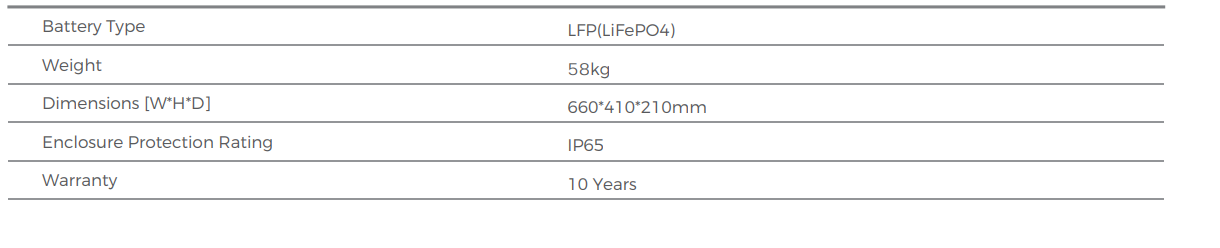

| Brand | RW Energy |

| Model NO. | Low Voltage LFP Battery |

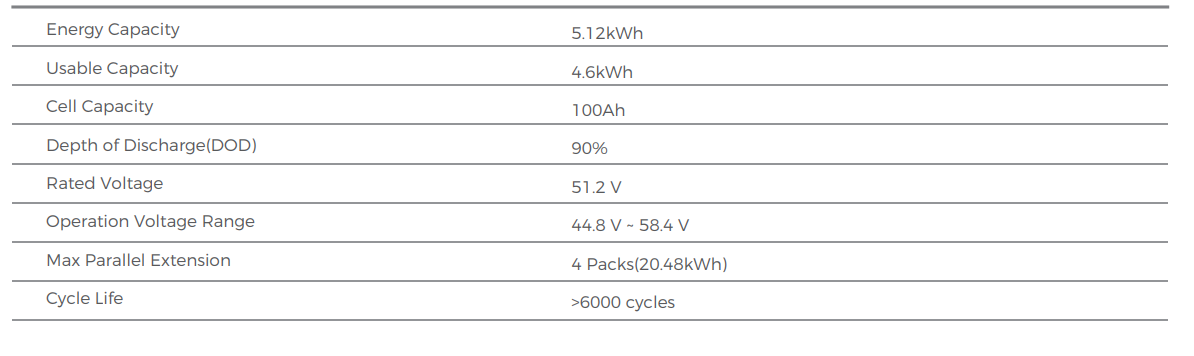

| Rated voltage | 51.2 V |

| Rated capacity | 5.12kWh |

| Series | Residential energy storage |

Features

> 6,000 cycles backed by Jinkosolar 10-years authoritive warranty.

Multiple battery protections including communication, MOS, 2nd fault mandatory protection to enable overall full protection.

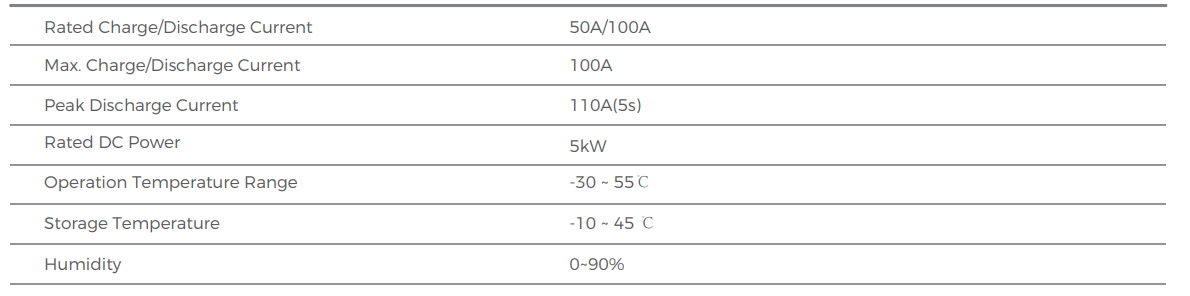

Compatible to charge/discharge at 0.5C and 1C, but at 0.5C is recommended.

Protection rating at IP65, cell-level independent fire-proof design, fire-resistant material can be exposed to 1200 degrees Celsius flame.

Compatible to diseal engine power plants and UPS application with on/off grid shifting times as low as 10 seconds.

Plug and play connecion saves 40% installation time.

Over 35 technical and services centers globally, world-widely distributed network and parters.

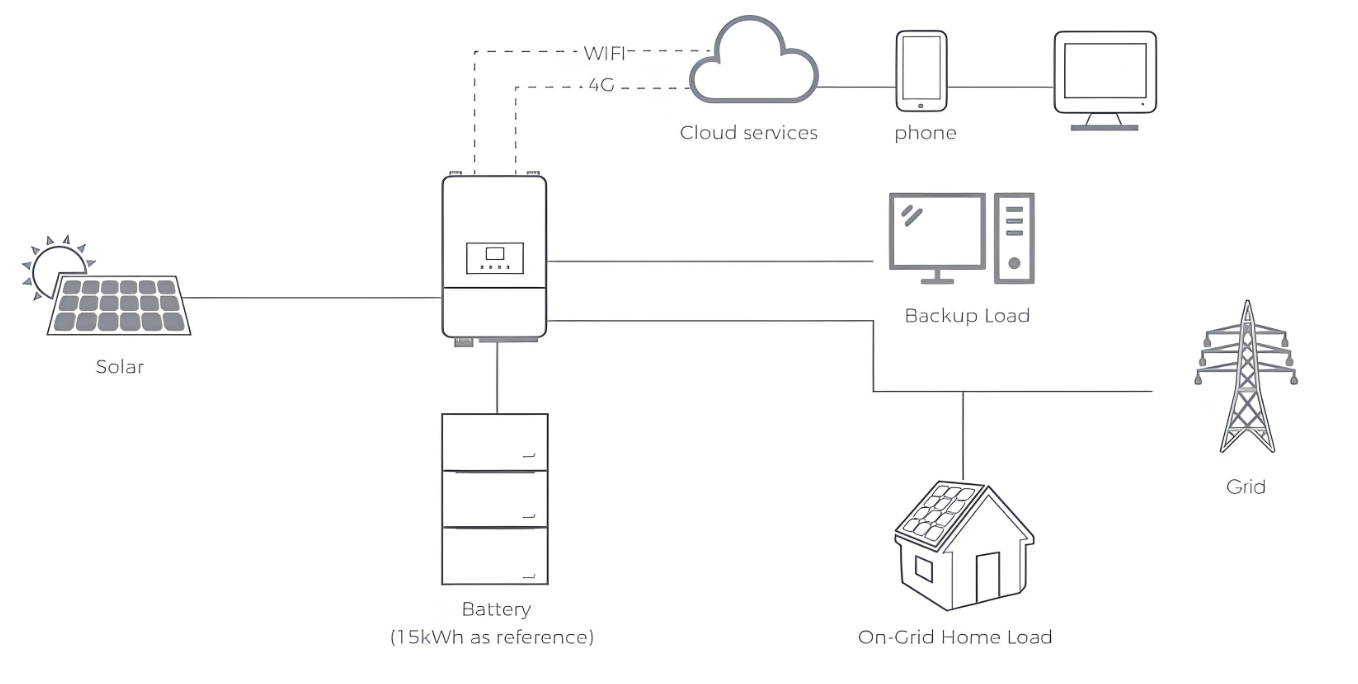

All-in-one PV+ solution provides packed warranty, one-stop service and support.

Physical

Electrical

Operation

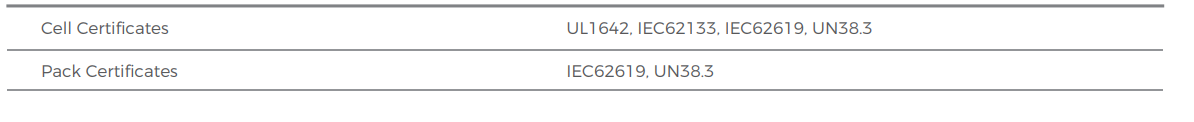

Certification

Power button

LED indicator

Hidden handle

Hidden cable connection box

What is a low-voltage LFP battery?

Low-voltage LFP battery refers to a lithium-ion battery that uses lithium iron phosphate (LiFePO4) as the cathode material and has a relatively low operating voltage. Generally, the overall voltage of the battery pack is in the range of several tens of volts (V).

Working principle:

Charging process:When the battery is charging, lithium ions are deintercalated from the cathode material (LiFePO4), move to the anode (usually graphite) through the electrolyte, and combine with the anode material to form a lithium intercalation compound.Electrons flow from the cathode to the anode through the external circuit to form a current.

Discharging process:When the battery is discharging, lithium ions are deintercalated from the anode, move back to the cathode through the electrolyte, and at the same time, electrons flow from the anode to the cathode through the external circuit to provide electrical energy to the load.