I. Core Innovation: A Dual Revolution in Materials and Structure

Two key innovations:

Material Innovation: Amorphous Alloy

What it is: A metallic material formed by ultra-rapid solidification, featuring a disordered, non-crystalline atomic structure.

Key Advantage: Extremely low core loss (no-load loss), which is 60%–80% lower than that of traditional silicon steel transformers.

Why it matters: No-load loss occurs continuously, 24/7, throughout a transformer’s lifecycle. For transformers with low load rates—such as those in rural grids or urban infrastructure operating at night—reducing no-load loss delivers significant energy savings and economic benefits.

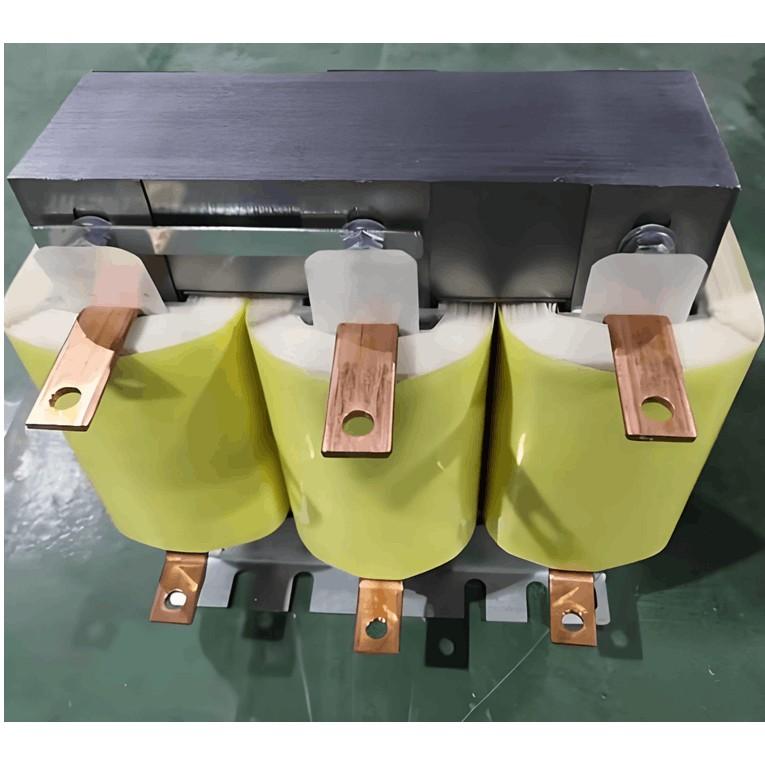

Structural Innovation: 3D Wound Core

What it is: Amorphous alloy ribbon is wound into three symmetrical rectangular columns, assembled into a robust立体 triangular structure—replacing traditional laminated or planar wound core designs.

II. Comparison with Traditional Transformers

| Characteristics |

Amorphous Alloy Three-Dimensional Wound Core Transformer |

Traditional Silicon Steel Transformer |

First-Generation Amorphous Alloy Transformer (Planar Type) |

| No-Load Loss |

Extremely Low (Reduced by 60% - 80%) |

High |

Low (Slightly Higher than Three-Dimensional Wound Structure) |

| Noise Level |

Relatively Low |

Relatively High |

Relatively High (Amorphous Material Has Strong Magnetostriction, Noise Problem is Prominent) |

| Mechanical Strength |

High (Triangular Three-Dimensional Structure) |

Average |

Relatively Low (Core is Brittle and Fragile) |

| Material and Process |

Amorphous Alloy Strip, Continuous Wound |

Silicon Steel Sheet, Laminated |

Amorphous Alloy Strip, Planar Wound |

| Energy-Saving Effect |

Optimal |

Standard |

Excellent, but with Shortcomings |

| Manufacturing Cost |

Relatively High |

Low |

Relatively High |

III. Transformative Significance and Market Prospects

A Green Solution Aligned with the "Dual Carbon" Strategy:

Under the goals of carbon peak and carbon neutrality, every component of the power grid is striving for ultimate energy efficiency. A single 110kV amorphous alloy 3D wound core transformer can save approximately 120,000 kWh of electricity annually, equivalent to reducing over 100 tons of CO₂ emissions—truly a "pioneer on the path to decarbonization."

Solving Pain Points of First-Generation Amorphous Alloy Transformers:

Although the first-generation amorphous transformers were energy-efficient, they suffered from high noise, brittleness, and poor short-circuit resistance, which limited their widespread adoption. The 3D wound core structure effectively suppresses vibration and noise while significantly enhancing mechanical strength through its robust design, resolving these long-standing industry challenges.

Breaking Through to Higher Voltage Levels, Unlocking Greater Markets:

Early amorphous transformers were mostly used in 10kV distribution networks. However, the world’s first 110kV amorphous alloy 3D wound core transformer was commissioned in October 2025 in Shantou, Guangdong—a landmark event. It demonstrates that this technology can advance into higher-voltage transmission and distribution networks, expanding its market potential from the distribution side to the main grid, with enormous growth prospects.

IV. Why Hasn’t It Been Widely Adopted Yet?

Despite its clear advantages, large-scale deployment still faces challenges.

High Manufacturing Cost: Both the production cost of amorphous alloy ribbon and the manufacturing complexity of the 3D wound core are higher than those of traditional silicon steel transformers, resulting in an initial investment that is approximately 30%–50% higher.

Raw Material Supply: High-performance amorphous alloy ribbon capacity and supply were once bottlenecks. Although domestic suppliers (e.g., Antai Technology) have achieved breakthroughs, costs still need further reduction.

Market Awareness and Inertia: For many users, upfront cost remains the primary concern. Without mandatory energy-efficiency standards or clear lifecycle cost benefits, the market inertia favoring traditional transformers remains strong.

V. Conclusion

The amorphous alloy 3D wound core transformer represents a classic case of "deep innovation." It does not create a new product category but instead achieves a transformative upgrade of a fundamental power device by integrating material science and structural engineering, elevating its core performance—energy efficiency—to unprecedented levels.

It is now at a critical inflection point, transitioning from demonstration projects toward mass adoption. As "dual carbon" policies intensify, mandatory efficiency standards tighten, and manufacturing scale drives down costs, it is poised to gradually replace traditional silicon steel transformers in medium- and low-load applications over the next 5–10 years, becoming a mainstream choice for green grid modernization.

VI. Comparison Between Amorphous Alloy 3D Wound Core Transformers and Solid-State Transformers

These two products represent fundamentally different technological innovation pathways—one being a "deep optimization" of the traditional transformer, the other a "complete disruption."

Below is a detailed comparative analysis across multiple dimensions.

| Dimension |

Amorphous Alloy Three-Dimensional Wound Core Transformer |

Solid-State Transformer (SST) |

| Technical Nature |

Innovation in Materials and Structure: Based on the traditional electromagnetic induction principle, amorphous alloy materials and three-dimensional wound structures are adopted. |

Fundamental Principle Overturn: Power electronic conversion circuits (high-frequency switches) are used to replace traditional magnetic cores and coils to achieve electric energy conversion. |

| Core Principle |

Faraday's Law of Electromagnetic Induction (Same as Traditional Transformers) |

High-Frequency Electric Energy Conversion (AC-DC-AC-AC or Similar Conversion) |

| Key Technologies |

Manufacturing Technology of Amorphous Alloy Strip, Winding Process of Three-Dimensional Wound Core |

Wide-Bandgap Semiconductors (e.g., SiC, GaN), High-Frequency Magnet Design, Digital Control Algorithms |

| Figurative Analogy |

Ultimate Optimization of Traditional Car Engines: Lighter and lower-friction new materials and processes are used, but it is still an internal combustion engine. |

Leap from Fuel Vehicles to Electric Vehicles: The power source and transmission method are completely changed. |

VII. Feature and Advantage Comparison

| Characteristic |

Amorphous Alloy Three-Dimensional Wound Core Transformer |

Solid-State Transformer (SST) |

| Energy Efficiency |

Extremely low no-load loss (60%-80% lower than traditional silicon steel transformers), and load loss is also optimized. |

High comprehensive efficiency (up to over 98%), and can maintain high efficiency in a wide load range. |

| Volume/Weight |

Compared with traditional transformers of the same capacity, the volume and weight are reduced, but the extent is limited. |

The volume and weight are significantly reduced (by more than 50%), achieving miniaturization and lightweight. |

| Functional Diversity |

Single function: only realizes voltage transformation and electrical isolation, consistent with traditional transformers. |

Highly integrated and intelligent functions: in addition to basic transformation, it can also realize reactive power compensation, harmonic governance, fault isolation, bidirectional energy flow, etc. |

| Control Capability |

Passive operation, no active control capability. |

Fully controllable, with precise and fast digital control achievable for voltage, current, and power. |

| Adaptability to New Power Grids |

Excellent energy-saving equipment, but cannot directly handle DC power or complex power quality issues. |

The "smart node" of future power grids, which can perfectly match DC power sources such as photovoltaics and energy storage, and is the key to building AC-DC hybrid microgrids. |

| Manufacturing Cost |

Relatively high, but industrialization has been achieved, and the cost is gradually decreasing. |

Very high, with high cost of core power devices, which is the main obstacle to current promotion. |

| Technical Maturity |

Relatively high, with demonstration applications of 110kV high voltage level realized, on the eve of large-scale promotion. |

Relatively low, mainly applied in laboratories and specific demonstration projects, and reliability and cost still need large-scale verification. |

| Main Application Scenarios |

Distribution networks sensitive to no-load loss (such as rural power grids, municipal lighting), data centers, and industrial energy-saving renovations. |

Future data centers (especially AI data centers), rail transit, smart microgrids, and high-end manufacturing industries. |

VIII. Conclusion and Outlook on Their Relationship

You can understand the relationship between the two as follows:

Different Innovation Paths:

The amorphous alloy 3D wound core transformer represents "incremental innovation." It operates within the existing technical framework, using optimized materials and processes to address the power grid’s most urgent challenge—energy consumption. It is more practical and closer to large-scale deployment.

The solid-state transformer (SST) embodies "disruptive innovation." It aims to redefine the very concept of a "transformer," transforming it from a simple electromagnetic device into an intelligent power router. It addresses future grid needs for "flexibility, controllability, and multi-function integration." It is more advanced and represents a long-term technological direction.

Different Market Positions:

The amorphous alloy transformer targets replacing inefficient traditional silicon steel transformers, serving as an upgrade for today’s market.

The solid-state transformer aims to create entirely new application areas—especially in scenarios where conventional transformers fall short or where extreme efficiency, power density, and compactness are required (e.g., multi-megawatt AI data centers), positioning itself as a creator of future markets.

Not a Simple Replacement Relationship:

In the foreseeable future, these two technologies will not compete in a zero-sum game, but rather coexist and complement each other.

For conventional AC distribution applications demanding maximum energy efficiency, high reliability, and low cost, the amorphous alloy 3D wound core transformer will be the preferred solution.

For next-generation power system nodes requiring ultra-high power density, intelligent control, and hybrid AC/DC power supply, the solid-state transformer will play an irreplaceable role.

In short, the amorphous alloy 3D wound core transformer marks the pinnacle of traditional transformer technology, while the solid-state transformer holds the key to the next generation of power conversion. Together, they are driving the electric power industry toward a future that is more efficient, intelligent, and sustainable.