Mar ghnáthúil atáim páirteach i réimsí oibriúchán na gcórais fhuinnimh, aithním go bhfuil ról lárnach ag meaisín-ille (MV) switchgear i ndeisiú, mheasú, agus cosaint fuinnimh. Tá sé ríthábhachtach a chinntiú go bhfuil sé sábháilte agus iontaofa le feidhmigh—d'fhéadfadh aon mífheidhmiú éigin an córas fuinnimh ar fad a chur as comhartha. Chun an iontaofacht a fheabhsú, caithfimid priomhaíocht a thabhairt do eagarthóireachtaí ag an leibhéal dearacháin, ag cumasú an MV switchgear a dhéanamh a chuid feidhmeanna a chomhlíonadh agus a chosaint sábháilteacht na gréasaí.

1. Míniú ar Meaisín-Ille Switchgear

I mo phrionsabal, cuireann MV switchgear i gcuimhne an t-switchgear clada metalach mar a dhéfinítear in GB 3906—2020 AC Metal-Clad Switchgear and Controlgear for Rated Voltages from 3.6 kV to 40.5 kV: uirlisí go hiomlán incloiste ag cathain mhetailgeach seachas isteach/amach conductors.

In gcórais fuinnimh, déanann MV switchgear feidhmeanna príomha: scuabadh, mheasú, deisiú, agus cosaint trína chéile i staidéar, tarraingt, agus deisiú. Le linn an oibrigh, d'eagraím é ar deghra an ghréasáin—ceangal nó scaradh uirlisí/feeder chun sábháilteacht a choimeád. Nuair a tharla teipeanna i nuaimh nó líne gréasáin, úsáidim MV switchgear chun an ceann teipthe a shcaradh go tapa, ag cinntiú deisiú leanúnach do na háiteanna nach bhfuil tionchar orthu.

2. Tábhacht a chinntiú ar Iontaofacht MV Switchgear

Tá MV switchgear in úsáid laethúil i gcórais fuinnimh. Mar gheall ar fhorbairt agus forbróid gréasaí na Síne, tá tuairimí níos trom agus níos casta á gcur orthu chun riachtanais sóisialta a shásamh. De réir mo thaithí, is amháin tríd an iontaofacht a chinntiú ar MV switchgear a bheidh sé in ann deisiú, mheasú, agus cosaint a chomhlíonadh go héifeachtach, ag coimeád sábháilteacht an gréasaí ar fad.

D'fhéadfadh aon imshábháil nó mífheidhmiú i MV switchgear an córas deisiú a chur as comhartha, ag cur isteach ar deisiú fuinnimh. In chásanna cruinne, d'fhéadfadh sé a bheith ina chúis le teipeanna forleathan, ag cur isteach ar fhorbairt sóisialta agus ag cruthú ballaí airgeadais. Mar sin, dírim mé ar an gcaoi chun an iontaofacht a fheabhsú ar MV switchgear trí chéile, ag cinntiú gur féidir leis an gcóras a dhéanamh a chuid feidhmeanna go stiúrtha agus a thacaíocht a thabhairt don gréasán.

3. Stratéisí chun Iontaofacht MV Switchgear a Fheabhsú

3.1 Dearadh Rialta ar Struchtúr Cathaí

Is bunús dearacháin eolaíoch a chuirtear ar chathaí an t-iontaofacht a chinntiú ar MV switchgear, rud a dhíríonn ar mo phrionsabal sa phrionsabal. Mar shampla:

Busbar Chamber Optimization: Úsáideann dearachtaí busbar chamber traidisiúnta insúlaithe ar branch busbars, ach cuardaíonn dust ar insúlaithe over time pose flashover risks. D'foghlaimim D-type main busbars instead—their higher strength and tensile resistance eliminate the need for insulators, resolving contamination-related safety issues.

Bushing Design: Implementing three-phase integrated bushing designs in busbar chambers prevents eddy current effects, improves electric field uniformity, and enhances creepage distance, thereby boosting insulation reliability.

These design optimizations align with industry best practices, ensuring MV switchgear meets safety and performance requirements in real-world operations.

3.2 Rational Design of Insulation Structure

To enhance the safety and reliability of medium-low voltage switchgear, strengthening insulation design is essential. In practical design, besides meeting insulation requirements, factors such as design cost and environmental protection should also be considered.

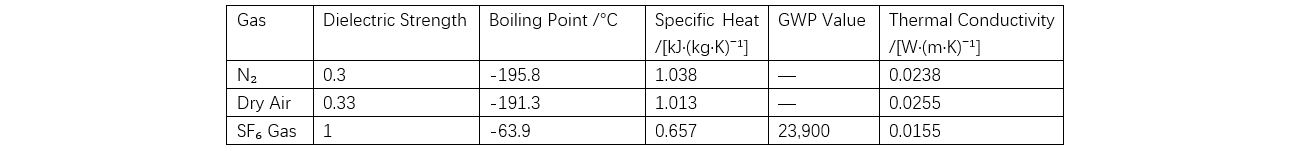

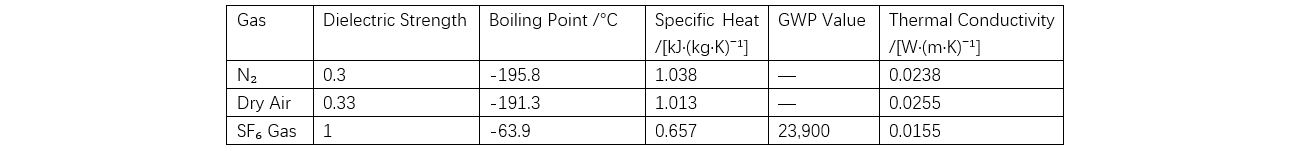

3.2.1 Rational Selection of Insulating Gases

In medium-voltage switchgear, SF₆ gas has been the primary insulating medium. However, it is not only toxic but also has an extremely high GWP (Global Warming Potential). While CO₂ is a greenhouse gas with a high GWP, SF₆ gas has a GWP 23,900 times that of CO₂, highlighting its significant harm to the natural environment. For medium-low voltage switchgear with non-critical interrupting performance requirements, design-wise, we can attempt to replace SF₆ gas with N₂ or dry air. Compared with SF₆ gas, the insulation performance of N₂ and dry air can reach 30% of that of SF₆ gas. The performance comparisons among N₂, dry air, and SF₆ gas are shown in Table 1.

As indicated in Table 1, N₂ and dry air are non-greenhouse gases, posing no threat to the ecological environment. They also have low boiling points, eliminating concerns about liquefaction during normal use, even in extremely cold regions. Notably, N₂, as the main component of air, features stable chemical properties. However, excessively high N₂ concentration can cause asphyxiation due to oxygen deprivation. When designing with N₂ as the insulating gas, ventilation and protective equipment must be configured. In contrast, using dry air as the insulating gas avoids such issues. Through comprehensive comparison, dry air can be adopted to replace SF₆ as the insulating gas in switchgear insulation design.

When using dry air as the insulating gas, the design of the minimum air gap should be considered. According to relevant standards, for a rated voltage of 12 kV, the minimum air gap between phases and from phase to ground should be 125 mm. If the condensation test is passed, the minimum air gap can be slightly smaller than 125 mm. Employing dry air as the insulating gas allows for an appropriate reduction in the minimum air gap.

3.2.2 Enhancing Breakdown Voltage in Gas Gaps

During the design process, to ensure the safety and reliability of medium-low voltage switchgear, the breakdown voltage in gas gaps should also be enhanced, with specific methods as follows:

Improving the electric field distribution in medium-low voltage switchgear. This can be achieved by optimizing electrode shapes based on actual conditions or making full use of space charges to enhance electric field uniformity. If the electric field uniformity is extremely poor, adding barriers is also an option.

Suppressing the ionization process of dry air. Applying high pressure in medium-voltage switchgear can weaken the ionization process of dry air. Alternatively, using high vacuum in medium-voltage switchgear can achieve the same effect.

When using high pressure or high vacuum, the gas tank strength is required to be extremely high, and leakage problems are prone to occur in practical applications, leading to serious consequences. Therefore, in actual design, improving the electrode shape and adding barriers in extremely inhomogeneous electric fields are more feasible methods to increase the breakdown voltage in gas gaps.

3.3 Rational Selection of Components

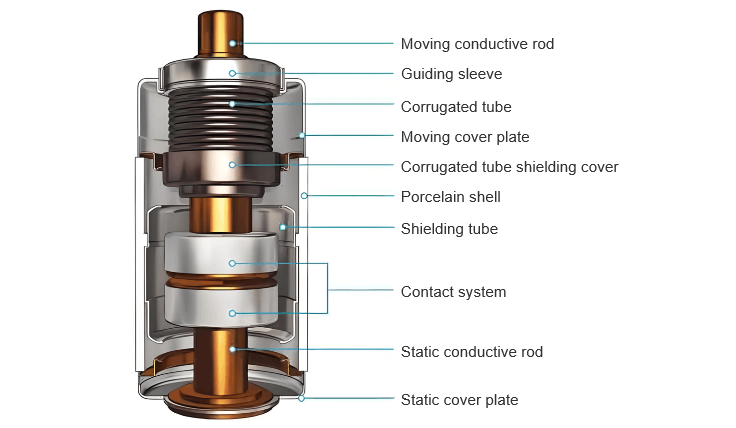

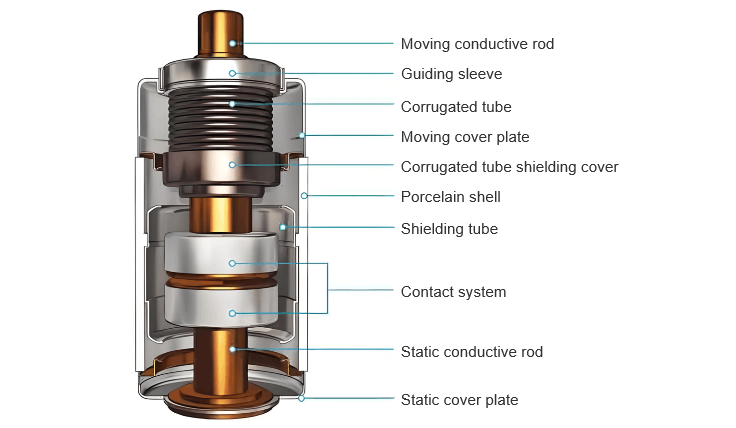

The core components of medium-voltage switchgear, including vacuum circuit breakers, vacuum interrupters, and contacts, directly affect the equipment's operational safety and reliability, requiring strict quality control.

Take ABB switchgear as an example. Its vacuum interrupters undergo rigorous pre-shipment inspections: automatic high-voltage tests verify the insulation strength, while spiral magnetron devices measure internal pressure within a chamber filled with inert gas. After a specified isolation period, a second pressure test is conducted, and results are compared to ensure sealing performance meets standards.

In manufacturing, ABB vacuum interrupters require strict environmental and process controls. Produced at CalorEmag's German factory, they are professionally assembled by regional medium-voltage switchgear enterprises before centralized supply. High-performance alloys like Cu-Cr and W-C-Ag are prioritized for component materials to ensure durability.Assembly occurs in dedicated cleanrooms using a "one-time sealing and exhausting" process: under 800°C high temperature, high vacuum is first achieved, followed by simultaneous welding and sealing to guarantee process reliability.

The R&D evolution of vacuum interrupters reflects continuous performance optimization: early assemblies exposed to air relied solely on insulating partitions for isolation. Subsequent improvements included insulating sleeves over interrupters and contacts to balance electric fields, followed by integral casting for interrupters and contacts to enhance phase-to-phase insulation and impact resistance, while adopting eco-friendly materials to integrate performance with environmental considerations.

3.4 Rational Planning of Design Validation Tests

After the design of medium-voltage switchgear is completed, experimental validation becomes a critical phase. The actual validation must strictly comply with relevant standards, such as GB 3906—2020 AC Metal-Clad Switchgear and Controlgear for Rated Voltages from 3.6 kV to 40.5 kV, GB/T 11022—2020 Common Technical Requirements for High-Voltage AC Switchgear and Controlgear Standards, and GB/T 1984—2014 High-Voltage AC Circuit Breakers.

Key Points for Type Tests

Comprehensive performance verification shall be conducted for the electrical components and auxiliary elements of medium-voltage switchgear to ensure technical parameters meet the requirements. When design processes or production conditions change, type tests must be re-conducted to guarantee equipment safety and reliability. For normally produced equipment, a temperature rise test is typically required every 8 years; mechanical operation tests are carried out to inspect operational performance; meanwhile, safety verification items such as short-time withstand current and peak withstand current tests are also necessary.

Taking ABB medium-voltage switchgear as an example, it has passed experimental validations in multiple countries under the most stringent standards to date, demonstrating exceptional safety and reliability. Take the internal arcing test as an example, which verifies:

The fixing methods and closed status of switchgear doors, covers, and other components;

The firmness of fixing dangerous components;

The structural stability of the equipment casing under combustion or other hazardous scenarios;

Whether indicators are arranged in compliance with production specifications;

The completeness of protective measures and the flammability rating of the equipment.

Only by ensuring the equipment's non-flammability can operational safety be fundamentally guaranteed.

4 Conclusion

As a core component of the power system, the operational reliability of medium-voltage switchgear directly affects grid safety. Therefore, it is essential to strengthen the safety and reliability design of the equipment, strictly optimize technical parameters in accordance with standards, and build a solid safety defense through systematic validation tests, ensuring that medium-voltage switchgear stably performs distribution, protection, and control functions in the power system.