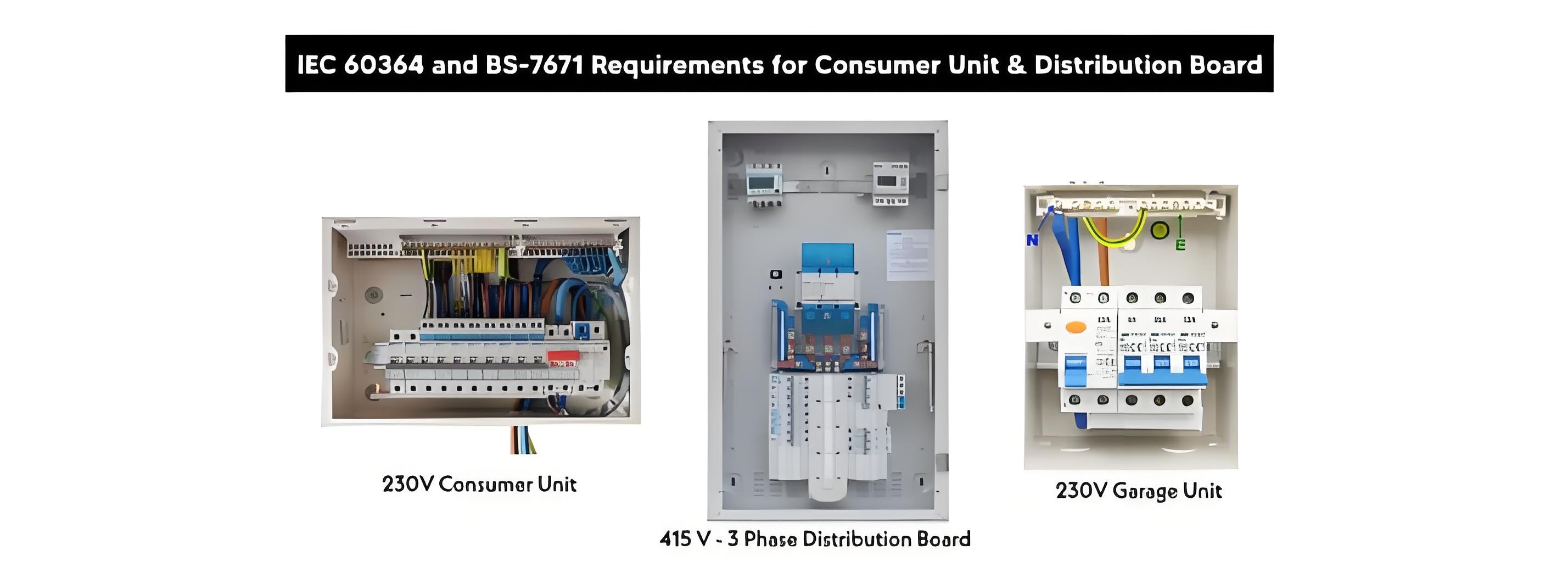

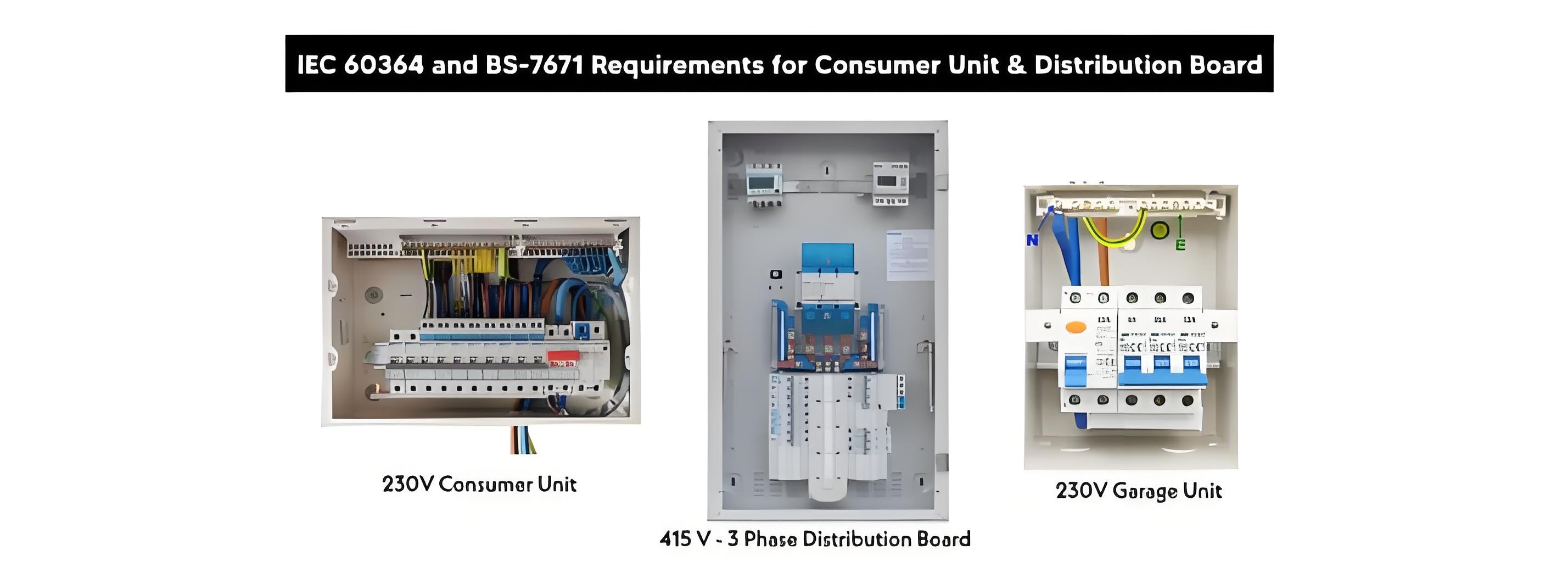

Directiva IEC-60364 et BS-7671 pro Unitates Garagorum, Unitates Consumatorum, et Tabulas Distributionis

Commissio Electrotechnica Internationalis (IEC) et Standard Britannicus BS 7671 ludunt partes cruciales in formando requisitiones pro installationibus electricis. Utrumque set standards offert directionem comprehensivam, praecipue ad tabulas fusorum sicut unitates garagorum, unitates consumatorum, et tabulas distributionis.

IEC 60364 est standard globaliter recognitus qui statuit optimas praxes internationales pro installationibus electricis. Praebet framework latum applicabile per diversas regiones, securitatem, fiduciam, et rectam functionem assecurans. Altera vero, BS 7671 – 2018, qui concordat cum IEC - aligned BS EN 61439, specialiter adaptatur ad Regnum Unitum. Hic standard superstruit principia internationalia dum regulas locales et considerationes pertinentes ad infrastructuram electricam Britannicam incorporat.

Sequentes sectiones penetrant in requisitiones claves stipulatas ab utroque IEC 60364 et BS 7671, in aspectus criticos relativos ad panes electricos in variis situibus concenteri. Haec directio est essentialis ad assecurandum ut installationes electricae adherant ad altissimos standards securitatis et performance, tutantes simul res et personas ab periculis electricis.

Directiva IEC-60364 et BS-7671 pro Unitates Garagorum, Unitates Consumatorum, et Tabulas Distributionis

1. Locatio et Accessibilitas

Secundum BS 7671: 132.12 et IEC 60364 - 5 - 52:

Accessibilitas: Tabulae electricae debent situi in locis facile accessibilibus pro operatione, maintenance, et inspectionibus routine. Hoc assecurat ut technici possint celeriter et secure accedere ad tabulas quando opus est.

Ambitus Residentialis: In ambientes residentiales, altitudo recommendata pro installatione tabularum distributionis et unitatum consumatorum varia est ab 1 ad 1.8 metrorum supra pavimentum. Pro commoditate seniorum et personarum cum disabilitatibus, altitudo 1.3 metrorum suggesta est, facilitans interactionem faciliorem cum panelibus electricis.

Ambitus Industrialis: In aedificiis industrialibus, pro tabula distributionis typica cum gradu protectionis IP54, area montandi debet habere latitudinem maximam 1.50 metrorum, altitudinem maximam 1.20 metrorum, et profunditatem maximam 0.50 metrorum, sicut in IEC 61439 specificatur.

Spacium Operativum: Spatium operativum sufficientem circum tabulas electricas praebendum est. BS 7671 accentuat importantiam assecurandi spatium adequadum pro accessu securi ad omnes componentes, periculum accidentum durante operatione vel maintenance minuens.

Installatio Switchgear: Switchgear generaliter foris installari debet. Tamen, potest intra installari si specialiter ad usum intra designatum est vel inclusum in armario cum gradu protectionis saltem IP4X, IP5X, aut IP6X, secundum BS 7671: Section 422.3.3.

Duplica Insulatio et Opercula: Quando tabulae distributionis metallicae installantur, duplica insulatio et opercula debent adhiberi pro partibus vivis ad contactum accidentalum prohibendum et securitatem augendam.

Conditiones Ambientales: Tabulae electricae debent installari in locis libris ab aqua, pulvere excessivo, et aliis factoribus ambientalibus adversis quae possent securitatem vel performance compromittere. Hoc adiuvat ad longevitatem panelorum prolongandam et operationem fidelam assecurandam.

2. Gradus Panelorum

Conformiter cum BS 7671: 536 et IEC 61439:

Selectio Componentium: Tabulae distributionis, unitates consumatorum, et dispositiva et apparatus conexam debent diligenter eligi ex capacitate portantium currentem et requisitionibus oneris totalis systematis electrici. Hoc assecurat ut paneli possint gerere demandata electrica sine supercrescendo vel deficiente.

Standardes Designi et Testendi: IEC 61439 regit designum, testum, et constructionem panelorum electricorum (assemblys switchgear et controlgear basso voltu). Hi standardes assecurant ut paneli strictis requisitionibus securitatis et performance satisfaciant, protectionem fidelem pro systematibus electricis praebentes.

Verificatio Dispositivorum Protectivorum: Omnia dispositiva protectiva usata in unitatibus consumatorum residentiarum et tabulis distributionis commercialibus/industrialibus debent verificari conformiter cum BS EN 61439 - 3 et compatere cum IEC - 60898 et IEC 60947 - 2 pro curvis B, C, et D. Hoc processus verificationis assecurat ut dispositiva protectiva recte operabuntur in casu defectus.

Adaptabilitas Ambientalis: Tabulae debent aptas esse pro ambiente intento, rationem habita ad gradus insulationis et temperaturae. Hoc assecurat ut paneli possint sustinere conditiones specificas loci installationis, sicut fluctuationes temperature et humiditas.

3. Isolatio et Commutatio

Ut BS 7671: Section 537 et IEC 60364 - 5 - 53 statuunt:

Provisiones Isolationis et Commutationis: Tabulae electricae debent instrui mediorum sufficientium pro isolatione et commutatione. Hoc permittit circuitos secure disconnectari durante activitatibus maintenance vel in casu emergency, preveniendo shocks electricos et damna apparatorum.

Requisitiones Isolatorum Principalium: Isolatores principales debent clare labelari et facile accessibili esse. In situatibus ubi isolatio pro securitate necessaria est, isolator debet capax esse disconnectandi omnes conductores vivos (phasem et neutralem) simul.

Disjunctio Emergency: Dispositivum interruptorius vel commutator disjunctivus emergency debet installari ad supplium principalem celeriter disconnectandum in casu emergency vel periculi. Hoc assecurat ut actio immediata possit agi ad tutandos personale et apparatum, sicut BS 7671: Sections 132.9 et 132.10 requirit.

4. Terrae et Conductores Protectivi

Secundum BS 7671: Caput 54 Sections 541 ad 544 et IEC 60364 - 5 - 54:

Importancia Terrae: Terra propria (grounding) est essens ad protegendum utentes et apparatum ab shock electrico. Praebet viam securam pro currentibus defectus dissipandis in terram, periculum accidentum electricorum minuens.

Connectiones Terrae Protectivae: Tabulae electricae debent instrui connectionibus terrae protectivis fidelibus. Bonding proprium assecurat ut partes conductivae expostae non periculum securitatis praebent equalizando potentialem electricum et prohibendo differentias tensionis periculosas.

Bonding Equipotential: Bonding equipotential debet implementari ad prohibendum developmentem tensionum periculosarum inter metalwork expostum. Hoc adiuvat ad creandum ambitem electricum securum assecurando ut omnia pars metallica sint eodem potentiiali electrico.

Compliance Protectionis Fulminis: Sicut BS 7671: 541.3, si systema protectionis fulminis praesens est, installatio debet compatere cum standardibus reference in BS EN 62305 ad protectionem effectivam contra surges electricos fulminis-related assecurandam.

Restrictiones Conductoris PEN: In hospitalibus, unitatibus emergency, et aliis locis medicis downstream tabulae distributionis principalis vel unitatis consumatorum, conductores PEN non debent uti, sicut in BS 7671 - 2028: 710.312.2 specificatur. Haec restrictio est in loco ad augmentandam securitatem electricam in his ambietibus healthcare criticis.

5. Selectio Dispositivorum Protectivorum

Conformiter cum BS 7671: 536.3 et IEC 60364 - 5 - 53:

Coordination Fault: Dispositiva protectiva intra panel electricum debent diligenter coordinari. Hoc assecurat ut in casu defectus, solus circuitus affectus disconnectetur, non totum systema. Coordinatio propria est crucialis ad maintenendum securitatem et fiduciam installationum electricarum, praecipue in systematibus multi-circuit complexis.

6. Protectio Overcurrent

Sicut BS 7671: Caput 43, Sections 420 ad 424 et IEC 60364 - 4 - 43:

Dispositiva Protectiva Overcurrent: Tabulae electricae debent instrui dispositivis overcurrent protectionis appropriate (OCPDs), sicut fusis, circuit breakers miniature (MCBs), residual current devices (RCDs), residual current breakers cum overload protection (RCBOs), arc-fault detection devices (AFDDs), et surge protection devices (SPDs).

Gradus et Design: OCPDs debent gradari ex designo circuiti electrici ad praeventionem damni wiring et reductionem periculi incendorum electricorum. OCPDs proprie gradati tripiunt quando currentus excessivus fluit, protegens systema electricum ab overheating et periculis potentialibus.

Requisitiones Coordinationis: BS 7671 mandat coordinationem properam inter conductores, OCPDs, et alia dispositiva protectiva. Hoc assecurat ut conductores protegantur contra damnum thermicum, maintenendo integritatem installationis electricae.

7. Protectio Short Circuit

Conformiter cum BS 7671: 434 et IEC 60364 - 4 - 43:

Provisiones Protectivae Short Circuit: Tabulae electricae debent instrui protectione contra short circuits. Dispositiva protectiva debent gradari ad interrupting maximum currentum defectus quod in systema occurrere potest. Hoc assecurat ut short circuits celeriter eliminantur, minuendo damnum apparatorum et periculum incendorum electricorum.

Selectio et Operation Dispositivorum: Dispositiva protectiva short circuit debent eligi ex levels expected fault current et debent operari celeriter ad isolandum defectum. Protectio short circuit quick-acting est essentialis ad maintenendum securitatem et fiduciam systematibus electricis.

8. RCDs, AFDDs, et Protectio Earth Fault

Sicut BS 7671: 415, 536, et IEC 60364 - 4 - 41:

Residual Current Devices (RCDs): RCDs requiruntur ad praebendum protectionem additionalis contra shock electricum, praecipue in circuitis supply socket outlets et apparatorum in locis umidis aut outdoor. Celeriter detectant et interrupt any imbalance in current flow, which can indicate a leakage current or a person coming into contact with a live conductor.

30mA High-Sensitivity RCDs: RCD sensibilis 30mA debet installari in unitate consumatorum pro circuitis socket-outlet, circuitis alimentantibus balneolas, et circuitis illuminationis, sicut in IEC 60364. Hoc level of sensitivity provides enhanced protection against electric shock hazards.

TT System Requirements: In a TT system where RCD protection is not present, double or reinforced insulation must be provided on all circuits upstream of the first RCD to ensure the safety of the operator. This alternative measure helps to prevent electric shock in the absence of RCD-based protection.

Earth Fault Protection: Earth fault protection must be in place to disconnect the power supply in the event of a fault that could lead to electrocution or equipment damage. This protection mechanism ensures that the electrical system is safely isolated when a fault occurs.

TN System Requirements: In a TN system, earth fault protection should be provided via a circuit breaker. The protective earth conductor (PE) and the exposed conductive parts of all insulated appliances and equipment must be connected to the consumer-installed earth electrode. This connection ensures that fault currents are safely diverted to the ground, protecting users and equipment.

9. Protectio Ambientalis (IP Ratings)

Secundum BS 7671: 512.2 et IEC 60364 - 5 - 52:

Selectio IP Rating: Tabulae electricae debent habere ratings Ingress Protection (IP) appropriatos ex suo environmente installationis. Sive installatae intra, extra, in locis pulverulentis, aut umidis, rating IP assecurat ut enclosure panelis praebeat protectionem adequatam contra ingressum objectorum solidorum et liquidorum, tecta componentes internos a damno.

Limites Temperaturae: Apparatus electrica debent installari modo qui assecurat ut temperatura designata non excedat limites specificatos, sicut in BS 7671: Section 134.1.5. Hoc prevenit overheating, quod ducere potest ad failurem componentum et pericula securitatis potentialia.

10. Segregation Circuituum

Sicut BS 7671: 514.10 et IEC 60364 - 5 - 52:

Segregatio Circuituum: Different types of circuits, such as power, lighting, and control circuits, must be segregated within the electrical panel. This segregation helps to prevent interference between circuits and reduces the risk of faults spreading from one circuit to another.

Separatio Gradus Tensionis: Cables and components with different voltage ratings should not be installed in the same compartment without adequate insulation or separation. This ensures that there is no electrical interaction between components with different voltage requirements, maintaining the safety and integrity of the electrical system.

11. Cables Usi in Systematibus Wiring

Secundum BS 7671: Section 422.3.4:

Material and System Standards:

Cables made from non-combustible materials must comply with EN 60332-1-2.

Conduit systems should adhere to BS-EN 61386-1.

Cable trunking and ducting systems must meet the requirements of BS-EN 50085.

Cable tray or ladder systems should comply with BS-EN 61537.

Power track systems must satisfy the flame propagation resistance requirements specified in BS-EN 61534.

Wiring systems with a high risk of flame propagation must meet the requirements of BS-EN 60332-3. These standards ensure the safety and reliability of the wiring system, minimizing the risk of electrical fires and other hazards.

12. Identification Circuituum et Labeling

Conformiter cum BS 7671: 514.1 et IEC 60364 - 5 - 51:

Labeling Circuituum: All circuits within the electrical panel must be clearly labeled to indicate their function and the areas they serve. A suitable indicator that complies with BS EN 60073 and BS EN 60447 should be positioned in a location that is clearly visible to the operator. This clear labeling helps technicians quickly identify and troubleshoot circuits during maintenance or repairs.

Information Protective Conductor: Information indicating the high-current protective conductor should be provided and be clearly visible to anyone working on or modifying the circuit, as per BS 7671-2028: 543.7.1.205. This information is crucial for ensuring proper installation and maintenance of the protective grounding system.

Diagram Provision: A single-line diagram, drawing, or general schematic diagram containing the full details of all electrical safety sources should be placed adjacent to the distribution board or consumer unit, as required by BS 7671-2028: 560.7.9 and 560.7.10. This diagram provides a comprehensive overview of the electrical system, aiding in understanding and troubleshooting.

Color Coding: The color coding of conductors should conform to established standards to ensure clarity for electricians and maintenance personnel. In BS 7671, the phase (live) conductor is brown, the neutral is blue, and the protective earth is green/yellow. However, some countries following British standards and IEC, including the UK prior to 2004, used red, black, and green for phase, neutral, and earthing conductors, respectively. For accurate color coding in AC and DC systems, it is essential to refer to the relevant IEC and NEC wiring color codes.

13. Verification et Testing

Sicut BS 7671: Part 6 et IEC 60364 - 6:

Post-Installation Inspection: After installation, electrical panels must undergo a thorough inspection and testing process to verify compliance with BS 7671 and IEC standards. This inspection ensures that all components are installed correctly and that the panel functions as intended.

Functionality Testing: The testing process should confirm the proper functionality of protective devices, correct wiring, and proper earthing. This includes checking that circuit breakers trip at the correct current levels, RCDs detect and interrupt leakage currents, and that the grounding system provides effective protection.

Periodic Inspections: Periodic inspections and testing are also required to ensure the ongoing safety of electrical installations. Regular checks help to identify any potential issues or deterioration over time, allowing for timely maintenance and repairs to prevent electrical accidents.

In conclusion, both IEC 60364 and BS 7671 play a vital role in ensuring the safety, reliability, and efficiency of electrical systems. Adhering to these comprehensive standards helps to prevent electrical fires, protect against electric shock hazards, and safeguard electrical equipment from damage, providing peace of mind for both installers and end-users.