Solid-State Transformer Technology: A Comprehensive Analysis

This report is based on tutorials published by the Power Electronic Systems Laboratory at ETH Zurich, providing a comprehensive overview of Solid-State Transformer (SST) technology. The report details the working principles of SSTs and their revolutionary advantages over traditional Line-Frequency Transformers (LFTs), systematically analyzes their key technologies, topologies, industrial application scenarios, and thoroughly explores current major challenges and future research directions. SSTs are regarded as key enabling technologies for future smart grids, renewable energy integration, data centers, and transportation electrification.

1. Introduction: Basic Concepts and Core Motivations of SST

1.1 Limitations of Traditional Transformers

Traditional line-frequency transformers (50/60 Hz), while highly efficient, reliable, and cost-effective, have inherent limitations:

Large size and weight: Low-frequency operation necessitates enormous magnetic cores and windings

Single functionality: No active control capabilities, unable to regulate voltage, compensate reactive power, or suppress harmonics

Poor adaptability: Sensitive to DC bias, load imbalance, and harmonics

Fixed interfaces: Typically support only AC-AC conversion, making direct integration with DC systems difficult

1.2 Core Advantages of SST

SSTs fundamentally transform energy conversion through high-frequency power electronic conversion technology:

High-frequency isolation: Uses Medium-Frequency Transformers (MFTs, typically at kHz levels), significantly reducing size and weight (volume ∝ 1/f)

Full controllability: Enables independent active/reactive power control, smooth voltage regulation, fault current limiting, and other advanced functions

Universal interfaces: Flexibly implements AC/AC, AC/DC, DC/DC conversions, making it an ideal hub for future AC/DC hybrid grids

High power density: Particularly suitable for space and weight-constrained applications (rail transit, ships, data centers)

2. In-depth Analysis of SST Key Technologies

2.1 Core Power Conversion Topologies

Dual Active Bridge (DAB): One of the most mainstream topologies. Regulates power by controlling the phase shift between bridges, enabling soft-switching (ZVS) to reduce losses. Suitable for applications requiring wide power control ranges.

DC Transformer (DCX): Operates at resonant frequency to achieve fixed voltage transformation ratios, transmitting power without active control like a "traditional transformer." Simple structure with high reliability, particularly suitable for multi-module series-input systems (e.g., ISOP), enabling natural voltage balancing.

Modular Multilevel Converter (MMC): Suitable for higher voltage levels, highly modular with good redundancy and high-quality output waveforms, though control and capacitor voltage balancing algorithms are complex.

Classification: Can be categorized as Input-Series Output-Parallel (ISOP), Isolated Front-End (IFE), Isolated Back-End (IBE), etc., to adapt to different application requirements.

2.2 Power Semiconductor Devices

SiC MOSFET: A key enabler for SST development. Its high breakdown field strength, fast switching speed, and low on-resistance make it ideal for medium-voltage, high-frequency applications. 10kV+ SiC devices are driving direct medium-voltage interfaces with single devices or few-series configurations, reducing module count and mitigating "modularity penalty."

IGBT: Currently the most widely used device in medium-voltage applications, with mature technology and relatively lower cost, though switching frequency and performance typically lag behind SiC.

2.3 Medium-Frequency Transformer (MFT)

The MFT represents the core and design challenge of SSTs:

Design challenges: Significant eddy current losses and proximity effects at high frequencies; insulation requirements (especially lightning impulse withstand level BIL) don't decrease with frequency, becoming a limiting factor for size; trade-offs exist between heat dissipation and insulation.

Materials: Silicon steel, amorphous alloys, nanocrystalline materials, ferrites, etc., selected based on frequency and power ratings.

Structure: Shell-type (E-core) structures are more common, facilitating control of leakage inductance and parasitic parameters.

Cooling: Efficient designs can use air cooling, while extreme power density requires liquid cooling (water or oil).

2.4 System-level Challenges

Isolation Coordination: Must meet stringent safety standards (e.g., IEC 62477-2), with creepage distance and clearance being key factors determining equipment size.

Protection: Lightning strikes and short circuits in medium-voltage grids can severely impact SSTs. Protection schemes must consider selectivity, speed, and reliability, with protection requirements significantly influencing SST input inductance and semiconductor selection.

Reliability: Multi-module designs can improve system reliability through redundancy (e.g., N+1 configuration). However, non-redundant components like control systems and auxiliary power supplies may become bottlenecks for system reliability.

3. Industrial Application Scenarios

3.1 Next-Generation Rail Transit Traction Systems

The earliest and most mature application field. Replaces line-frequency traction transformers on locomotives, implementing AC-DC conversion. Significant advantages include >50% weight reduction, 2-4% efficiency improvement, and space savings.

3.2 Renewable Energy and New Power Grids

Wind/Solar: Enables medium-voltage DC collection for wind turbines/PV arrays, reducing cable losses and costs while facilitating HVDC transmission integration.

DC Microgrids: Serves as AC/DC and DC/DC interface, enabling flexible integration of renewable energy, storage, and loads with energy management capabilities.

Smart Grids: Functions as an "energy router," providing voltage support, power quality regulation, and bidirectional power flow control.

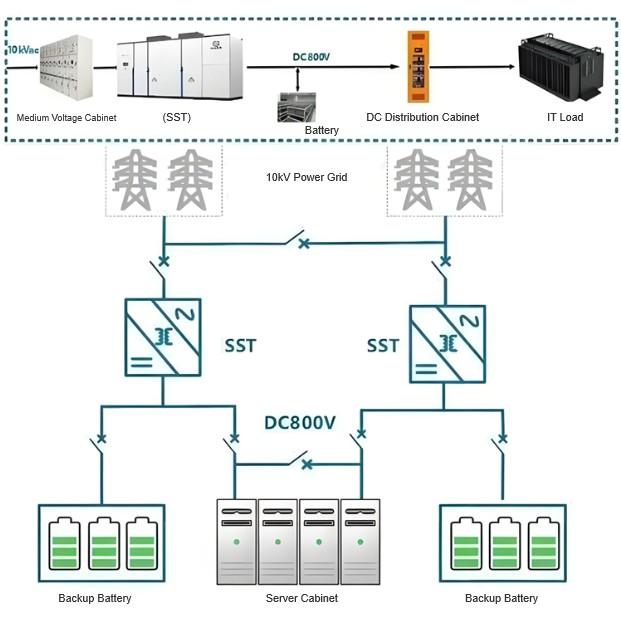

3.3 Data Center Power Supply

Replaces traditional "LFT + server power supply" architecture, converting MVAC directly to LVDC (e.g., 48V) or even lower voltages, reducing conversion stages and improving overall efficiency. Challenge: Current SST efficiency and power density advantages over high-efficiency LFT+SiC rectifier solutions are not yet clear, with higher complexity and cost.

3.4 Electric Vehicle Ultra-Fast Charging (XFC)

Direct connection to medium-voltage grids (10kV or 35kV) provides MW-level charging power, enabling "gas station-like" experience. Energy hubs integrate local storage and PV for peak shaving and grid services (V2G).

3.5 Other Specialized Applications

Marine Electric Propulsion: Used in medium-voltage DC distribution systems to optimize generator load distribution and integrate energy storage.

Aviation Power Systems: Provides lightweight, high-power-density power distribution solutions for more-electric/all-electric aircraft.

Port "Cold Ironing": Supplies medium-voltage shore power to docked vessels, allowing auxiliary engines to be shut down, reducing emissions and noise.

4. Challenges and Future Research Directions

4.1 Current Major Challenges

Excessive Cost: Current SST capital expenditure (CAPEX) far exceeds traditional LFT solutions.

Modularity Penalty: Increasing module count leads to non-linear growth in system size, weight, and complexity, offsetting the high power density advantages of MFTs.

Efficiency Bottleneck: Multi-stage conversion (AC-DC + DC-DC + DC-AC) makes it difficult to surpass the efficiency of high-efficiency LFT (>99%) + high-efficiency converter (>99%) combinations.

Standardization and Reliability: Lack of unified standards and long-term field operation data; reliability validation and lifetime prediction are critical for industrialization.

4.2 Future Research Directions

Devices and Materials: Develop higher-voltage (>15kV) SiC devices; create new low-loss, high-thermal-conductivity, high-insulation-strength materials.

Topology and Integration: Optimize topologies to reduce switch count; explore more compact structures like MMC; develop system-level integration techniques to reduce auxiliary system and protection volume.

Demonstration Projects: Build full-scale (full voltage, full power, full standards) demonstration projects for objective evaluation.

System Studies: Conduct comprehensive Total Cost of Ownership (TCO) and Life Cycle Assessment (LCA) studies to clarify SST's true value proposition.

Sustainability: Consider repairability, recyclability, and circular economy from the design phase to address electronic waste challenges.

5. Summary and Outlook

The Solid-State Transformer (SST) is far more than just a replacement for traditional transformers—it's a multifunctional, controllable smart grid node. While current costs and maturity levels prevent comprehensive competition with traditional solutions, its revolutionary advantages in functional diversity, controllability, and natural support for DC grids are undeniable. Future development depends on interdisciplinary collaboration (power electronics, materials, high-voltage insulation, thermal management, control) and clear application-driven approaches. In specific fields like traction systems, marine applications, and DC collection, SSTs have already demonstrated irreplaceable value. With continuous advancements in SiC technology, topological innovations, and system optimization, SSTs are expected to gradually expand into broader market applications over the next decade, becoming a foundational technology for building efficient, flexible, and resilient future energy systems.