Selectio et Installatio Apparatorum Distributionis Basata in GIS

Nunc, apparatus distributionis communiter usitati praecipue includunt apparatum switchgear aeris insulati aperti foris, GIS traditionalem intus, GIS structurae ferreae intus, et GIS hybrida foris. Haec studia ad substationes in Indonesia spectant, ut compleantur installationes apparatorum distributionis pro substationibus prefabricatis intelligentibus. Plurima substationum in Indonesia in regionibus cum terris complicatis et densitatibus oneris parvis locantur. Secundum planum actuale, strategia developmentis rete electricae regionalis est uti lineis existentibus 110 kV ad construendas substationes parvorum capacitatum. Super hoc, gradatim diminuentur niveles tensionis, ut maxime efficaciam investimenti, utilitatem apparatorum, et deponantur officia substationum 35 kV. Substationes in rete electrico Indonesiano sunt magnae, cum summa investimenti et costibus apparatorum, et longis temporibus constructionis, quod necessitat ulterius optimisationem in selectione apparatorum et installatione apparatorum distributionis.

GIS hybrida foris integrat circuit breakers et disconnectores, utendo busbaris consuetudinariis. Hoc dispositio potest numerum flangiarum et apparatorum foris minuere, ita ut crescat efficiens usus terrae in area targeta. Praeterea, abordus GIS hybridus posset difficilatem installationis et expansionis minuere, facilitans installationem et maintenance apparatorum in regionibus montanis et collinis.

Indonesia habet climatam humidiora cum multis diebus alti caloris, sic controllo intelligenti exiguntur severiores conditiones ambientales. In Indonesia, cabinets controllo intelligenti generaliter requirunt humorem relativum inter 5% - 95% et temperaturam ambientalem inter -5 - 55°C, sine formatione gelidi permittenda. Ad refrigerationem, dehumidificationem, et preventionem condensationis pro cabinetis controllo foris, hoc studium methodum adoptionem air-conditioners ad latera portarum cabinetorum instaurat.

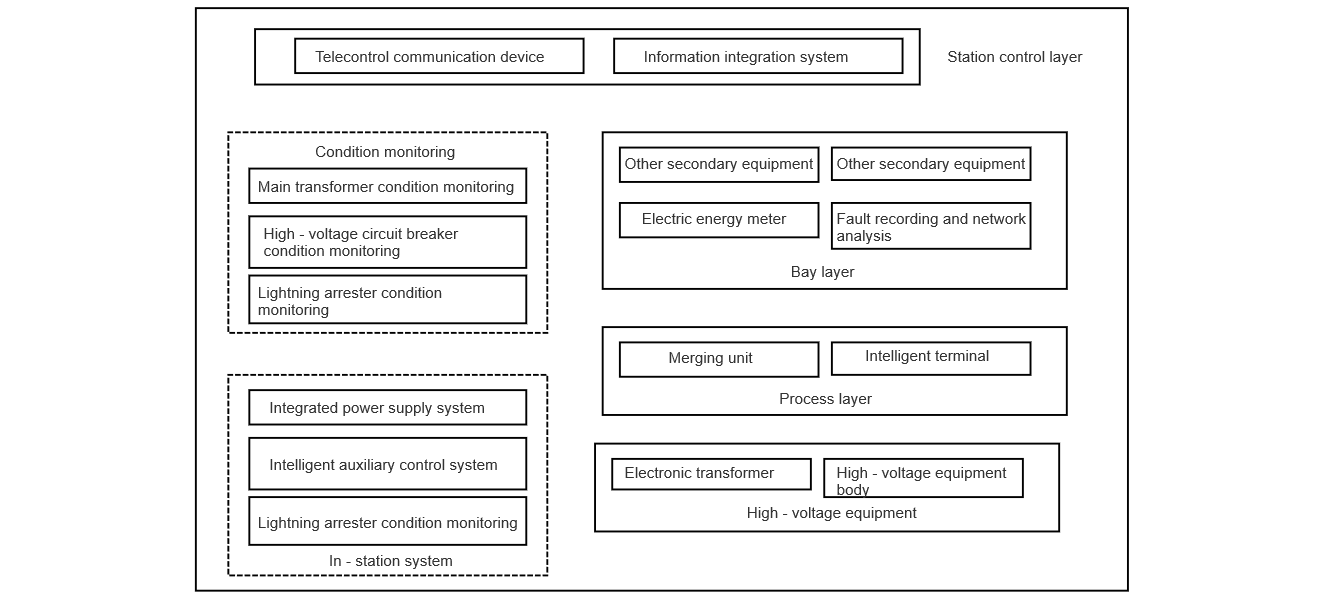

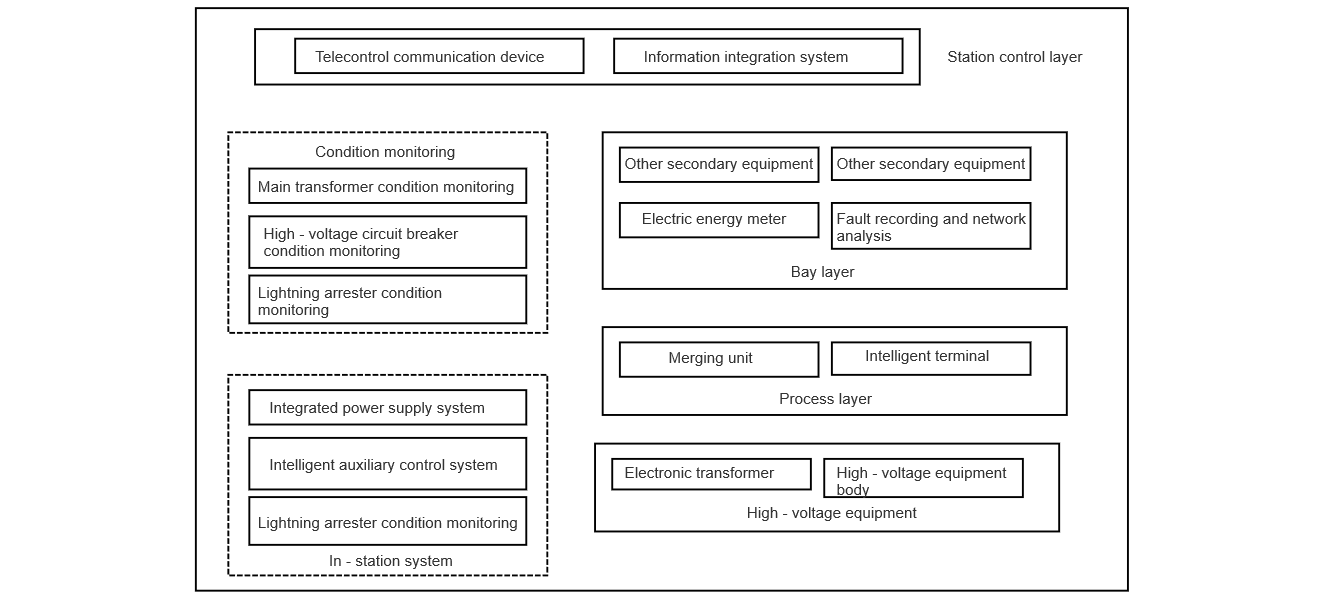

Quod attinet ad principale commutatorium electricum, est necessarium securitatem, economicitatem, operabilitatem, et securitatem in operatione confirmare. Pro wiring 110 kV single-busbar, saepissime sectio wiring vel bridge-type wiring adoptatur. Wiring bridge-type pauciores circuit breakers et minus investimenti habet, sed securitas eius inferior est quam sectio wiring, et difficultas modificationis et expansionis subsequentis maior est. Itaque, hoc studium utitur circuit breakers ad sectionem busbar. Hac methodo sectio wiring, quando una sectio busbar deficere coepit, reliquae partes adhuc normaliter supple possunt, securitatem servantes. Sectio wiring single-busbar est comparativus simplicior, cum paucioribus componentibus apparatorum, et securitate et operabilitate alta. Structura substationis intelligentis meliorata ostenditur in Figura 1.

Transformatores intra substationem, ut apparatus cruciales, ludunt partem vitalem in detectione status. Considerando costus investimenti et applicationes, design scheme huius studii utitur device monitoraggio gas dissoluto in oleo online et device detectionis currentis terreni nucleo ferri online. Prior, pretio circa 200,000 RMB per set, utitur ad detectionem insulationis internae transformatoris principalis, posterius vero ad detectionem currentis terreni nucleo ferri in real-time. Ambae technologiae sunt maturae et latius applicatae.

Transformator intelligens integra apparatus primarios et secundos, idoneus ad perceptionem status et assessmentem status operationalis. Ut facilius sit maintenance cotidianam et monitoring shifts et reducatur laboris maintenance, naturalis circulatio olei aeris refrixionis eligitur ut modus refrixionis pro transformatore principe.

GIS hybridus integrat circuit breakers, switches, et current transformers in unum corpus, simplificans processum reconstructionis per reductionem numeri apparatorum. Praeterea, GIS hybridus foris pauciores apparatos et flanges habet, offerens securitatem maiorem et resistentiam corrosionis, quod eum bene perficere facit in area targeta. Tensio nominata equipment bay GIS hybridus est 126 kV, et currentus nominatus 2000 A. Unum equipment bay GIS hybridus constat sensoribus, cabinetis controllo intelligenti, et SF₆ gas state detection devices. Haec dispositiva possunt statum gas et status operationis apparatorum detectare, permittentes mensurationem digitalem, informationem interactionem, et functiones status inquiry pro high-voltage switches.

Optimizatio Apparatorum Distributionis et Dispositio Generalis

In design originali substationis intelligentis, configuratio cabinetorum terminalis intelligentis et cabinetorum control-gathering GIS hybridus sequitur dispositionem duorum cabinetorum per bay. Verum haec approach resultat in numerosis loop-circuitis cable-crossing, quod non favorabile est pro maintenance cotidiana. Itaque, circuitus secundi terminales intelligentis et mechanismi GIS hybridus integrari possunt. Per combinationem panel control, loops interlocking, loops anti-tripping, et loops non-in-phase in terminalis intelligentis, design integratum obtineri potest.

Optimizatio cabinetorum controllo intelligenti praecipue tres aspectos continet: (1) Simplificatio circuitus per substitutionem logic hard-wiring logica software localis terminalis; (2) Facilitatio communicationis inter bays per terminals intelligentes et technologiam object-oriented event substation; (3) Adoptionem design integratum terminalium intelligentium et circuitus control circuit breaker ad reducendum functiones redundantes sicut loops pressure interlocking. Praeter haec improvementes circuitus, dispositio terminalium intelligentium intra cabinetos control-gathering originarios retinetur, et connectiones inter cabinetos control-gathering intelligentes et apparatos correspondentes optimantur.

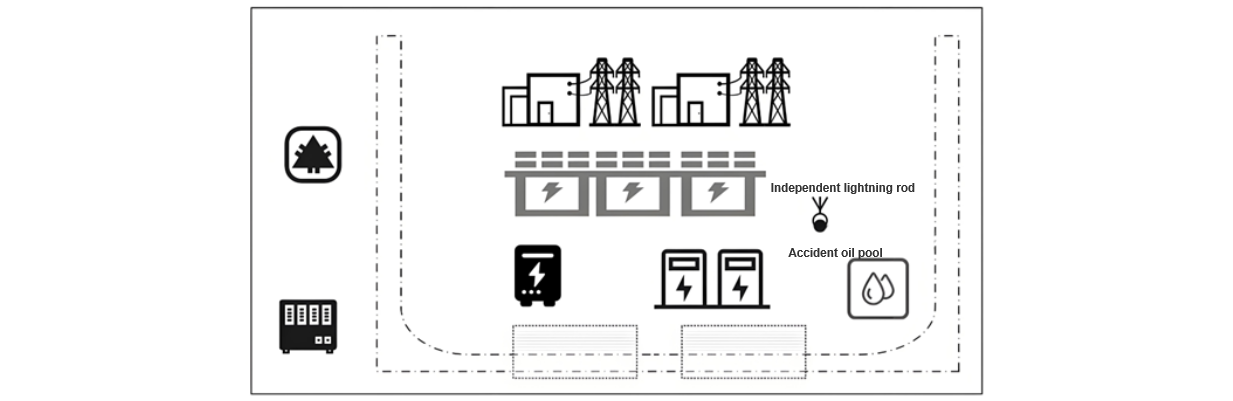

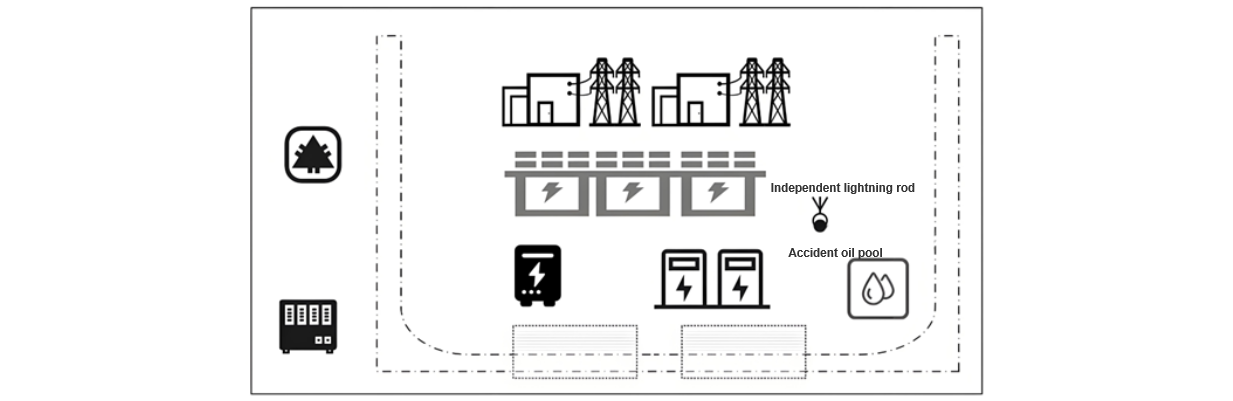

Design scheme propositum in hoc studio adoptat modello cabin modularis prefabricatus. Dispositio substationis debet basari super conditionibus naturalibus et requirementibus engineering target area, et possidere advantages sicut securitas, reliable, environmental friendliness, fire protection, et convenient operation and maintenance. In target area, 110 kV distribution equipment et main transformers disponentur ab aquilone ad meridiem. Ad satisfaciendum requisitionibus transportationis, via ignis circularis intra substationem constituitur, et installatio apparatorum in situ utitur layout minimus. Per hanc dispositionem, 18% superficiei terrae salvare potest. General layout distribution equipment in design scheme ostenditur in Figura 2.

In terms of optimization of distribution dimensions

Design scheme proposed in the research arranges hybrid GIS equipment in two rows, and the 110 kV distribution equipment adopts outdoor aluminum-magnesium alloy support tube busbars. The standard sectional bay layout typically features a linear arrangement of soft conduit busbars at both ends, which occupies a large amount of lateral space. Thanks to the integration of hybrid GIS equipment, its layout is more compact. The research sets the lateral dimension of the sectional bay at 8 m, which is 2 m shorter than before. The standard longitudinal length is 39 m. To optimize the longitudinal dimension, the proposed scheme uses integrated equipment, removes the incoming line structure, and modifies the busbar framework, thereby reducing the occupation of longitudinal space. Through these two improvements, the longitudinal dimension in the scheme is 25.2 m, 13.8 m shorter than the standard length, effectively reducing the space occupied by the equipment.

Performance and Cost Analysis of Intelligent Prefabricated Substations

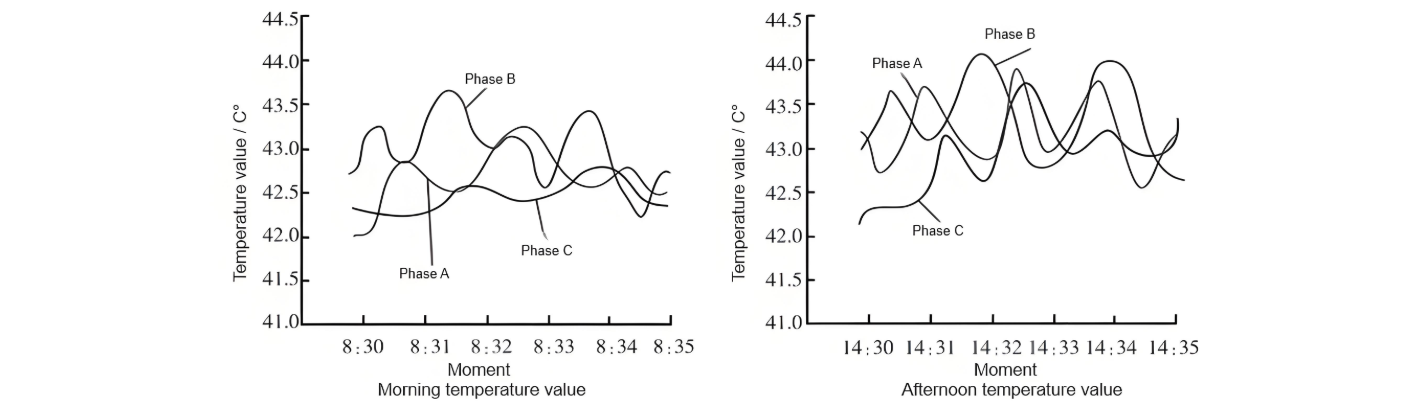

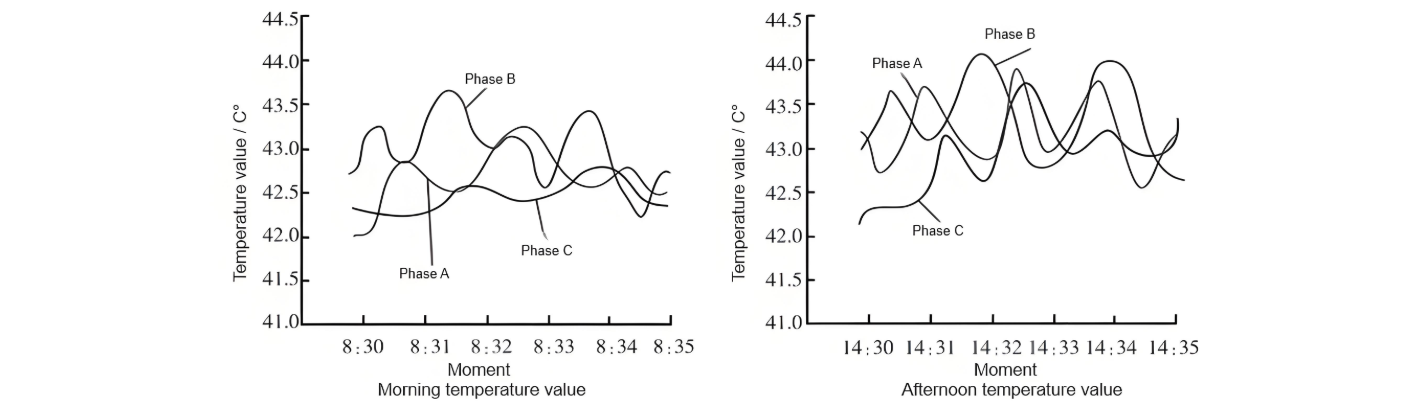

Postquam constructio substationis prefabricatae completa est, steps commissioning pertinentes exercendi sunt, ut certificetur functions singulorum apparatorum posse satisfacere requirementibus design et communicationem normalem inter apparatos et software fieri. Experimentum records et analyzat data sicut current, voltage values, active power, transformer temperature, et power factor of each switch in the prefabricated substation, ut stabilem operationem equipment substationis confirmet. Inter ea, values temperature transformatoris in different time periods ostenduntur in Figura 3.

Observando Figuram 3(a), inveniri potest valores temperature phase A, phase B, et phase C omnes in statu stabiliori manere. Temperatura phase B est maxima, attingens 43.6 °C ab 8:31 ad 8:32; temperatura phase A variat inter 42.0 - 43.2 °C; et temperatura phase C permanet circa 42.5 °C. In Figura 3(b), variation in values temperature collecta in postmeridiano est etiam parva. Propter mutationes ambientales, valores totales temperature phase A, phase B, et phase C sunt altiores quam valores matutini sed adhuc in range normali. Ad 14:32, value temperature phase B est 44.1 °C, et tunc values temperature phase A et phase C sunt 42.9 °C et 42.6 °C respectiviter. Totius tempore mensurae, minima temperature phase C est 42.2 °C et maxima 43.7 °C, dum temperature phase A fluctuat inter 42.6 - 43.8 °C.

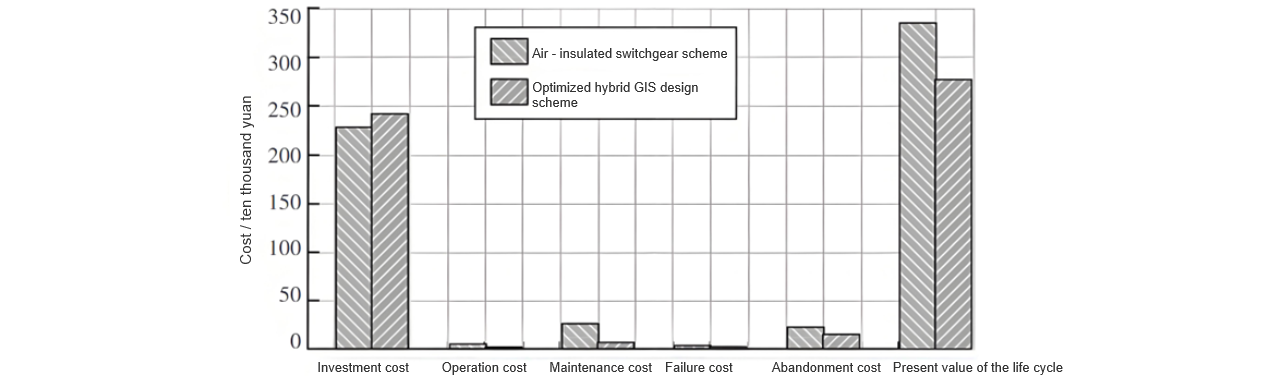

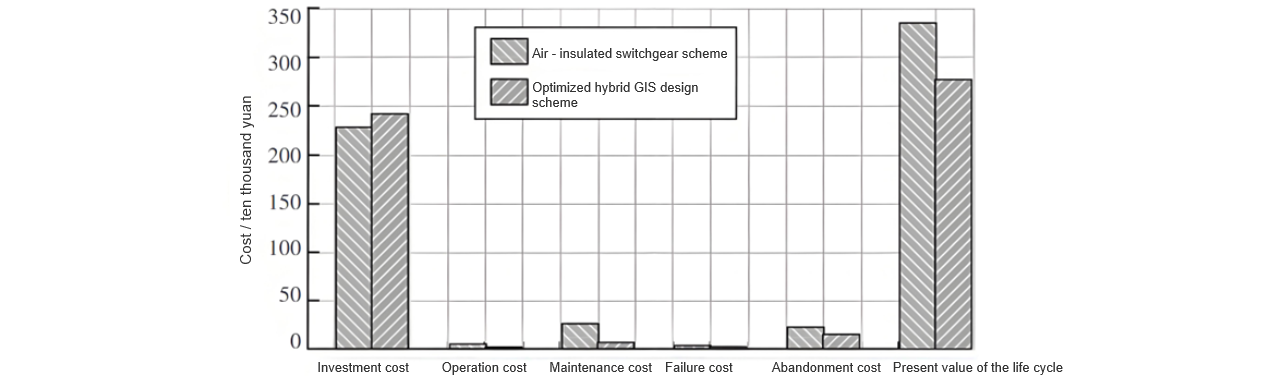

Analysis of the on-site test data shows that the data of the prefabricated substation all meet the design requirements and comply with relevant acceptance standards. In terms of economic utility, based on the life-cycle cost theory, the experiment analyzes and calculates the various costs of the 110 kV distribution equipment, and selects the air-insulated switchgear scheme for comparison. The comparison results are shown in Figure 4.

In Figura 4, initial investment cost for the optimized hybrid GIS design scheme is 2.413 million RMB, which is 0.133 million RMB higher than that of the air-insulated switchgear scheme. This is mainly because the equipment procurement cost of the hybrid GIS design scheme is higher than that of the air-insulated switchgear scheme, and the installation engineering cost is also slightly higher.

During the operation and maintenance phase, the required cost proportion is relatively small. Since the substation of the optimized hybrid GIS design scheme is an unmanned substation, only a small amount of regular manual inspections are needed, which reduces the daily operation and maintenance costs. Therefore, the operation and maintenance cost is much lower than that of the air-insulated switchgear scheme.

The annual failure probability of the optimized hybrid GIS design scheme has been significantly reduced, resulting in a notable decrease in maintenance costs. Moreover, its demolition cost is only 89% of that of the air-insulated switchgear scheme. Considering all factors, the present value of the life-cycle cost of the optimized hybrid GIS design scheme is 0.549 million RMB lower than that of the air-insulated switchgear scheme. Additionally, the 110 kV GIS intelligent substation scheme is superior to the conventional air-insulated switchgear scheme.

Conclusion

In order to conserve urban land resources, shorten the construction period, and enhance the economic efficiency and reliability of prefabricated substations, this research proposes an outdoor hybrid GIS design scheme that integrates circuit breakers and disconnectors. By optimizing the circuit and adopting single-busbar sectional wiring, and optimizing the overall layout, the number of failures is reduced and the maintenance cost is lowered.

The test results show that during the collection of transformer temperature, the temperature values of phase A, phase B, and phase C remain relatively stable. In the morning, the temperature of phase A varies between 42.0 - 43.2 °C, while that of phase C stays around 42.5 °C. In the afternoon, the temperature of phase C ranges from a minimum of 42.2 °C to a maximum of 43.7 °C, and the temperature of phase A fluctuates between 42.6 °C and 43.8 °C. The data of the prefabricated substation meet the design requirements and comply with relevant acceptance standards.

In the life-cycle cost analysis, although the upfront investment cost of the optimized hybrid GIS design scheme is 2.413 million RMB, 0.133 million RMB higher than that of the air-insulated switchgear scheme, the optimized hybrid GIS design scheme requires only a small amount of regular manual inspections. This reduces the daily operation and maintenance costs, making the operation and maintenance cost much lower than that of the air-insulated switchgear scheme, and significantly reducing the maintenance cost as well. Calculations show that the present value of the life-cycle cost of the optimized hybrid GIS design scheme is 0.549 million RMB lower than that of the air-insulated switchgear scheme, demonstrating that the optimized 110 kV GIS intelligent substation scheme is superior to the conventional air-insulated switchgear scheme.

However, this research only analyzes and optimizes the primary substation design. In the future, a more comprehensive intelligent design for secondary substations needs to be carried out by comprehensively considering communication and land construction.