Kipengele cha kuzuia nguo ni aina ya kipengele cha kuzuia nguo ambacho chenye nyuzi na mzunguko wa kutumia vifaa vya kuzuia uwezo wa kupata namba katika vipengele viwili. Kama mwanga wa kuzuia na kudhibiti vifaa vya umeme na vifaa vya kudhibiti vifaa vya umeme kwenye maeneo ya kiuchumi na madini, kipengele cha kuzuia nguo cha umeme chenye nguvu ya juu unachotumiwa ndani ya nyumba unatumika kwa urahisi na unaweza kuwekwa katika magari makubwa, magari ya kati, na magari miwili.

Huu makala unaanaliza matatizo ya kipengele cha kuzuia nguo cha EIB kutokua inaweza kufunguliwa au kufunga vizuri kutokana na utendaji wa mara kwa mara. Kutokana na majaribio, limetambuliwa kuwa kusakinisha springi ya upande wa kulia wa msipa mkubwa ni sababu ya kipengele cha kuzuia nguo kutokua inaweza kufunguliwa au kufunga vizuri. Imetolewa hatua ya kuboresha ya kuweka vitufe vilivyotengenezwa ili kuhakikisha utendaji wa kawaida wa kipengele cha kuzuia nguo, ambayo ina umuhimu wa kutosha kwa usimamizi wa amani wa uchumi wa kampuni.

Muundo wa Kipengele cha Kuzuia Nguo

Kipengele cha kuzuia nguo cha umeme kinajumuisha sehemu kama vile chumba cha kuzuia nguo lenye nguvu ya ukame, mfumo wa kudhibiti, na msingi.

Chumba cha Kuzuia Nguo Lenye Nguvu ya Ukame

Pia linatafsiriwa kama suti ya kuzuia nguo, chumba cha kuzuia nguo lenye nguvu ya ukame linatumia tabia nzuri ya kuzuia nguo ya mazingira ya ukame ndani ya suti, kusaidia kutumia mzunguko wa kuzuia nguo na kutumia nguvu za kati na nguvu za juu baada ya kukata nguvu ya umeme. Miundo yake muhimu ni:

Mfumo wa Ukuu: Hii ni kiguruka kilicho kufunika kwenye mazingira ya ukame, linalozungumzwa kwa kiguruka cha ukuu, kivuli cha upande wa kasi, kivuli cha upande wa juu, na bawa la stainless steel. Ili kuhakikisha ukuu, hutumika taratibu zisizoweza kubadilishwa kwenye viungo vya kufunga. Pia, vinavyohitajika ni vifaa vya ukuu vya daraja chache, na punguza kiasi cha gasi chenye kutoka ndani kwa kiwango chache.

Mfumo wa Kutumia Namba: Unajumuisha eleki moja na eleki yenye kutumika. Eleki moja inajumuisha mtaani moja, stiki moja, na sura moja ya kutumia nguo. Eleki yenye kutumika inajumuisha mtaani mwingine, stiki mwingine, na sura mwingine ya kutumia nguo. Aina za mtaani yanaweza kugawanyika kwa kutumia mtaani wa mapinduzi ya magnetic field, mtaani wa longitudinal magnetic field, na aina ya cylindrical. Mfumo wa kudhibiti hujenga mtaani mawili kutumia stiki mwingine, huku akimaliza mzunguko wa kutumia namba.

Mfumo wa Kupunguza: Unajumuisha kivuli cha kupunguza, kivuli cha kupunguza, na vifaa vingine. Kivuli vya kupunguza vinavyotumika sasa ni kama vile kivuli cha kupunguza la bawa la stainless steel na kivuli kikuu cha kupunguza kifuani kwa mtaani. Kivuli kikuu cha kupunguza kinaweza kupunguza nguvu ya magnetic field, kuongeza uwiano mzuri wa electric field ndani ya chumba cha kuzuia nguo, ambayo ni muhimu kwa kutumia chumba cha kuzuia nguo cha ukame. Pia, inaweza kupunguza nguvu za arc products kutembelea kivuli cha kupunguza, kuhakikisha kwamba kivuli cha kupunguza hakipunguza nguvu ya kupunguza. Inaweza pia kupunguza nguvu za arc products, kusonga arc products, na kusonga mzunguko wa kuzuia nguo baada ya kupunguza.

Mfumo wa Kudhibiti

Aina mbalimbali za kipengele cha kuzuia nguo hutumia aina tofauti za mfumo wa kudhibiti. Mfumo wa kudhibiti unayotumika ni spring operating mechanism, EIB spring-energy-storage operating mechanism, CT8 spring-energy-storage operating mechanism, CT19 spring-energy-storage operating mechanism, CD10 electromagnetic operating mechanism, CD17 electromagnetic operating mechanism, na wengine. Katika hayo, spring operating mechanism una faida kama vile ukoo ndogo, current ya kufunga ndogo, na uhakika kubwa, na tangu sasa unatumika kwa urahisi kwenye switchgear za tofauti za kiwango cha nguvu.

Fanya na Sifa za Kipengele cha Kuzuia Nguo

Fanya na Sifa

Katika mazingira ya kawaida, kipengele cha kuzuia nguo cha umeme cha ukame kinaweza kuhakikisha kwamba itafanya kazi kwa uhakika na kwa kawaida katika gridi ya umeme ya kiwango cha nguvu lililo sahihi. Umri wa mekaniko wa kipengele cha kuzuia nguo cha umeme cha ukame ni karibu 20,000 mara, na idadi ya kuzuia nguo ya full-capacity short-circuit current ni 50 mara. Inaweza kutumika mara kwa mara au kuzuia nguo ya short-circuit current mara kwa mara ndani ya mzunguko wa kutumia namba. Kipengele cha kuzuia nguo cha umeme cha ukame cha nguvu ya juu kina faida kama vile uhakika kubwa, kutumika kila wakati, kutumika bila kuhifadhi, fanya zote, na kufanana kwa kutosha, na kinafaidika kwa reclosing operations zenye sifa mbalimbali. Kipengele cha kuzuia nguo cha umeme cha ukame kinatumia vertical insulation cylinder na solid insulation structure - integrated solid-sealed pole columns, ambayo inaweza kuzuia nguvu za mazingira mbalimbali na kuhifadhiwa. Pia, kipengele cha kuzuia nguo cha umeme cha ukame kina njia mbalimbali za kutumika, ambazo zinaweza kuwekwa kwa njia ya kutohifadhiwa, kutumika kwa njia ya kutohifadhiwa, au kuwekwa kwenye frame.

Ushauri wa Sifa

Wakati mtaani wa kutumika na mtaani wa kutumika wa kipengele cha kuzuia nguo cha umeme cha ukame wanafunguliwa wakati wanapokuwa wenye nguvu, arc vacuum utengenezwa kati ya mtaani. Arc huiongeza joto la mtaani, kufanya metal vapor kutokana na mtaani. Tangu mtaani wanapotumika, katika mjadala wa magnetic field uliotengenezwa, arc hukabiliana haraka kulingana na tangent direction ya mtaani. Metal vapor na charged particles katika arc column huongezeka kwa urahisi, na ubwoko wa metal vapor na charged particles kunywesha kwa kiwango chache. Wakati arc hutembea kwa kawaida zero, medium kati ya mtaani hukabiliana haraka kutoka kwa conductor hadi insulator, nguvu hukata, na arc hukuzwa.

Maelezo na Tathmini ya Sababu za Matatizo

Tofauti za kipengele cha kuzuia nguo cha umeme cha ukame kutokua inaweza kufunguliwa au kutokua inaweza kufunga vizuri kutokana na utendaji wa mara kwa mara, katika mahakama, limetambuliwa kuwa bolti ya upande wa kulia wa msipa mkubwa imesakinisha, ikisababisha springi ya tripping ya upande wa kulia kushuka na kushikwa kwenye msipa mkubwa. Mfumo wa tripping unatumia tu springi ya tripping ya upande wa kulia wa msipa mkubwa, huku akimaliza kipengele cha kuzuia nguo kutokua inaweza kufunga vizuri. Ingawa ukweli wa hili tatizo ni chache, litumaini wake linaweza kusababisha matatizo ya amani ya uchumi. Kwa hiyo, ni lazima kuanaliza sababu za tatizo, kufuta hatari, na kuhakikisha amani ya uchumi.

Solution na Mipango ya Kutathmini

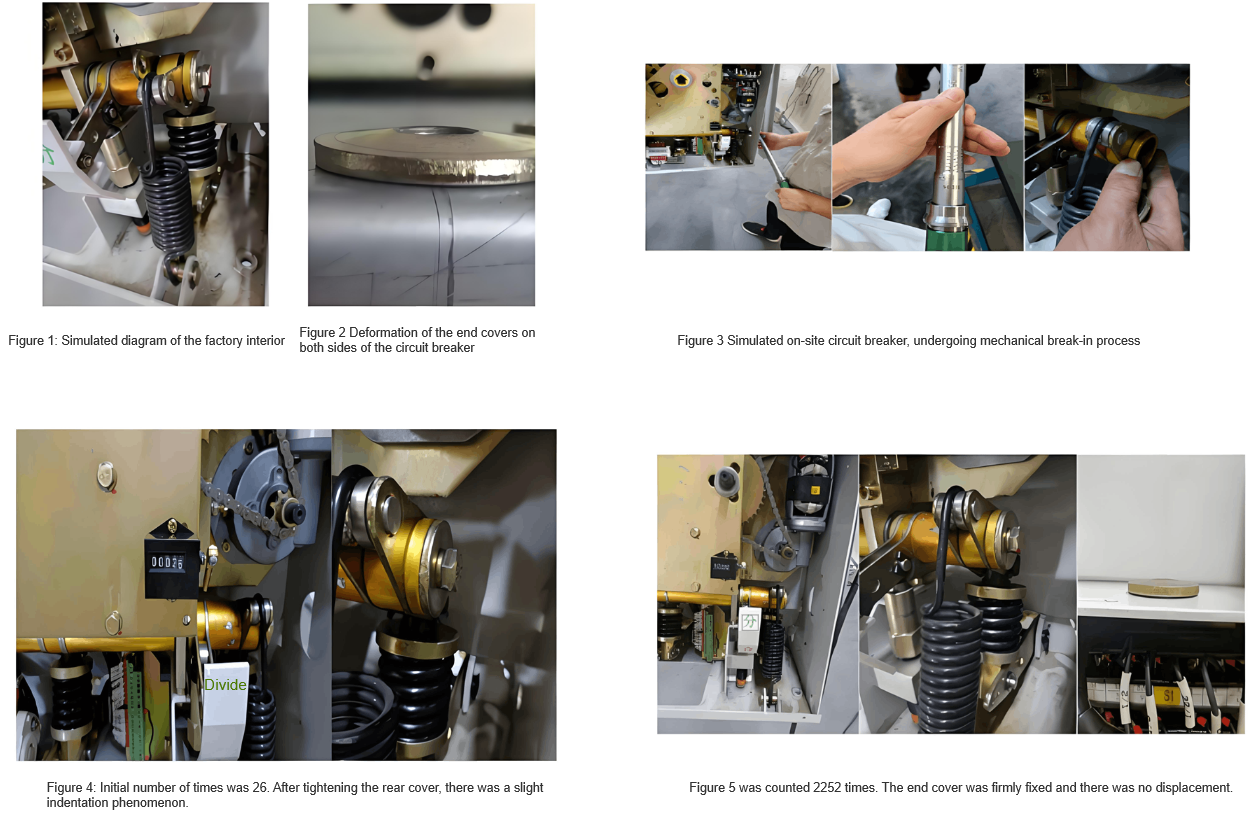

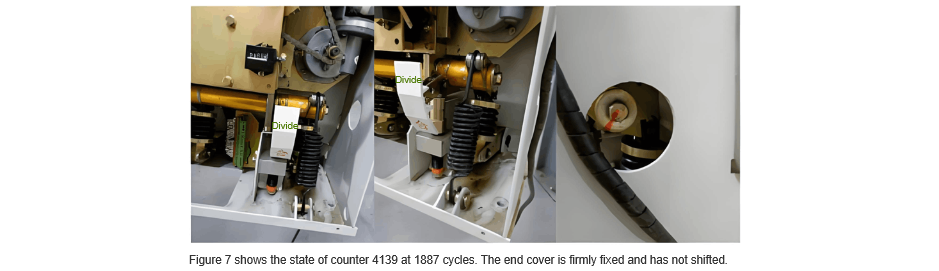

Screw zinazofungua springi za tripping kwenye upande wa kulia na upande wa kulia wa msipa mkubwa wa kipengele cha kuzuia nguo cha EIB ni ordinary screws + spring washers (angalia Fig. 1). Baada ya miaka mingi ya utendaji wa mara kwa mara, screw zinazofungua springi ya tripping ya upande wa kulia wa msipa mkubwa yakasakinisha kutokana na uharibifu, ikisababisha springi ya tripping ya upande wa kulia kushuka na kushikwa kwenye msipa mkubwa. Mfumo wa tripping unatumia tu springi ya tripping ya upande wa kulia wa msipa mkubwa, huku akimaliza kipengele cha kuzuia nguo kutokua inaweza kufunga vizuri. Kutokana na utafiti wa mahali, imeonekana kuwa kuna tofauti ya urefu wa axial kati ya spline shaft ya upande wa kulia wa msipa mkubwa na outer casing, na end cover imebadilika na kukanda ndani (angalia Fig. 2). Kubwa kwa hili tatizo, ambalo ni kipengele cha kuzuia nguo kutokua inaweza kufunga vizuri kutokana na springi ya tripping kushuka kutokana na bolti ya end ya msipa mkubwa ya kufunga na kufunga, ili kutathmini, kipengele cha kuzuia nguo chenye muundo wa kipekee limerekebishwa kwa ajili ya kutathmini tatizo:

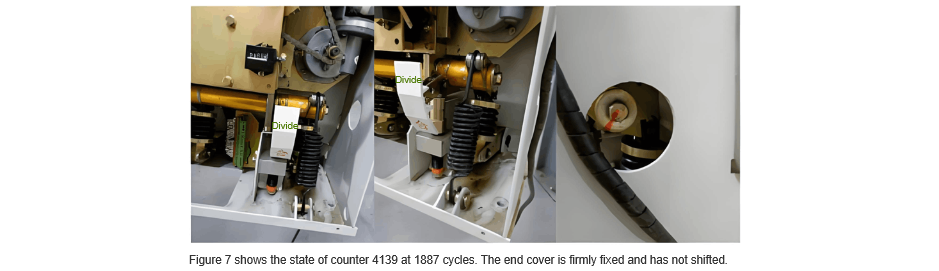

Badilisha urefu wa axial kati ya spline shaft ya upande wa kulia wa msipa mkubwa wa kipengele cha kuzuia nguo hiki na outer casing ili kujenga gap wa karibu 4mm (angalia Fig. 3), na tumia wrench ya torque kutofautiana kwa torque wa 45Nm. Push it into the mechanical running-in chamber for mechanical running-in. Initial counter reading is 26 times, and the end cover shows a slight sunken phenomenon after tightening. The process is shown in Figure 4.

In conclusion, when the specified torque is 45 Nm, even if the axial length between the shaft sleeve and the spline shaft reaches 4 mm and the end cover is deformed and sunken, it remains well-fixed until more than 2,200 operations. Then, it proceeds to the verification of the second stage.

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a 4-mm gap. Use a torque wrench to tighten it with a torque of 35 Nm, and use the deformed and sunken end cover from stage 1. Mark it with a scribing line. Push it into the mechanical running-in chamber for mechanical running-in. The initial count is 2,252.In summary, when the torque is 35 Nm, even if the axial length between the shaft sleeve and the spline shaft reaches 4 mm and the end cover is deformed and sunken, it remains well-fixed until more than 1,887 operations. Then, it proceeds to the verification of the third stage (see Figure 6).

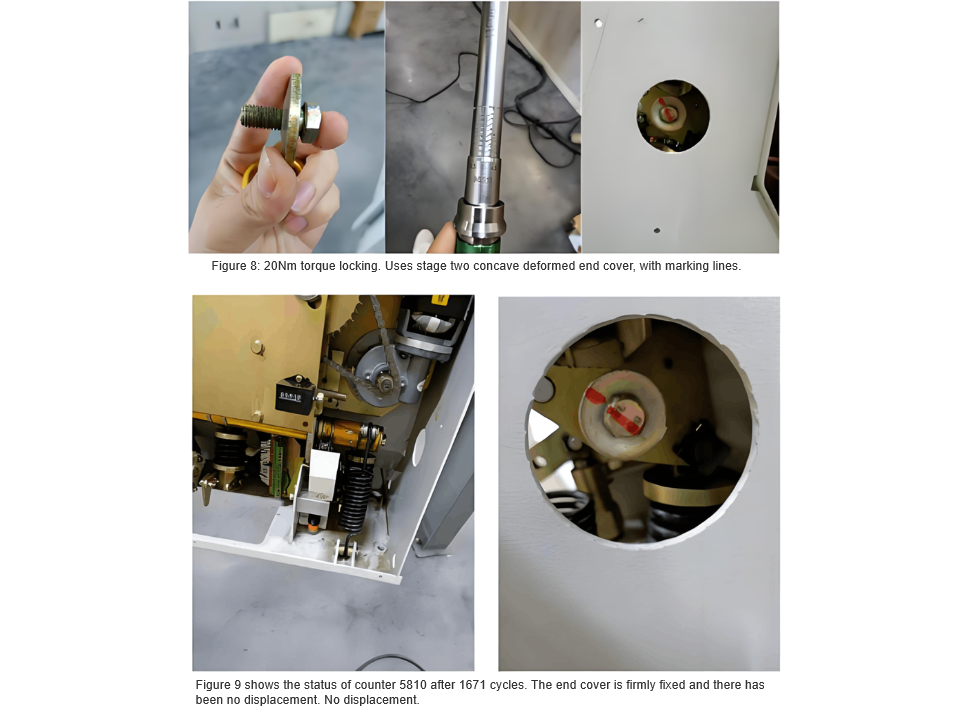

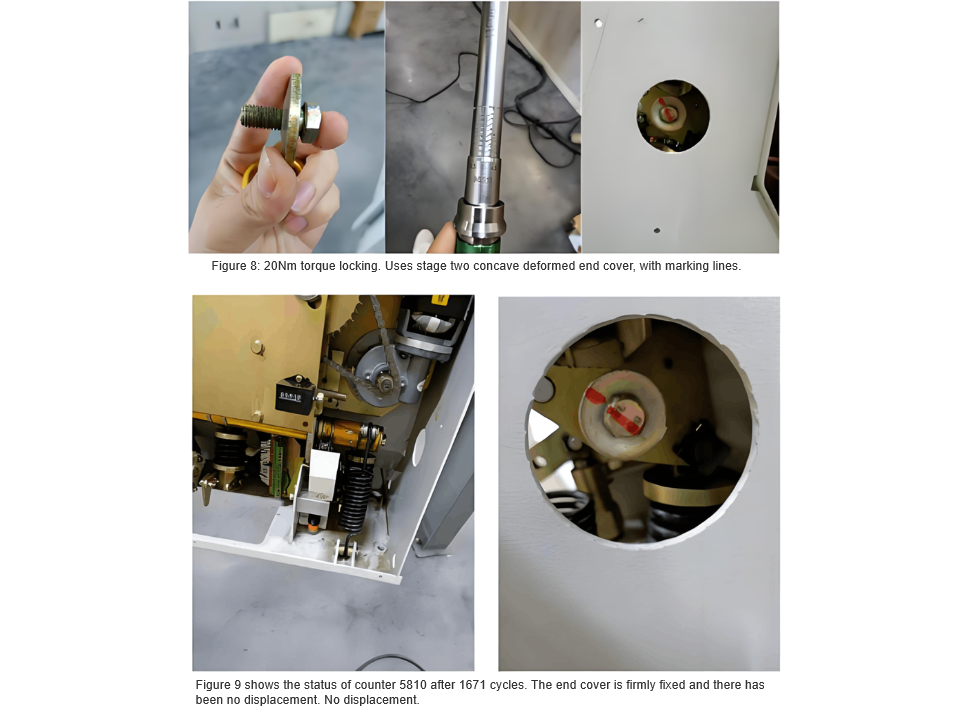

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a 4-mm gap. Use a torque wrench to tighten it with a torque of 20 Nm, and use the deformed and sunken end cover from the third stage. Mark it with a scribing line. Push it into the mechanical running-in chamber for mechanical running-in. The initial count is 4,139 (see Figure 7).

In conclusion, when the torque is 20 Nm, even if the axial length between the shaft sleeve and the spline shaft reaches 4 mm and the end cover is deformed and sunken, it remains well-fixed until more than 1,671 operations. Then, it proceeds to the verification of the fourth stage (see Figure 8 and Figure 9).

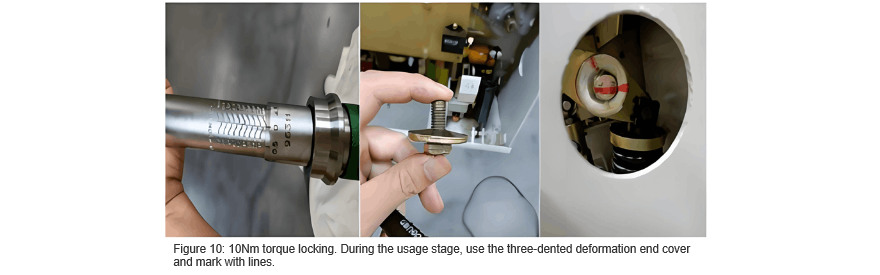

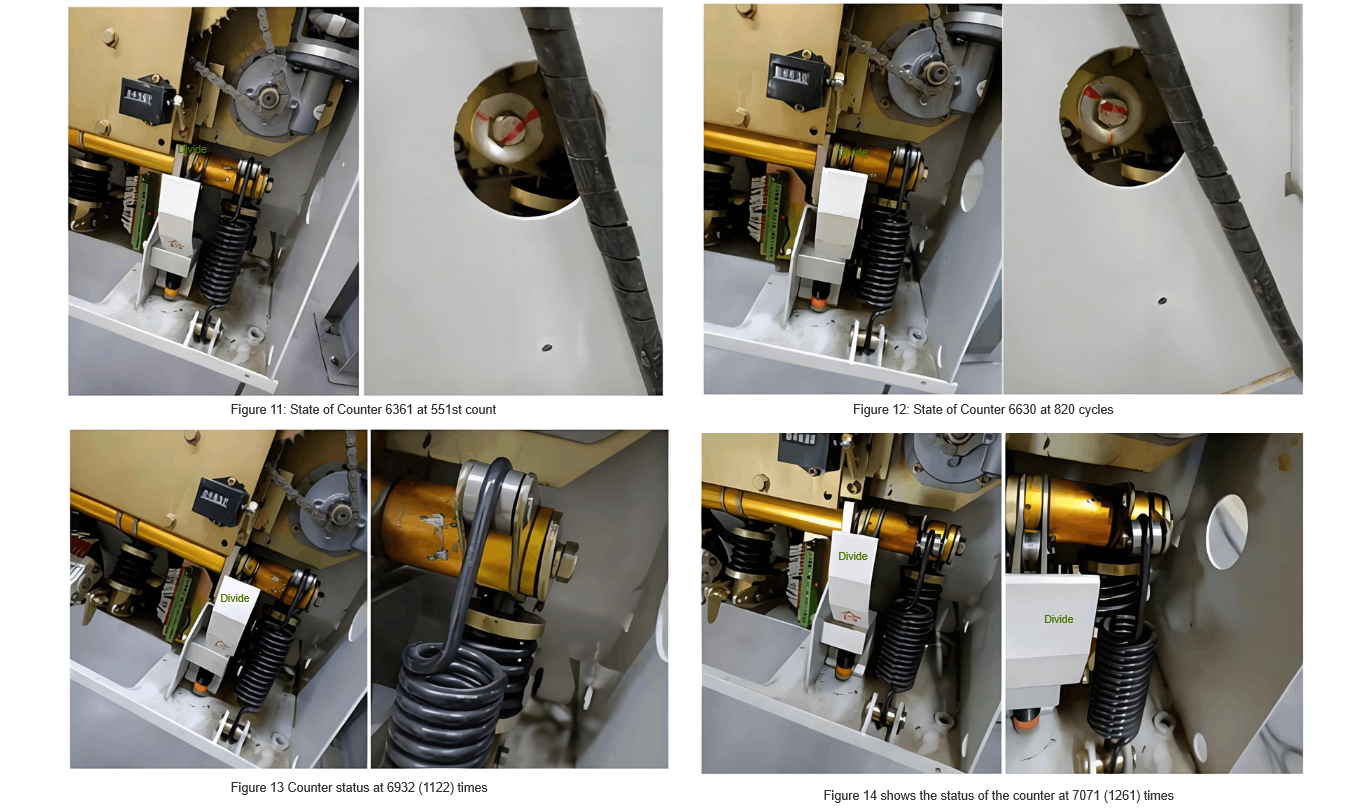

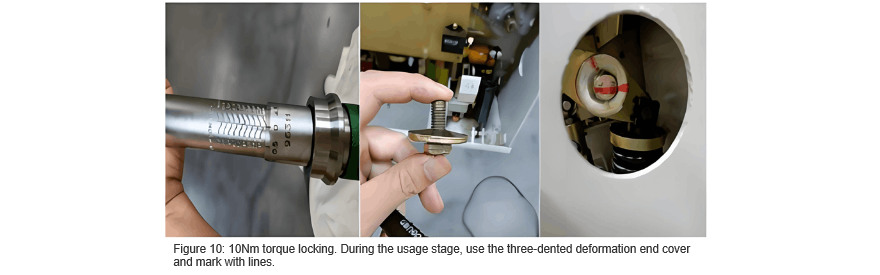

Adjust the axial length between the spline shaft on the right side of the main shaft of this simulated circuit breaker and the outer casing to create a 4-mm gap. Use a torque wrench to tighten it with a torque of 10 Nm, and use the deformed and sunken end cover from the fourth stage. Mark it with a scribing line. Push it into the mechanical running-in chamber for mechanical running-in. The initial count is 5,810 (see Figure 10).

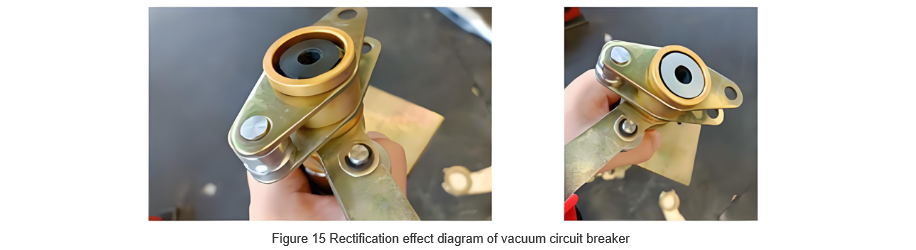

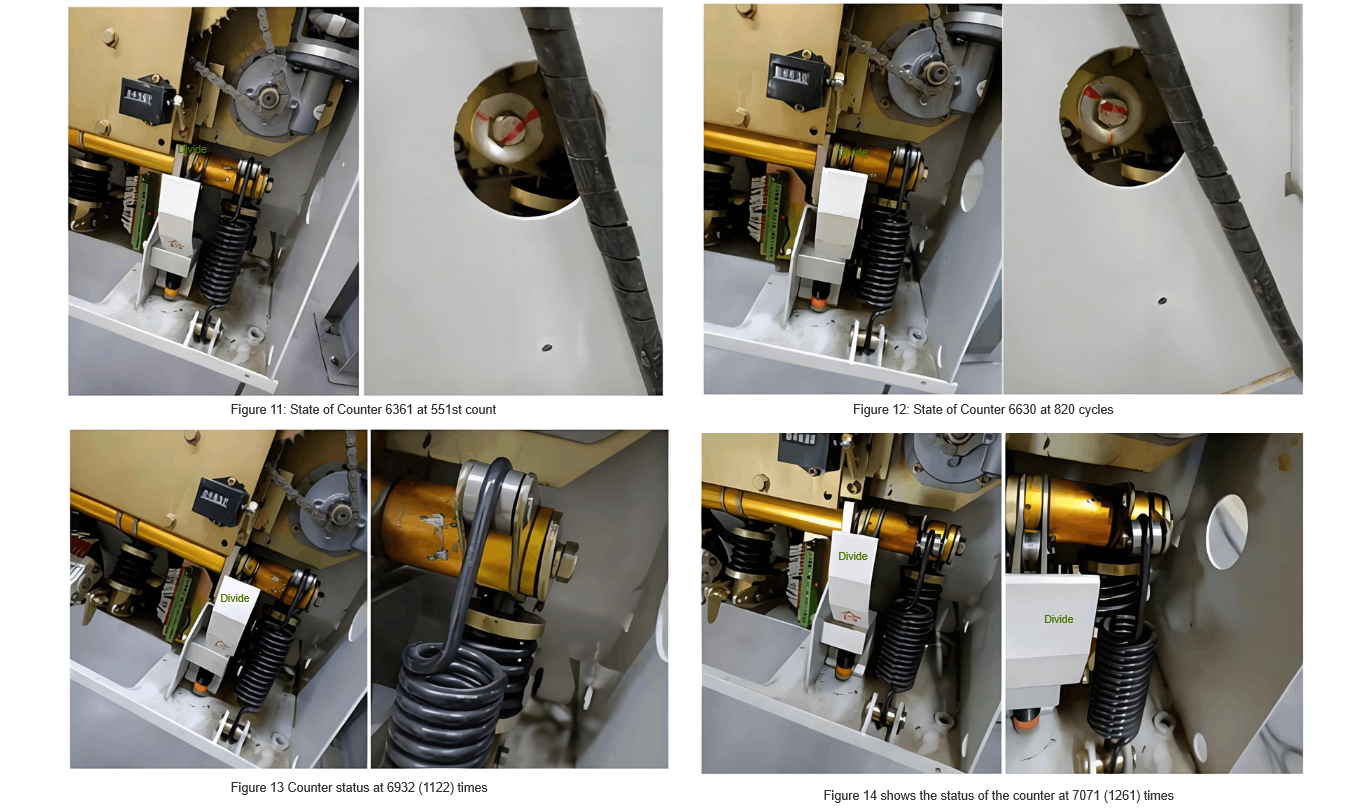

During the test process, it was found that when the counter reached 551 operations, the end cover started to rotate slightly relative to the initial position (see Figure 11); when the count increased to 820 operations, the end cover rotated slightly relative to the position at 551 operations (see Figure 12); when the count reached 1122 operations, the tripping spring was visibly loose to the naked eye (see Figure 13); when the count increased to 1261 operations, the tripping spring fell off (see Figure 14).

Summary of the Test Process

The spindle design of the EIB spring operating mechanism is based on the design of the Belgian EIB company. After the crank arms are accurately positioned, bolts on both sides are tightened to the specified torque value. Spring washers (made of spring steel) are used for anti-loosening via friction. After assembly, the washers are flattened, and their rebound force maintains clamping force and friction between threads. This spindle structure design and anti-loosening measures were proven reliable in mechanical life type tests at the China Electric Power Research Institute (CEPRI).

Early Process Issues of the EIB Mechanism Spindle

In the early assembly process, workers had to adjust sleeves of different tolerance grades to balance dimensions, making assembly quality inconsistent and hard to control. After the circuit breaker spindle was assembled, cumulative errors caused axial length deviations between the internal spline shaft and external sleeve. When bolts were tightened to the specified torque, the middle of the end covers would sag inward. Since the end covers are made of non-spring steel elastic materials, they cannot recover after deformation. Additionally, the spindle sleeve may creep due to impacts during operation, which may gradually reduce the bolt tightening torque (with no obvious changes in fasteners like bolts and end covers until the torque weakens significantly). Conventional maintenance also struggles to apply sufficient torque with ordinary wrenches. Eventually, when the torque drops below 10 Nm, the end covers accelerate loosening, destroying the anti-loosening effect of the spring washers.

Improved Process

To eliminate torque weakening caused by end cover sagging, the process was adjusted: after overall assembly, adjustment shims are uniformly added for balancing. Thread-locking adhesive is applied to bolts, which are then tightened to 45 Nm with a torque wrench. With shims installed, there is no longer space for the end covers to sag inward. The end covers will not gradually reduce the tightening torque due to plastic deformation, ensuring stable and reliable operation of the circuit breaker throughout its service life under sufficient torque.

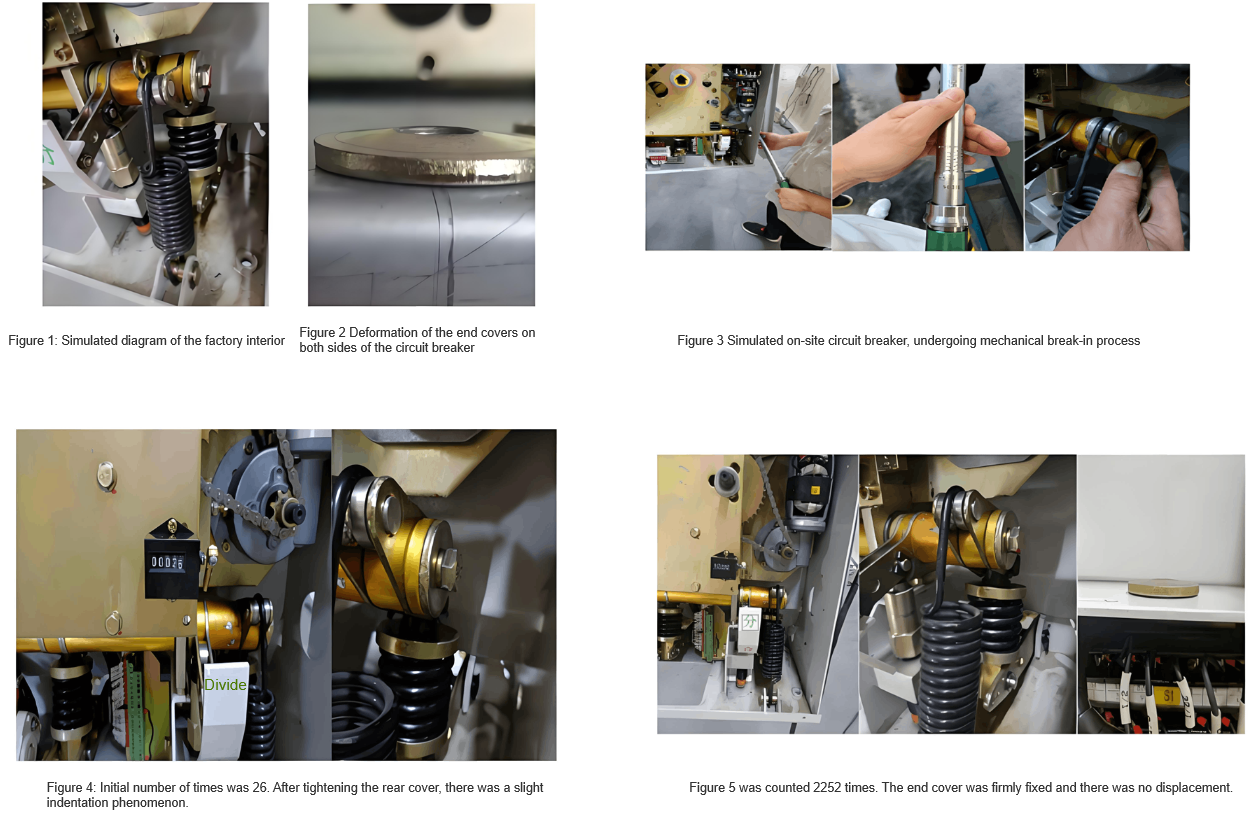

Rectification Measures

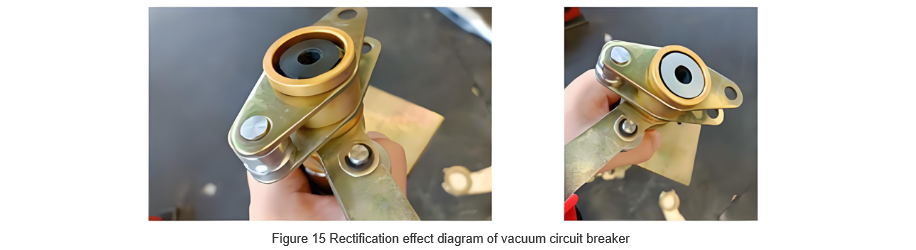

For the circuit breaker with this fault, as shown in Figure 15, install adjustment shims. After aligning the end face of the internal main shaft with the outer sleeve, lock it with bolts. Apply thread-locking adhesive on the bolts and use a torque wrench to tighten them to a torque of 45 Nm.

To prevent the occurrence of such low-probability events, conduct a comprehensive inspection of the circuit breakers that have been put into operation, and install adjustment shims accordingly to ensure that the put-into-operation circuit breakers can work normally and reliably.

Conclusion

This paper focuses on the situation of the high-voltage AC vacuum circuit breaker failing to open properly. By means of simulation analysis and experimental verification, it analyzes the causes of the tripping spring falling off. It is found that the end gasket deforms due to the main shaft gap, and then, after long-term closing and opening vibrations, the tripping spring falls off, resulting in the circuit breaker being unable to open. For this, a solution is proposed, and the feasibility of the solution is demonstrated in detail. Corresponding rectification measures are put forward, so as to eliminate the fault, restore the normal use of the high-voltage vacuum circuit breaker, and ensure the normal production of the enterprise.