1 Instrumenta Electrica Defectus et Conservatio

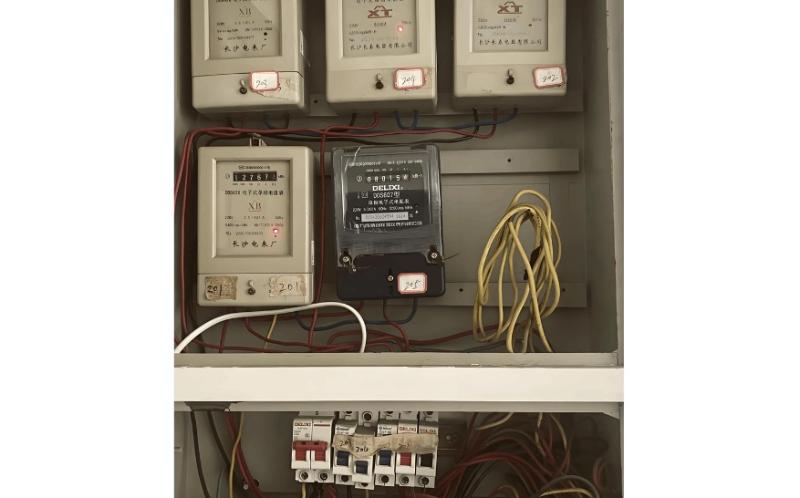

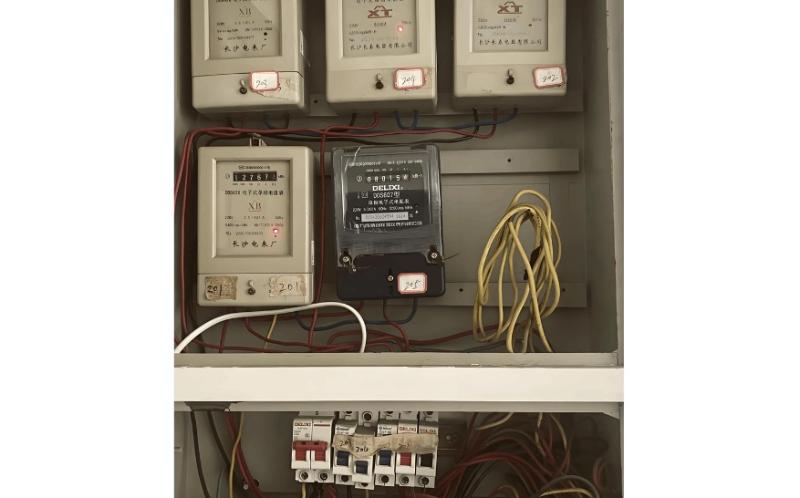

1.1 Defectus et Conservatio Contatorum Electricitatis

Temporis decursu, contatores electricitatis possunt experiri diminutionem accurate praeter componentium senectutem, usum, vel mutationes ambientales. Haec amissio precisionis potest ad mensurationes inexactas ducere, causans perdas pecuniarias et controversias ut utentibus ita et companiis distributionis electricitatis. Praeterea, interventus externi, interferentia electromagnetica, vel defectus interni possunt ad errores mensurae energiae ducere, resultantes in facturis inexactis et laedendo interessibus amborum partium. Etiam, defectus in modulis communicationis, problemata software, vel damna hardware possunt impedire lecturas remotas, augmentando requisitiones laboris manualis et reducendo efficientiam operationalem.

Conservatio effectiva instrumentorum electricorum requirit calibrationem regularem. Estabili schedulem calibrationis periodicam et utere aequipmentis professionalibus ad certificandam accuratam contatorum electricitatis per adjustmentes routinales. Secundo, fac inspecciones et conservationem regulares per examinationem omnium componentium—sensores, chips mensurae, et displaya—mundans pulverem et reliquias ad garantendum operationem normalem. Simul, inspecta firmitatem clavorum, connectorum, et aliorum partium ad conservandum integritatem mechanicam.

Substitue componentes seniles periodiciter secundum vitam servicii contatoris et recommendationes manufacturarum, et considera transmigrationem ad technologias noviores ad augendam performance et fiduciam. Praeterea, conserve systema lectionis remotae per certificandum modulum communicationis functionare recte, inspectionem regularis dispositivorum communicationis, et update software systematis ad certificandum securitatem et functionalitatem recentem. Hae measures adjuvant ad garantendum operationem fidelem, reducendum inexactitudines et defectus, et conservandum accurate datarum et fidelitatem systematis.

1.2 Defectus et Conservatio Instrumentorum Monitorum Aparatus Substationis

Defectus communicationis in instrumentis monitoribus—causati per modulos communicationis defectuosos, problemata network, vel errores configurationis—possunt impedire accessum realtim ad status aparatorum, affectando monitoringem et controllem remotos. Datae monitoriae inexactae possunt oriri ex defectu sensorum, defectibus internis instrumentorum, vel erroribus acquisitionis datarum, potentialiter ad maljudicium status aparatorum et incrementum periculi defectus aparatorum. Praeterea, malfunctiones display, problemata software, vel problemata energiae possunt causare displays instrumentorum abnormes, difficultando interpretamentum correctum status aparatorum per operatores et incrementando probabilitatem errorum operationalium.

Measures conservationis pro instrumentis monitoribus substationis includunt:

Inspectionem regularem systematis monitorii—inspecta componentia hardware sicut supplys energiae, sensore, et displaya; fac checks software regularis ad certificandum operationem sine erroribus.

Conservationem aequipmentorum communicationis—inspecta modulis communicationis, connectionibus network, et cavis regulariter. Pro systemis wireless, verificetur fortitudo et stabilitas signalis ad certificandum transmissionem fidelem.

Updates software—fac checks regularis pro novis versionibus software monitorii, upgrade prompto ad gainendam features et securitatem enhance, et certifica configurationem correctam compatibile cum dispositivis et network.

Calibrationem et conservationem aequipmentorum—calibra sensors periodiciter ad certificandam accurate datarum; fac inspections internas includentes mundationem et securitatem connectors.

Backup et recovery—fac backup regularis datae systematis monitorii ad preventandum loss; estabili planos disaster recovery ad restituendum functionality systematis celeriter in casu defectus. Haec practices meliorant stabilitatem systematis, certificant accurate monitoringem realtim, et supportant operations substationis securas et fideles.

1.3 Defectus et Conservatio Instrumentorum Monitorum Status Disjunctorum Circuitarum

Instrumenta monitoria status disjunctorum circuitarum possunt pati perdam signali, falsas alarmas, vel missas alarmas. Inspectio regularis, mundatio sensorum, et calibratio instrumentorum sunt essentialia ad certificandam accurate monitoringem conditionis.

2 Strategiae Conservationis pro Instrumentis Electricis in Systematibus Controlis Automaticis

In systematibus controlis automaticis, defectus instrumentorum possunt significanter impactare stabilitatem et performance systematis. Sequentes sunt key strategiae conservationis:

2.1 Inspectio et Conservatio Regulares

Inspectio et mundatio regulares sunt passus fundamentales ad certificandam operationem instrumentorum propriam. Estabili schedulem inspectionis routinae ad checkandam damnum physicam appearance, connectionum, et cabling, certificando omnia componentia criticalia functionare normaliter. Determina frequentiam inspectionis basatum in typis aequipmentorum, environmentis operationis, et recommendationibus manufacturarum.

Inspecta superficies, enclosure, et connectors instrumenti pro fissuras, deformationes, vel alia damna. Check connectiones cabling pro lassitudine vel corrosione, et examine sheathing cabling pro integritate. Verificetur indicatores et displaya sint claros, sine flickering vel distortione. Si sensors vel probes adsint, confirmetur position et status operationis eorum. Recorda unicuique inspectioni, notando issues identificatas, actiones susceptas, et items requirientes follow-up.

Certifica superficies instrumentorum esse mundas ad preventandum dust, dirt, vel contaminants affectare performance sensorum vel display. Utere toolis appropriatis (e.g., soft brushes, lint-free cloths) ad remove dust et grime. Mund connectors si necessario ad certificandam connections fideles, utendo cleaners suitable sine damaging materials. Clear ventilation openings ad maintinendum airflow proper et preventandum overheating. Documenta dates et procedures cleaning pro tracking historiarum maintenance. Inspectio et mundatio regulares augmentant reliability instrumentorum, extendunt lifespan, et reducunt defectus causatos per damage physicum vel contamination.

2.2 Diagnosi Defectus et Troubleshooting

Deploying a fault diagnosis system is crucial for real-time monitoring and identifying instrument anomalies, improving system reliability and efficiency.

Select a compatible fault diagnosis system that integrates well with existing instruments.

Sensor and data acquisition—integrate various sensors (e.g., temperature, pressure, current) and set high sampling rates for accurate real-time data.

Real-time monitoring and analysis—enable continuous monitoring to detect abnormalities promptly; use data analysis algorithms to identify patterns and predict potential failures.

Automated alerts—set threshold values for parameters; trigger alerts via SMS, email, or other means when thresholds are exceeded.

Remote access and control—allow remote monitoring and, where possible, integrate remote control for rapid intervention.

Historical data storage and analysis—store historical data for trend analysis and troubleshooting.

Fault codes and reports—the system should generate fault codes and detailed reports (including causes and repair suggestions) to assist technicians.

Such systems enable quick response to instrument anomalies, minimizing downtime and enhancing system performance.

2.3 Firmware and Software Updates

Regularly check instrument firmware versions and update to the latest release to fix known issues and improve performance. Keep associated control software updated to ensure hardware compatibility and apply the latest security patches.

2.4 Remote Monitoring and Management

Implement a remote monitoring system to track instrument status in real time and issue alerts upon anomalies. Where feasible, enable remote maintenance capabilities, allowing engineers to diagnose and resolve common issues remotely.

3 Conclusion

In summary, maintaining stable operation of electrical instruments is critical for power supply reliability and operational stability within power companies. By implementing these maintenance strategies, the impact of instrument failures on automatic control systems can be minimized, ensuring overall system stability, reliability, and efficient operation.