| Brand | Schneider |

| Model NO. | Trihal Cast resin transformer up to 36kV |

| Rated voltage | 12/17.5kV |

| Series | Trihal |

Product at a glance

Cast resin, 50 Hz, three-phased distribution transformers with the following characteristics:

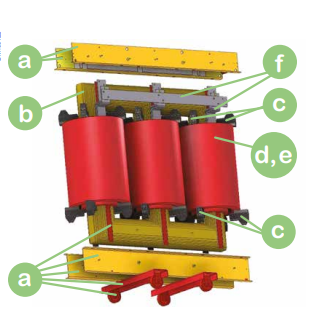

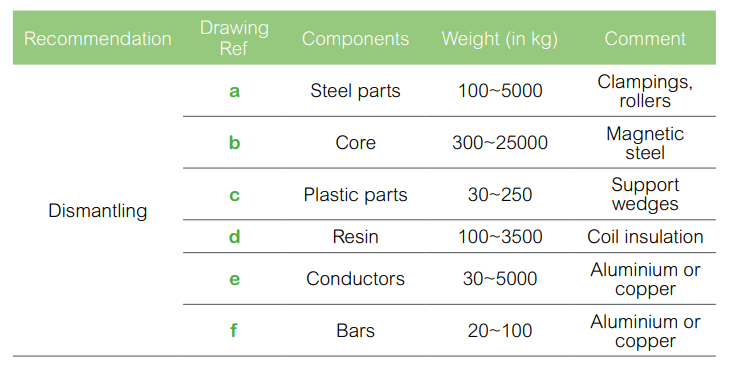

The components of the products

Compliance:

These transformers comply with standards:

Schneider Electric guarantees that its transformers are silicone free and certified:

Trihal

Up to 3150 kVA, 12 kV, losses

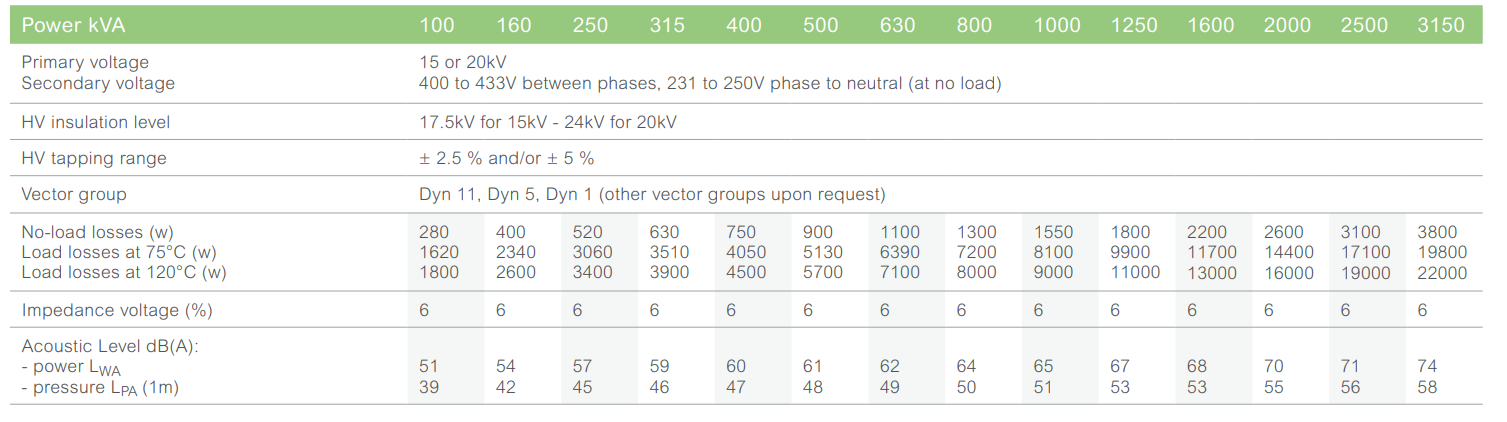

Main electrical characteristics

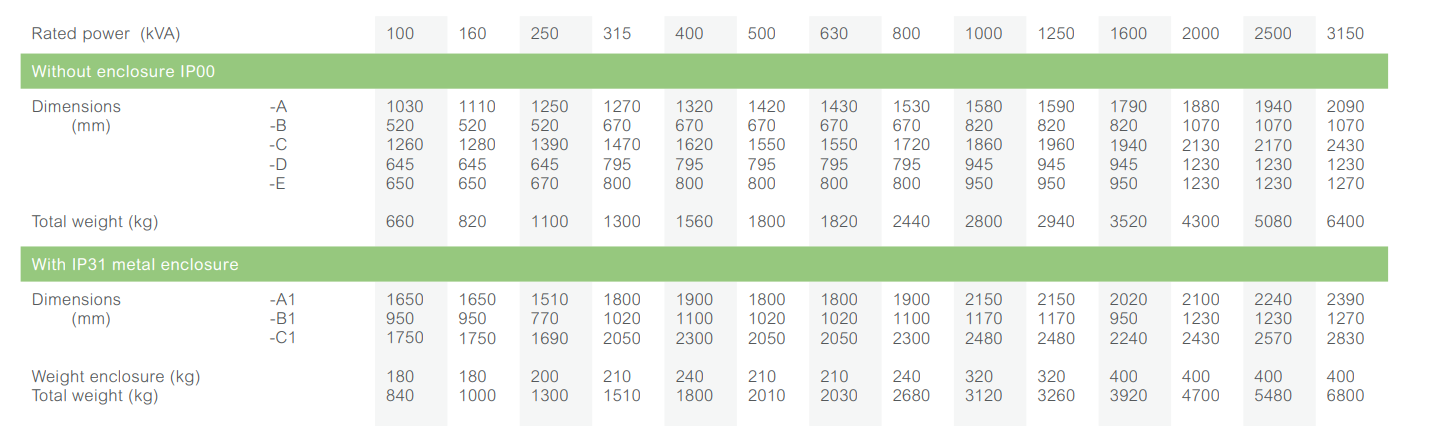

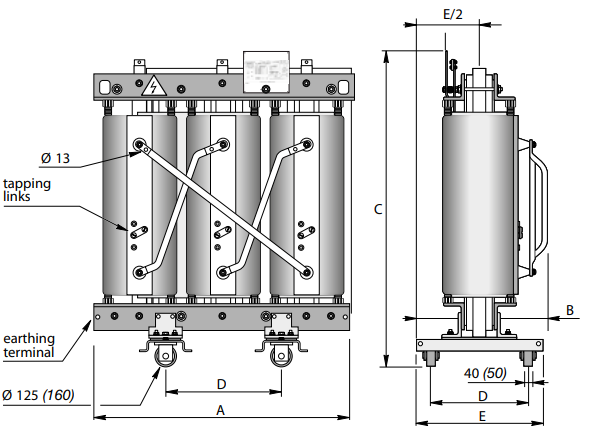

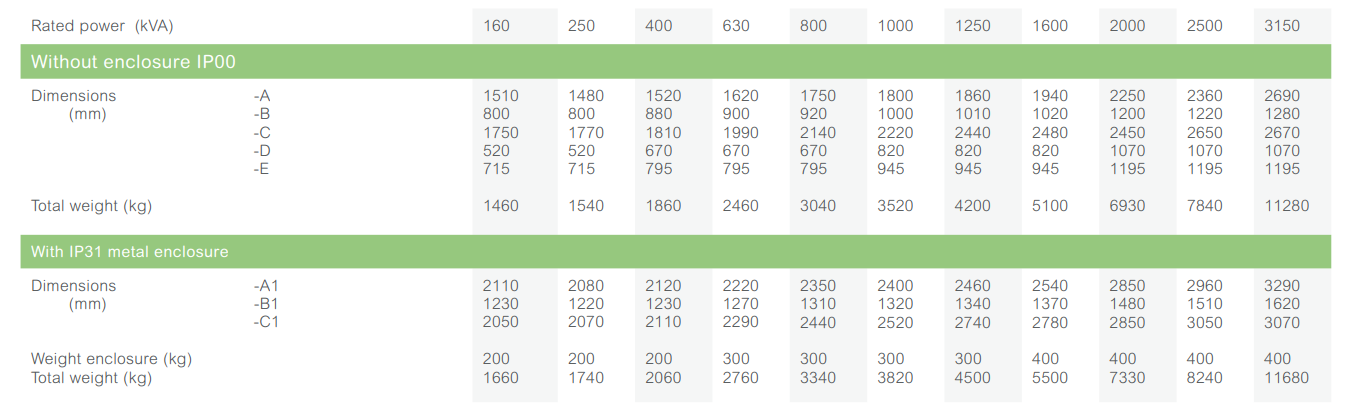

Dimensions* and weights

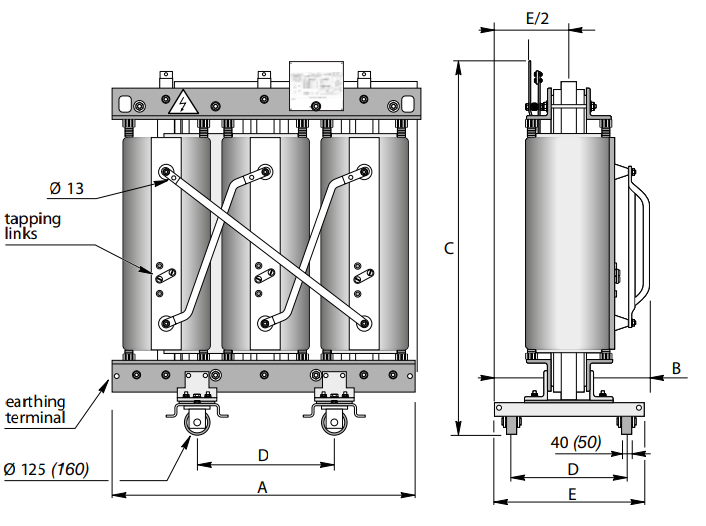

Without enclosure (IP00)

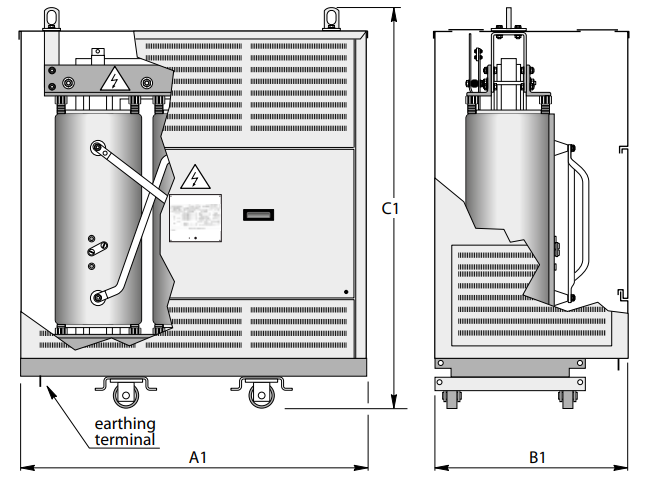

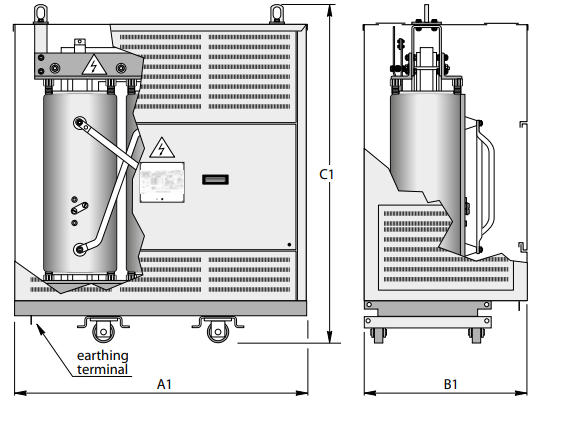

With IP31 metal enclosure

Trihal

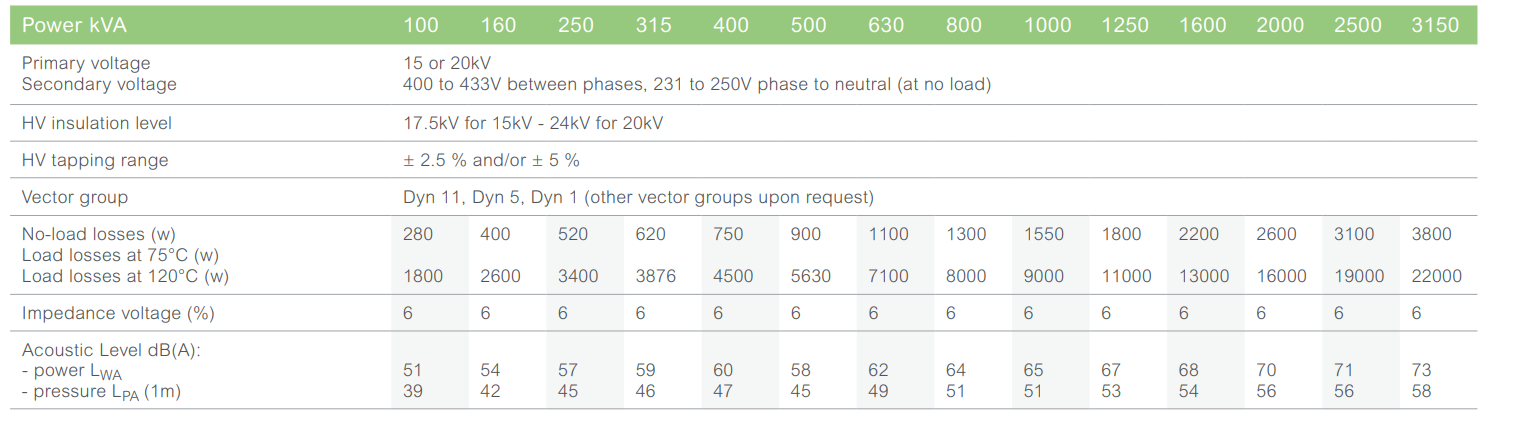

Up to 3150 kVA, 17.5 to 24 kV, losses

Main electrical characteristics

Dimensions* and weights

Without enclosure (IP00)

With IP31 metal enclosure

Trihal

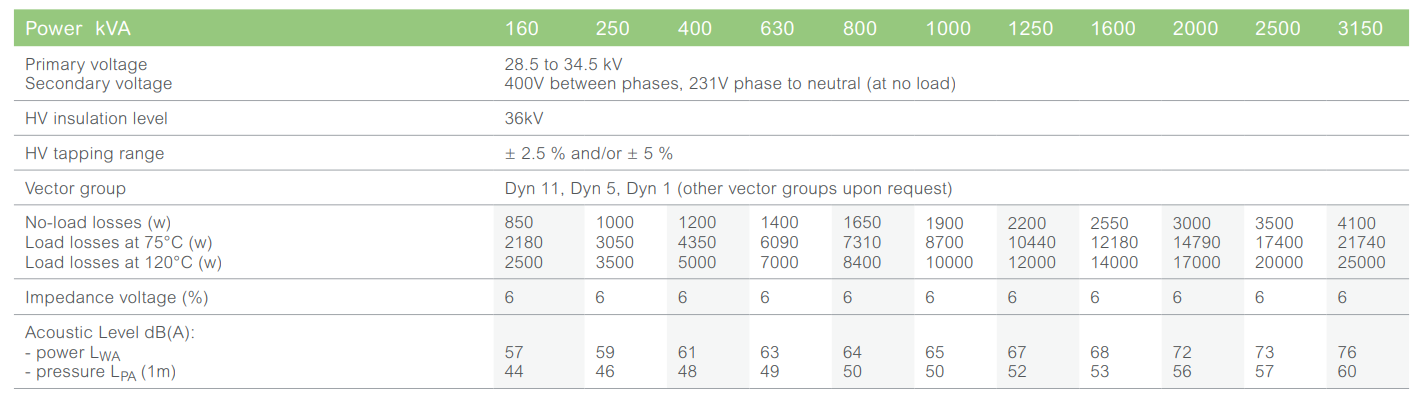

Up to 3150 kVA, 36 kV, losses

Main electrical characteristics

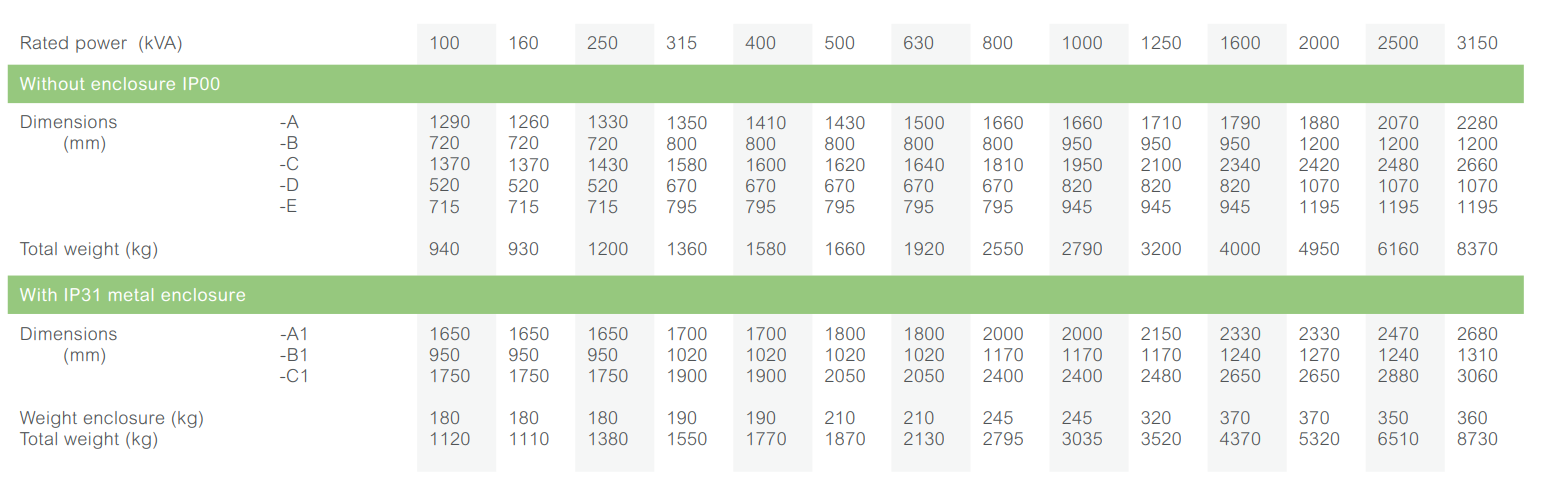

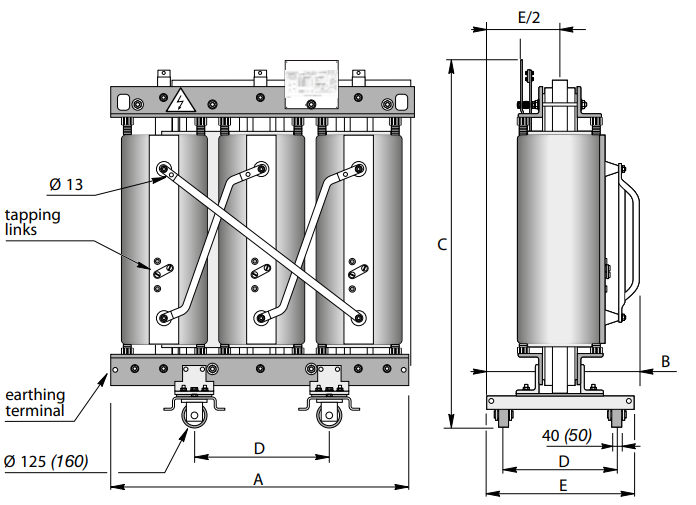

Dimensions* and weights

Without enclosure (IP00)

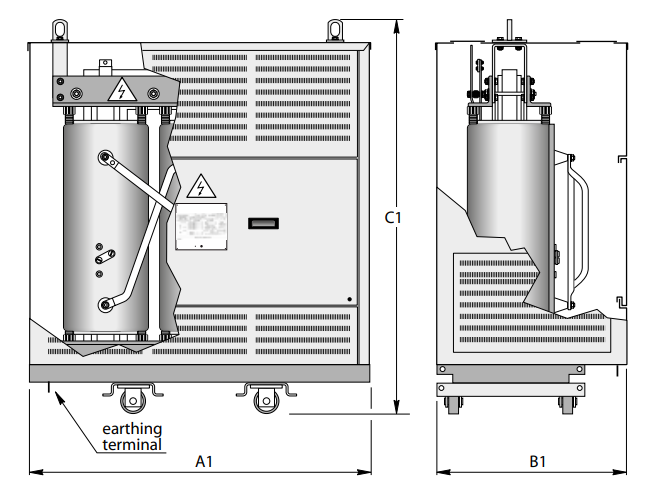

With IP31 metal enclosure

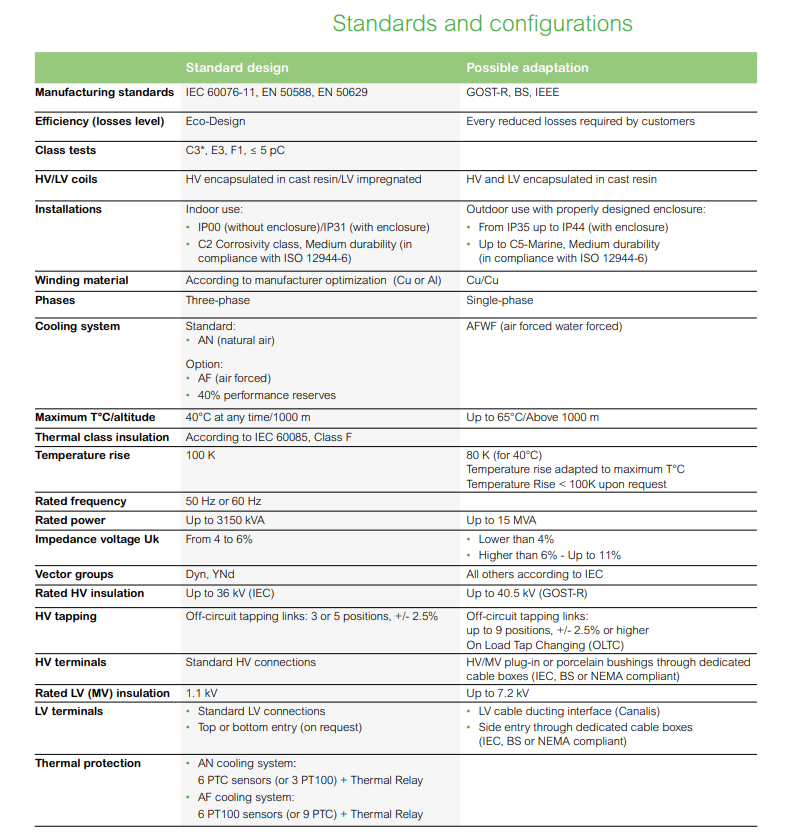

All available Trihal technical range

Trihal

Options and accessories

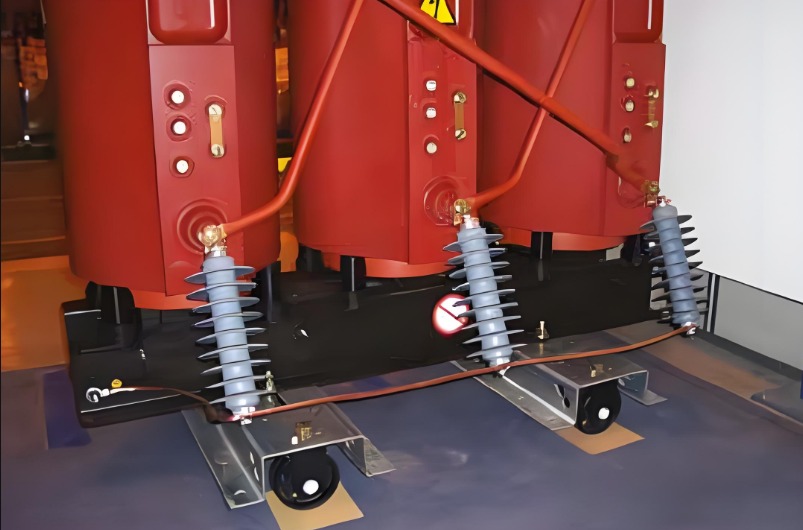

High voltage surge arresters

If the installation is likely to be subjected to overvoltage of any kind (atmospheric or switching), the transformer must be protected by phase-to-earth surge arresters, installed directly on the transformer’s HV connection terminals (either at the top or the bottom).

It is essential to install these surge arresters:

High voltage surge arresters on the lower part

Vibration damping

Roller anti-vibration pads

This accessory, placed under the rollers, avoids vibrations being transmitted from the transformer to its environment.

Damper unit

This device is installed instead of the roller and enables transmission of vibrations to the transformer environment to be attenuated.

Anti-damping accessories

Protective Enclosure

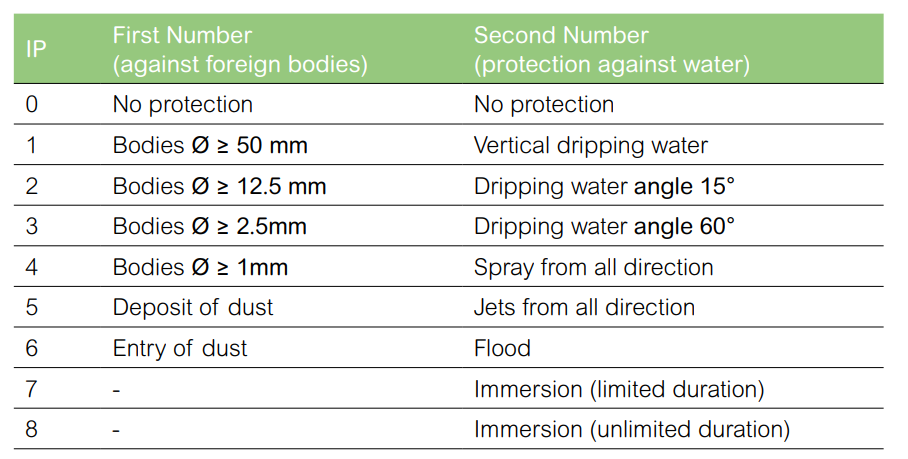

The IP and IK protective indices refer to the following criteria:

IP protection indices

Protective enclosure IP31, IK7