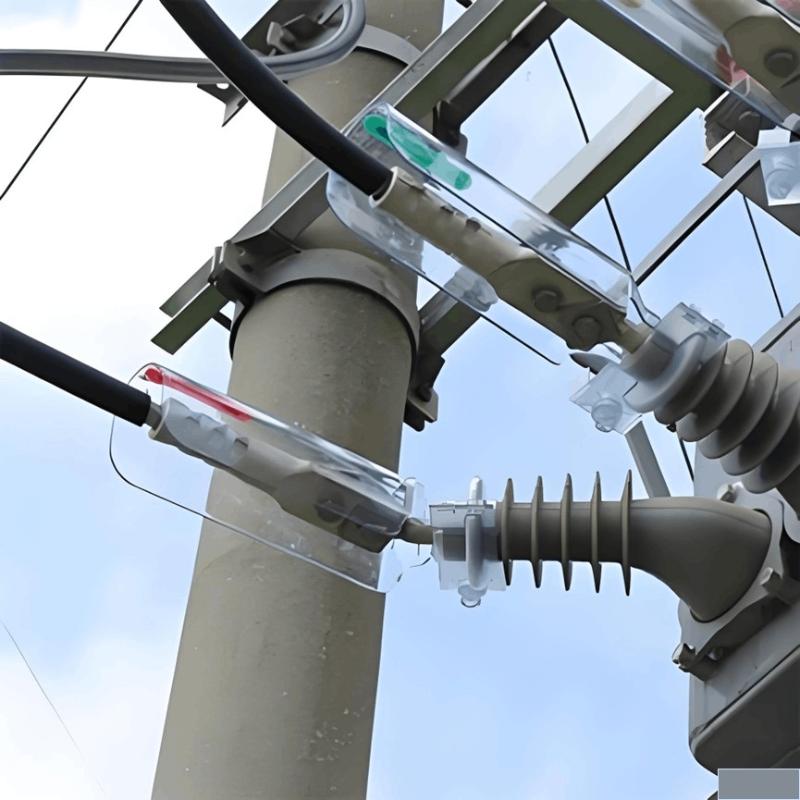

Due to their lighter weight compared to large three-phase reclosers, single-phase units are typically mounted directly onto utility poles or substation steel structures using their integrated mounting brackets, eliminating the need for additional support frames.

Depending on the design, single-phase reclosers may feature either hydraulic control (integrated within the recloser’s oil tank) or electronic control (housed in a separate control cabinet).

Notably, single-phase reclosers are now also available in a cutout-style form factor, representing a high level of integration between primary and secondary components. These can be installed directly onto standard fuse cutout mounting bases and are commonly used for branch circuit protection, with typical rated currents up to 200 A.

A representative manufacturer is S&C Electric Company (USA), whose TripSaver® II product exemplifies this type, as shown below:

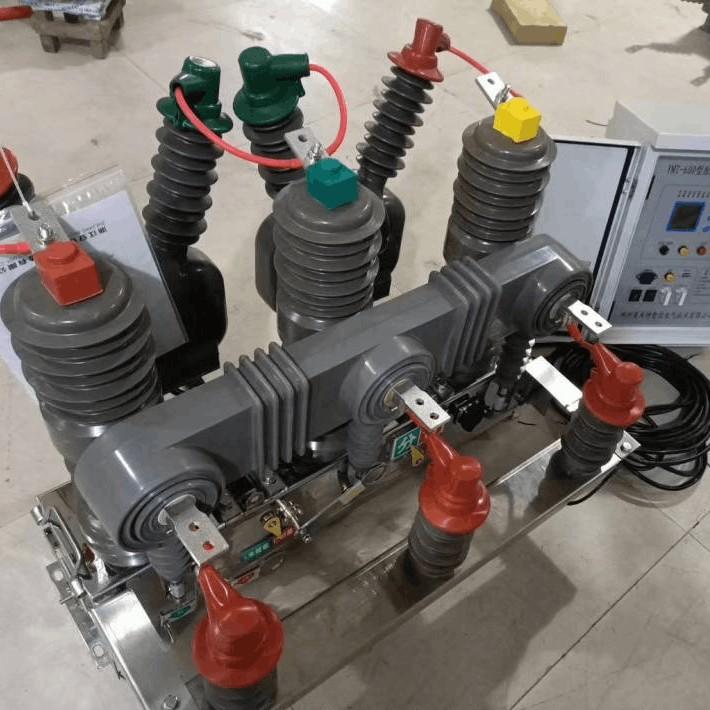

5.2 Three-Phase Reclosers

Three-phase reclosers are used on three-phase distribution lines to enhance system reliability. In the event of any permanent fault, all three phases are simultaneously locked out, thereby preventing the risk of single-phasing for critical three-phase loads—such as large three-phase motors—which could otherwise be damaged by unbalanced or incomplete voltage supply.

The selection of a three-phase recloser is based on required electrical ratings, interrupting and insulation medium (e.g., oil, vacuum, or environmentally friendly gases), and the choice between hydraulic control (integrated within the unit) or electronic control (housed in a separate control cabinet).

5.3 Operating Mode: Three-Phase Trip and Three-Phase Lockout

This is the standard operating mode for larger reclosers. Regardless of whether the fault is a single-phase-to-ground fault, a phase-to-phase fault, or a three-phase fault, all three poles trip simultaneously during each operation. The tripping and reclosing of all three phases are mechanically linked and driven by a single operating mechanism, ensuring synchronized performance.

Three-phase reclosers support various mounting configurations, including:

5.4 Triple-Single Reclosers

Triple-single reclosers are electronically controlled and offer three operating modes:

Three-phase trip and three-phase lockout

All three phases trip simultaneously due to overcurrent, reclose simultaneously, and operate in the same sequence.

Single-phase trip and three-phase lockout

Each phase independently performs overcurrent tripping and reclosing. If any one phase enters the lockout sequence due to a permanent fault, or if a local/remote "lockout" command is issued, the other two phases will also trip and enter lockout, thereby preventing prolonged single-phasing of three-phase loads.

Single-phase trip and single-phase lockout

Each phase trips and locks out independently, without affecting the others. This mode is primarily used for residential loads, or in scenarios where three-phase loads are already protected against single-phasing by other means.

Triple-single reclosers can be mounted on poles using a pole mount frame, or installed on substation frames or directly onto substation steel structures.

6. Recloser Control Types

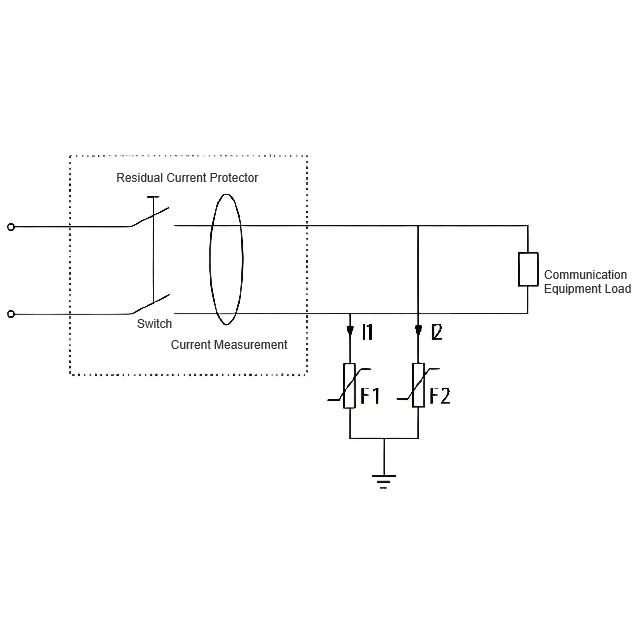

The "intelligence" that enables a recloser to sense overcurrent, select time-current characteristics, perform tripping and reclosing operations, and ultimately lock out comes from its control system. There are two main types of control: integral hydraulic control and electronic control housed in a separate control cabinet.

Hydraulic control

Hydraulic control is widely used in most single-phase reclosers and some three-phase reclosers. It exists as an integral part of the recloser itself. With this control method, overcurrent is detected by a trip coil connected in series with the line. When overcurrent flows through the trip coil, the coil pulls a plunger, causing the recloser contacts to trip open.

Timing and sequence operations are achieved by hydraulic oil flowing through different hydraulic chambers or orifices. In smaller reclosers, the energy required for reclosing is provided by springs, which are charged by the plunger of the series-connected trip coil during the overcurrent protection operation. In larger reclosers, closing is performed by a separate closing solenoid powered by the line voltage from the source side of the recloser.

7. Microprocessor-based or electronic control

Microprocessor-based or electronic control recloser control systems are typically installed in separate control cabinets, allowing operating parameters to be adjusted at any time. They can be combined with various accessories to customize basic functions to meet a wide range of application requirements. Compared to hydraulic control, these control methods offer greater flexibility, easier programming and parameter customization, and advanced protection, metering, and automation capabilities.

Microprocessor-based control is usually used together with PC-based interface software for configuring control settings, recording metering data, and setting communication parameters. The control system also provides multiple analytical tools, including fault locating, event recording, and oscillography functions. Electronic control has been widely applied to most three-phase reclosers since the mid-1980s, and many of these units remain in reliable operation today.

8. Recloser interrupting mediums

8.1Oil interrupters

Reclosers that use oil for current interruption employ the same oil as the primary insulation medium. Some reclosers with hydraulic control also use this same oil to perform timing and counting functions.

8.2 Vacuum interrupters

Vacuum interrupters enable fast, low-energy arc interruption and offer advantages such as long contact and interrupter life, low mechanical stress, and high operational safety. Since the arc is extinguished in a vacuum, the contact and interrupter life far exceeds that of other interrupting mediums. Depending on the model, the insulation medium for vacuum reclosers may be oil, air, or epoxy.