What is an Armature?

An armature is the component of an electric machine (i.e., a motor or generator) that carries alternating current (AC). The armature conducts AC even on DC (Direct Current) machines via the commutator (which periodically reverses current direction) or due to electronic commutation (e.g., in a brushless DC motor).

The armature provides housing and support to the armature winding, which interacts with the magnetic field formed in the air gap between the stator and the rotor. The stator can be either a rotating part (rotor) or a stationary part (stator).

The term armature was introduced in the 19th century as a technical term meaning “keeper of a magnet”.

How Does an Armature Work in an Electric Motor?

An electric motor transforms electrical energy into mechanical energy through electromagnetic induction. This occurs when a current-carrying conductor within a magnetic field is forced to move, as explained by Fleming’s left-hand rule.

In an electric motor, the stator produces a rotating magnetic field by using permanent magnets or electromagnets. The armature, which is usually the rotor, carries the armature winding that is connected to the commutator and brushes. The commutator switches the direction of the current in the armature winding as it rotates so that it always aligns with the magnetic field.

The interaction between the magnetic field and the armature winding generates a torque that causes the armature to rotate. The shaft attached to the armature transfers the mechanical power to other devices.

How Does an Armature Work in an Electric Generator?

An electric generator converts mechanical energy into electrical energy by using the principle of electromagnetic induction. When a conductor moves in a magnetic field, it induces an electromotive force (EMF) according to Faraday’s law.

In an electric generator, the armature is usually the rotor that is driven by a prime mover, such as a diesel engine or a turbine. The armature carries the armature winding that is connected to the commutator and brushes. The stator produces a stationary magnetic field by using permanent magnets or electromagnets.

The relative motion between the magnetic field and the armature winding induces an EMF in the armature winding, which drives an electric current through the external circuit. The commutator switches the direction of the current in the armature winding as it rotates so that it produces an alternating current (AC).

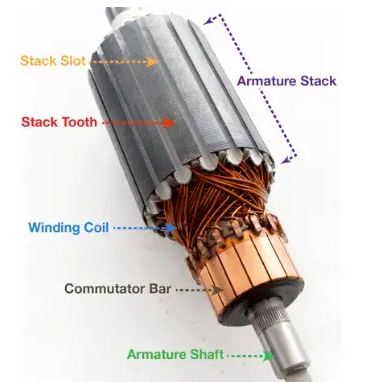

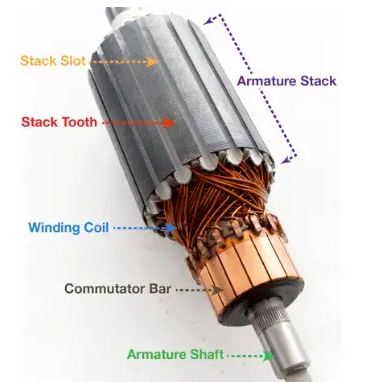

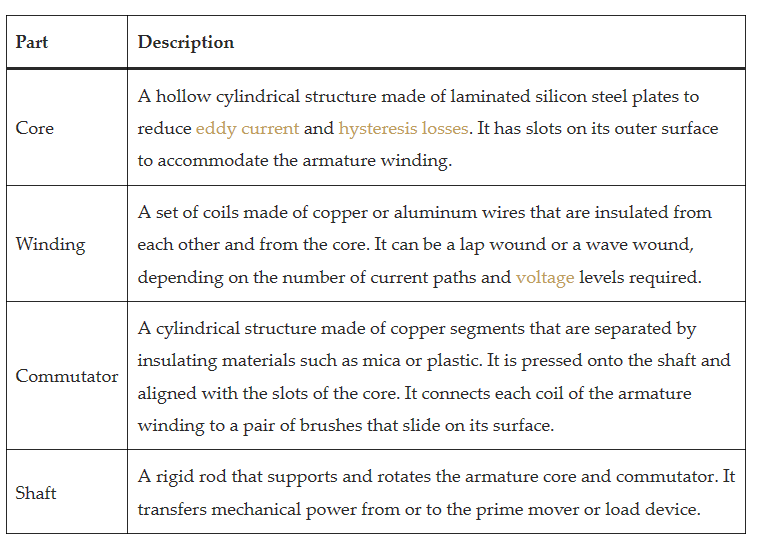

Armature Parts & Diagram

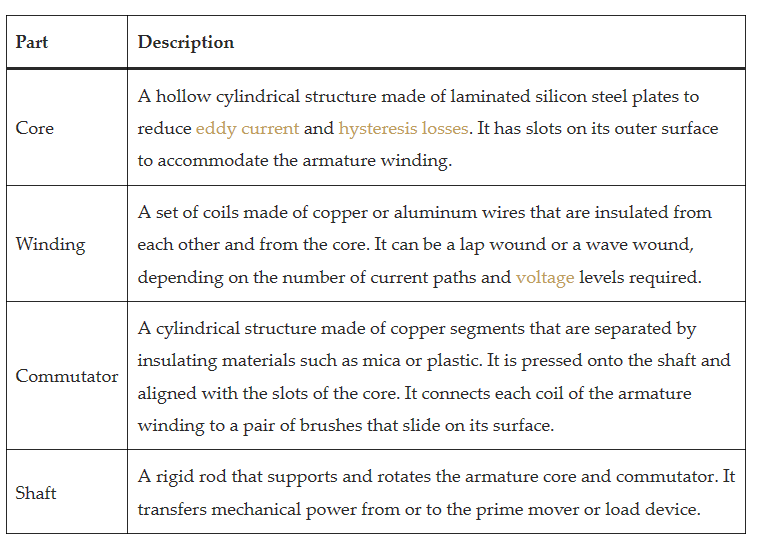

The armature is composed of four essential components: the core, winding, commutator, and shaft. Below is a diagram illustrating these parts.

Armature Losses

The armature in electric machines incurs several losses, diminishing its efficiency and performance. These losses include:

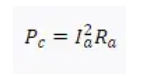

where Pc is the copper loss, Ia is the armature current, and Ra is the armature resistance.

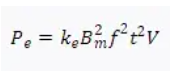

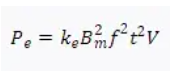

Eddy current loss: This is the power loss due to the induced currents in the core of the armature. These currents are caused by the changing magnetic flux and produce heat and magnetic losses. The eddy current loss can be reduced by using laminated core materials or increasing the air gap. The eddy current loss can be calculated by using the formula:

where Pe is the eddy current loss, ke is a constant depending on the core material and shape, Bm is the maximum flux density, f is the frequency of flux reversal, t is the thickness of each lamination, and V is the volume of the core.

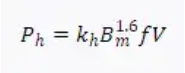

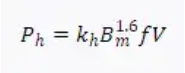

where Ph is the hysteresis loss, kh is a constant depending on the core material, Bm is the maximum flux density, f is the frequency of flux reversal, and V is the volume of the core.

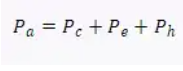

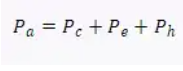

The total armature loss can be obtained by adding these three losses:

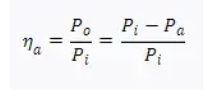

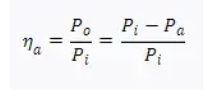

The armature efficiency can be defined as the ratio of the output power to the input power of the armature:

where ηa is the armature efficiency, Po is the output power, and Pi is the input power of the armature.

Armature Design

The armature design is crucial for the electric machine’s performance and efficiency, influenced by several key factors:

The number of slots: The slots are used to accommodate the armature winding and provide mechanical support. The number of slots depends on the type of winding, the number of poles, and the size of the machine. Generally, more slots result in better distribution of flux and current, lower reactance and losses, and smoother torque. However, more slots also increase the weight and cost of the armature, reduce the space for insulation and cooling, and increase the leakage flux and armature reaction.

The shape of slots: The slots can be opened or closed, depending on whether they are exposed to the air gap or not. Open slots are easier to wind and cool, but they increase the reluctance and leakage flux in the air gap. Closed slots are more difficult to wind and cool, but they reduce the reluctance and leakage flux in the air gap.

The type of winding: The winding can be a lap wound or wave wound, depending on how the coils are connected to the commutator segments. Lap winding is suitable for high-current and low-voltage machines, as it provides multiple parallel paths for current flow. Wave winding is suitable for low current and high voltage machines, as it provides a series connection of coils and adds up the voltages.

The size of the conductor: The conductor is used to carry the current in the armature winding. The size of the conductor depends on the current density, which is the ratio of current to cross-sectional area. Higher current density results in higher copper loss and temperature rise, but lower conductor cost and weight. Lower current density results in lower copper loss and temperature rise, but higher conductor cost and weight.

The length of the air gap: The air gap is the distance between the stator and rotor poles. The length of the air gap affects the flux density, reluctance, leakage flux, and armature reaction in the machine. Smaller air gap results in higher flux density, lower reluctance, lower leakage flux, and higher armature reaction. Larger air gap results in lower flux density, higher reluctance, higher leakage flux, and lower armature reaction.

Armature Design (continued)

Some of the methods used to design the armature are:

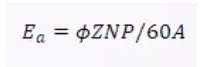

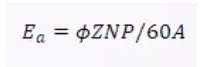

EMF equation: This equation relates the induced EMF in the armature to the flux, speed, and number of turns of the winding. It can be used to determine the required dimensions and parameters of the armature for a given output voltage and power.

where Ea is the induced EMF in volts, ϕ is the flux per pole in webers, Z is the total number of conductors in series, N is the speed of rotation in rpm, P is the number of poles, and A is the number of parallel paths.

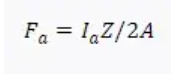

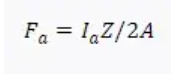

where Fa is the MMF in ampere-turns, Ia is the armature current in amperes, Z is the total number of conductors in series, and A is the number of parallel paths.

where T is the torque in Newton meters, P is the power in watts, and ω is the angular speed in radians per second.

Conclusion

The armature, a vital component of electric machines, carries alternating current and engages with the magnetic field. Comprising a core, winding, commutator, and shaft, it functions either as a motor or a generator to convert energy forms.

The armature design affects the performance and efficiency of the machine, and it can be determined by using various equations relating to EMF, MMF, and torque. The armature also suffers from various losses such as copper loss, eddy current loss, and hysteresis loss, which reduce its output power and increase its temperature. The armature can be tested for any faults or damages by measuring its resistance, continuity, and insulation. Armatures are widely used in various applications such as industrial machines, household appliances, vehicles, and power generation.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.