1.Flame-Retardant Cable Classification Standards

The flame-retardant standard system is divided into two main categories. The first category follows the "Classification of Burning Behavior for Electric and Optical Fiber Cables" GB 31247. Cables complying with this standard system are widely used in densely populated areas such as high-speed railways and subways. This standard imposes strict requirements on parameters such as smoke density, heat release, and total smoke production, and cables typically use low-smoke, halogen-free materials.

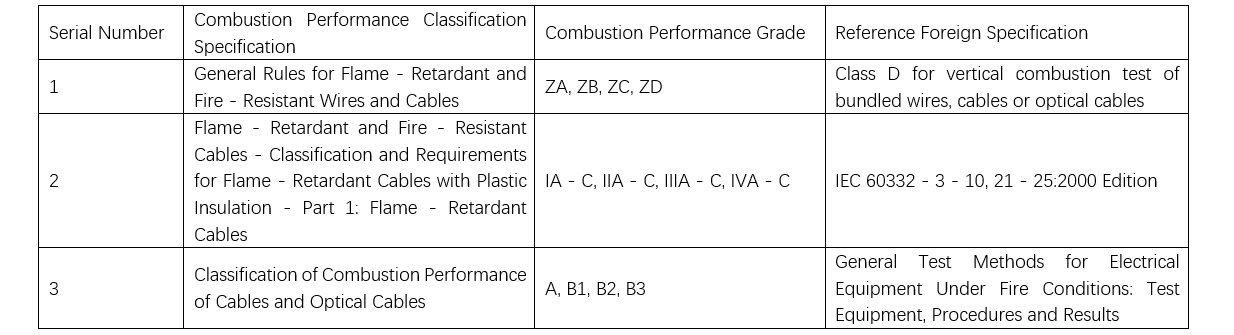

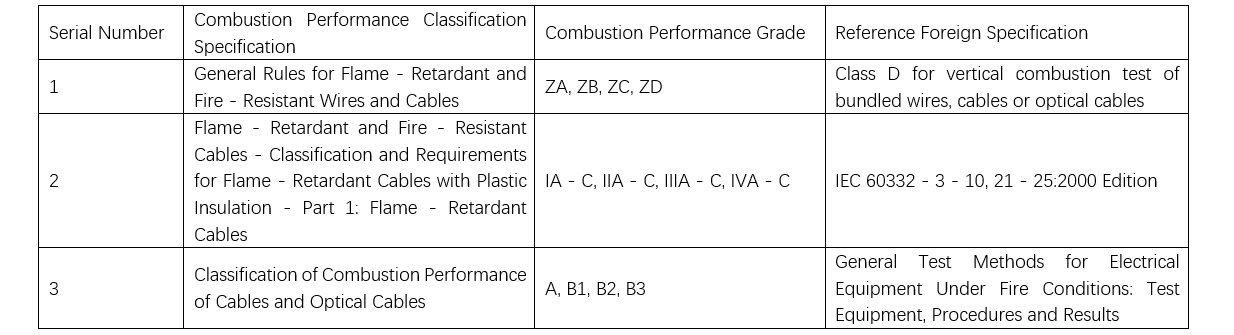

The second category is the "General Rules for Flame-Retardant or Fire-Resistant Electric Wires, Cables, or Optical Cables" GB/T 19666. Before the introduction of GB 31247, this standard was widely applied across all types of facilities in China. The GB/T 19666 system also specifies values for parameters like smoke density, and during bidding, additional prefixes are often specified, such as WD (low-smoke, halogen-free). The corresponding test standards for cable flame-retardant ratings are shown in the table below:

Classification Standard for Item 1: The standard "General Rules for Flame-Retardant or Fire-Resistant Electric Wires, Cables, or Optical Cables" GB/T 19666 uses the familiar ZA, ZB, ZC classifications known to power design institutes. However, its referenced test method, "Test on the vertical flame propagation for bunched wires or cables under fire conditions – Part 3: Test methods for bunched wires or cables" GB 18380.3-2001, has been withdrawn. This test standard was based on IEC 60332-3-25:2000, "Tests on electric and optical fibre cables under fire conditions – Part 3-25: Test for vertical flame spread of vertically-mounted bunched cables – Category D."

Classification Standard for Item 2: The standard "Flame-retardant and Fire-resistant Cables – Part 1: Flame-retardant Cables" GA 306.1-2007, classifies cables according to the updated test methods GB 18380.31~36-2008, which replaced GB 18380.3-2001. Its main distinction is the inclusion of additional criteria such as smoke toxicity (GB 20285), light transmittance, and corrosion resistance, further subdividing the A, B, and C classes into five distinct grades.

Classification Standard for Item 3: The "Classification of Burning Behavior for Electric and Optical Fiber Cables" GB 31247 is the most recent standard. Its corresponding test method is "Flame spread, heat release and smoke production characteristics of cables or optical fiber cables in fire conditions" GB 31248, which references EN 50399:2011, "Common test methods for cables under fire conditions – Measurement procedures of heat release and smoke production for the test of vertical flame spread of bunched wires and cables – Apparatus, procedure and general results." The key difference is that it evaluates flame spread, total heat release, peak heat release rate, and total smoke production. The criteria between these two classification systems differ significantly. The GB 31247 system (B1 class) emphasizes low-halogen and low-smoke characteristics, meaning the classifications are not directly equivalent. Even the "B" class within the ZA/ZB/ZC system fails to meet the requirements of the B1 class.

2. Reasons Why B1 Class is Unavailable for High-Voltage Cables

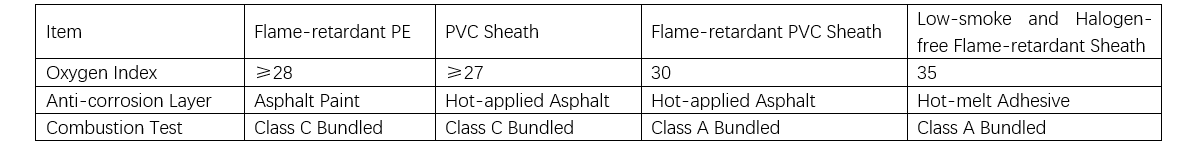

2.1 Lack of Low-Smoke, Corrosion-Resistant Materials

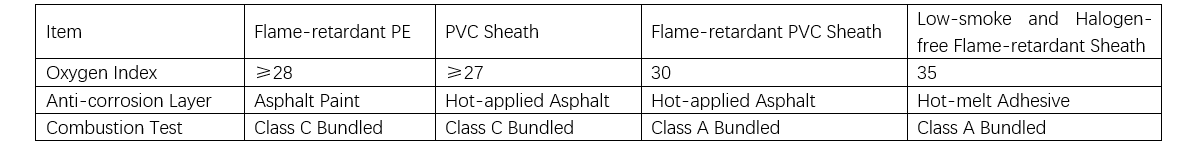

Achieving low-smoke performance typically requires the use of bituminous paint. However, bituminous paint does not meet corrosion resistance requirements, and its use is also prohibited by European standards. Therefore, the low-smoke performance criterion cannot be met. High-voltage power cables use a metallic aluminum sheath with a bituminous anti-corrosion structure, which generates significant smoke during combustion. While abroad, bituminous paint or hot-melt adhesive is generally used, this structure has neither been manufactured by any domestic manufacturer nor used in any engineering project. Consequently, the material field for high-voltage power cable outer sheaths restricts the ability to achieve the low-smoke performance required for the B1 class.

2.2 Insulation Resistance Reduction in Low-Halogen Cables

A significant difference between high-voltage and medium-voltage power cables lies in the choice of outer sheath material. Due to high current capacity, high overvoltage, and the single-core design of high-voltage cables, the outer sheath must have excellent insulation properties for operational safety. Therefore, the outer sheath of high-voltage cables is specified as "insulation-grade," whereas medium-voltage cables use "sheath-grade" material.

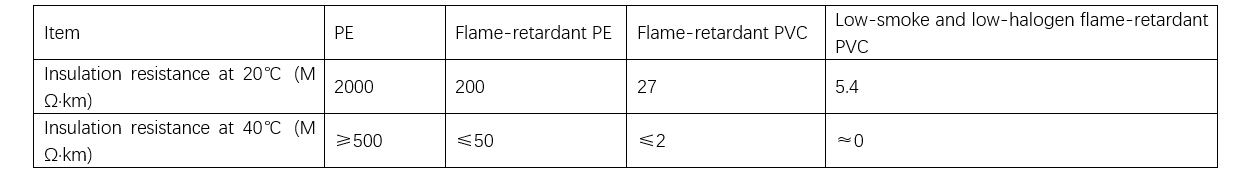

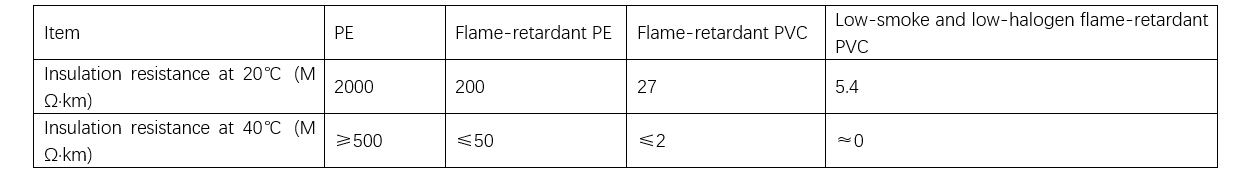

However, low-smoke, halogen-free sheathing compounds contain large amounts of inorganic flame retardants, which result in relatively poor insulation resistance for the sheath. Current sheath material insulation performance follows the order: PE ≥ Flame-retardant PE ≥ PVC ≥ Low-smoke, halogen-free series. Because of this, current high-voltage cable standards such as GB/T 11017 and GB/T 18890 have not incorporated low-smoke, halogen-free sheathing compounds into their standard systems. In contrast, for medium-voltage cables, where the requirements for sheath insulation performance are less stringent, low-smoke, halogen-free sheathing compounds have already been included in the standard system.

Power grid companies have organized multiple cable industry conferences, primarily due to the poor performance of two key indicators: the water absorption rate of outer sheaths under saturated water absorption conditions and the insulation resistivity under saturated water absorption conditions.

The fire prevention situation in high-voltage power cable tunnels is severe. Currently, high-voltage cables are mainly purchased in flame-retardant models. As the name suggests, flame-retardant materials are conventional sheath materials with added formulations such as flame retardants, endowing the materials with flame-retardant properties. The flame-retardant performance of common sheaths is shown in Table 3.

Taking a PE sheath as an example, flame-retardant PE is standard PE sheathing material with added flame retardants. Flame retardants are divided into inorganic and organic types. Currently, most products on the market primarily use inorganic flame retardants, with common types including magnesium oxide and aluminum oxide. These materials readily absorb moisture and undergo hydration reactions under normal conditions. Therefore, sheathing materials are typically put into production immediately after procurement; otherwise, moisture absorption can easily occur, leading to defects such as voids during extrusion. Only after the flame retardant particles are micronized, undergo surface modification, and have their material compatibility enhanced, can flame-retardant sheathing compounds achieve good processability.

Waterproof cables usually refer to cables with a complete, sealed metallic sheath. If a plastic sheath is used as the waterproof layer, moisture can penetrate into the cable through the plastic. Moisture ingress is a relatively slow process. During actual cable operation, the sheath surface temperature can reach as high as 60°C, which accelerates moisture penetration. Therefore, for newly commissioned cable sheaths, the insulation resistance generally meets requirements. However, after a period of operation, the sheath insulation resistance of many lines drops sharply, and this issue is typically discovered within several months to about a year. Once the sheath insulation resistance decreases to a certain level, the rate of decline tends to stabilize and slow down.

2.4 Poor Crack Resistance of Low-Halogen Cables

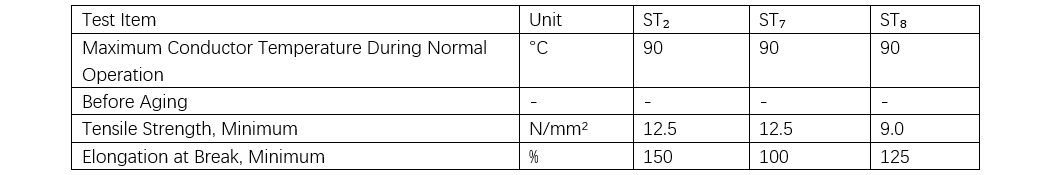

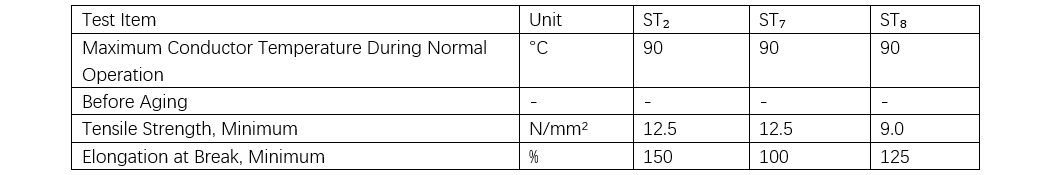

In Table 5, ST2 refers to PVC, ST7 to PE, and ST8 to halogen-free, low-smoke material. From the perspective of sheath mechanical properties, the tensile strength and elongation at break of halogen-free, low-smoke materials are significantly inferior. The installation of halogen-free, low-smoke cables has strict requirements, especially in outdoor areas in northern regions, because these sheaths are prone to cracking at low temperatures and may even develop cracking during operation. Numerous similar quality incidents have already occurred with medium- and low-voltage cables in China. Some construction projects use halogen-free, low-smoke cables during winter, partly because the work is conducted indoors where temperatures are higher.

Halogen-free, low-smoke cables are primarily used indoors in buildings and densely populated areas such as stations, subways, and public buildings. The power compartment of a utility tunnel does not belong to a densely populated area.

3 Conclusion

Based on the above analysis, halogen-free, low-smoke materials perform worse than the current insulation-grade flame-retardant sheathing materials and are more prone to problems. For this reason, current high-voltage cable standards such as GB/T 11017 and GB/T 18890 have not incorporated halogen-free, low-smoke sheathing materials into their standard systems.

The "Classification of Burning Behavior for Electric and Optical Fiber Cables" GB 31247 strengthens fire behavior control. This is appropriate for densely populated areas like subways and high-speed rail stations, where there are many combustible materials, due to safety considerations for life and property. Most cables used in these areas are medium- or low-voltage, for which electrical performance requirements are not as stringent as for high-voltage cables.

It is particularly important to note that the Class B rating in "General Rules for Flame-Retardant or Fire-Resistant Electric Wires, Cables, or Optical Cables" GB/T 19666 is not equivalent to the B1 rating in "Classification of Burning Behavior for Electric and Optical Fiber Cables" GB 31247. The two standards have completely different fire performance criteria and intended application areas. They should not be used interchangeably. It is recommended to use high-voltage cables meeting GB/T 19666 Class B, and not recommended to use high-voltage cables meeting GB 31247 B1 or B2 ratings. Although both are labeled "B," they belong to different standard systems, resulting in completely different performance outcomes. Using high-voltage cables meeting GB 31247 B1 or B2 ratings would place enormous pressure on construction and operation & maintenance departments.

Given the stringent fire protection requirements in power tunnels, after upgrading the flame-retardant rating to Class B:

For conduits or direct burial installations where flame retardancy is not required, PE outer sheaths (without flame retardant additives, providing stable insulation resistance) can be selected.

For high-voltage cables installed in tunnels, PVC outer sheaths are recommended (the disadvantage is the release of toxic gases during combustion; the advantage is that formulation can enhance water resistance, and the insulation resistance is more stable compared to Class B flame-retardant PE cables).

Furthermore, it is recommended to promptly initiate joint research on sheath materials and structures to fundamentally resolve the conflict between insulation resistance and flame retardancy.