Gas insulation is primarily based on SF₆ gas. SF₆ has extremely stable chemical properties and exhibits excellent dielectric strength and arc-quenching performance, making it widely used in electrical power equipment. SF₆-insulated switchgear features a compact structure and small size, is unaffected by external environmental factors, and demonstrates exceptional adaptability.

However, SF₆ is internationally recognized as one of the six major greenhouse gases. Leakage from SF₆-insulated switchgear is an unavoidable practical issue. From an environmental protection perspective, the use of sulfur hexafluoride should be reduced or minimized. The international community has reached a consensus on gradually phasing out and ultimately discontinuing the use of SF₆ gas.

1. Technical Characteristics of 12 kV SF6 Gas-Free Ring Main Unit

1.1 Green and Environmentally Friendly

Dry air (or nitrogen) is used as the primary insulating medium, eliminating SF₆ and avoiding emissions of toxic or greenhouse gases. Environmental impact throughout the product’s entire life cycle is considered, with continuous exploration of new materials and manufacturing processes to improve material recyclability. The compact and space-saving design effectively reduces raw material consumption, production energy usage, and land occupation.

1.2 Safe and Reliable

Mature vacuum switching technology ensures stable and reliable interruption performance and long service life. The rated gas filling pressure is low (0.12 MPa absolute), making it easier to achieve a low leakage rate (≤0.1%). High dielectric strength allows normal operation even at zero gauge pressure. The three-position disconnector supports electric or remote operation and features comprehensive “five-prevention” interlocks with the load switch/circuit breaker, enhancing operational safety during maintenance.

1.3 Environmental Adaptability

All high-voltage primary components are sealed within a 3 mm stainless steel welded gas compartment, fully isolated from external environments. Additional protective structures can be added to the switching mechanism and low-voltage compartment as needed, truly meeting requirements for corrosion resistance, moisture protection, and low-temperature operation under special conditions.

1.4 Intelligent Leadership

The product can be optionally equipped with intelligent control systems, self-powered integrated protection, and panoramic smart power distribution platforms according to user needs. It integrates functions such as data acquisition, control, monitoring, diagnostics, protection, and communication into a unified system, enabling remote operation/maintenance and facilitating big data applications in power distribution.

2. Current Status and Development Trends of 12 kV Ring Main Units

2.1 Current Status of 12 kV Ring Main Units

Over the past century, Earth's climate has undergone significant changes characterized primarily by global warming. This warming results from natural climate variability combined with enhanced greenhouse effects caused by human activities. Reducing greenhouse gas emissions and mitigating climate change are the primary goals of the United Nations Framework Convention on Climate Change (UNFCCC) and the Kyoto Protocol.

At the 1997 Kyoto Protocol conference in Japan, SF₆ was listed as one of the most potent greenhouse gases and included among substances subject to usage and emission restrictions. Although CO₂ contributes over 60% to the greenhouse effect—the largest share—SF₆ accounts for only about 0.1%. Despite its currently small contribution, SF₆ poses significant potential risks: one SF₆ molecule has a global warming potential 23,900 times greater than that of a CO₂ molecule, and its atmospheric lifetime is approximately 3,200 years. About 50% of globally produced SF₆ is used in the power industry, of which 80% goes into switchgear. As a developing country, China faces increasing pressure to reduce greenhouse gas emissions.

2.2 Development Trends of 12 kV Ring Main Units

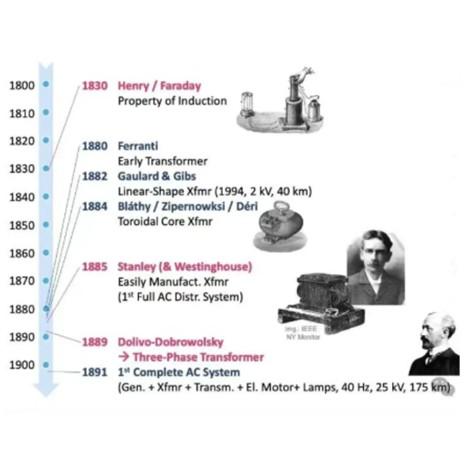

From a technical perspective, the ring main unit industry had, by around 2014, progressed through several stages: air insulation, semi-SF₆ insulation, full SF₆ insulation, and solid insulation. This evolution reflects continuous innovation and technological advancement focused on safety, reliability, miniaturization, and environmental friendliness.

Currently, both domestically and internationally, solid-insulated switchgear was once considered an ideal alternative to SF₆-based products. However, due to challenges such as the difficulty in recycling epoxy resin (widely used in solid-insulated units), lack of broad acceptance of alternative thermoplastic engineering materials, irrecoverable breakdown after insulation failure, and unresolved issues related to temperature rise under high-capacity operation, interest in solid insulation has cooled almost as rapidly as it rose.

In contrast, full SF₆-insulated ring main units—despite their environmental drawbacks—continue to dominate the market due to their compact size, excellent environmental resilience, high reliability, and low maintenance requirements.

In the past 2–3 years, eco-friendly gas-insulated switchgear has gradually become a focal point of interest for grid operators and leading manufacturers, driven by advancements in several key areas:

Mature application of vacuum switching technology (including encapsulated designs);

Deepened understanding of insulation technologies (gas insulation, solid interface insulation, composite insulation, etc.);

Extensive operational experience with SF₆-insulated equipment (RMUs, C-GIS);

Breakthroughs in research on SF₆ alternative gases (by companies like ABB and 3M);

Industry discussions advocating a return to fixed-type medium-voltage products, supported by significantly improved reliability of core components.

As China accelerates the transformation and upgrading of its power sector and faces urgent demands for energy conservation and emission reduction, regulating atmospheric humidity and controlling air pollution have become pressing priorities. For the rapidly evolving power industry, developing SF6 gas-free ring main unit is an inevitable trend. Future transmission and distribution equipment will increasingly focus on safety, reliability, miniaturization, and environmental sustainability.

Notably, State Grid Corporation of China shows significantly higher recognition of eco-friendly switchgear compared to general industrial users. The "State Grid Corporation Key Promoted New Technologies Catalog (2017 Edition)" explicitly stipulates that from 2016 to 2018, SF6 gas-free ring main unit must account for "no less than 30% of total new installations in new and retrofit projects, with an annual growth rate of no less than 8%." Furthermore, the latest version (2017) of the "Standardized Design Recommendations for 12 kV Ring Main Units," jointly developed by State Grid’s Operation & Maintenance Department and China Electric Power Research Institute, has formally incorporated eco-friendly gas-insulated ring main units and established clear technical specifications for future procurement tenders.

3.Conclusion

In summary, as China accelerates the transformation of its power industry and faces growing urgency in energy conservation and emission reduction, addressing atmospheric humidity and air pollution has become an immediate priority. As a typical terminal power distribution device, the 12 kV ring main unit is extensively deployed across power systems and various industrial applications, serving as an indispensable component of a robust and intelligent grid and directly impacting the safety and reliability of power supply. In response to the rapid development of the power sector, the development of eco-friendly gas-insulated ring main units represents an irreversible trend. Future transmission and distribution equipment will continue to evolve around the core demands of safety, reliability, miniaturization, and environmental friendliness.