Dandalin halitta da rashin kariyar abubuwan gina cikin shafin yanayi yana iya hada da dandamalin tattalin arziki. Babban dandanlun abubuwan gina cikin shafin yanayi sun ƙunshi kayan metal na samun mataki bisa ga nau’i na kayan saba, misali copper murna, karbon steel, da stainless steel. Lokacin da suka yi amfani da suwa sosai, rashin kyauwar kayan metal sun hada da kuskuren abubuwan gina, wanda ya nuna alama mai mahimmanci zuwa ne mai tsoro don rashin kariyar halittar halittar shafin yanayi.

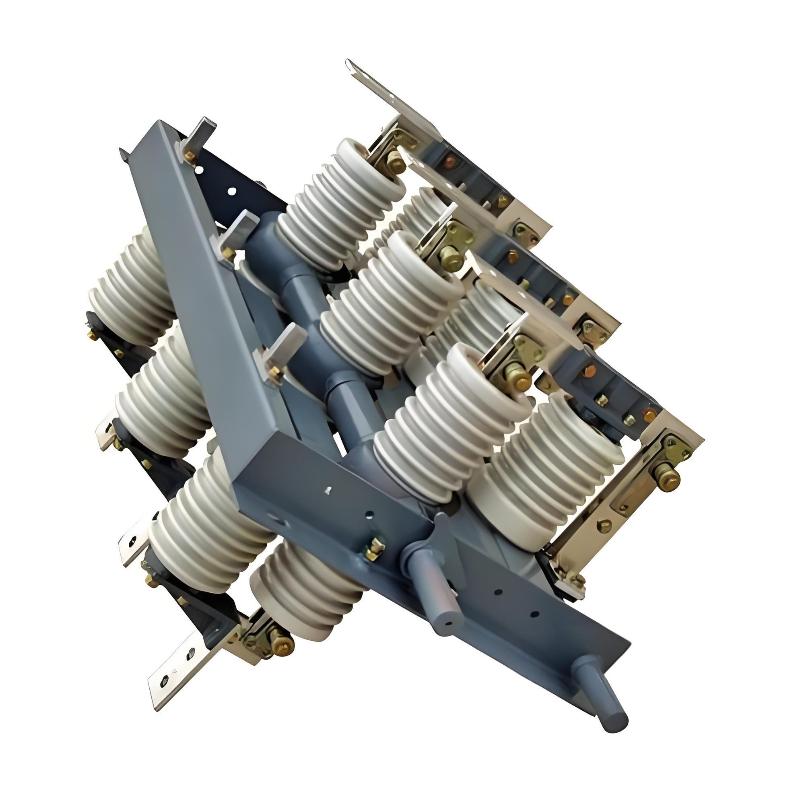

Abubuwan gina na sama na uku masu girma (outdoor high-voltage disconnectors) suna da misali mai kyau. Ayyukansu na tsayawa ba hanya ga iyaka, kariya, da rashin kariyar halittar shafin yanayi ba, amma kuma rukan kansu zai iya shiga da sauya a fagen tattalin arziki ta duniya. Don haka, yau da kullum yana muhimmiyar zurfi domin bada bayani kan dalilin kuskure na abubuwan gina cikin shafin yanayi, sannan sauya wasu hanyoyin kariya.

1. Tattaunawar Abubuwan Ginar Sama Na Uku Masu Girma

Abubuwan ginar sama na uku masu girma a cikin wani shafin yanayi na 330 kV suna ne abubuwan GW4 na farko da aka girma da takardar girman umar da aka girma da takardar gine-ginen umar. Suna da tsakon juzu'i biyu na horizontal na dabbobi da sauƙi, sun ƙunshi base, support brackets, insulators, da main conductive assembly. Main conductive assembly ke ƙunshi flexible connectors, terminal clamps, conductive rods, contacts, contact fingers, springs, da rain shields.

Watan Satumba 2017, yayin da aka yi maintenance na yau, masu amfani sun gano cewa wasu daga cikin abubuwan ginar sama sun nuna kuskure a matsayin musamman, tare da korosi mai zurfi. Wannan ya nuna alamar tsoro mai mahimmanci yayin da aka yi amfani da shi ta hannu. Saboda haka, aka yi la'akari da tambaya kan taswirar kuskure. A kuma, aka yi microscopic metallographic analysis akan contaminants da aka collect shi daga gaban clamp da gaban terminal na support brackets. A kuma, aka amfani da spectrometer don yi comprehensive analysis akan composition na kimia na support brackets, conductive rods, da wasu contaminants.

2. Matakan Tambayar Kuskure na Support Bracket

2.1 Taswirar Fassara

Kayan coating na disconnector support brackets sun fara kere, wanda ya nuna korosi mai zurfi. An nuna abubuwan da aka haƙurar korosi a tsakiyar bracket da conductive rod. Kuskure sun nuna alamar brittle fracture, da an nuna alamar chevron ("herringbone") a cikin taswirar kuskure. Alamar kuskure da wurin taro suna rawaran black ko dark gray.

Garin girman zane-zane ya nuna canjin wurin 3.0 mm a gaban terminal-board da 2.0 mm a gaban clamp, wanda ya tabbata canji mai zurfi a cikin tsakon bracket.

2.2 Taswirar Microscopic

Microscopic metallographic analysis ya nuna girman layer na contaminants na 1.1–3.3 mm a gaban clamp da 3.2–3.5 mm a gaban terminal-board na support bracket.

2.3 Tambayar Spectral

Spectrometric analysis na support bracket, conductive rod, da contaminants ya kawo wasu bayanan mai mahimmanci (duba Table 1):

Support bracket ya ƙunshi 94.3% aluminum, wanda ya nuna cewa ya darawa ne dari alloy.

Conductive rod ya ƙunshi 92.7% copper, tare da wasu elementai mai yawa, wanda ya tabbata cewa shine copper alloy tube.

Contaminants kuma ya ƙunshi 94.3% aluminum.

A cikin halayyin damuwa mai zurfi, aluminum (daga bracket) da copper (daga conductive rod) suna yi galvanic couple, wanda ya kirkirar electrochemical (galvanic) corrosion reaction. Wasu abubuwan da aka haƙurar korosi suna ƙunshi aluminum-ion-rich—wanda aka identifai cewa wanda ya nuna sabon abubuwan da ya haƙuri, wanda ya kirkira canji na kayan aiki har ma kuskure.

| Sunan Daeji |

Muhimmanci Abincin Kwakwalwa |

| Al |

Zn |

Mn |

Cu |

Fe |

Si |

| Isolator Support |

94.3 |

0.33 |

0.39 |

2.64 |

0.76 |

-- |

| Conductive Rod |

6.12 |

0.26 |

< 0.017 |

92.66 |

< 0.028 |

0.936 |

| Contaminant |

94.3 |

0.34 |

0.28 |

2.51 |

0.61 |

1.13 |

3. Sake da Tatta da Hanyar Ayyukan Gudanawa

3.1 Wuyar Sake da Tatta da Hanyar Gudanawar Kari

A karkashin, rukunin kayan dabe suna iya karewa ne zuwa wasu nau’ikan abubuwa:

Abubuwan na gida: masu alaƙa da ingancin kayan aikin da tsarin fabbataci;

Abubuwan na waje: masu alaƙa da halayyen aiki kamar yadda ya kamata ake shigar da hankali, lokaci, tsawon, da tsarin gini.

3.1.1 Wuyar Abubuwan Na Gida

A cikin mabudin tattalin arziki, abubuwan dabe na logamai suna da kyauwar inganci—yana da ma'anar kayan aikin da tsawon shekaru da suka yi—kafin an shigar da su. Zabtacciyar yanayi ta nuna cewa mai amfani na zahiri na voltage mai yawa ke aiki a cikin juyawa mai sauƙi, kuma matsayinta ke da wakiltar halayyen aiki na waje domin bayanai daga cikin kayan aikin. Don haka, an farko da gurji a cikin kari na disconnector bai zama saboda kayan aikin maras kyau ba, amma yake da wakiltar yanayin gidajin.

3.1.2 Wuyar Abubuwan Na Waje

Sabitun 330 kV ke wurin aƙarsasa, wanda ke cikin yanayin tsokace mai tsokace mai yanki—wanda aka fi saba, manyan rana, da girman tsawon ranar da shekaru. Rana suna ci gaba da waya da waya da waya, yayin da rayuwa suna ci gaba da waya amma waya.

Karin alloy na aluminum na disconnector ya kasance a cikin wannan yanayin juyawa, ya kara kama da karfi, canjin tsawon, burfi, da wani lokaci teburin—halayyen da suka haɗa da stress corrosion cracking (SCC).

SCC yana nufin karewar kayan dabe na musamman a cikin yanayin da ke sauya. Lokacin da yake butsuwa, ana buƙatar wasu abubuwan muhimmi: hankali na tensile da wasu madadi mai sauya.

A wannan halayi:

Hankali na tensile sun kasance a daban-daban a farko na kari, suna da hankali mai goyan sama a farko, suna da adadin hankali.

Wannan adadin hankali ya haɓaka plastic strain da dislocation slip a cikin kayan dabe, ya kara SCC, ya kara, sai dai kuma ya kare.

An samu kari na cast aluminum alloy. A cikin halayyar ruwa da zararen gini wanda zai samu contaminants da za a iya kaiwa, galvanic da crevice corrosion suna faruwa sosai—na iyakar waje na gap, inda ruwa ko burfi za su iya kaiwa.

Taimakon hankali na tensile da attack na corrosion akwai gurji.

A mataimakin, SCC fracture surfaces suna nuna wuraren gurji ko gray-black due to corrosion, tunda sudden brittle fracture areas suna nuna alamar radial ko chevron ("herringbone") markings—wanda ya dace da nazarin fracture na disconnector bracket. Wannan ya tabbata cewa mechanism na karewa shine stress corrosion cracking.

3.2 Hanyoyin Ayyukan Gudanawa Da Za A Yi Gaba da Gurji na Kari

Kamar yada su ne abubuwan da aka samuwa a cikin sabiton, outdoor disconnectors suna da wucewa mai yawa lokacin da suke aiki a cikin yanayin juyawa—na musamman tare da damar yin amfani da sabiton mara mai amfani, wanda ya richa da kyauyar matsayi. Ana iya amfani da hanyoyin gudanawa na hudu:

3.2.1 Shigar da Fasaha

Don outdoor disconnectors suna da kyauyar yanayin atmosferik—and particularly vulnerable in extreme climates (e.g., alpine cold, high heat, coastal salinity, or icing zones)—installing isolation shields or protective enclosures can create a controlled micro-environment, significantly mitigating corrosion.

3.2.2 Kare Wa Yanke Tsaro

Don hankali na adadin hankali da halayyar juyawa ya haɗa SCC, mai amfani dole ne ya kare wa tsaron gudu da tsaron kimiyya na abubuwan muhimmi—na musamman base supports da clamping structures—to detect early signs of deformation, corrosion, or cracking and prevent secondary damage or safety incidents.

3.2.3 Kare Wa Yanke Tsaro da Corrosion

Tsaron halayyar aikin a cikin sabita bai hanya mai kyauwa ce don kara tsaro ba, amma kuma ita ce babban ilimin gina abubuwa a cikin shekaru. Dole ne a amfani da advanced corrosion detection da real-time monitoring technologies don evaluation na zaman kansu, don outdoor disconnectors da abubuwan da suka haɗa da su.

3.2.4 Amfani da Coatings mai Kyauyar Gudanawa

Yin amfani da coatings mai kyauyar gudanawa shine dari dari bisa kaɗan dari bisa kaɗan yadda za a iya kare corrosion a cikin abubuwan sabita. A cikin support brackets na disconnector, coatings da suka da kyauyar gudanawa da suka iya kare oxygen, ruwa, da contaminants ionics za su iya kare sararin kayan dabe daga abubuwan da ke sauya. Wadannan coatings suna bada gudanarwa mai kyau, suna kirkirar kofar gudanawa na farko da zai iya kare halayyar juyawa.

4. Kammalitin

Base on comprehensive testing and analysis of the support bracket, conductive rod, and contaminants from the 330 kV substation’s outdoor high-voltage disconnector, the following conclusions are drawn:

(1) The primary cause of the support bracket cracking is stress corrosion cracking (SCC). Uneven tensile stress at the bracket base, combined with crevice corrosion in the clamp-side gap under fluctuating climatic conditions, accelerated material degradation and ultimately led to fracture.

(2) Tushen da zama da za suka ba da gano masana'antu, kamar fitowa masana'antu na kwalba, amfani da kwalba mai yawa da kyau, yanayin daidaita tattalin daidai, da kuma yi tattalin kwalba na dabi'a. Don hukuma daidai, ya kamata a yi ra'ayin tsari mai yawa don kwalba da za su ba da shi daidai don tabbatar da dukamta, hankali da kalmomin da za suke da shiga aiki na muhimmiya na zawar da za suke da shiga aiki.