1 Technical Challenges

1.1Stability of Device Paralleling

In practical applications, the current-carrying capacity of a single power electronic device is relatively limited. To meet high-current requirements, multiple devices are often connected in parallel. However, parameter variations between devices—such as slight differences in on-resistance and threshold voltage—can cause uneven current distribution during parallel operation. During switching transients, parasitic inductance and capacitance further lead to inconsistent current change rates among parallel devices, exacerbating current imbalance. If not addressed promptly, this imbalance can cause certain devices to overheat and fail due to excessive current, thereby reducing the service life of the solid-state circuit breaker.

1.2 Fault Detection Delay

In DC systems, fault current characteristics differ significantly from AC systems, lacking zero-crossing points that assist in fault detection and interruption. This requires solid-state circuit breakers to employ microsecond-level fault detection algorithms to accurately identify faults and respond rapidly. Traditional fault detection methods suffer from significant delays when dealing with rapidly changing DC fault currents, making them unable to meet the demands of fast protection.

1.3Contradiction Between Heat Dissipation and Volume

To meet modern power systems' demand for high power density, solid-state circuit breaker designs must achieve greater power handling within limited space. However, higher power density leads to a sharp increase in heat generated by power electronic devices. Inadequate heat dissipation causes excessive temperatures, degrading device performance and potentially triggering thermal runaway and equipment failure. Conventional cooling techniques perform poorly with high-power-density solid-state breakers. While liquid cooling can improve heat dissipation efficiency, it increases equipment size and cost. Thus, how to balance efficient cooling with reasonable volume control—achieving synergistic optimization—remains a key challenge in solid-state circuit breaker design.

2 Key Technology Research

2.1Wide-Bandgap Device Application Technology

(1) SiC MOSFET Selection and Packaging

Among various wide-bandgap devices, low-conduction-loss SiC MOSFETs offer significant advantages. To enhance their performance in multi-device parallel applications, a symmetrical Direct Bonded Copper (DBC) layout is adopted. This layout effectively reduces parasitic inductance, which is crucial for improving device switching characteristics. During switching, especially at turn-off, interaction between parasitic inductance and device capacitance causes gate voltage oscillation. Experimental tests show that with a symmetrical DBC layout, gate voltage oscillation during turn-off can be controlled to less than 5%. This not only improves dynamic stability during parallel operation but also reduces the risk of device damage caused by voltage oscillation.

(2) Dynamic Current Sharing Control

To address the challenge of current imbalance in parallel devices, a control strategy combining a current-sharing bus with adaptive PI regulation is introduced. The current-sharing bus, through unique structural design, provides a balanced current distribution path for each parallel branch at the physical level. On this basis, an adaptive PI regulation algorithm dynamically adjusts the drive signals of each device based on real-time monitoring of branch currents, achieving more precise current sharing control.

2.2 Fast Fault Detection and Interruption Technology

(1) Fault Detection Based on Gate Voltage

Analysis of SiC MOSFET short-circuit characteristics reveals that during a short-circuit fault, the drain-source voltage (VDS) rapidly spikes to 900V while the gate voltage significantly drops with a slope exceeding 10 V/ns. Leveraging this characteristic, a dual-threshold comparator is designed for rapid fault detection, setting two current thresholds: Ith1 = 500 A and Ith2 = 1.2 kA. When the detected current exceeds Ith1, a preliminary warning is triggered; exceeding Ith2 indicates a confirmed short-circuit fault. The designed detection circuit and signal processing algorithm achieve a detection delay of only 0.8 μs. This approach bypasses the complex signal conversion and processing of traditional methods by utilizing the SiC MOSFET's inherent electrical characteristics, significantly improving fault detection accuracy.

(2) Multi-Objective Optimized Interruption Strategy

To achieve high-performance fault interruption in solid-state circuit breakers, interruption time (Δt), energy absorption (EMOV), and inrush current (Ipeak) are set as objective functions, optimized using a multi-objective particle swarm optimization (MOPSO) algorithm. Shorter interruption time provides better protection for system equipment; energy absorption affects the selection and lifespan of protective components like MOVs; excessive inrush current causes significant electrical stress, impacting normal equipment operation.

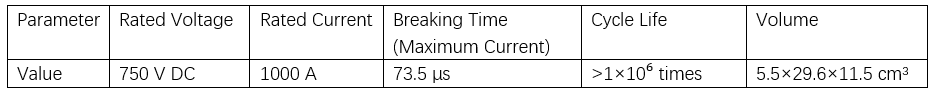

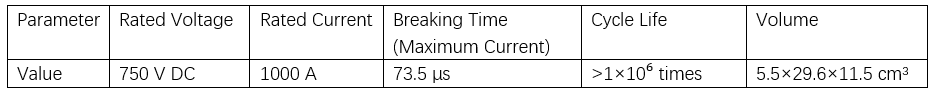

Through multiple iterations of MOPSO optimization, optimal parameters are determined: current-limiting inductor LB = 15 μH and MOV voltage-limiting coefficient γ = 1.8. Using these optimized parameters, the interruption time is reduced to 73.5 μs, and the maximum current is limited to 526 A. To visually demonstrate the optimization effect, the TOPSIS decision-making method compares results before and after optimization. The comparison shows significant improvements in key indicators such as interruption time, energy absorption, and inrush current, greatly enhancing overall performance and better meeting practical engineering requirements for fast and reliable interruption by solid-state circuit breakers.

2.3 High-Reliability Mechanical Structure Design

(1) Permanent Magnet Isolator Switch

To improve the reliability and stability of solid-state circuit breakers, a permanent magnet isolator switch employing a bistable permanent magnet mechanism is designed. In this structure, the holding force for closing and opening is primarily provided by permanent magnets, with the coil energized only momentarily during switching operations. This reduces power consumption by approximately 90% compared to traditional electromagnetic isolator switches. Adams dynamic simulation analysis shows that the mechanical life of this permanent magnet isolator switch exceeds 1 million operations, with a contact separation speed of 3 m/s. The high contact separation speed ensures rapid circuit disconnection upon fault occurrence, reducing the likelihood of arc generation and enhancing the switch's interruption capability. The long mechanical life ensures stable performance over extended use, reducing maintenance and replacement frequency, thus providing strong support for the efficient operation of the solid-state circuit breaker.

(2) Thermal Management Solution

To address heat dissipation challenges in high-power-density designs, a hybrid cooling solution combining evaporative cooling with forced air cooling is proposed. Evaporative cooling utilizes the principle of liquid evaporation absorbing heat, enabling efficient heat transfer within compact spaces. Forced air cooling further enhances heat dissipation through fan-driven forced convection. This hybrid cooling method stabilizes the module's hotspot temperature below 75°C, with a temperature rise rate of less than 5°C/min, meeting standard requirements.III. Experimental Verification

3 Experimental Verification

3.1 Prototype Parameters

To verify the effectiveness of the key technologies and design schemes, a prototype of a low-voltage DC solid-state circuit breaker was developed, with the main parameters as follows:

3.2 Type Test Results

Comprehensive type tests were conducted on the prototype to evaluate whether its performance meets the requirements for practical applications:

(1) Short-Circuit Interruption Test

Short-circuit faults are among the most severe fault types in power systems, and the enormous instantaneous current they generate poses a significant threat to equipment operation. To simulate this extreme condition, a 23 kA short-circuit current test environment was established—posing a rigorous challenge for the solid-state circuit breaker. At the start of the test, the prototype rapidly activated, and its built-in fast fault detection and interruption technology began to function. This technology, through high-precision current monitoring and a rapid response mechanism, detected the abnormal current within an extremely short time and immediately triggered the interruption process.

During interruption, test personnel closely observed the breaker's performance, and no arc re-ignition occurred throughout the process. This result not only demonstrates the high efficiency of the fast fault detection and interruption technology but also highlights the solid-state circuit breaker's superior interruption performance. In traditional circuit breakers, arc re-ignition is a difficult-to-avoid issue that often leads to secondary faults or even severe equipment damage. By contrast, the solid-state circuit breaker successfully avoids this problem through advanced interruption techniques, thereby providing strong support for the stable operation of power systems.

(2) Temperature Rise Test

Thermal performance is another key factor in evaluating solid-state circuit breakers. To effectively assess the device's heat dissipation capability during prolonged operation, a temperature rise test was conducted. The prototype was required to operate continuously for 24 hours, during which significant heat was generated [9]. After the test, temperature sensors were used to measure the prototype's temperature. The results showed a temperature rise of ΔT = 32 K. This data confirms the effectiveness of the hybrid cooling solution combining evaporative cooling and forced air cooling. By integrating the natural heat dissipation principle of evaporative cooling with the forced convection of forced air cooling, the system efficiently dissipates heat generated during operation, ensuring the device remains within an acceptable temperature range. Good thermal management not only ensures stable operation of the solid-state circuit breaker but also extends its service life.

(3) Lifetime Test

Service life is a critical indicator for determining whether a solid-state circuit breaker can be widely applied in real power systems. Therefore, to verify its lifespan performance, the prototype underwent an endurance test of one million operational cycles. Throughout the test, personnel closely monitored changes in the contact resistance of the prototype. After the test, contact resistance was measured and found to have changed by less than 5%. This result validates the effectiveness of the long-life design of the permanent magnet isolator switch. Even after prolonged and frequent operations, the switch contacts maintain excellent conductivity, ensuring reliable on/off functionality of the solid-state circuit breaker.

4 Conclusion

In summary, this paper presents a technical solution for low-voltage DC solid-state circuit breakers based on in-depth research into key technologies, including optimization of wide-bandgap devices, intelligent control algorithms, and high-reliability structural design. Experimental validation shows that the developed prototype achieves leading performance in key indicators such as interruption speed, fault detection accuracy, and operational lifespan.

It successfully realizes microsecond-level fast interruption and a million-cycle operational life, providing a practical and feasible solution for protection in new energy power distribution systems. Looking ahead, there are many promising research directions for low-voltage DC solid-state circuit breakers. For example, establishing a device-packaging-system level integrated simulation model could more comprehensively simulate the performance of solid-state circuit breakers under various operating conditions, thereby providing more accurate theoretical support for design optimization.