1. Muhimmanci Abubuwa

1.1 Karkashin Cikakken Ayyukan Tattalin Arziki

A cikin hanyoyin amfani, zama na iya daidai tsari kan tattalin arzikin da yake da shi a wuri. Don inganta matsayinta tsari, ana amfani da kungiyoyi daban-daban ta hanyar cikakken ayyuka. Amma, farkon paramatar da aka samu bayan ayyukan—kamar farkon tasiri a kan on-resistance da threshold voltage—za su iya haifar da cikakken cikin tsari a lokacin cikakken ayyuka. A lokacin transients na cikakken, inductance da capacitance masu wasa suna iya haifar da cikakken darajarun lashe tsari a cikin ayyukan, wanda ya fi yawa cikakken tsari. Idan ba a tabbatar da wannan haifara a lokacin, za su iya haifar da waɗannan ayyukan zuwa gajerar tsari da kuma gagamta, wanda zai ƙara tsari da ƙasarta, don haka ya ƙara ƙarin mulkin tattalin arzikin solid-state.

1.2 Yawancin Samun Gajerar Tsari

A cikin systemo mai tsari, siffar gajerar tsari suna ɗauke da systemo mai tsari na AC, ba su da zero-crossing points wadanda suke taimaka a samun gajerar tsari da kuma ƙaramin samun. Wannan ya ba tattalin arzikin solid-state abin da suka buƙata a amfani da alamar samun gajerar tsari na microseconds-level don inganta samun gajerar tsari da kuma ƙaramin samun da ma'ana. Hanyoyin samun gajerar tsari na musamman suna da yawancin samun idan an amfani da su a cikin gajerar tsari na DC, wanda ba su iya inganta tsohon hanyoyin ƙaramin samun.

1.3 Farkon Jirgin Dahuwa Da Yawan Inganci

Don inganta talabina masu power density mai yawa a cikin systemo mai tattalin arziki, tattalin arzikin solid-state suna buƙata a yi ƙarin power handling a cikin yanki mai yawa. Amma, power density mai yawa ya haifar da ƙarin jirgin da ake fitowa a cikin tattalin arzikin. Ba da jirgin da ba ake bace ba, ya ƙara tsari, wanda ya ƙara ƙarin mulki da kuma ƙarfin gagamta. Hanyoyin jirgin da ake amfani a halin yanzu suna da rashin da ba su iya inganta tattalin arzikin solid-state na power density mai yawa. Idan an amfani liquid cooling, zai ƙara ingantaccen jirgin, amma zai ƙara yawan inganci da cost. Saboda haka, yadda ake buƙata ingantaccen jirgin da yawan inganci—wanda ke nufin buƙatun optimizaciya—sunana ɗaya daga muhimman abubuwan da ke ƙasa a cikin cutar tattalin arzikin solid-state.

2 Bincike na Ƙwarewa Masu Saye

2.1 Ƙwarewa Masu Saye na Amfani da Ayyukan Wide-Bandgap

(1) Zabi da Kutumta SiC MOSFET

Daga cikin ayyukan wide-bandgap, SiC MOSFET na low-conduction-loss suna da muhimmanci sosai. Don inganta ƙwarewa masu saye a cikin amfani na kungiyoyi daban-daban, an amfani Direct Bonded Copper (DBC) layout na symmetrical. Wannan layout ya ƙara parasitic inductance, wanda ke muhimmanci don inganta ƙwarewa masu saye na cikakken ayyuka. A lokacin cikakken, hasashen inductance na wasa da capacitance na ayyuka suna haifar da gate voltage oscillation. Amfani na aiki sun nuna cewa, tare da DBC layout na symmetrical, gate voltage oscillation a lokacin turn-off zai ƙara zuwa 5% kawai. Wannan ya ƙara ƙarin dynamic stability a lokacin cikakken ayyuka, kuma ya ƙara riskin gagamta na ayyukan da aka haifar da gate voltage oscillation.

(2) Ƙwarewa Dynamic Current Sharing Control

Don inganta abubuwan haifara na cikakken tsari a cikin ayyukan, an buƙata ƙwarewa na current-sharing bus tare da adaptive PI regulation. Current-sharing bus, tare da tushen ƙwarewa na musamman, ya ba da path na cikakken tsari ga kungiyoyin ayyukan a lokacin physical. A nan, adaptive PI regulation algorithm ya ƙara drive signals na ayyukan daga kungiyoyi a lokacin real-time monitoring na branch currents, wanda ya ƙara ƙarin precise current sharing control.

2.2 Ƙwarewa Fast Fault Detection and Interruption Technology

(1) Samun Gajerar Tsari Ta Gate Voltage

Binciken ƙwarewa short-circuit na SiC MOSFET sun nuna cewa, a lokacin gajerar tsari, drain-source voltage (VDS) ya ƙara zuwa 900V, sannan gate voltage ya ƙara zuwa ƙarin da slope na 10 V/ns. Tare da wannan ƙwarewa, dual-threshold comparator ya ƙara a buƙata don samun gajerar tsari na microseconds, tare da setting two current thresholds: Ith1 = 500 A da Ith2 = 1.2 kA. Idan an samu current na Ith1, ya faru warning na farko; idan an samu Ith2, ya nuna gajerar tsari na confirmed. Ƙwarewa na detection circuit da signal processing algorithm ya ƙara detection delay na 0.8 μs. Wannan ƙwarewa ta ƙara amfani da electrical characteristics na SiC MOSFET, wanda ya ƙara ƙarin accuracy na samun gajerar tsari.

(2) Ƙwarewa Multi-Objective Optimized Interruption Strategy

Don inganta ƙwarewa high-performance fault interruption a cikin tattalin arzikin solid-state, interruption time (Δt), energy absorption (EMOV), da inrush current (Ipeak) suna buƙata objective functions, tare da optimization using multi-objective particle swarm optimization (MOPSO) algorithm. Ƙarin interruption time ya ƙara ƙarfi na protection na equipment; energy absorption ya ƙara selection da lifespan na components like MOVs; ƙarin inrush current ya ƙara electrical stress, wanda ya ƙara ƙarfin normal operation na equipment.

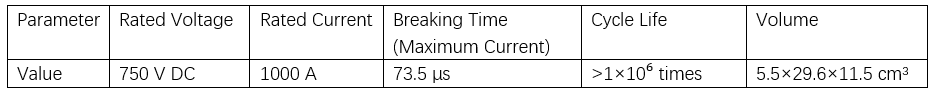

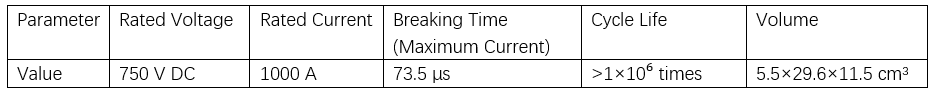

Tare da iterations of MOPSO optimization, optimal parameters an samu: current-limiting inductor LB = 15 μH da MOV voltage-limiting coefficient γ = 1.8. Tare da wannan optimized parameters, interruption time ya ƙara zuwa 73.5 μs, da maximum current ya ƙara zuwa 526 A. Don nuna ƙwarewa na optimization, TOPSIS decision-making method ya ƙara compare results before and after optimization. Comparison ya nuna ƙarin improvements in key indicators such as interruption time, energy absorption, da inrush current, wanda ya ƙara ƙarin overall performance da kuma ƙara tsohon requirements for fast and reliable interruption by solid-state circuit breakers.

2.3 Ƙwarewa Mechanical Structure Design na Ƙarfi

(1) Permanent Magnet Isolator Switch

Don inganta ƙarfi da ƙarhan tattalin arzikin solid-state, permanent magnet isolator switch employing a bistable permanent magnet mechanism ya ƙara a buƙata. A cikin wannan structure, holding force for closing and opening suna ƙara a bayyana min permanent magnets, tare da coil energized only momentarily during switching operations. Wannan ya ƙara power consumption zuwa 90% compared to traditional electromagnetic isolator switches. Adams dynamic simulation analysis ya nuna cewa, mechanical life na wannan permanent magnet isolator switch ya ƙara zuwa over 1 million operations, da contact separation speed na 3 m/s. Ƙarin contact separation speed ya ƙara rapid circuit disconnection upon fault occurrence, wanda ya ƙara ƙarfi na arc generation da kuma ƙara ƙarin interruption capability. Ƙarin mechanical life ya ƙara stable performance over extended use, da kuma ƙara maintenance and replacement frequency, wanda ya ƙara strong support for the efficient operation of the solid-state circuit breaker.

(2) Ƙwarewa Thermal Management Solution

Don inganta abubuwan haifara na jirgin a cikin designs na high-power-density, hybrid cooling solution combining evaporative cooling with forced air cooling ya ƙara a buƙata. Evaporative cooling ya ƙara principle of liquid evaporation absorbing heat, wanda ya ƙara efficient heat transfer within compact spaces. Forced air cooling ya ƙara ƙarin heat dissipation through fan-driven forced convection. Wannan hybrid cooling method ya ƙara stabilize the module's hotspot temperature below 75°C, da temperature rise rate na less than 5°C/min, wanda ya ƙara standard requirements.III. Experimental Verification

3 Experimental Verification

3.1 Prototype Parameters

Don inganta effectiveness of the key technologies and design schemes, prototype of a low-voltage DC solid-state circuit breaker ya ƙara a buƙata, da main parameters as follows:

3.2 Type Test Results

Comprehensive type tests were conducted on the prototype to evaluate whether its performance meets the requirements for practical applications:

(1) Short-Circuit Interruption Test

Short-circuit faults are among the most severe fault types in power systems, and the enormous instantaneous current they generate poses a significant threat to equipment operation. To simulate this extreme condition, a 23 kA short-circuit current test environment was established—posing a rigorous challenge for the solid-state circuit breaker. At the start of the test, the prototype rapidly activated, and its built-in fast fault detection and interruption technology began to function. This technology, through high-precision current monitoring and a rapid response mechanism, detected the abnormal current within an extremely short time and immediately triggered the interruption process.

During interruption, test personnel closely observed the breaker's performance, and no arc re-ignition occurred throughout the process. This result not only demonstrates the high efficiency of the fast fault detection and interruption technology but also highlights the solid-state circuit breaker's superior interruption performance. In traditional circuit breakers, arc re-ignition is a difficult-to-avoid issue that often leads to secondary faults or even severe equipment damage. By contrast, the solid-state circuit breaker successfully avoids this problem through advanced interruption techniques, thereby providing strong support for the stable operation of power systems.

(2) Temperature Rise Test

Thermal performance is another key factor in evaluating solid-state circuit breakers. To effectively assess the device's heat dissipation capability during prolonged operation, a temperature rise test was conducted. The prototype was required to operate continuously for 24 hours, during which significant heat was generated [9]. After the test, temperature sensors were used to measure the prototype's temperature. The results showed a temperature rise of ΔT = 32 K. This data confirms the effectiveness of the hybrid cooling solution combining evaporative cooling and forced air cooling. By integrating the natural heat dissipation principle of evaporative cooling with the forced convection of forced air cooling, the system efficiently dissipates heat generated during operation, ensuring the device remains within an acceptable temperature range. Good thermal management not only ensures stable operation of the solid-state circuit breaker but also extends its service life.

(3) Lifetime Test

Service life is a critical indicator for determining whether a solid-state circuit breaker can be widely applied in real power systems. Therefore, to verify its lifespan performance, the prototype underwent an endurance test of one million operational cycles. Throughout the test, personnel closely monitored changes in the contact resistance of the prototype. After the test, contact resistance was measured and found to have changed by less than 5%. This result validates the effectiveness of the long-life design of the permanent magnet isolator switch. Even after prolonged and frequent operations, the switch contacts maintain excellent conductivity, ensuring reliable on/off functionality of the solid-state circuit breaker.

4 Conclusion

In summary, this paper presents a technical solution for low-voltage DC solid-state circuit breakers based on in-depth research into key technologies, including optimization of wide-bandgap devices, intelligent control algorithms, and high-reliability structural design. Experimental validation shows that the developed prototype achieves leading performance in key indicators such as interruption speed, fault detection accuracy, and operational lifespan.

It successfully realizes microsecond-level fast interruption and a million-cycle operational life, providing a practical and feasible solution for protection in new energy power distribution systems. Looking ahead, there are many promising research directions for low-voltage DC solid-state circuit breakers. For example, establishing a device-packaging-system level integrated simulation model could more comprehensively simulate the performance of solid-state circuit breakers under various operating conditions, thereby providing more accurate theoretical support for design optimization.