Ang vacuum circuit breaker mao ang tipo sa circuit breaker diin ang arc-extinguishing medium ug insulating medium sa gap sa pagitan sa mga contact human sa arc-extinction mao ang vacuum. Isip usa ka protection ug control unit alang sa power equipment ug power-driven equipment sa industriyal ug mining enterprises, ang indoor AC high-voltage vacuum circuit breakers adunay daghang aplikasyon ug mahimong isulod sa fixed cabinets, middle-mounted cabinets, ug double-layer cabinets. Isip usa ka importante nga electrical device sa switchgear, ang high-voltage circuit breakers angkop sa mga lugar nga nanginahanglan og paborito nga operasyon sa rated working current o multiple interruptions sa short-circuit current.

Ang paper na siya nag-analisa sa problema sa switch sa EIB vacuum circuit breaker nga dili magbukas o magtira ng maayo tungod sa paborito nga operasyon. Tungod sa mga eksperimento, natukdon nga ang tripping spring sa right side sa main shaft nga namatay mao ang sanhi sa circuit breaker nga dili magbukas o magtira ng maayo. Gitawag ang improvement measure sa pag-install sa adjustment shims aron masiguro ang normal nga operasyon sa circuit breaker, kini may sigurado nga reference significance alang sa safety construction sa enterprise production.

Structure of Vacuum Circuit Breaker

Ang vacuum circuit breaker gisangpot sa mga komponente sama sa vacuum arc-extinguishing chamber, operating mechanism, ug support.

Vacuum Arc-Extinguishing Chamber

Gisulti usab kini og vacuum switch tube, ang working principle sa vacuum arc-extinguishing chamber mao ang paggamit sa excellent insulation property sa vacuum medium sa loob sa tube, nahimo kini ang medium-ug high-voltage circuit nga makapadali nga mapatay ang arc ug putlii ang current human sa power supply naputlii. Ang iyang main structures mao ang sumala:

Air-tight Insulation System: Kini usa ka closed container sa vacuum environment, gisangpot kini sa air-tight insulation cylinder, moving-end cover plate, fixed-end cover plate, ug stainless-steel bellows. Aron masiguro ang air-tightness, kinahanglan ang strict nga operating processes sa sealing joints. Kasagaran, ang materials nga may extremely low air permeability ang gikinahanglan, ug ang internal gas release amount usab ang gikinahanglan limitahan sa minimum value.

Conductive System: Kini gisangpot sa fixed electrode ug moving electrode. Ang fixed electrode gisangpot sa fixed contact, fixed conducting rod, ug fixed arc-running surface, samtang ang moving electrode gisangpot sa moving contact, moving conducting rod, ug moving arc-running surface. Ang contact structure types mahimong mahati sa transverse magnetic field type sa spiral-groove arc-running surface, longitudinal magnetic field type, ug cylindrical type. Ang operating mechanism mosiguro nga ang duha ka contacts mogapit pinaagi sa movement sa moving conducting rod, kini magkumpleto sa circuit connection.

Shielding System: Kini gisangpot sa shielding cylinder, shielding cover, ug uban pang devices. Ang commonly used shielding covers kasagaran ang mga tipo sama sa bellows shielding cover ug main shielding cover sa palibot sa contacts. Ang main shielding cover mahimo nimong bawasan ang local field strength, mapahimulos ang uniformity sa internal electric field distribution sa arc-extinguishing chamber, kini ang favorable sa miniaturization sa vacuum arc-extinguishing chamber. Sa parehas nga oras, kini mosiguro nga ang arc products dili mag-splash sa inner wall sa insulating housing human sa arcing process, masiguro ang insulation effect sa housing dili maapektuhan sa arc discharge. Kini usab makapakighubad sa arc energy, condense arc products, ug accelerate ang recovery sa dielectric strength sa post-arc gap.

Operating Mechanism

Ang uban nga tipo sa circuit breakers gamiton ang uban nga tipo sa operating mechanisms. Ang commonly used operating mechanisms sama sa spring operating mechanisms, EIB spring-energy-storage operating mechanisms, CT8 spring-energy-storage operating mechanisms, CT19 spring-energy-storage operating mechanisms, CD10 electromagnetic operating mechanisms, CD17 electromagnetic operating mechanisms, ug uban pa. Sa dihang ang spring operating mechanism adunay advantages sa small size, small closing current, ug high reliability, kasagaran kini gamiton sa switchgear sa uban nga voltage levels.

Function and Principle of Vacuum Circuit Breaker

Function and Characteristics

Sa normal nga operasyon, ang vacuum circuit breaker nga naa sa technical parameter range makapahimulos sa iyang safe ug reliable nga operasyon sa power grid sa corresponding voltage level. Ang mechanical life sa vacuum circuit breaker mahimong 20,000 times, ug ang number sa full-capacity short-circuit current interruptions mao ang 50 times. Kini mahimong operasyon paborito o interrupt short-circuit current multiple times sa working current range. Ang high-voltage vacuum circuit breakers adunay advantages sama sa high reliability, all-weather operation, maintenance-free, complete functions, good interchangeability, ug strong versatility, ug mahimong gamiton sa reclosing operations sa uban nga characteristics. Ang vacuum circuit breakers adunay vertical insulation cylinder ug solid insulation structure-integrated solid-sealed pole columns, kini makapahimulos sa resistance sa uban nga special environments ug maintenance-free. Samtang, ang vacuum circuit breakers adunay multiple usage methods, mahimong isulod sa fixed manner, gamiton sa withdrawable way, o isulod sa frame.

Principle Introduction

Kung ang moving ug static contacts sa vacuum circuit breaker gibukas habang charged, ang vacuum arc mahimong generate sa pagitan sa contacts. Ang arc makapataas sa surface temperature sa contacts, nagresulta sa metal vapor nga magpakita sa contact surface. Batas sa special shape sa contacts, kung ang current mopasa, sa action sa magnetic field nga itomog, ang arc mogilis pinaagi sa tangent direction sa contact surface. Ang metal vapor ug charged particles sa arc column continuously diffuse outward, ug ang density sa metal vapor ug charged particles nagpatuloy nga namatay. Kung ang arc naturally pass through zero, ang medium sa pagitan sa contacts makapabilis nga recover gikan sa conductor ngadto sa insulator, ang current naputlii, ug ang arc matay.

Fault Cause Summary and Analysis

Ang analisis sa situation diin ang vacuum circuit breaker dili magbukas o dili magtira ng maayo tungod sa paborito nga operasyon, sa on-site inspection natukdon nga ang bolt sa right-hand end sa switch main shaft namatay, nagresulta sa right-hand tripping spring namatay ug stuck sa main shaft sa parehas nga oras. Ang mechanism's tripping depende lamang sa tripping spring sa left side sa main shaft, resulta kini ang switch dili magtira ng maayo. Bagama ang probability sa fault na siya mogamit kasagaran gamay, ang occurrence niini mahimong makaapekto sa production safety accidents. Kini mahimong importante nga analisin ang fault cause, eliminate potential safety hazards, ug masiguro ang safe production.

Solution and Verification Plan

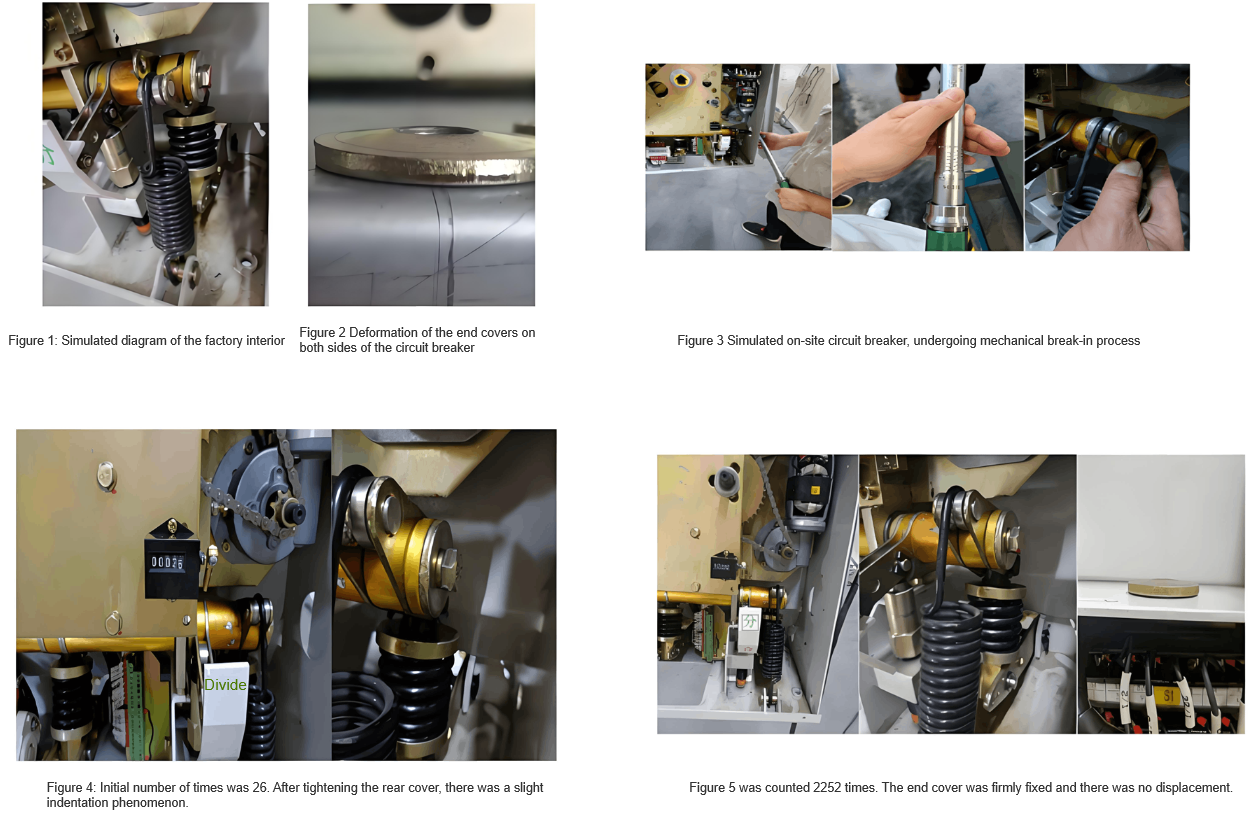

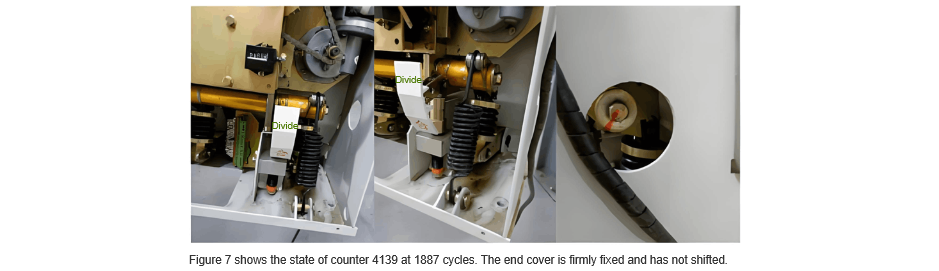

Ang screws nga nagsiguro sa tripping springs sa both sides sa switch main shaft sa EIB mechanism circuit breaker ordinary screws + spring washers (see Figure 1). Human sa tuig nga paborito nga switch operation, ang screw nga nagsiguro sa tripping spring sa right side sa main shaft namatay tungod sa vibration, nagresulta sa right-hand tripping spring namatay ug stuck sa main shaft sa parehas nga oras. Ang mechanism's tripping depende lamang sa tripping spring sa left side sa main shaft, resulta kini ang switch dili magtira ng maayo. Sa on-site investigation, natukdon nga adunay axial length difference sa about 4mm sa spline shaft sa right side sa main shaft ug outer casing, ug ang end cover deformed ug sunken inward (see Figure 2). Tungod sa fault na siya, ang circuit breaker failure gikan sa tripping spring namatay tungod sa loosening sa end bolt sa closing and opening main shaft, aron masiguro, ang reassembled circuit breaker sa corresponding structure gi-simulate ang fault:

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a gap of about 4mm (see Figure 3), and use a torque wrench to tighten it with a torque of 45Nm. Push it into the mechanical running-in chamber for mechanical running-in. The initial counter reading is 26 times, and the end cover shows a slight sunken phenomenon after tightening. The process is shown in Figure 4.

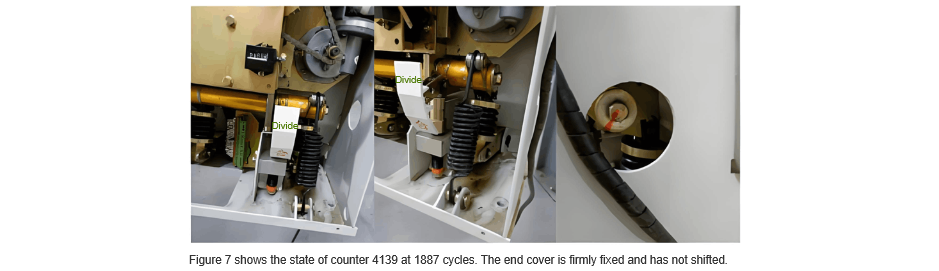

In conclusion, when the specified torque is 45 Nm, even if the axial length between the shaft sleeve and the spline shaft reaches 4 mm and the end cover is deformed and sunken, it remains well-fixed until more than 2,200 operations. Then, it proceeds to the verification of the second stage.

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a 4-mm gap. Use a torque wrench to tighten it with a torque of 35 Nm, and use the deformed and sunken end cover from stage 1. Mark it with a scribing line. Push it into the mechanical running-in chamber for mechanical running-in. The initial count is 2,252. In summary, when the torque is 35 Nm, even if the axial length between the shaft sleeve and the spline shaft reaches 4 mm and the end cover is deformed and sunken, it remains well-fixed until more than 1,887 operations. Then, it proceeds to the verification of the third stage (see Figure 6).

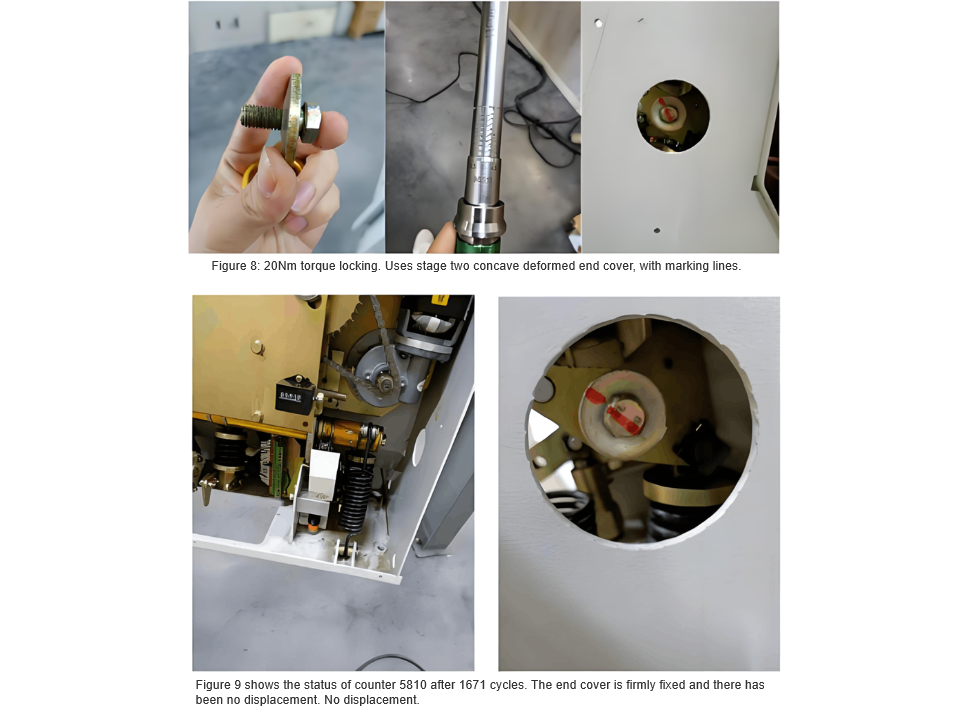

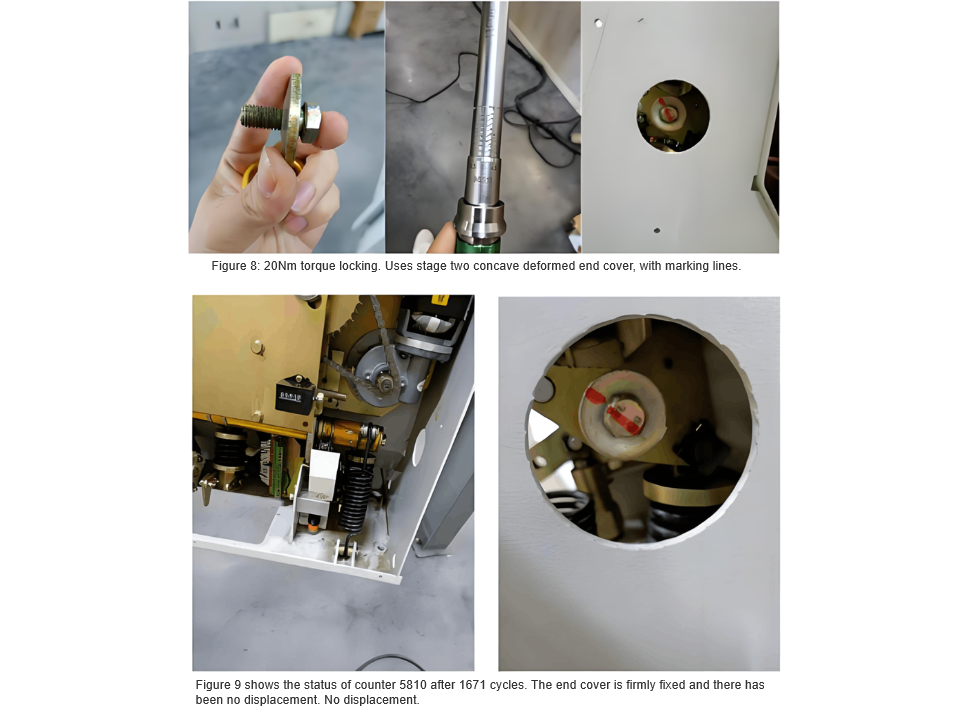

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a 4-mm gap. Use a torque wrench to tighten it with a torque of 20 Nm, and use the deformed and sunken end cover from the third stage. Mark it with a scribing line. Push it into the mechanical running-in chamber for mechanical running-in. The initial count is 4,139 (see Figure 7).

In conclusion, when the torque is 20 Nm, even if the axial length between the shaft sleeve and the spline shaft reaches 4 mm and the end cover is deformed and sunken, it remains well-fixed until more than 1,671 operations. Then, it proceeds to the verification of the fourth stage (see Figure 8 and Figure 9).

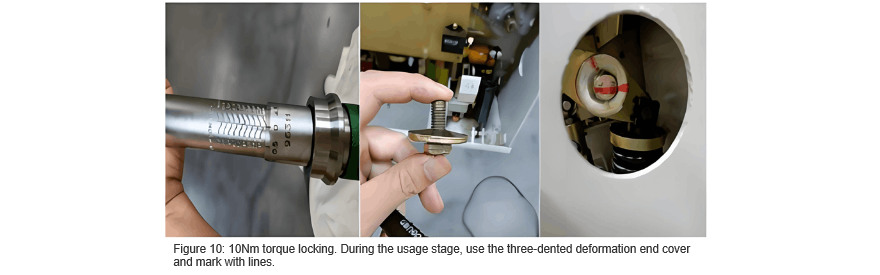

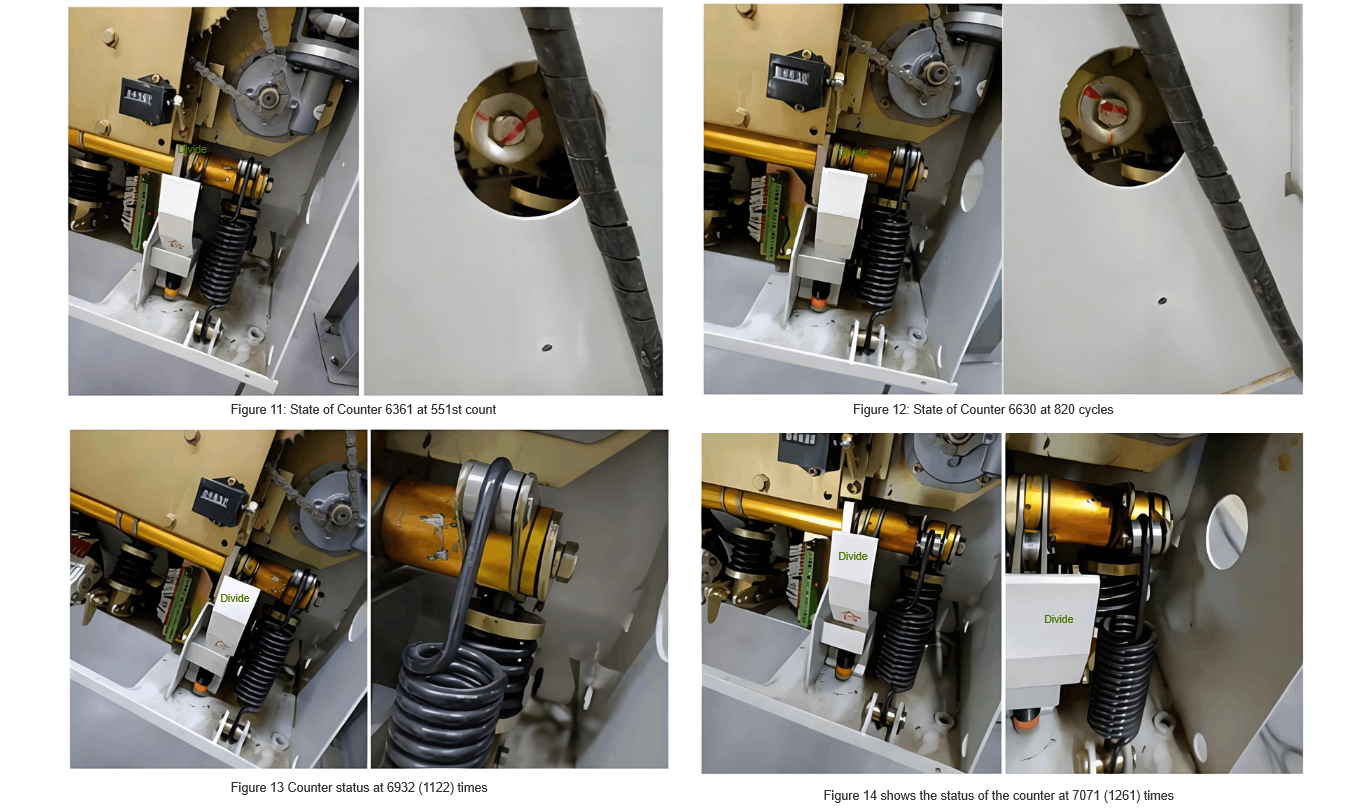

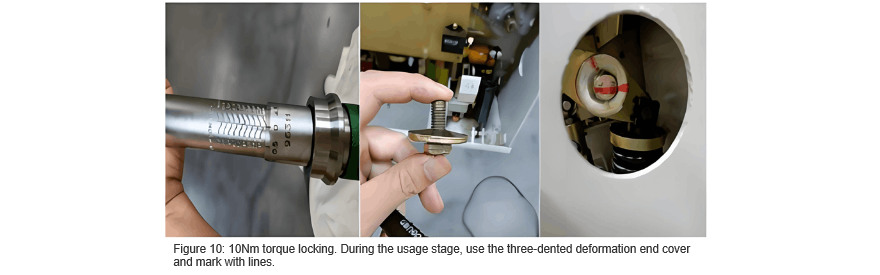

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a 4-mm gap. Use a torque wrench to tighten it with a torque of 10 Nm, and use the deformed and sunken end cover from the fourth stage. Mark it with a scribing line. Push it into the mechanical running-in chamber for mechanical running-in. The initial count is 5,810 (see Figure 10).

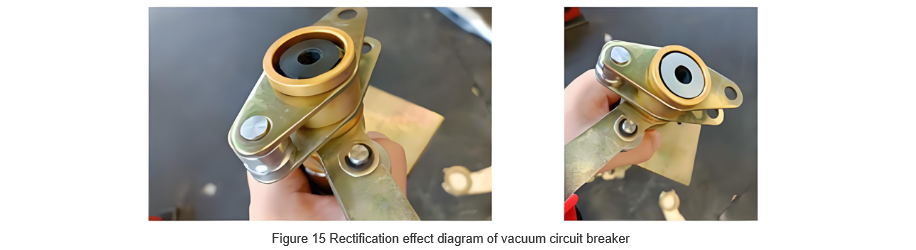

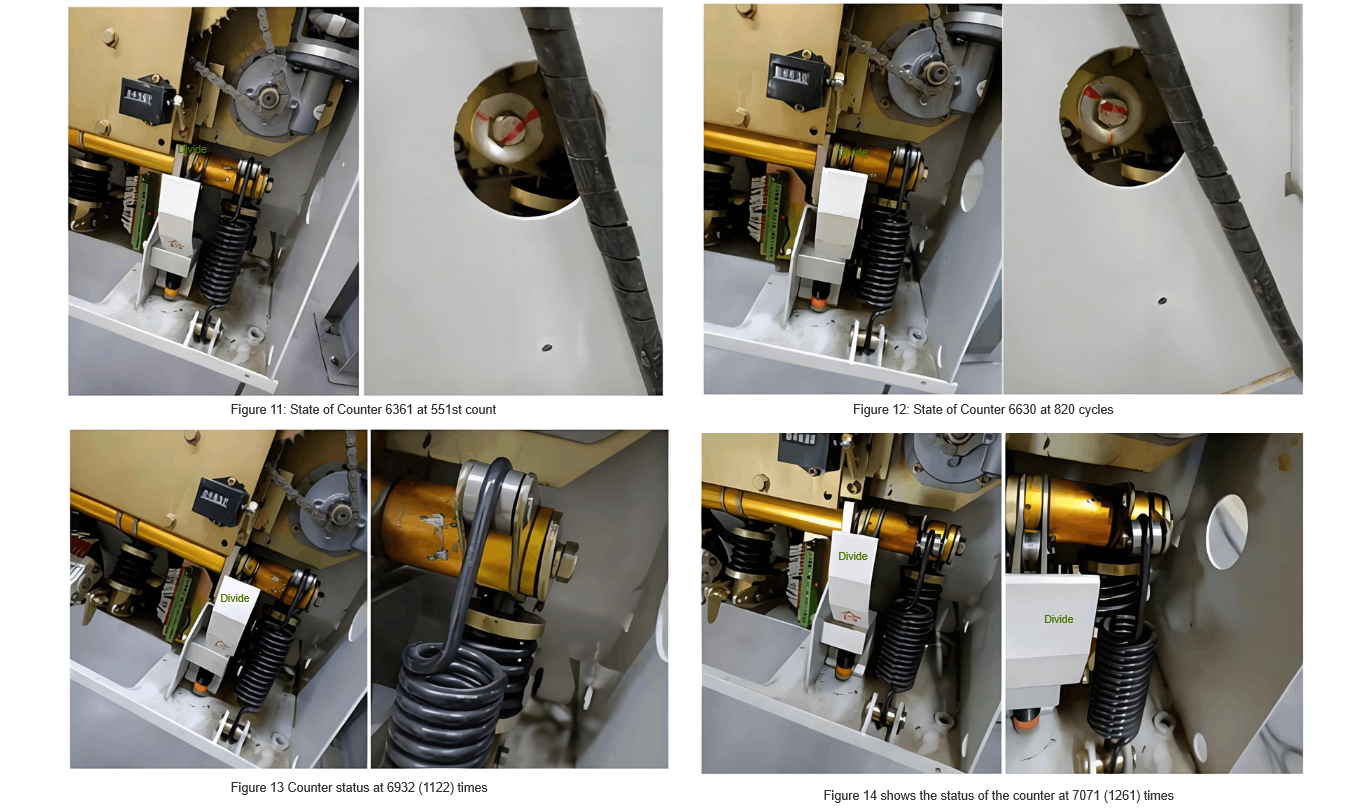

During the test process, it was found that when the counter reached 551 operations, the end cover started to rotate slightly relative to the initial position (see Figure 11); when the count increased to 820 operations, the end cover rotated slightly relative to the position at 551 operations (see Figure 12); when the count reached 1,122 operations, the tripping spring was visibly loose to the naked eye (see Figure 13); when the count increased to 1,261 operations, the tripping spring fell off (see Figure 14).

Summary of the Test Process

The spindle design of the EIB spring operating mechanism is based on the design of the Belgian EIB company. After the crank arms are accurately positioned, bolts on both sides are tightened to the specified torque value. Spring washers (made of spring steel) are used for anti-loosening via friction. After assembly, the washers are flattened, and their rebound force maintains clamping force and friction between threads. This spindle structure design and anti-loosening measures were proven reliable in mechanical life type tests at the China Electric Power Research Institute (CEPRI).

Early Process Issues of the EIB Mechanism Spindle

In the early assembly process, workers had to adjust sleeves of different tolerance grades to balance dimensions, making assembly quality inconsistent and hard to control. After the circuit breaker spindle was assembled, cumulative errors caused axial length deviations between the internal spline shaft and external sleeve. When bolts were tightened to the specified torque, the middle of the end covers would sag inward. Since the end covers are made of non-spring steel elastic materials, they cannot recover after deformation. Additionally, the spindle sleeve may creep due to impacts during operation, which may gradually reduce the bolt tightening torque (with no obvious changes in fasteners like bolts and end covers until the torque weakens significantly). Conventional maintenance also struggles to apply sufficient torque with ordinary wrenches. Eventually, when the torque drops below 10 Nm, the end covers accelerate loosening, destroying the anti-loosening effect of the spring washers.

Improved Process

To eliminate torque weakening caused by end cover sagging, the process was adjusted: after overall assembly, adjustment shims are uniformly added for balancing. Thread-locking adhesive is applied to bolts, which are then tightened to 45 Nm with a torque wrench. With shims installed, there is no longer space for the end covers to sag inward. The end covers will not gradually reduce the tightening torque due to plastic deformation, ensuring stable and reliable operation of the circuit breaker throughout its service life under sufficient torque.

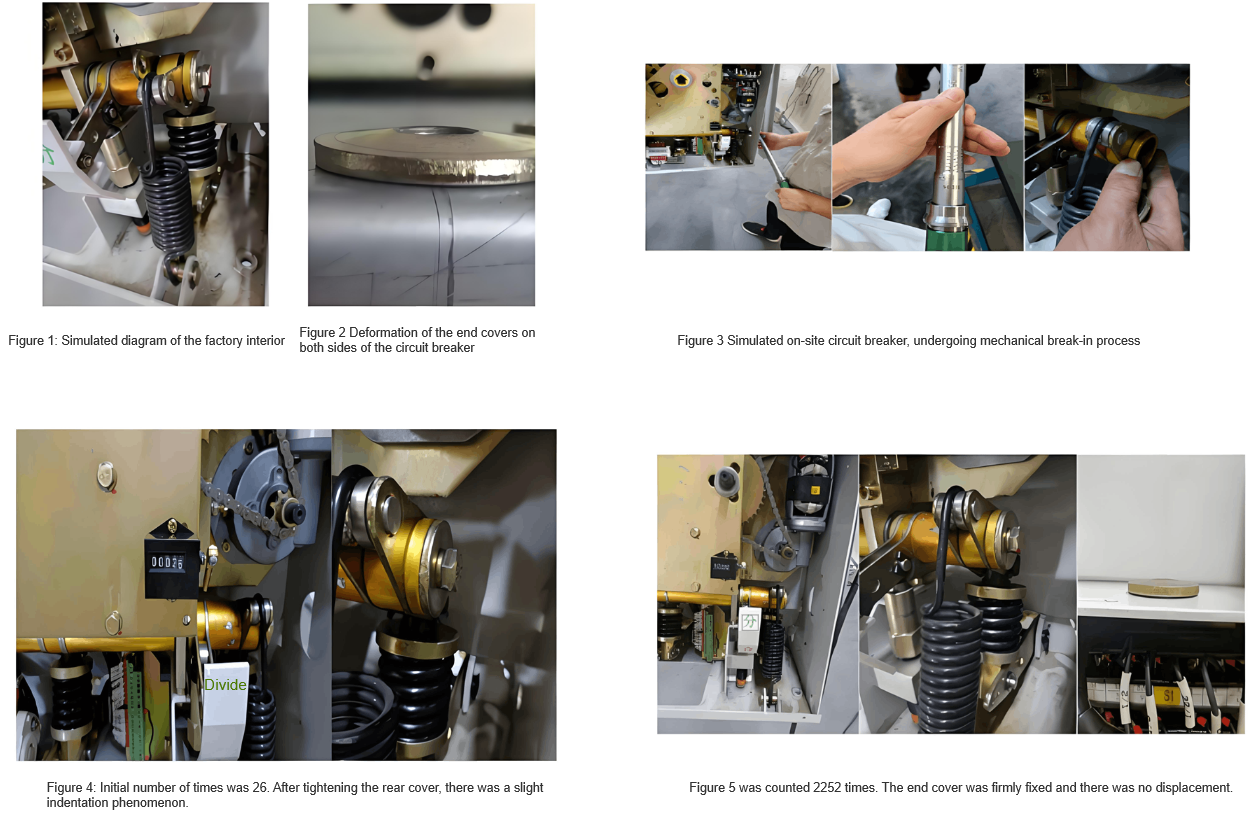

Rectification Measures

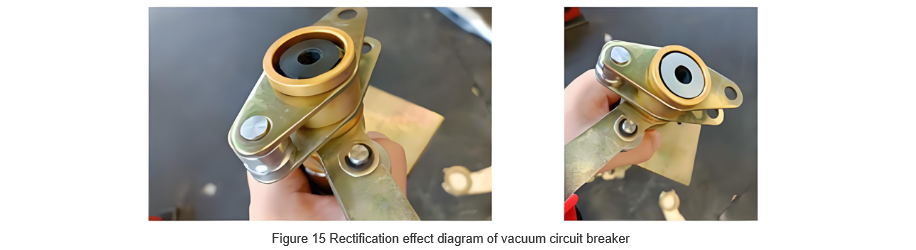

For the circuit breaker with this fault, as shown in Figure 15, install adjustment shims. After aligning the end face of the internal main shaft with the outer sleeve, lock it with bolts. Apply thread-locking adhesive on the bolts and use a torque wrench to tighten them to a torque of 45 Nm.

To prevent the occurrence of such low-probability events, conduct a comprehensive inspection of the circuit breakers that have been put into operation, and install adjustment shims accordingly to ensure that the put-into-operation circuit breakers can work normally and reliably.

Conclusion

This paper focuses on the situation of the high-voltage AC vacuum circuit breaker failing to open properly. By means of simulation analysis and experimental verification, it analyzes the causes of the tripping spring falling off. It is found that the end gasket deforms due to the main shaft gap, and then, after long-term closing and opening vibrations, the tripping spring falls off, resulting in the circuit breaker being unable to open. For this, a solution is proposed, and the feasibility of the solution is demonstrated in detail. Corresponding rectification measures are put forward, so as to eliminate the fault, restore the normal use of the high-voltage vacuum circuit breaker, and ensure the normal production of the enterprise.