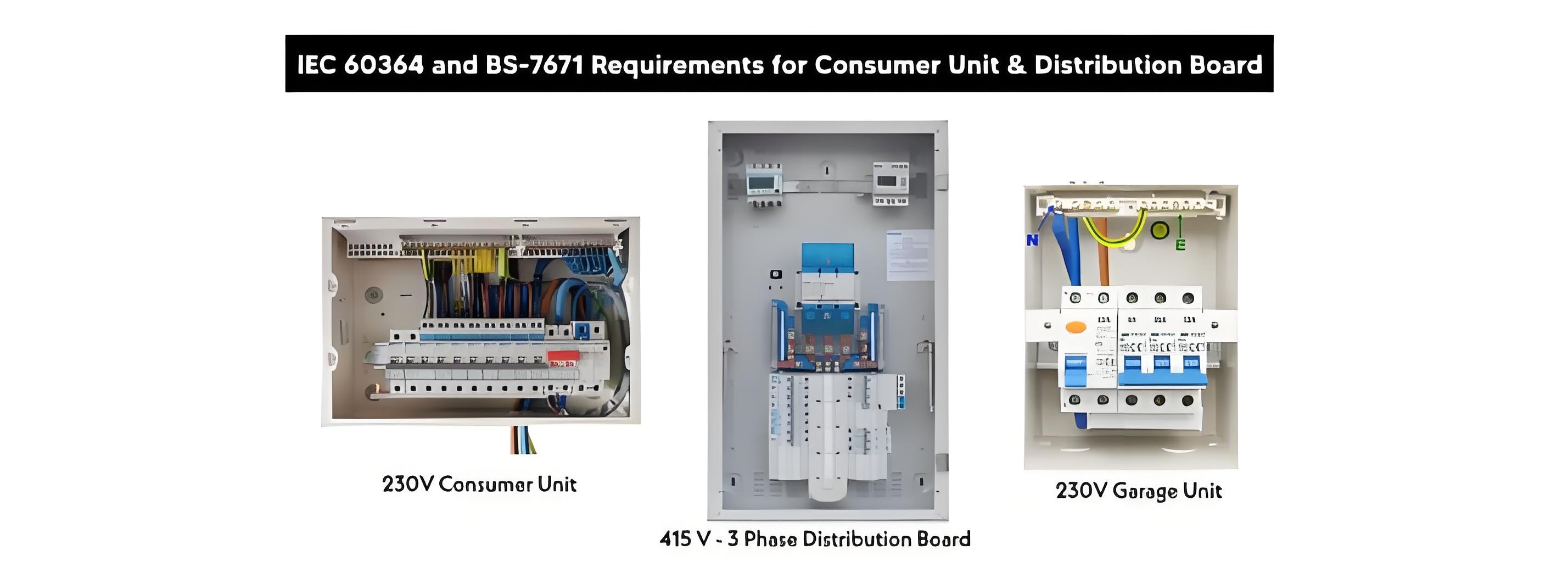

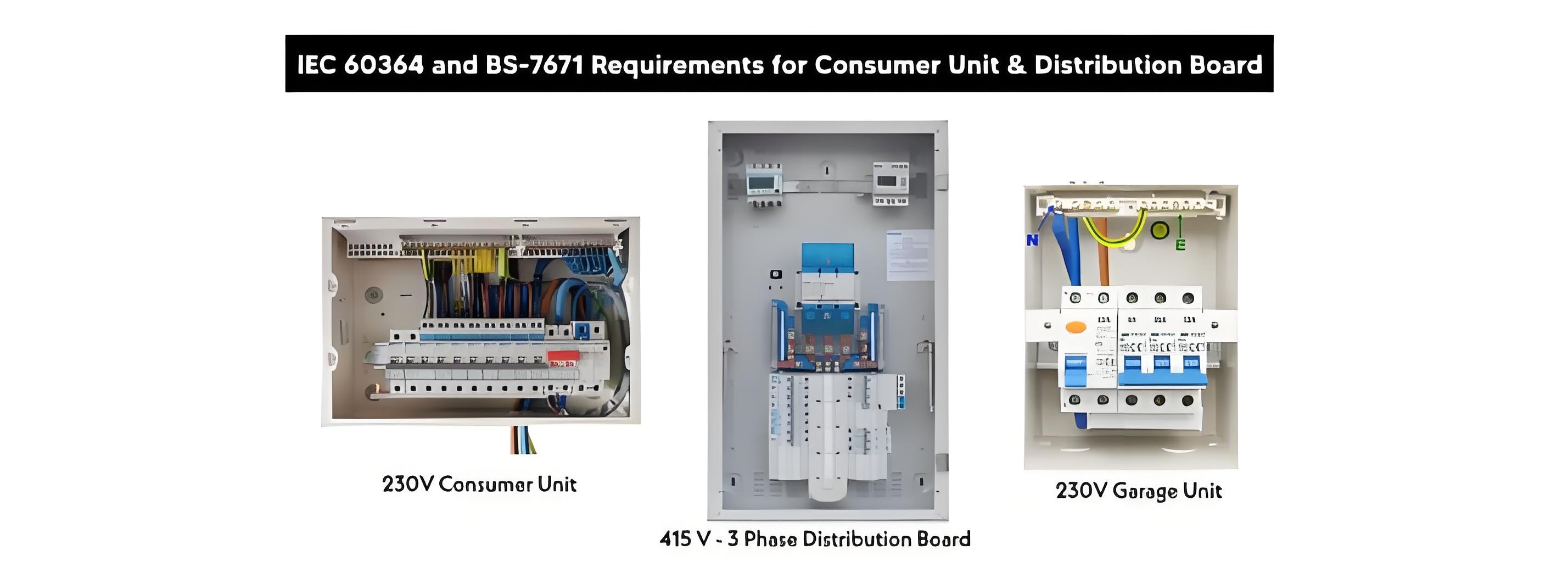

IEC-60364 ug BS-7671 Guidelines para sa Garage Units, Consumer Units, ug Distribution Boards

Ang International Electrotechnical Commission (IEC) ug ang British Standard BS 7671 naglalaro og dako nga papel sa paghukom sa mga requirement alang sa electrical installations. Ang duha ka set sa standards maghatag og komprehensibong guidance, partikular sa fuse boards sama sa garage units, consumer units, ug distribution boards.

Ang IEC 60364 usa ka global na nailhan nga standard nga gitakda ang international best practices alang sa electrical installations. Gitahasan kini og maluwas, reliable, ug maayo nga pag-operate. Sa uban pang bahin, ang BS 7671 – 2018, nga harmonized sa IEC - aligned BS EN 61439, gipagtugyan sa United Kingdom. Kini nga standard nagbase sa international principles apan nagsama usab sa lokal nga regulations ug considerations nga relevant sa UK electrical infrastructure.

Ang sumusunod nga sections magtumong sa key requirements gihatagan sa IEC 60364 ug BS 7671, nagfocus sa critical aspects related sa electrical panels sa iba't ibang settings. Kini nga guidelines importante aron siguraduhon nga ang electrical installations adunay pinaka taas nga safety ug performance standards, protektado ang property ug mga tawo gikan sa electrical hazards.

IEC-60364 and BS-7671 Guidelines for Garage Units, Consumer Units, and Distribution Boards

1. Location ug Accessibility

Batasan sa BS 7671: 132.12 ug IEC 60364 - 5 - 52:

Accessibility: Kinahanglan nga ang electrical panels mahimong makit-an ug ma-access sa routine operation, maintenance, ug inspections. Kini nag-siguro nga ang mga technicians makapunta ngadto sa panels ngadto sa oras nga kinahanglan.

Residential Settings: Sa residential environments, ang recommended installation height para sa distribution boards ug consumer units mao ang 1 hangtod 1.8 meters gikan sa floor. Para sa convenience sa elderly individuals ug disabled, gi-recommend ang 1.3 meters, mas sayon ang interaction sa electrical panels.

Industrial Settings: Sa industrial buildings, para sa typical distribution board nga may IP54 degree of protection, ang mounting area dapat adunay maximum width nga 1.50 meters, maximum height nga 1.20 meters, ug maximum depth nga 0.50 meters, gisangpot sa IEC 61439.

Clearance: Kinahanglan nga adunay sapat nga working space sa palibot sa electrical panels. Ang BS 7671 nag-emphasize sa importansya sa ensuring adequate room para sa safe access sa tanang components, reducing the risk of accidents during operation or maintenance.

Switchgear Installation: Ang switchgear dapat install sa outdoor. Apan, mahimo usab sila install sa indoor kon designed sila para sa indoor use o enclosed sa cabinet nga may protection degree of at least IP4X, IP5X, or IP6X, batasan sa BS 7671: Section 422.3.3.

Double Insulation ug Covers: Kon metallic distribution boards ang gina-install, double insulation ug covers kinahanglan gamiton para sa live parts aron maprotektahan ang accidental contact ug enhance safety.

Environmental Conditions: Ang electrical panels dapat install sa areas nga free from water, excessive dust, ug other adverse environmental factors nga mahimong kompromiso sa safety o performance. Kini nagtabang sa prolong the lifespan sa panels ug ensures reliable operation.

2. Panel Ratings

Batasan sa BS 7671: 536 ug IEC 61439:

Component Selection: Ang distribution boards, consumer units, ug related devices ug equipment kinahanglan mapili basehan sa ilang current-carrying capacity ug overall load requirements sa electrical system. Kini nag-siguro nga ang panels mahatagan sa electrical demands without overheating or failing.

Design ug Testing Standards: Ang IEC 61439 nag-govern sa design, testing, ug construction sa electrical panels (low-voltage switchgear ug controlgear assemblies). Kini nga standards nag-siguro nga ang panels nakakita sa strict safety ug performance requirements, providing reliable protection for electrical systems.

Protective Device Verification: Tanang protective devices gina-usab sa residential consumer units ug commercial/industrial distribution boards kinahanglan verified batasan sa BS EN 61439 - 3 ug comply sa IEC - 60898 ug IEC 60947 - 2 for B, C, ug D curves. Kini nga verification process nag-siguro nga ang protective devices will operate correctly in the event of a fault.

Environmental Suitability: Ang panel boards kinahanglan suitable sa intended environment, taking into account insulation ug temperature ratings. Kini nag-siguro nga ang panels mahatagan sa specific conditions sa ilang installation location, such as temperature fluctuations ug humidity.

3. Isolation ug Switching

Batasan sa BS 7671: Section 537 ug IEC 60364 - 5 - 53:

Isolation ug Switching Provisions: Ang electrical panels kinahanglan equipped with adequate means for isolation ug switching. Kini allows circuits to be safely disconnected during maintenance activities or in case of emergencies, preventing electrical shocks ug damage to equipment.

Main Isolator Requirements: Ang main isolators dapat clear labeled ug easily accessible. Sa situations where isolation is necessary for safety, ang isolator must be capable of disconnecting all live conductors (phase ug neutral) simultaneously.

Emergency Disconnect: An interrupting device or emergency disconnect switch must be installed to enable the main power supply to be quickly disconnected in the event of an emergency or danger. Kini ensures that immediate action can be taken to protect personnel ug equipment, as required by BS 7671: Sections 132.9 ug 132.10.

4. Earthing ug Protective Conductors

Batasan sa BS 7671: Chapter 54 Sections 541 to 544 ug IEC 60364 - 5 - 54:

Earthing Importance: Proper earthing (grounding) essential for protecting users ug equipment from electric shock. Kini provides a safe pathway for fault currents to dissipate into the ground, reducing the risk of electrical accidents.

Protective Earth Connections: Ang electrical panels kinahanglan equipped with reliable protective earth connections. Proper bonding ensures that exposed conductive parts do not pose a safety risk by equalizing electrical potential ug preventing dangerous voltage differences.

Equipotential Bonding: Equipotential bonding should be implemented to prevent the development of dangerous voltages between exposed metalwork. Kini helps to create a safe electrical environment by ensuring that all metal parts are at the same electrical potential.

Lightning Protection Compliance: Batasan sa BS 7671: 541.3, if a lighting protection system is present, the installation should comply with the reference standards in BS EN 62305 to ensure effective protection against lightning-related electrical surges.

PEN Conductor Restrictions: Sa hospitals, emergency units, ug other medical locations downstream of the main distribution board or consumer unit, PEN conductors shall not be used, as specified in BS 7671 - 2028: 710.312.2. Kini restriction is in place to enhance electrical safety in these critical healthcare environments.

5. Selection of Protective Devices

Batasan sa BS 7671: 536.3 ug IEC 60364 - 5 - 53:

Fault Coordination: Ang protective devices within the electrical panel should be carefully coordinated. Kini ensures that in the event of a fault, only the affected circuit is disconnected, rather than the entire system. Proper coordination is crucial for maintaining the safety ug reliability of electrical installations, especially in complex multi-circuit systems.

6. Overcurrent Protection

Batasan sa BS 7671: Chapter 43, Sections 420 to 424 ug IEC 60364 - 4 - 43:

Overcurrent Protection Devices: Ang electrical panels kinahanglan equipped with appropriate overcurrent protection devices (OCPDs), such as fuses, miniature circuit breakers (MCBs), residual current devices (RCDs), residual current breakers with overload protection (RCBOs), arc-fault detection devices (AFDDs), ug surge protection devices (SPDs).

Rating ug Design: Ang OCPDs should be rated based on the design of the electrical circuit to prevent damage to wiring ug reduce the risk of electrical fires. Properly rated OCPDs will trip when excessive current flows, protecting the electrical system from overheating ug potential hazards.

Coordination Requirements: Ang BS 7671 mandates proper coordination between conductors, OCPDs, ug other protective devices. Kini ensures that conductors are protected against thermal damage, maintaining the integrity of the electrical installation.

7. Short Circuit Protection

Batasan sa BS 7671: 434 ug IEC 60364 - 4 - 43:

Short Circuit Protection Provision: Ang electrical panels kinahanglan equipped with protection against short circuits. Ang protective devices should be rated to interrupt the maximum fault current that could occur in the system. Kini ensures that short circuits are quickly cleared, minimizing damage to equipment ug reducing the risk of electrical fires.

Device Selection ug Operation: Ang short circuit protection devices should be selected based on the expected fault current levels ug should operate rapidly to isolate the fault. Quick-acting short circuit protection is essential for maintaining the safety ug reliability of electrical systems.

8. RCDs, AFDDs, ug Earth Fault Protection

Batasan sa BS 7671: 415, 536, ug IEC 60364 - 4 - 41:

Residual Current Devices (RCDs): Ang RCDs required to provide additional protection against electric shock, particularly in circuits supplying socket outlets ug equipment in wet or outdoor locations. Kini quickly detect ug interrupt any imbalance in current flow, which can indicate a leakage current or a person coming into contact with a live conductor.

30mA High-Sensitivity RCDs: A 30mA high-sensitivity RCD must be installed in the consumer unit for socket-outlet circuits, circuits feeding bathrooms, ug lighting circuits, as per IEC 60364. Kini level of sensitivity provides enhanced protection against electric shock hazards.

TT System Requirements: Sa TT system where RCD protection is not present, double or reinforced insulation must be provided on all circuits upstream of the first RCD to ensure the safety of the operator. Kini alternative measure helps to prevent electric shock in the absence of RCD-based protection.

Earth Fault Protection: Ang Earth fault protection must be in place to disconnect the power supply in the event of a fault that could lead to electrocution or equipment damage. Kini protection mechanism ensures that the electrical system is safely isolated when a fault occurs.

TN System Requirements: Sa TN system, earth fault protection should be provided via a circuit breaker. Ang protective earth conductor (PE) ug the exposed conductive parts of all insulated appliances ug equipment must be connected to the consumer-installed earth electrode. Kini connection ensures that fault currents are safely diverted to the ground, protecting users ug equipment.

9. Environmental Protection (IP Ratings)

Batasan sa BS 7671: 512.2 ug IEC 60364 - 5 - 52:

IP Rating Selection: Ang electrical panels must have appropriate Ingress Protection (IP) ratings based on their installation environment. Whether installed indoors, outdoors, in dusty, or wet areas, the IP rating ensures that the panel enclosure provides adequate protection against the ingress of solid objects ug liquids, safeguarding the internal components from damage.

Temperature Limits: Ang electrical equipment should be installed in a manner that ensures the design temperature does not exceed the specified limits, as per BS 7671: Section 134.1.5. Kini prevents overheating, which can lead to component failure ug potential safety hazards.

10. Segregation of Circuits

Batasan sa BS 7671: 514.10 ug IEC 60364 - 5 - 52:

Circuit Segregation: Ang different types of circuits, such as power, lighting, ug control circuits, must be segregated within the electrical panel. Kini segregation helps to prevent interference between circuits ug reduces the risk of faults spreading from one circuit to another.

Voltage Rating Separation: Ang cables ug components with different voltage ratings should not be installed in the same compartment without adequate insulation or separation. Kini ensures that there is no electrical interaction between components with different voltage requirements, maintaining the safety ug integrity of the electrical system.

11. Cables Used in Wiring Systems

Batasan sa BS 7671: Section 422.3.4:

Material ug System Standards:

Cables made from non-combustible materials must comply with EN 60332 - 1 - 2.

Conduit systems should adhere to BS - EN 61386 - 1.

Cable trunking ug ducting systems must meet the requirements of BS - EN 50085.

Cable tray or ladder systems should comply with BS - EN 61537.

Power track systems must satisfy the flame propagation resistance requirements specified in BS - EN 61534.

Wiring systems with a high risk of flame propagation must meet the requirements of BS - EN 60332 - 3. Kini nga standards ensure the safety ug reliability of the wiring system, minimizing the risk of electrical fires ug other hazards.

12. Circuit Identification ug Labeling

Batasan sa BS 7671: 514.1 ug IEC 60364 - 5 - 51:

Circuit Labeling: Tanang circuits within the electrical panel must be clearly labeled to indicate their function ug the areas they serve. A suitable indicator that complies with BS EN 60073 ug BS EN 60447 should be positioned in a location that is clearly visible to the operator. Kini clear labeling helps technicians quickly identify ug troubleshoot circuits during maintenance or repairs.

Protective Conductor Information: Information indicating the high-current protective conductor should be provided ug be clearly visible to anyone working on or modifying the circuit, as per BS 7671 - 2028: 543.7.1.205. Kini information is crucial for ensuring proper installation ug maintenance of the protective grounding system.

Diagram Provision: A single-line diagram, drawing, or general schematic diagram containing the full details of all electrical safety sources should be placed adjacent to the distribution board or consumer unit, as required by BS 7671 - 2028: 560.7.9 ug 560.7.10. Kini diagram provides a comprehensive overview of the electrical system, aiding in understanding ug troubleshooting.

Color Coding: The color coding of conductors should conform to established standards to ensure clarity for electricians ug maintenance personnel. Sa BS 7671, the phase (live) conductor is brown, the neutral is blue, ug the protective earth is green/yellow. Apan, some countries following British standards ug IEC, including the UK prior to 2004, used red, black, ug green for phase, neutral, ug earthing conductors, respectively. For accurate color coding in AC ug DC systems, it is essential to refer to the relevant IEC ug NEC wiring color codes.

13. Verification ug Testing

Batasan sa BS 7671: Part 6 ug IEC 60364 - 6:

Post-Installation Inspection: After installation, electrical panels must undergo a thorough inspection ug testing process to verify compliance with BS 7671 ug IEC standards. Kini inspection ensures that all components are installed correctly ug that the panel functions as intended.

Functionality Testing: The testing process should confirm the proper functionality of protective devices, correct wiring, ug proper earthing. Kini includes checking that circuit breakers trip at the correct current levels, RCDs detect ug interrupt leakage currents, ug that the grounding system provides effective protection.

Periodic Inspections: Periodic inspections ug testing are also required to ensure the ongoing safety of electrical installations. Regular checks help to identify any potential issues or deterioration over time, allowing for timely maintenance ug repairs to prevent electrical accidents.

In conclusion, both IEC 60364 ug BS 7671 play a vital role in ensuring the safety, reliability, ug efficiency of electrical systems. Adhering to these comprehensive standards helps to prevent electrical fires, protect against electric shock hazards, ug safeguard electrical equipment from damage, providing peace of mind for both installers ug end-users.