A cikin tattalin da na aiki a tattalin karamin kuli, ina sanin cewa takalmi mai yawa (MV) suna da muhimmanci a karamin kuli, kudin kuli da inganci. In ba da kyau a zama shiga wannan takalma ya kamata kan haɗaƙuwa da kuma amincewar masu amfani a cikin tattalin karamin kuli. Don haka, muna bukatar inganta a cikin tsarin bayanai, don haka za a iya samun takalmi mai yawa (MV) suka yi ayyukansa da kuma a inganta cin karamin kuli.

1. Bayanar Takalmi Mai Yawa (MV)

A cikin tattalin da na yi, takalmi mai yawa (MV) suna nufin takalmi mai yawa da ke fadada metal kamar yadda aka bayyana a GB 3906—2020 AC Metal-Clad Switchgear and Controlgear for Rated Voltages from 3.6 kV to 40.5 kV: wuraren da suke fadada metal duk da abubuwan da suke fito daga jirgin zuwa fito.

A cikin tattalin karamin kuli, takalmi mai yawa (MV) suna da muhimman abubuwa: kudin kuli, kudin kuli, karamin kuli, da kuma inganci a cikin tushen karamin kuli, kudin kuli, da karamin kuli. A lokacin da na yi ayyuka, na gina sarrafa tsarin bayanai na baya ga hira da take da tattalin karamin kuli—na kofara ko kofar wani wurare/wurare biyu don haka za a iya da shiga. Idan an samu matsalolin a cikin tattalin da kuma lissafi, na amfani da takalmi mai yawa (MV) don isali kafin bayanin da ba a sa shi, don haka za a iya ci gaba da karamin kuli a wurare da ba a sa shi ba.

2. Muhimman Ingantaccen Takalmi Mai Yawa (MV)

Takalmi mai yawa (MV) suna da amfani a cikin tattalin karamin kuli. Saboda hira da karamin kuli na China ta fi yawa da kuma ya fi kawo, tattalin karamin kuli suna da hira masu yawa don hana magana ga tattalin da ake bukata. Daga tattalin da na yi, musamman muna bukatar inganta a cikin takalmi mai yawa (MV) don haka za a iya samun karamin kuli, kudin kuli, da kuma inganci, don haka za a iya da shiga a cikin tattalin karamin kuli.

Idan an samu matsala ko kofin aiki a cikin takalmi mai yawa (MV), za a iya haɗaƙuwa a cikin tattalin karamin kuli, kuma za a iya haɗaƙuwa a cikin karamin kuli. A lokutan da yake da yawa, zai iya haɗaƙuwa a cikin tattalin karamin kuli, kuma zai iya haɗaƙuwa a cikin karamin kuli. Saboda haka, na tattauna wajen inganta takalmi mai yawa (MV) a cikin babban abubuwa, don haka za a iya samun aiki da kuma tattalin karamin kuli.

3. Tattalin Ingantaccen Takalmi Mai Yawa (MV)

3.1 Tsarin Fadada Yawan Karkashin

Tsarin fadada yawan karkasha suna da muhimmanci a cikin ingantaccen takalmi mai yawa (MV), wanda muna bukatar a cikin tattalin da na yi. Misalai:

Ingantaccen Karkashin Mai Yawa: A cikin tsarin da ake amfani a karkashin mai yawa, ana amfani da insulatoci a karkashin mai yawa, amma idan kaza ta gane a cikin insulatoci, yana iya haɗaƙuwa a cikin karkashin. Na amfani da karkashin mai yawa na D-type saboda hanyar da suke da kyau da kuma tensile resistance, kuma har yanzu ba a bukata insulatoci, kuma har yanzu an gane da matsalolin da suka haɗaƙuwa a cikin karkashin.

Tsarin Fitting: Amfani da tsarin fitting na uku a cikin karkashin mai yawa, wanda yana iya haɗaƙuwa a cikin eddy current effects, yana iya inganta electric field uniformity, da kuma yana iya inganta creepage distance, kuma har yanzu an inganta insulation reliability.

Wadannan tsarin ingantaccen suna daidai da tsarin industry best practices, kuma har yanzu an inganta takalmi mai yawa (MV) suka tabbata a cikin tsarin da ake amfani a cikin tattalin karamin kuli.

3.2 Tsarin Fadada Insulation Structure

Don haka muna bukatar tsarin fadada insulation structure a cikin takalmi mai yawa (MV). A cikin tsarin da na yi, a cikin tsarin fadada insulation, muna bukatar kafofin tsarin da kuma tsarin environmental protection.

3.2.1 Tsarin Fadada Insulating Gases

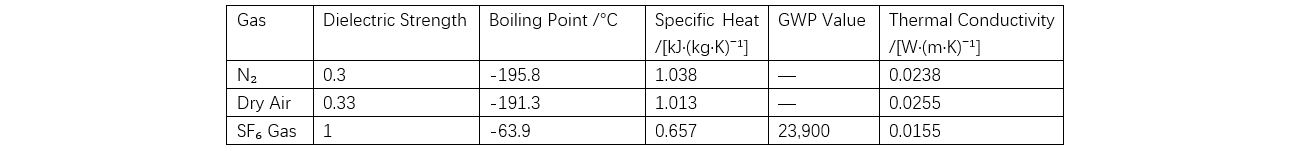

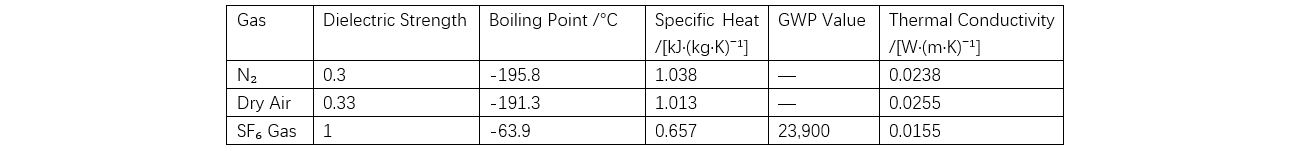

A cikin takalmi mai yawa (MV), SF₆ gas suna da amfani a cikin tsarin fadada insulation. Amma, gas suna da dukan toxic da kuma GWP (Global Warming Potential) da yake da yawa. CO₂ suna da GWP da yake da yawa, amma SF₆ gas suna da GWP da yake da yawa 23,900 times that of CO₂, kuma har yanzu an gane da matsalolin da suka haɗaƙuwa a cikin environment. A cikin takalmi mai yawa (MV) da ba a bukata critical interrupting performance requirements, a cikin tsarin, muna bukatar kafofin SF₆ gas with N₂ or dry air. Compared with SF₆ gas, the insulation performance of N₂ and dry air can reach 30% of that of SF₆ gas. The performance comparisons among N₂, dry air, and SF₆ gas are shown in Table 1.

Kamar yadda aka bayyana a Table 1, N₂ and dry air suna da non-greenhouse gases, ba su ba da yawa ga environment. Suna da low boiling points, kuma ba su ba da yawa ga liquefaction during normal use, even in extremely cold regions. Notably, N₂, as the main component of air, features stable chemical properties. However, excessively high N₂ concentration can cause asphyxiation due to oxygen deprivation. When designing with N₂ as the insulating gas, ventilation and protective equipment must be configured. In contrast, using dry air as the insulating gas avoids such issues. Through comprehensive comparison, dry air can be adopted to replace SF₆ as the insulating gas in switchgear insulation design.

When using dry air as the insulating gas, the design of the minimum air gap should be considered. According to relevant standards, for a rated voltage of 12 kV, the minimum air gap between phases and from phase to ground should be 125 mm. If the condensation test is passed, the minimum air gap can be slightly smaller than 125 mm. Employing dry air as the insulating gas allows for an appropriate reduction in the minimum air gap.

3.2.2 Enhancing Breakdown Voltage in Gas Gaps

During the design process, to ensure the safety and reliability of medium-low voltage switchgear, the breakdown voltage in gas gaps should also be enhanced, with specific methods as follows:

Improving the electric field distribution in medium-low voltage switchgear. This can be achieved by optimizing electrode shapes based on actual conditions or making full use of space charges to enhance electric field uniformity. If the electric field uniformity is extremely poor, adding barriers is also an option.

Suppressing the ionization process of dry air. Applying high pressure in medium-voltage switchgear can weaken the ionization process of dry air. Alternatively, using high vacuum in medium-voltage switchgear can achieve the same effect.

When using high pressure or high vacuum, the gas tank strength is required to be extremely high, and leakage problems are prone to occur in practical applications, leading to serious consequences. Therefore, in actual design, improving the electrode shape and adding barriers in extremely inhomogeneous electric fields are more feasible methods to increase the breakdown voltage in gas gaps.

3.3 Rational Selection of Components

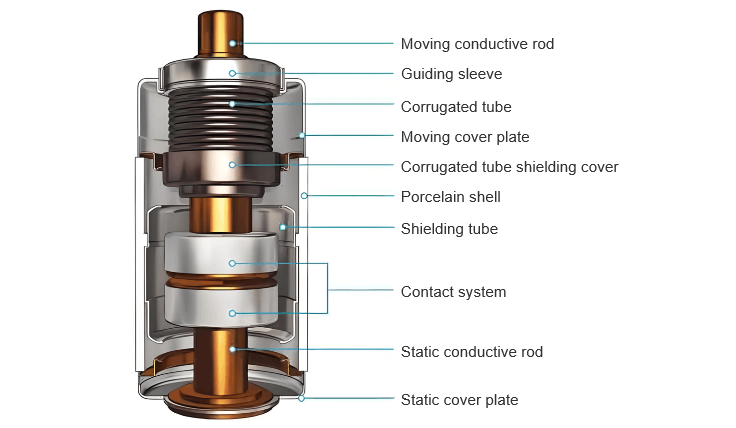

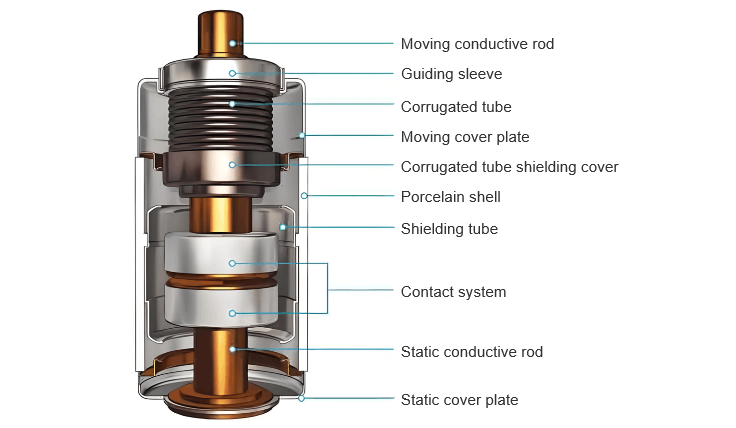

The core components of medium-voltage switchgear, including vacuum circuit breakers, vacuum interrupters, and contacts, directly affect the equipment's operational safety and reliability, requiring strict quality control.

Take ABB switchgear as an example. Its vacuum interrupters undergo rigorous pre-shipment inspections: automatic high-voltage tests verify the insulation strength, while spiral magnetron devices measure internal pressure within a chamber filled with inert gas. After a specified isolation period, a second pressure test is conducted, and results are compared to ensure sealing performance meets standards.

In manufacturing, ABB vacuum interrupters require strict environmental and process controls. Produced at CalorEmag's German factory, they are professionally assembled by regional medium-voltage switchgear enterprises before centralized supply. High-performance alloys like Cu-Cr and W-C-Ag are prioritized for component materials to ensure durability.Assembly occurs in dedicated cleanrooms using a "one-time sealing and exhausting" process: under 800°C high temperature, high vacuum is first achieved, followed by simultaneous welding and sealing to guarantee process reliability.

The R&D evolution of vacuum interrupters reflects continuous performance optimization: early assemblies exposed to air relied solely on insulating partitions for isolation. Subsequent improvements included insulating sleeves over interrupters and contacts to balance electric fields, followed by integral casting for interrupters and contacts to enhance phase-to-phase insulation and impact resistance, while adopting eco-friendly materials to integrate performance with environmental considerations.

3.4 Rational Planning of Design Validation Tests

After the design of medium-voltage switchgear is completed, experimental validation becomes a critical phase. The actual validation must strictly comply with relevant standards, such as GB 3906—2020 AC Metal-Clad Switchgear and Controlgear for Rated Voltages from 3.6 kV to 40.5 kV, GB/T 11022—2020 Common Technical Requirements for High-Voltage AC Switchgear and Controlgear Standards, and GB/T 1984—2014 High-Voltage AC Circuit Breakers.

Key Points for Type Tests

Comprehensive performance verification shall be conducted for the electrical components and auxiliary elements of medium-voltage switchgear to ensure technical parameters meet the requirements. When design processes or production conditions change, type tests must be re-conducted to guarantee equipment safety and reliability. For normally produced equipment, a temperature rise test is typically required every 8 years; mechanical operation tests are carried out to inspect operational performance; meanwhile, safety verification items such as short-time withstand current and peak withstand current tests are also necessary.

Taking ABB medium-voltage switchgear as an example, it has passed experimental validations in multiple countries under the most stringent standards to date, demonstrating exceptional safety and reliability. Take the internal arcing test as an example, which verifies:

The fixing methods and closed status of switchgear doors, covers, and other components;

The firmness of fixing dangerous components;

The structural stability of the equipment casing under combustion or other hazardous scenarios;

Whether indicators are arranged in compliance with production specifications;

The completeness of protective measures and the flammability rating of the equipment.

Only by ensuring the equipment's non-flammability can operational safety be fundamentally guaranteed.

4 Conclusion

As a core component of the power system, the operational reliability of medium-voltage switchgear directly affects grid safety. Therefore, it is essential to strengthen the safety and reliability design of the equipment, strictly optimize technical parameters in accordance with standards, and build a solid safety defense through systematic validation tests, ensuring that medium-voltage switchgear stably performs distribution, protection, and control functions in the power system.