As a critical carrier for power transmission, ultra-high-voltage (UHV) transmission lines place exceptional emphasis on the safety and efficiency of live-line operations. Facing extremely high voltage levels and complex working environments, maintenance technologies for live-line operations on UHV transmission lines have long encountered a series of challenges. Therefore, it is crucial to continuously strengthen research on maintenance technologies for live-line operations on UHV transmission lines.

1.Research Background

Live-line operations on UHV transmission lines refer to maintenance, inspection, or construction activities performed while the lines are energized and operating at voltage levels of ±800 kV or above 1,000 kV. This type of operation carries high risks, requiring technicians to be thoroughly prepared in terms of safety and possess technical capabilities sufficient to address complex issues. Maintenance technology significantly influences operational effectiveness. This paper briefly investigates key maintenance technologies for live-line operations on UHV transmission lines from the following aspects:

1.1 Insulation Technology

In live-line operations on UHV transmission lines, insulation technology is fundamental to ensuring operational safety. It employs materials with high insulating performance—such as composite insulators—that can withstand intense electric fields under UHV conditions. Equipment and tools used during live-line work must exhibit excellent aging resistance to endure prolonged outdoor exposure and must respond rapidly to voltage fluctuations to prevent arc formation. Insulation technology not only significantly enhances operational safety and effectively reduces the risk of electric shock but also extends the service life of insulating equipment, thereby establishing a solid technical foundation for the reliable operation of UHV lines.

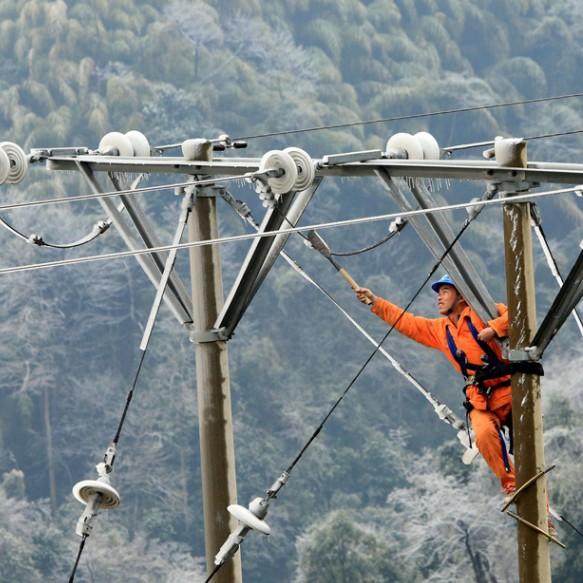

1.2 Equipotential Operation Technology

Equipotential operation technology is a key technique in live-line operations on UHV transmission lines. By connecting personnel to the same potential as the energized equipment, it effectively eliminates potential differences and greatly reduces the risk of electric shock. This technology relies on equipotential platforms, insulated tools, and protective suits. Its key features include achieving potential balance, ensuring operational stability, and supporting rapid switching to adapt to complex operational scenarios. These characteristics not only substantially lower the risk of direct contact with energized components but also provide a stable working environment, thereby improving both efficiency and quality of operations.

1.3 Safety Monitoring and Early Warning Technology

Safety monitoring and early warning technology is essential for ensuring the safety of live-line operations on UHV transmission lines. It involves real-time monitoring of line conditions, environmental parameters, and equipment performance, combined with advanced data analysis techniques to identify anomalies and risks. Once potential hazards are detected, the early warning system immediately issues alerts to guide personnel in taking preventive measures. The advantage of this technology lies in its ability to effectively prevent accidents and significantly reduce losses through rapid response to abnormal situations, thus safeguarding operational safety.

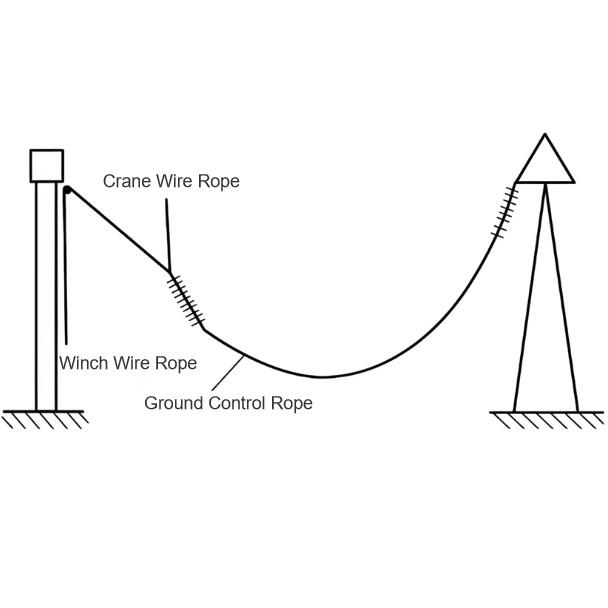

1.4 Robotic Operation Technology

Robotic operation technology plays a pivotal role in live-line operations on UHV transmission lines. Through remote control and autonomous navigation capabilities, robots can perform hazardous or hard-to-reach tasks such as line inspection and defect repair in complex environments. Their multifunctionality allows them to be equipped with various tools to flexibly meet diverse operational needs. The primary benefit of this technology is the significant reduction in personnel exposure to dangerous areas, while precise robotic execution effectively enhances operational quality.

1.5 Equal-Potential Insulation Isolation Technology

Equal-potential insulation isolation technology is a vital safety measure in live-line operations on UHV transmission lines. It uses high-insulation devices—such as insulating barriers and shielding covers—to effectively isolate energized zones from work zones, thereby protecting personnel. This technology offers high insulation performance and structural stability, capable of withstanding mechanical stresses during operations.

Its design emphasizes rapid deployment to facilitate flexible execution. The application advantages include significantly enhanced isolation effectiveness, effective prevention of personnel contact with energized parts, and provision of greater workspace and flexibility for operators under assured safety conditions.

2. Development Trends of Maintenance Technologies for Live-Line Operations on UHV Transmission Lines

With continuous technological advancement and rapid development of UHV transmission technology, maintenance technologies for live-line operations are also evolving and upgrading. Based on current technological trajectories, future maintenance technologies for live-line operations on UHV transmission lines will trend toward intelligence and technologization.

2.1 Intelligent and Automated Capabilities Will Continue to Improve

The enhancement of intelligent and automated capabilities will be a major direction in the development of live-line operation technologies for UHV transmission lines. By integrating advanced technologies such as artificial intelligence and machine learning, operation robots will be able to perform more complex tasks—such as autonomous defect identification and automatic fault repair.

Intelligent systems will analyze large volumes of real-time data to predict potential risks and automatically adjust operational strategies. The introduction of automated equipment will reduce manual intervention, improving both efficiency and safety. Furthermore, the integration of smart wearable devices and virtual reality technology will provide operators with more intuitive guidance and augmented reality experiences.

2.2 Application of Remote Operation and Telecontrol Technologies

Remote operation and telecontrol technologies will enable personnel to operate robots or equipment from safe distances. With advances in communication technologies—particularly 5G and IoT—remote operations will become increasingly stable and reliable. These technologies will greatly reduce the risk of direct contact with energized components while enhancing operational flexibility and efficiency. Future remote operation systems will prioritize user-friendly human-machine interaction and intuitive control interfaces to ensure precise equipment manipulation even from remote locations.

2.3 Development and Application of New Insulating Materials

In live-line operations on UHV transmission lines, the selection and application of insulating materials directly impact operational safety and line reliability. As UHV transmission technology advances, requirements for insulating materials continue to rise. Current trends indicate that the development of new composite insulators will be a focal point. These insulators are typically composed of multiple materials—such as silicone rubber and polyimide—combining advantages like the high insulation performance of silicone rubber and the heat resistance of polyimide.

Additionally, nanoscale insulating materials are attracting significant attention. Nanomaterials possess unique physical and chemical properties—such as high dielectric constants and low loss tangents—offering great potential for enhancing insulation performance. Incorporating nanomaterials into insulation systems can significantly improve dielectric strength and aging resistance.

2.4 Upgrading of Safety Monitoring and Early Warning Systems

Upgraded safety monitoring and early warning systems will be essential for ensuring live-line operation safety. Future systems will integrate more sensors to monitor line status, environmental parameters, and equipment performance in real time. Leveraging big data analytics and AI algorithms, these systems will more accurately identify anomalies and potential risks and issue timely warnings.

Warning systems will become more intelligent, offering personalized safety recommendations and emergency response plans tailored to specific operational environments and equipment conditions. Moreover, user interfaces will be more intuitive, enabling rapid comprehension and response by operators. With the integration of IoT and cloud computing, these systems will enable real-time data sharing and remote access, facilitating remote monitoring and decision-making. They will also feature self-learning and self-optimization capabilities, continuously refining warning models through historical data analysis to improve accuracy and timeliness.

3. Conclusion

Maintenance technologies for live-line operations on UHV transmission lines are advancing toward intelligence, automation, remote operation, and higher efficiency. In the future, with ongoing technological progress, the application of new insulating materials, intelligent monitoring systems, and robotic technologies will further enhance the safety, reliability, and efficiency of live-line operations. The development of these maintenance technologies remains a formidable task, requiring continuous exploration and innovation to ensure the safe and stable operation of power grids.