1. Introduction

In the ever - evolving industrial sector of Vietnam, maintaining a reliable and efficient power supply is of utmost importance. One crucial component in achieving this is the auto recloser, specifically the 630A variant. An auto recloser, or automatic circuit recloser, is a precision automatic switchgear device equipped with smart sensors and electronics. It plays a pivotal role in protecting power lines, grid systems, and electrical equipment in industrial settings.

2. Functioning of Auto Reclosers

2.1 Basic Working Principle

At its core, an auto recloser is designed to automatically isolate faults in the electrical system and restore power if the defect has been corrected. When a short - circuit occurs, the recloser opens (cuts - off) the circuit. After a pre - set period of time t1, it will close automatically. If the problem persists, the recloser will open the circuit again, and after a while t2, it will attempt to close once more. This process can repeat a programmed number of times. For example, it may repeat at least 3 times before completely disconnecting the circuit from the electrical system if the fault remains unresolved. The number of cuts and the switching times are programmable by the user, providing flexibility in adapting to different industrial power requirements.

2.2 Components and Their Roles

Overload Protection: This is a fundamental feature of the auto recloser. In industrial scenarios where there can be sudden surges in power demand, overload protection ensures that the electrical system and connected equipment are safeguarded from damage due to excessive current.

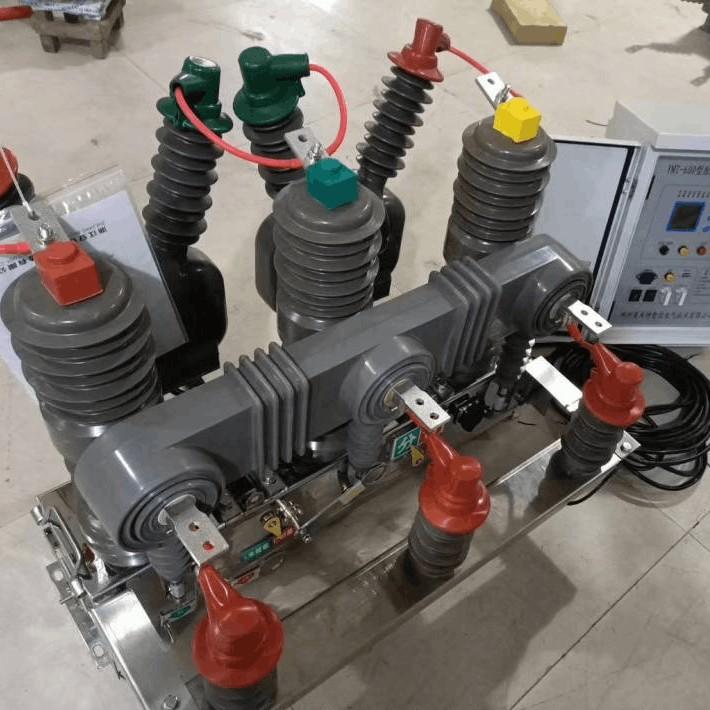

3 - Phase Recloser for Column Installation: The 630A auto reclosers often come in a 3 - phase configuration for column installation. They may use a vacuum chamber for arc stamping, which is highly efficient in extinguishing electrical arcs. Some models are insulated by SF6 gas or solid dielectric materials, providing reliable insulation in various environmental conditions. Additionally, there is often an available position on the outside of the recloser for lightning protection, which is essential in Vietnam's climate where lightning strikes are common.

Control Unit: The control unit of the auto recloser is a vital component. In Vietnam's tropical conditions, it is installed in an outdoor pole - mounted cabinet. It utilizes an electronic chip and has functions for measuring, protecting, and saving events. Moreover, it enables local and remote monitoring and control, and can be connected to the overall industrial power management system. This connectivity is crucial for industrial plants to manage their power distribution efficiently, especially in large - scale industrial complexes where real - time monitoring and control can prevent major disruptions.

3. Significance in Vietnam's Industrial Sector

3.1 Power Reliability for Industrial Operations

Vietnam's industrial sector has been growing steadily, with industries ranging from manufacturing to textiles and electronics. A reliable power supply is the lifeblood of these industries. The 630A auto reclosers help in maintaining power continuity. Since many short - circuit cases in the medium - voltage supply sources, which are commonly used in industrial areas, are transient in nature, the auto recloser can quickly restore power after a fault. This reduces downtime significantly. For example, in a garment manufacturing factory, any power interruption can lead to halted production lines, wasted raw materials, and delayed orders. The auto recloser's ability to rapidly restore power minimizes such losses.

3.2 Integration with Smart Grid Initiatives

As Vietnam moves towards a more intelligent and efficient power grid, auto reclosers are key components in this transition. They can be easily integrated into smart grid applications. With advanced capabilities such as loop automation and automatic changeover, they enhance the overall operation of the medium - voltage grid. In industrial parks, where multiple factories are connected to the grid, the auto recloser can recognize a fault area and restore power in a problem - free area using a fuse switch or load breaker. This not only improves the reliability of power supply to individual industries but also contributes to the overall stability and efficiency of the grid.

4. Technical Specifications and Features of 630A Auto Reclosers

4.1 Rated Current and Voltage Compatibility

The 630A auto reclosers are designed to handle a significant amount of current. This makes them suitable for various industrial applications where the power demand can be high. They can be used in power distribution systems with rated voltages ranging from 11kV up to 38kV, depending on the specific industrial requirements. For example, in a large - scale manufacturing plant that operates numerous high - power machines, the 630A auto recloser can effectively protect the electrical system from overloads and short - circuits while ensuring a stable power supply.

4.2 Durability and Performance

These auto reclosers are built to last. Many models are designed to withstand a high number of mechanical operations, often up to 30,000 times. This durability ensures a long and reliable service life, reducing the need for frequent replacements and maintenance. Additionally, they have a high breaking capacity, typically around 25kA in some models. This allows them to safely interrupt high - fault currents, protecting the electrical system and connected equipment from damage.

4.3 IP65 Rating: Protection Against the Environment

The IP65 rating of the auto reclosers is a significant advantage in Vietnam's diverse environmental conditions. The IP65 rating means that the device is dust - tight (the '6' in IP65) and protected against water jets (the '5' in IP65). In industrial areas, there can be a lot of dust, especially in manufacturing processes such as cement production or metalworking. The dust - tight feature ensures that the internal components of the auto recloser are not affected by dust, which could otherwise cause malfunctions. Moreover, Vietnam experiences heavy rainfall during the monsoon season, and the protection against water jets ensures that the auto recloser can continue to operate reliably even in wet conditions.

5. Certification and Compliance in Vietnam

5.1 TCVN 8526

In Vietnam, the TCVN (Technical Standards of Vietnam) 8526 standard is relevant in the context of energy - related regulations. Although originally developed for certain equipment like household washing machines in terms of energy efficiency, the principles of compliance and standardization it represents are also applicable to industrial electrical equipment. Auto reclosers need to meet certain quality and safety standards, and the TCVN framework helps in ensuring that the products available in the Vietnamese market are of a certain quality level. Manufacturers of 630A auto reclosers need to ensure that their products meet the requirements related to electrical safety, performance, and durability as per the overall regulatory environment inspired by standards like TCVN 8526.

5.2 EVN Certification

The Electricity of Vietnam (EVN) is the major power utility in the country. EVN certification is crucial for auto reclosers used in the Vietnamese power grid, especially in industrial applications. To obtain EVN certification, auto reclosers must pass a series of tests related to electrical performance, reliability, and compatibility with the existing power grid infrastructure. This certification ensures that the auto recloser can function seamlessly within the EVN - managed power grid, whether it is in an industrial park or a large - scale industrial plant connected to the main grid.

6. Market and Deployment of Auto Reclosers in Vietnam

6.1 Market Trends

The market for auto reclosers in Vietnam is on the rise. As industries expand and the demand for reliable power increases, there is a growing need for advanced electrical protection devices like auto reclosers. Local and international manufacturers are vying for a share in this market. There is also a trend towards more intelligent and connected auto reclosers, which can be integrated into the smart grid initiatives that Vietnam is promoting. These smart auto reclosers can provide real - time data about the line status, such as power (A, W, var), voltage (V), or frequency (f) values. This data is invaluable for industrial plants to optimize their power consumption and for grid operators to manage the power distribution more efficiently.

6.2 Deployment in Industrial Areas

Auto reclosers are being deployed in various industrial areas across Vietnam. In industrial parks such as the Song Than Industrial Park in Binh Duong province, which is home to numerous manufacturing companies, auto reclosers are installed at key points in the power distribution network. They are placed at the station as the main protection device of the system, on the main lines but far from the station to segment long lines, and on the trunk lines to protect the mainline from damage caused by branch failures. This strategic deployment ensures that power outages are minimized, and industrial operations can continue smoothly.

7. Conclusion

The 630A auto reclosers with their advanced features, IP65 protection, and compliance with certifications like TCVN 8526 and EVN are playing a crucial role in Vietnam's industrial power infrastructure. They are essential for maintaining power reliability, integrating with smart grid initiatives, and protecting industrial electrical systems. As Vietnam's industrial sector continues to grow and modernize, the importance of auto reclosers in ensuring a stable and efficient power supply will only increase. Manufacturers and power utilities need to continue to invest in research and development to further improve the performance and capabilities of these devices, meeting the evolving needs of Vietnam's industrial landscape.