Abstract: Based on the analysis of the main types and characteristics of high and low voltage distribution cabinets in distribution rooms, this paper discusses the basic principles for selecting these cabinets. From the perspectives of technical reliability, installation convenience, and economy, the optimization measures for selecting high and low voltage distribution cabinets are analyzed, which plays a certain role in improving their technical and economic performance.

Keywords: Distribution Room; High and Low Voltage Distribution Cabinets; Optimization; Configuration

0 Introduction

With the continuous rise in economic development levels, electrical energy has become one of the essential energy sources for current production and daily life. To ensure normal production and daily activities, every aspect of the power supply must be reasonably controlled to enhance the stability and reliability of the grid power supply. The distribution cabinets in the distribution room represent the final link delivering electrical energy to end-users. Ensuring the stability and economy of these high and low voltage distribution cabinets, and achieving their optimal selection, are crucial measures for guaranteeing the safety and stability of the power grid.

1 Main Types and Characteristics of High and Low Voltage Distribution Cabinets in Distribution Rooms

Before optimizing the selection of distribution cabinets, it is necessary to understand their main types to provide a concrete basis for selection.

1.1 High Voltage Distribution Cabinets

High voltage distribution cabinets do not exist as individual units within the power system. They primarily consist of several interconnected components including control equipment, high voltage switches, monitoring equipment, signal transmission devices, and protection equipment, forming a multi-functional complex system.

Since the 1980s, technical reforms have been undertaken for high voltage distribution cabinets in China. With the accumulation of R&D technology and application experience, numerous new technologies have been applied in their development, leading to several technologically advanced products such as the KYN28 cabinet and the XGN15-12 cabinet.

(1) Operating Characteristics of the KYN28 Cabinet

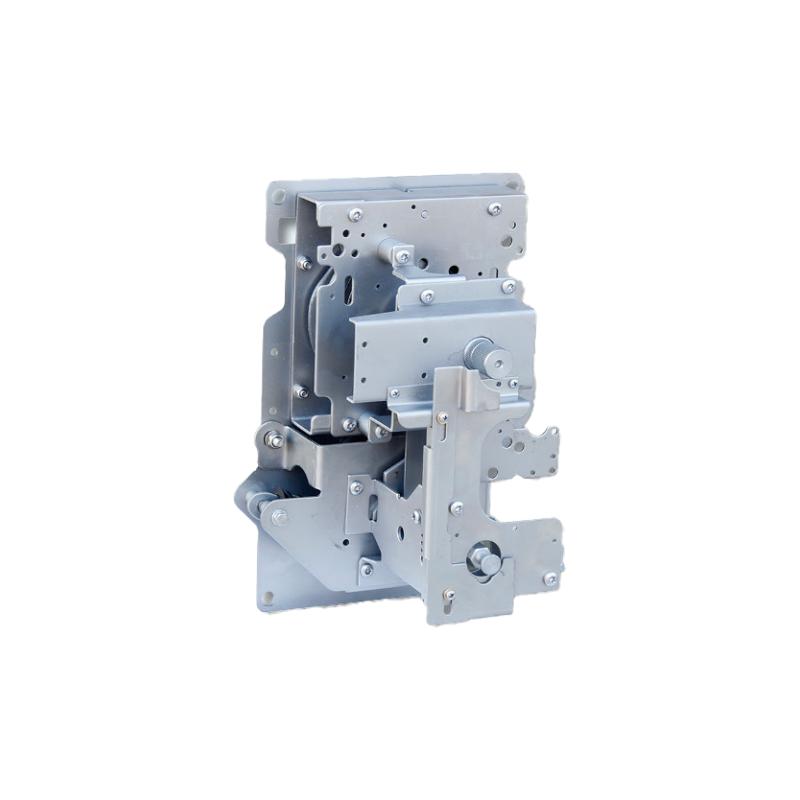

This type of high voltage cabinet structurally consists of two main parts: the handcart (withdrawable part) and the cabinet body. The cabinet body is primarily assembled from stamped metal partitions, divided into four independent compartments: the cable compartment, handcart compartment, busbar compartment, and instrument compartment. The handcarts are categorized into types such as circuit breaker handcarts, metering handcarts, and PT handcarts. The primary electrical components include vacuum circuit breakers, high-voltage fuses, copper busbars, insulating components, and high-voltage reactors. The secondary electrical components mainly include air circuit breakers, buttons, meters, comprehensive protection devices, and signal lights. Utilizing a middle-mounted withdrawable handcart allows it to be racked in and out, creating a safe disconnection point between the primary system and other systems of the high voltage cabinet.

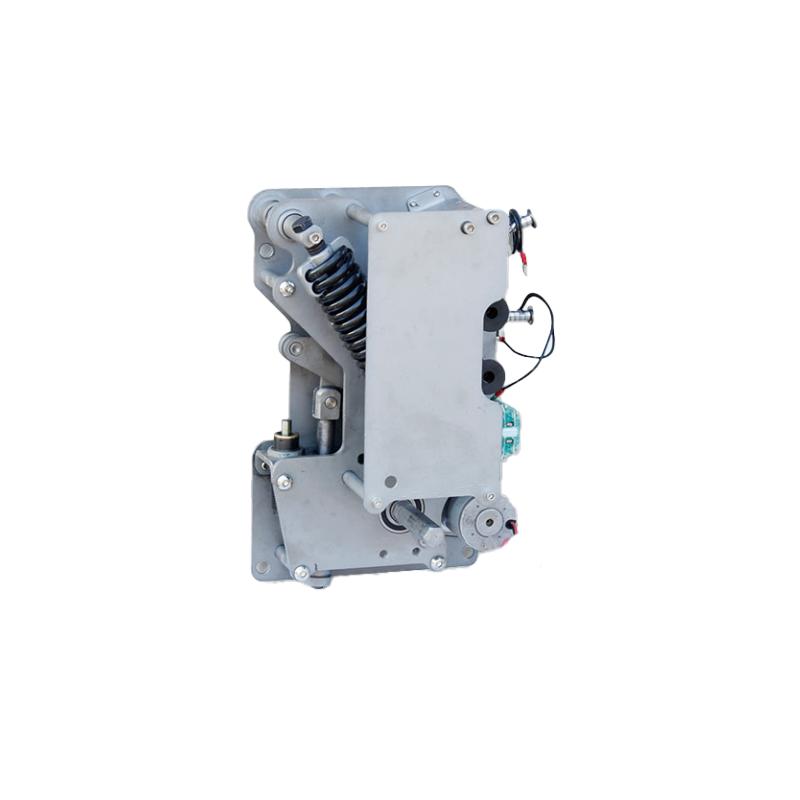

(2) Operating Characteristics of the XGN15-12 Cabinet

The XGN15-12 is a new type of high-voltage complete switchgear product developed based on national standards for 35kV AC metal-enclosed switchgear. It features not only a small size (only 60% of the volume of ordinary switchgear) but also high circuit breaker reliability, excellent performance, and a forced interlocking function. It can be used in applications with rated voltages from 3.5kV to 12kV and rated currents from 630A to 3150A, achieving a protection class of IP2X. Users can choose between spring-operated or electromagnetic operating mechanisms.

1.2 Low Voltage Distribution Cabinets

In the product series of low voltage distribution cabinets, there are mainly two categories: products developed based on relevant international technology that have passed international quality certification, and foreign products. Among them, series products developed based on international technology mainly include GCK low-voltage switchgear, GCS low-voltage switchgear, and GGD low-voltage AC switchboards. Foreign products are primarily represented by the MNS series distribution cabinets produced by ABB Switzerland.

(1) Operating Characteristics of the GCS Cabinet

The GCS cabinet is one of the most common product series of drawer-type switchgear. It uses 8MF open-section steel as the main frame of the cabinet body, with side plates featuring threaded holes with a modulus of 20mm/100mm and an internal diameter of 9.2mm [3]. Various functional compartments are independent and separated, mainly including the drawer unit compartment, cable compartment, and busbar compartment. The cable compartment is arranged with independent separation, allowing cables to enter and exit conveniently from the top or bottom. Each GCS feeder cabinet can accommodate 11 full-unit drawers or 22 half-unit drawers, enhancing the flexibility of drawer combinations. Furthermore, a mechanical interlock device is installed within the drawer unit to facilitate the disconnection and closing of the output drawer.

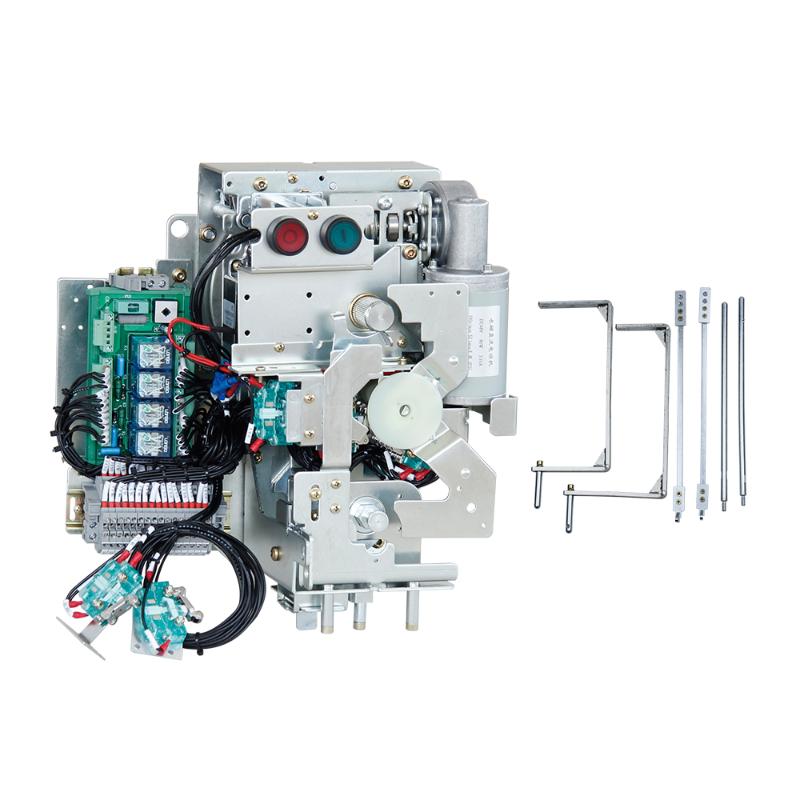

(2) Operating Characteristics of the MNS Cabinet

This type of switchgear is also a form of low-voltage withdrawable成套 switchgear. It employs a shell made from bent steel plates, dividing the internal space into three basic compartments: the busbar compartment, cable compartment, and unit compartment (for drawers). Since the busbar compartment is located at the rear, it can also be configured as a double-sided cabinet. The busbar style used is similar to the GCS type. The unit drawer height is 200mm, and it is equipped with a mechanical interlocking device.

2 Basic Principles for Selecting High and Low Voltage Distribution Cabinets

In the selection process for distribution cabinets, the primary requirement is to ensure that the chosen high and low voltage cabinets meet the project's usage needs and guarantee the reliability and stability of equipment operation. Simultaneously, other related performance aspects of the product, such as operational simplicity, must be analyzed to select equipment that is relatively easy to operate, thereby improving operational accuracy. Additionally, it is essential to analyze the project's cost requirements, determine the accurate project budget, reasonably control construction costs during implementation, fully utilize raw materials and resources, and achieve effective cost control.

2.1 Reliability Principle

When selecting the type of high voltage distribution cabinet, based on the actual operation of the distribution room, the fundamental goal is to ensure product safety and reliability. Comprehensive consideration should be given to the actual operating conditions of the high voltage cabinet to select products with higher reliability.

2.2 Simplicity Principle

Currently, most high voltage distribution cabinets use traditional protection devices. Due to the high complexity of such equipment, the probability of failure is also relatively high, which poses significant challenges for subsequent operation and maintenance. Therefore, during the selection process, based on the determined project investment situation and specific configuration requirements of the equipment, and adhering to the basic requirements for power supply reliability, products should be chosen ensuring that the withdrawable components in the handcart cabinet can be directly installed on the trolley and satisfy the principles of convenient maintenance and easy replacement.

3 Optimal Selection of High and Low Voltage Distribution Cabinets in Distribution Rooms

3.1 Optimal Selection of High Voltage Distribution Cabinets

(1) Ensuring Operational Reliability of High Voltage Cabinets

When selecting high voltage distribution cabinets, investigations must be conducted into the specific conditions of the power supply equipment and the construction project investment. The requirements for power supply reliability should be analyzed before making a comprehensive selection. To ensure power supply reliability, the withdrawable assembly components in the handcart must be completely removable onto the trolley and allow for simple operation and replacement, facilitating convenient and quick maintenance of the high voltage cabinet. However, when using handcart cabinets, the requirements for civil construction quality, especially the floor levelness, are higher. To facilitate the trolley moving in and out of the switchgear, the top surface of the rails inside the cabinet should be level with the floor outside the cabinet. Laying rubber pads can be used during adjustment to reduce cabinet vibration frequency and enhance the operational stability of the switchgear.

(2) Practicality of Equipment Operation

In the Chinese high voltage distribution cabinet market, imported cabinets account for about 50% of the market share, comparable to domestic products. Judging from operational stability and other related conditions, these two types of cabinets have their respective advantages and disadvantages. In practical application, selection must be made reasonably according to the actual situation.

Although domestic high voltage cabinets have advantages such as moderate price, high reliability, and comprehensive after-sales service, their volume is mostly large, requiring substantial installation space. When the installation space in the distribution room is limited, imported high voltage cabinets must be selected. Relatively speaking, imported high voltage cabinets not only have reasonable component layout, small size, and high reliability but also have a relatively wide range of applications. However, their price is significantly higher than domestic equipment, and after-sales support may not be as responsive. During the optimization selection process, a comprehensive trade-off based on these strengths and weaknesses is necessary.

(3) Simple Operation and Maintenance

Low maintenance requirements and simplified maintenance are important future development directions for distribution cabinets. Currently, most high voltage distribution cabinets in China use traditional electrical control and protection relay technology. This technology not only increases the probability of failure but also adds to the complexity of the equipment, leading to increased maintenance工作量 during subsequent use. Based on this, distribution cabinets equipped with advanced intelligent protection devices should be selected to reduce maintenance workload and save labor costs. From an economic perspective, intelligent high voltage distribution cabinets are a good choice during the selection process.

3.2 Optimal Selection of Low Voltage Distribution Cabinets

(1) Reasonably Determining Technical Parameters of Low Voltage Cabinets

Before selecting the model of the low voltage distribution cabinet, its technical parameters must be determined, and the selection should be made according to these predetermined parameters. On this basis, the rated voltage, rated current, rated frequency, installation space, and other parameters of the low voltage cabinet must be clarified. Parameters such as the withstand current the cabinet must endure during power supply peaks and the peak current of the main busbar should be analyzed. Additionally, the functional unit type, maximum rated current, and enclosure protection rating (IP code) of the distribution cabinet need to be confirmed.

(2) Optimizing Functional Requirements for Components in Low Voltage Cabinets

During the optimal selection process for low voltage distribution cabinets, an analysis of the component requirements should be conducted, mainly including installation method, functional modules of the cabinet, installation simplicity, operating ambient temperature, and cabinet dimensions. Simultaneously, attention must be paid to the selection of circuit breakers, ensuring the main breaker has functions such as memory, ground fault protection, alarm, fault indication, and three-stage protection (LSI). It should also support different levels of interlocking operations like zone-selective interlocking, striving to achieve modularization of various functional accessories.

3.3 Optimal Selection of Protection Components in Distribution Cabinets

A suitable distribution cabinet must be able to adapt to different usage environments and possess corresponding functional protection capabilities. Typically, high and low voltage distribution cabinets use fuses or circuit breakers as protection components. When the current exceeds a set value, the fuse link melts due to heating, or the circuit breaker trips, thereby disconnecting the circuit and protecting the distribution system. Protection components can be optimally selected from different perspectives.

(1) Cost Perspective

From the perspective of component cost, the market price of fuses is low, while the market price of Molded Case Circuit Breakers (MCCBs) or Miniature Circuit Breakers (MCBs) can be several times to tens of times higher than that of fuses. If the overall project budget is low, fuses can be chosen as the protection component.

(2) Maintenance Convenience Perspective

When a short-circuit fault occurs and causes a trip, the contacts of an MCB/MCCB may suffer damage. Over time, this can lead to failure of the breaker to operate correctly. Therefore, after a short-circuit fault trip occurs in a fuse, the fuse link must be replaced promptly to ensure the protection function is restored. After a short-circuit trip of an MCB/MCCB, inspection is recommended, and replacement might be necessary if damaged.

(3) Circuit Protection Requirements Perspective

Because fuses have relatively low sensitivity to line overloads, they are usually used only for short-circuit protection, except in common lighting circuits. In contrast, MCBs/MCCBs have high sensitivity to overload and overcurrent. When protecting circuits such as heating loops, socket outlets, and control circuits, MCBs/MCCBs must be used as the protection components.

4 Conclusion

With the increasing demand for electrical energy in residential production and daily life, the economy and stability of the power supply have become important goals for the optimization of distribution systems. The distribution cabinets in the distribution room represent the final link delivering power to end-users, and they are used in large quantities. To ensure that the electricity demands of production and daily life are met while achieving economic benefits in the construction of distribution room cabinets, the selection scheme for distribution cabinets must be optimized from both technical and economic perspectives, ensuring that both technical reliability and economy are satisfied simultaneously.