Kwa maendeleo yasiyofikika ya sekta ya umeme, mazingira ya chini ya karboni, uchakataaji na usalama wa mazingira imeingia sana katika ubuni na ujanja wa bidhaa za umeme za kusambaza na kupatikana. Ring Main Unit (RMU) ni kitu muhimu katika mitandao ya kusambaza. Usalama, ustawi wa mazingira, uhakika ya kufanya kazi, ufanisi wa nishati, na utetezi ni vitendo vya hali ndogo katika maendeleo yake. RMUs zamani zinazofaa ni SF6 gas-insulated RMUs. Kwa sababu ya uwezo mzuri wa SF6 wa kutumia arc-extinguishing na ufanisi wa insulation mkubwa, zimekuwa zinatumika sana. Lakini, SF6 huongeza greenhouse effect. Kwa kuongezeka kwa pressure ya regulations za greenhouse gases, kutengeneza RMUs za gas-insulated zenye ustawi wa mazingira kama alternative za SF6 imekuwa trend inayohitajika.

Sasa, RMUs zenye ustawi wa mazingira zinazotengenezwa ni nitrogen-insulated RMUs na dry air-insulated RMUs. Vitabu vilivyotolewa kuhusu options hizi. Ingawa ufanisi wa insulation wa nitrogen na dry air ni tu asilimia moja ya tatu ya SF6. Hivyo basi, kukabiliana ili ufanisi wa insulation wa jumla wa RMU na switches zake za ndani si isiyoweza kutathmini kwa sababu ya ufanisi mdogo wa medium, na kukosa cabinet space iliyopo, ni muhimu sana. Hii inaelezea kwa ubuni wa electrical structure na insulation structure za ndani. Ubuni wa electrical na insulation structure unaweza kukabiliana na ukiu wa performance ya medium.

Makala haya yanafanana na isolating gap katika 12kV air-insulated RMU fulani. Yanatanzia distribution ya electric field yenye karibu na uniformity yake, kuhakikisha ufanisi wa insulation huko, na kufanya structural optimization ili kurudia probability ya discharge na kuboresha ufanisi wa insulation. Tafiti hii inatafsiriwa kutoa chanzo cha insulation design kwa bidhaa sawa.

1 Structure of the Air-Insulated RMU

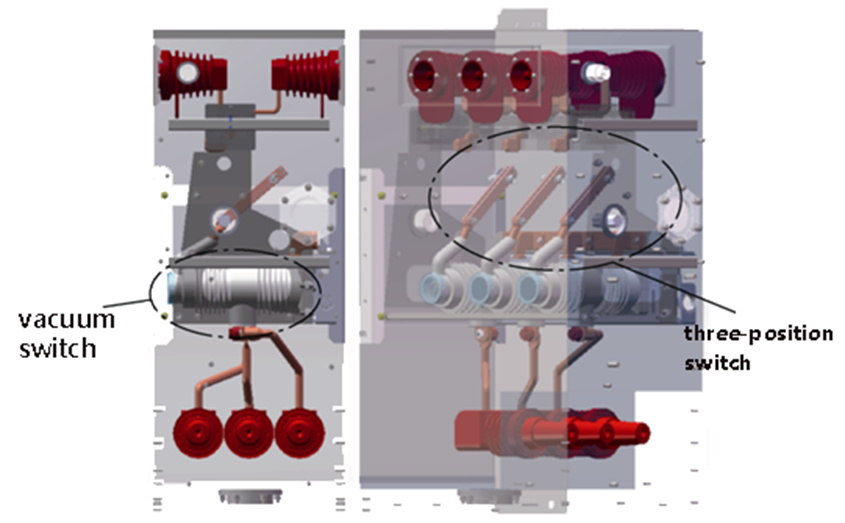

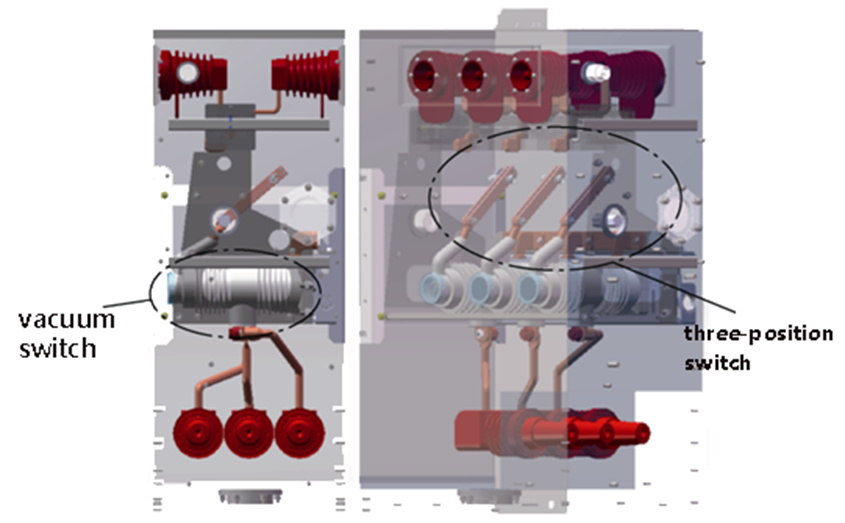

Model ya structure 3D ya air-insulated RMU ambayo imetutumiwa katika makala haya inatafsiriwa kwenye Figure 1. Scheme ya main circuit structure ya RMU inatumia vacuum switch na three-position switch. Layout inatumia scheme ambayo three-position switch inapatikana upande wa busbar, yaani, three-position switch inapangwa upande wa juu wa RMU, na vacuum switch inapangwa upande wa chini kwa kutumia solid-insulated pole.

Tangu vacuum switch ipate enclosed katika pole, exterior lake ina insulated kwa kutumia epoxy resin. Ufanisi wa insulation wa epoxy resin ni wazi kushinda wa air, hivyo hakikisha requirements za insulation. Zaidi, connecting busbar katika sealed end ya solid-insulated pole ina rounded corners, curved designs, na silicone rubber sealing, inarudia partial discharge issues hapa. Insulation clearances kati ya busbars na ground zimeundwa kulingana na requirements za insulation na regulations.

Isolating blade ya three-position switch inatumia kabisa air medium kwa insulation. Kama movable connecting component, ubuni wake una metal parts kama vile pins, springs, disc springs, na retaining rings ili kuboresha contact pressure kati ya isolating contacts. Lakini, kwa sababu ya shapes tofauti za metal parts hizi, zinaweza kuleta electric field distribution sio uniform, kusababisha partial discharge. Hii ina risk ya breakdown discharge, ikisababisha ufanisi wa insulation huko. Hivyo basi, ubuni wa electrical structure hapa ni muhimu sana.

Kulingana na product design requirements, isolating gap lazima iweze kudumu rated short-time power-frequency withstand voltage ya 50kV. Minimum electrical clearance ya isolating gap imeundwa kama 100mm. Kwa kuangalia complex ya isolating blade structure, grading shields zimeongezwa pande mbili za isolating blade ili kuboresha uniformity ya electric field na kurudia occurrence ya partial discharge. Model 3D ya three-position switch inatafsiriwa kwenye Figure 2. Kwa hivyo, makala haya yanafanya electric field simulation analysis kwenye isolating gap.

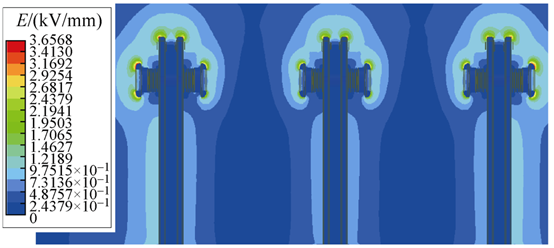

Software ya finite element limeatumika kufanya simulation ya electric field ya RMU, kuanaliza intensity distribution ya electric field kwenye isolating gap kwenye rated short-time power-frequency withstand voltage ya 50kV. Scenarios mbili za electrostatic field simulation zimeundwa:

- Scenario 1: Busbar side (side with the isolating static contact seat) connected to low potential (0V), line side (side with the isolating blade head) connected to high potential (50kV).

- Scenario 2: Busbar side (side with the isolating static contact seat) connected to high potential (50kV), line side (side with the isolating blade head) connected to low potential (0V).

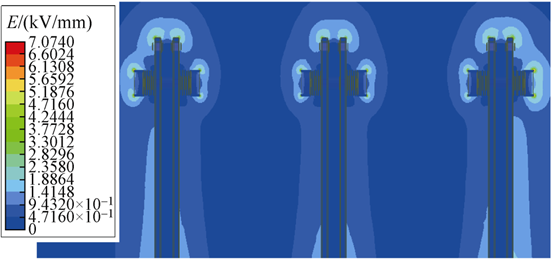

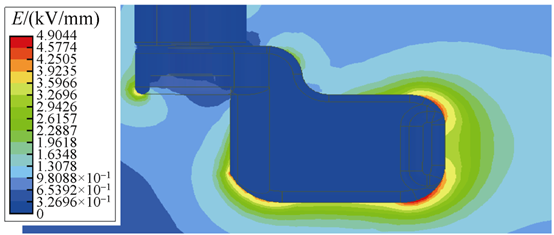

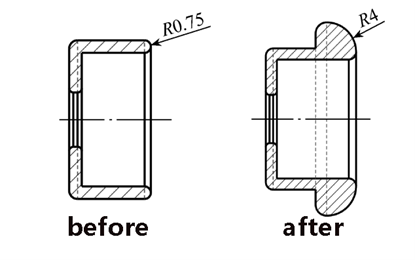

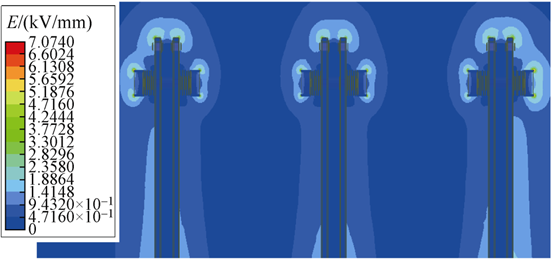

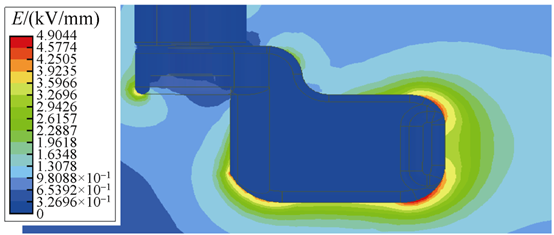

Electric field distributions kwenye location ya maximum electric field intensity kwenye isolating gap kwa scenarios mbili zimepatikana kutoka kwa simulation. Electric field intensity distribution kwenye isolating blade head kwa Scenario 1 inatafsiriwa kwenye Figure 3, na hii kwenye isolating static contact seat kwa Scenario 2 inatafsiriwa kwenye Figure 4. Maximum electric field intensity kwenye Scenario 1 inapatikana mwishoni mwa grading shield, inawezekana 7.07 kV/mm. Maximum kwenye Scenario 2 inapatikana chamfer ya isolating static contact seat, inawezekana 4.90 kV/mm.

Critical breakdown electric field strength kwa air kwenye standard conditions ni mara nyingi 3 kV/mm. Figures 3 na 4 inashow kwa kuwa localized areas kwenye isolating gap zinazozidi 3 kV/mm, intensity katika areas nyingine zinaendelea chini ya threshold hii, kusababisha breakdown discharge si rahisi. Lakini, partial discharge itakuwa kwenye localized positions ambazo intensity zinaozidi 3 kV/mm.

Wakati air hupata kuchanjika kutoka kwenye dry hadi humid, ufanisi wake wa insulation unapungua. Critical breakdown electric field strength kwenye uniform field conditions unapanda chini ya 3 kV/mm. Zaidi, extremely non-uniform electric field distribution pia kunapungua critical breakdown field strength wa air. Vyombo vyote vya viwango hivi vinaweza kuboresha possibility na risk ya breakdown. Ili kurudia impact ya external environmental conditions kwenye air insulation medium na kuboresha uniformity coefficient ya electric field, makala haya yanataka kudetermine degree ya uniformity ya electric field kwenye isolating gap na withstand voltage value ya gap. Hii itakuwa basis kwa kuboresha ufanisi wa insulation wa isolating gap.

3 Air Insulation Characteristics

3.1 Determination of Electric Field Non-Uniformity Coefficient

Electric fields sio uniform kabisa katika practice; electric fields zote ni non-uniform. Kulingana na non-uniformity coefficient f, electric fields zinapatambuliwa kama slightly non-uniform electric fields wakati f ≤ 4; na extremely non-uniform electric fields wakati f > 4. Electric field non-uniformity coefficient f anadetermine kwa f = E_max / E_avg, ambapo E_max ni local maximum electric field strength, inapatikana kutoka kwa simulation results, na E_avg ni average electric field strength, inahesabiwa kama applied voltage divided by minimum electrical clearance.

Kwenye Figure 3, E_max = 7.07 kV/mm na E_avg = 0.5 kV/mm (50kV / 100mm). Hivyo basi, non-uniformity coefficient kwenye isolating gap f = 14.14 > 4, akibainisha kuwa ni extremely non-uniform field. Stable partial discharge phenomena zinaweza kujenga karibu na extremely non-uniform fields. The greater the degree of non-uniformity, the more pronounced the partial discharge, and the larger the discharge magnitude. Kwa 12kV RMU, requirement ni kwamba total partial discharge ya entire cabinet itaweza kuwa chini ya 20pC. Reducing the non-uniformity coefficient f is beneficial for decreasing partial discharge magnitude.

3.2 Determination of Air Withstand Voltage

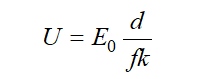

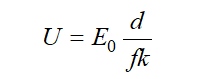

Non-uniformity coefficient hupunguza withstand voltage ya dry air. Wakati field ni slightly non-uniform, withstand voltage ni:

Formula (1)

Ambapo:

- U ni withstand voltage.

- d ni minimum electrical clearance kati ya electrodes.

- k ni reliability factor, mara nyingi anaweza kuwa 1.2 hadi 1.5 kutegemea na experience.

- E₀ ni gas breakdown electric field strength. Katika practice, hii inaunganishwa na electrode structure. Air breakdown field strength hupungua kwenye different electrode structures na clearances. Kwa comparative analysis katika makala haya, E₀ = 3 kV/mm imewezeshwa.

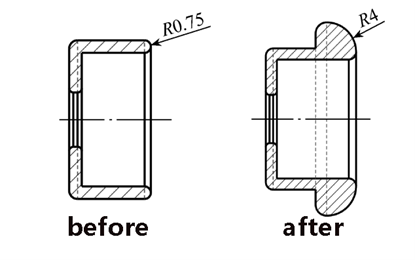

Kwenye Formula (1), increasing the minimum electrical clearance d au decreasing the non-uniformity coefficient f can improve the air's withstand voltage. Wakati field ni extremely non-uniform, kwa electrodes na minimum clearance d ingawa 100mm, withstand voltage inadetermine kwa:

Formula (2)

Ambapo ni lightning impulse 50% breakdown voltage kwa electrode na electrical clearance ya d. Kwenye extremely non-uniform fields, breakdown voltage ina dispersion kubwa na long discharge time delay, ikisababisha instability kubwa.

Katika engineering practice, U<sub>50%(d)</sub> inadetermine kwa multiple lightning impulse tests: applied voltage ambayo breakdown inapatikana kwa 50% probability inadefinika kama U<sub>50%(d)</sub>. Hii inategemea product structure na degree ya field uniformity. Imewezeshwa kuwa lower non-uniformity coefficient inaweza kupunguza breakdown voltage dispersion, inaboresha breakdown voltage, na kwa hiyo, inaboresha withstand voltage. Hivyo basi, reducing the non-uniformity coefficient f improves the withstand voltage of the isolating gap.

4 Structural Optimization

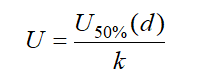

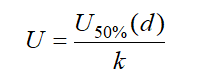

Ili kuboresha uniformity ya electric field kwenye isolating blade head na kureduce non-uniformity coefficient, grading shield structure iliyopimwa.

Ingawa kwenye original design, optimized grading shield ina thickened end na rounded corner design. Fillet radius imeongezeka kutoka 0.75mm hadi 4mm, inaboresha curvature radius kwenye area hii, ikisaidia kufikia uniform field distribution zaidi. Electric field intensity distribution kwenye optimized isolating blade head inatafsiriwa kwenye Figure 7. Figure inashow maximum electric field intensity kwenye position hii sasa ni 3.66 kV/mm, kwa gharama gani ya half ya value kabla ya optimization, inaelezea improvement kubwa.

Kulingana na formula f = E_max / E_avg, electric field non-uniformity coefficient baada ya optimization ni 7.32. Ingawa kwenye pre-optimization state, hii imepungua kwa half. Uniformity ya electric field karibu na isolating blade head imeboresha kwa kiasi kubwa, inaelezea reasonableness ya structural optimization.

Optimized grading shield structure imepunguza risk ya breakdown discharge kwenye isolating gap. Lakini, electric field kwenye gap bado ni extremely non-uniform, na withstand voltage yake bado inadetermine kwa U<sub>50%(d)</sub>. Kiasi cha withstand voltage kinaweza kuongezeka linaweza kudetermine kwa field tests zifuatazo.

5 Conclusion

Kwa electric field analysis kwenye isolating gap kwenye 12kV air-insulated RMU, makala haya yamekufikia hatua zifuatazo:

- Kwa sababu ya ufanisi mdogo wa insulation wa air kuliko SF6, kutumia air kwa insulation kwenye three-position switch katika RMUs inahitaji kuboresha distribution ya electric field ili kuboresha ufanisi wa insulation.

- Kwa sababu ya complexity ya moving parts (isolating blade) kwenye three-position switch kwenye air-insulated RMUs, electric field intensity distribution kwenye localized positions inaweza kuwa highly non-uniform. Ili kurudia non-uniformity, grading shields zinaweza kuongezwa pande mbili za isolating blade ili kushield electric field intensity karibu na ends za blade connectors, kusakinisha maximum local field intensity kwenye ends za grading shields. Makala haya imewezeshwa kuongeza curvature radius kwenye end ya grading shield kutoka 0.75mm hadi 4mm. Hii imepunguza maximum local electric field intensity na non-uniformity coefficient kwa half ya values zao za awali, inaelezea desired effect.

- Degree ya uniformity ya electric field, au non-uniformity coefficient, inaweza kusababisha partial discharge na breakdown discharge. Extremely non-uniform fields zinaweza kuunda stable partial discharge (corona discharge) rahisi. Kwa both slightly na extremely non-uniform fields, higher non-uniformity coefficient unaelezea lower withstand voltage kati ya two electrodes.