Dawerî, prosesên dibandkirina û sprâykirina di fabrikaya xwe de piştî hate çêkirin, ku îzolatekerên RTV bi tamamîn wekî pirûzek ênîn hatine serderandin, ku ji bo kontrol û qebûlkirina serperest bû, ku kaliteya pirûzekê bi sereke hate veguhtî û serperestkirina weha bi sereke hate girtî. Lê, serperestkirina RTV bi nerxîna mekanîkî ya bihêvi û tarazkirina interfacî yên zêde û serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkir......Keramik û şîşê çendkaran derbarê nîşan dên dest pê karkeriya îzolatekirina û nerxîna mekanîkî, lê bêtirîn di veketina zorî de girîng e ku bi serkeftinîya şebîka elektrîkê tehdit bibin. Ji bo serperest kirina girîngkirina tewrî, fesîlkarên serperestkirina RTV (silikon rubberî vulkanizî ya temperatûra yekemîn) bi xasîyên hîrofîbî û hîrofîbî transîre yên werazerdar di ser rêvanên îzolateker da bike, wê ji bo kerterîn rezaçê hatine rast. Sipasî, serperestkirina RTV di Çîn de li ser dema xwe hate bikar anîn, metoda ku ji bo serperestkirina karîgiriya bilind û kontrola kaliteyê nîşan dên nehatiye.

Dawerî, prosesên dibandkirina û sprâykirina di fabrikaya xwe de piştî hate çêkirin, ku îzolatekerên RTV bi tamamîn wekî pirûzek ênîn hatine serderandin, ku ji bo kontrol û qebûlkirina serperest bû, ku kaliteya pirûzekê bi sereke hate veguhtî û serperestkirina weha bi sereke hate girtî. Lê, serperestkirina RTV bi nerxîna mekanîkî ya bihêvi û tarazkirina interfacî yên zêde û serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkirina serperestkir......

Îzolatekerên diskî kompozît keramik bi îzolatekeri tamamî keramik wekî nîvînê, bi HTV (silikon rubberî vulkanizî ya temperatûra bilind) bi derengî minîmum 3 mm, di serperestkirina yekdemîn de bi injeksiyonîya temperatûra bilind hate çêkirin. HTV ji bo RTV nerxîna mekanîkîya zêde û performansa werazerdar di ser track û erozîyê, retardancya şîşê, xasîyên elektrîk, resistanceya qadimî û dayînîyê hatine rast.

Ji bo guherandina glaze layer di ser rêvanên keramik û bikaranîna coupling agents yên xasî, tarazkirina interfacî yên nîvendî di keramik û silikon rubber HTV de hate veguhtî, ku ji bo integritî û uniformityya parçeyê dest pê kir. Belki, îzolatekerên diskî kompozît keramik bi performansa mekanîkî û anti-pollution flashover zêde û dem û karkeriya operasyonan û baxtir bike, rota nû ji bo serperestkirina dera xwe hate vegerîn.

Taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybetmendîya taybet............

1 Setupî serperestkirina impulsekî hawî

1.1 Nîşan

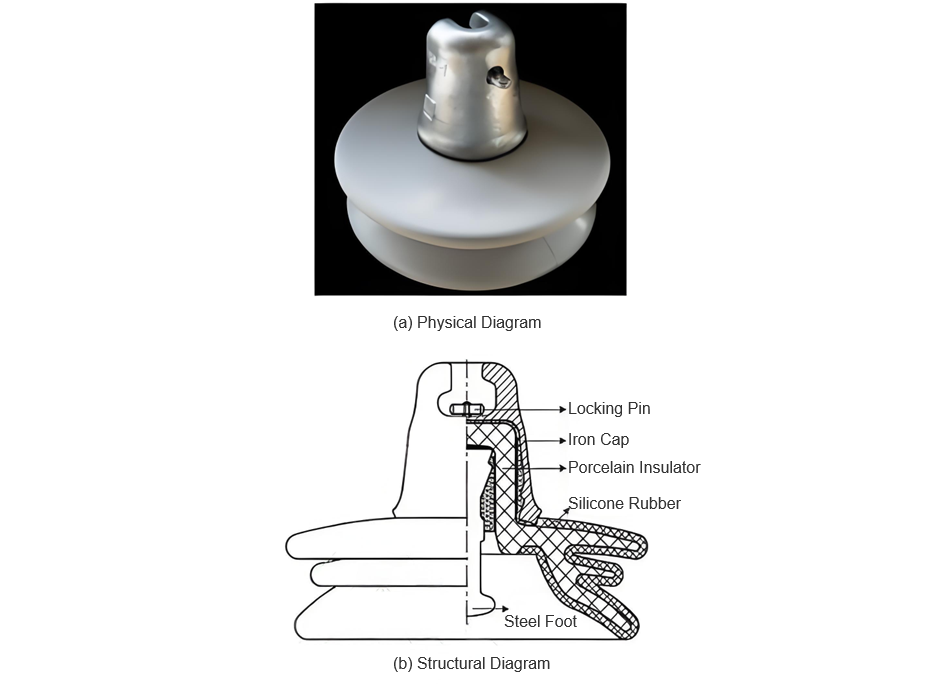

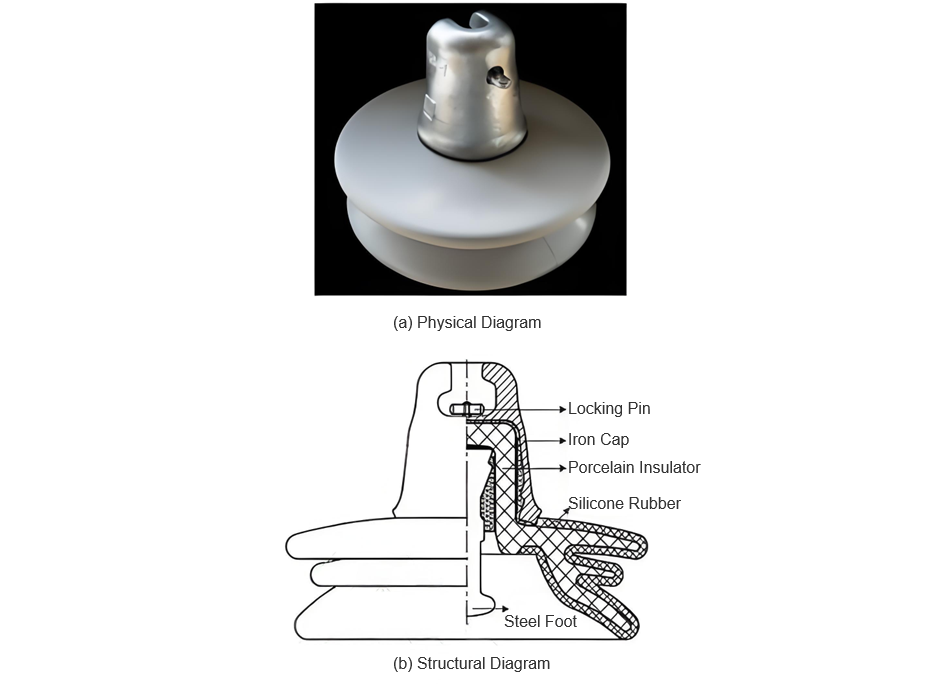

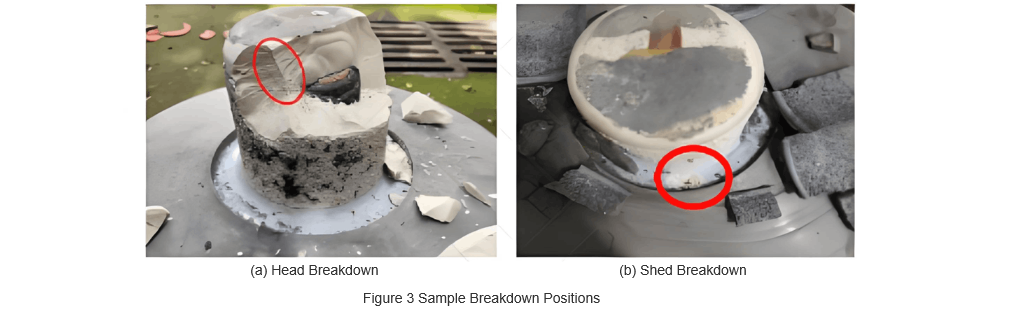

Îzolateker diskî kompozît keramik HU550B240/650T AC ji bo fesîlkar bi sereke hate hilbijartin da ku wekî nîşana testê hatine serderandin. Îzolateker ênîn di structure û şêweka triple-umbrella de hate çêkirin, wê ji bo Figure 1 hate nîşan dand. Parametreyên performansa serekan ênîn di Table 1 de hate taybet kirin.

1.2 Platform û Şema Testê

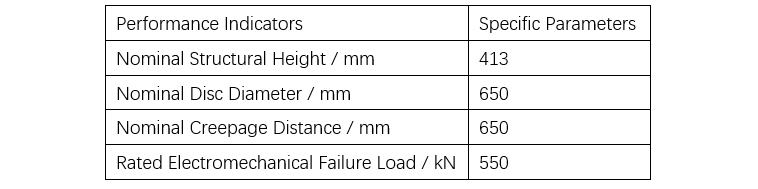

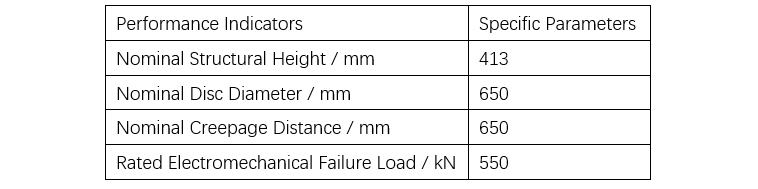

Ji bo testê generator împulsekî voltage 2400 kV hatine bikar anîn. Kepî îzolateker di plate metalî yên serdastî de hate nîşan dand, û socket ball standard di pin end de hate serderandin da ku girîngkirina zorî elektrîkî di serdastî de veguhtî. Setup îzolateker di Figure 2 de hate nîşan dand.

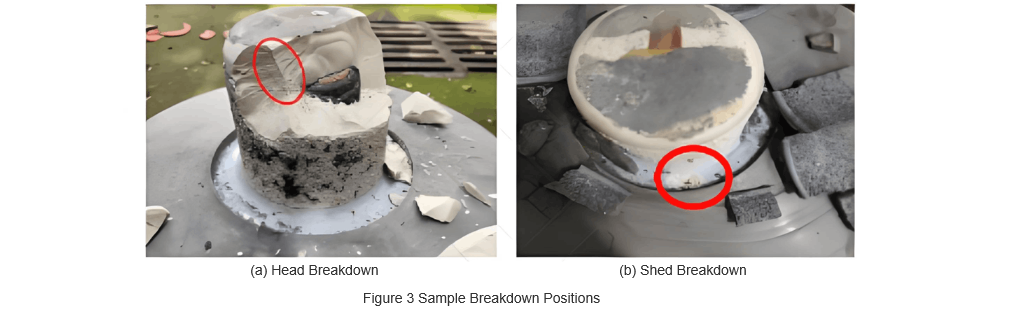

Testan serperestkirina impulsekî hawî di ser 20 nîşana îzolateker de hate serkirin. Metoda testan serperestkirina impulsekî hawî di ser steepness method û amplitude method de hate bûyerhatin, metoda amplitude bi sereke ji bo îzolatekerên diskî hatine bikar anîn.

Ew metoda amplitude nehatiye bikar anîn, ku linearity ya front împulsekî nehatiye dixwazin, lê tenha amplitude ya breakdown voltage bi sereke hate bike, ji bo front time di dema 100 û 200 ns de kontrol kirin û amplitude deviation di dema ±10% de. Ji bo test, her îzolateker derbasî pênc impulse positive-polarity û pênc impulse negative-polarity hatine serkirin, û ev cih û ber vêgerî hatine serkirin. Di navbera impulseyan de dema 1 û 2 minût de kontrol kirin.

Karên wan û navendî yên din dikarin biguhezin ku coating îzolatekeran bi silikon rubber ratey propagation streamers di rêvanên keramik de guhertirin, ku ji bo performansa serperestkirina steep-front impulse reduce bibe. Lê, performansa insulation di head îzolateker de di operasyonê de nehatiye veguhetin.

Ev fenomen ji bo zimanên wan û navendî yên din hatine rastî kirin: jî berî profile shed deep-rib û alternating-umbrella type, jî berî structure head cylindrical û conical, hemî îzolatekeran bi degreeyekî reduce performansa breakdown steep-wave di serperestkirina RTV de hate guhertin.

Bi vê yekê, standardsên yekemîn hatine guhertin, ku amplitudeya test serperestkirina impulsekî hawî di ser 2.8 p.u. ji bo îzolatekeran diskî coated RTV ji 2.8 p.u. ji 2.2 p.u. hate reduce kirin. Rezultatên testan serekan dikarin biguhezin ku breakdown rarely di 2.2 p.u. de dibînin. Ji bo vê yekê, ew îzolatekeran keramik bêtirîn RTV coating hatine hilbijartin û testan serperestkirina impulsekî hawî di voltage standard test 2.8 p.u. de hate serkirin, ji bo front time voltage di dema 100–200 ns de kontrol kirin.

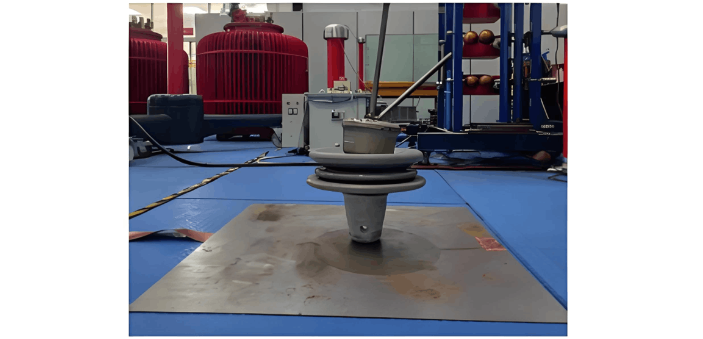

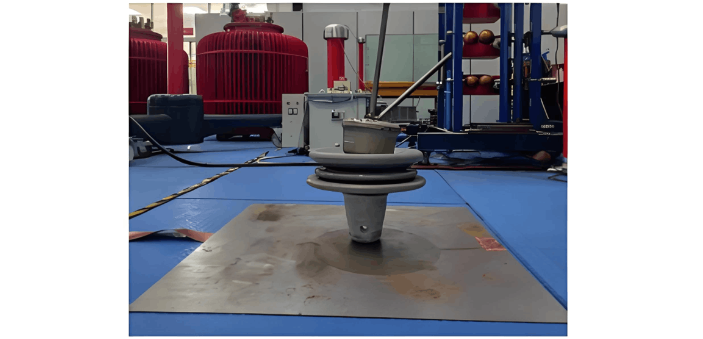

Analizî statistîkî tevahî yên voltage polarity û location breakdown dikarin biguhezin ku ji 15 breakdown event, 14 ji bo positive polarity û tenha yek ji bo negative polarity dibînin. Ji bo breakdown positive-polarity, 8 ji bo head û 6 ji bo sheds dibînin; breakdown yekane negative-polarity ji bo head dibîne. Ji sêmî, arcing ji bo surface îzolateker di navbera breakdown sheds de hatine girtî, lê ji sêmî arcing ji bo breakdown head nehatiye girtî.

Lê, di reference de, hemî breakdown steep-front îzolatekeran keramik ji bo head dibînin, û di reference de, îzolatekeran keramik ji bo head dibînin ji roja RTV coating. Ji bo vê yekê, test ênîn dikare biguheze ku bêtirîn injection-molded HTV overcoat, breakdowns steep-wave di batch îzolatekeran keramik de ji bo head dibînin. Ji bo HTV overmolding, breakdowns di composite îzolatekeran keramik de ji bo head û neck dibînin, ku ji bo coating HTV silicone rubber path breakdown guhertirin.

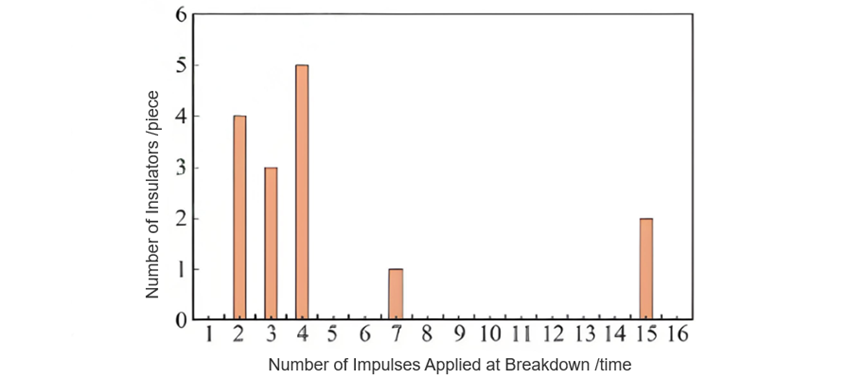

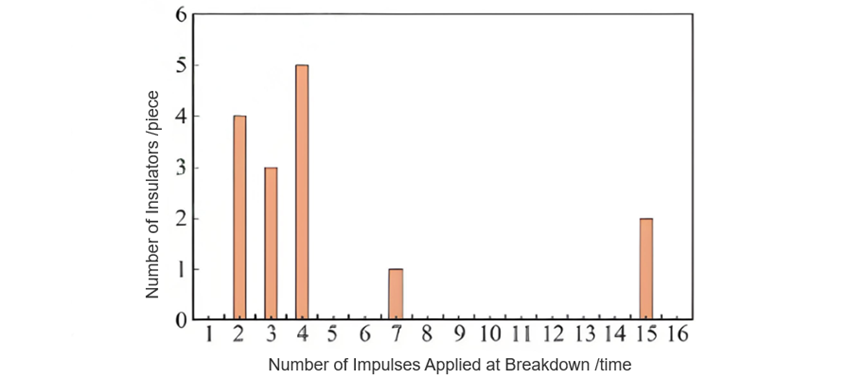

Number of impulses before breakdown recorded, with results shown in Figure 4. As illustrated, 12 insulators broke down within the first five impulses, one broke down on the 7th impulse, and two broke down on the 15th impulse. Reference indicates that porcelain insulators coated with RTV exhibit a significant reduction in steep-wave withstand performance, with higher breakdown probability for larger-tonnage insulators, suggesting that silicone rubber coating degrades steep-wave resistance. In this test, 80% of the HTV overmolded composite insulators broke down within the first four impulses, further demonstrating that the presence of HTV silicone rubber significantly reduces the insulator's ability to withstand steep-front impulses.

3 Electric Field Distribution Simulation at Steep-Wave Voltage Peak

Analysis of the test results in Section 2 reveals that, compared to porcelain insulators, the breakdown path of composite insulators has changed and their steep-wave withstand performance has significantly decreased. This section employs simulation to calculate the electric field distribution of the composite insulator at the peak of the impulse voltage, aiming to investigate the causes of the altered breakdown path and reduced steep-wave performance.

2.1 Simulation Model

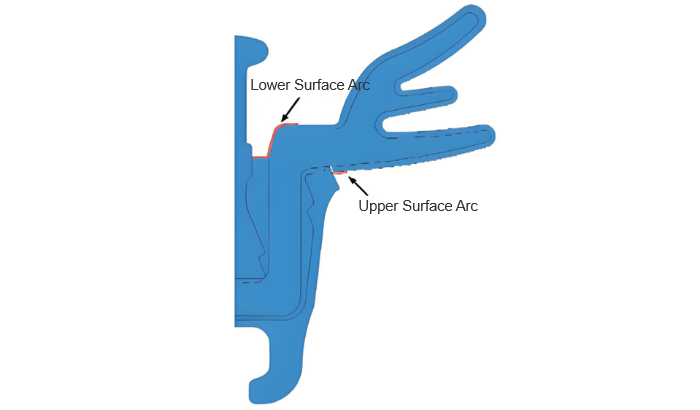

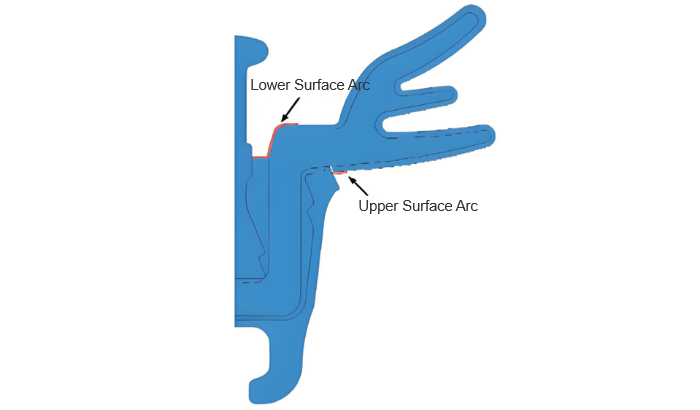

Observations from the air impulse breakdown tests indicate that when shed flashover occurs in composite insulators, arcs develop along the insulator surface to the breakdown location. The presence of arcs influences the electric field distribution and must be considered in the model. However, due to the irregular shape of arcs, establishing a 3D model for computation would be challenging, especially because the silicone rubber layer is thin and much smaller in dimension compared to the overall insulator, making 3D meshing difficult. Therefore, to qualitatively analyze the impact of the silicone rubber layer and arcs on the electric field distribution, a two-dimensional axisymmetric model is adopted for simplification in this section. The simulation model is shown in Figure 5.

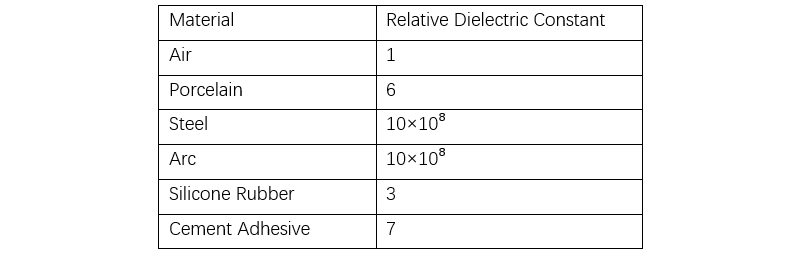

2.2 Materials and Boundary Conditions

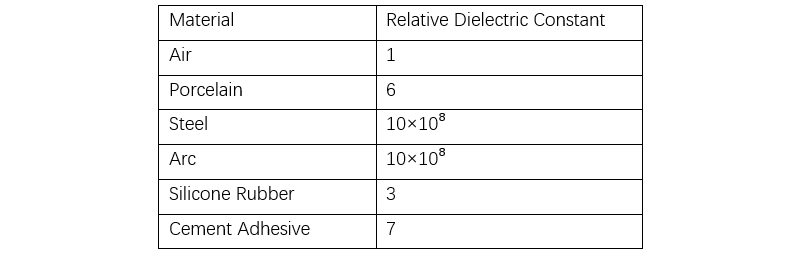

The 50% lightning impulse flashover voltage of the insulator is 145 kV, and the peak value of the 2.8 p.u. steep-front impulse voltage is 406 kV. Since most of the test specimens experienced positive-polarity breakdown, in the simulation, the pin (steel pin) is set as the high potential (406 kV) and the cap (steel cap) as zero potential. The relative permittivity values of the materials are listed in Table 2.

2.3 Simulation Results and Analysis

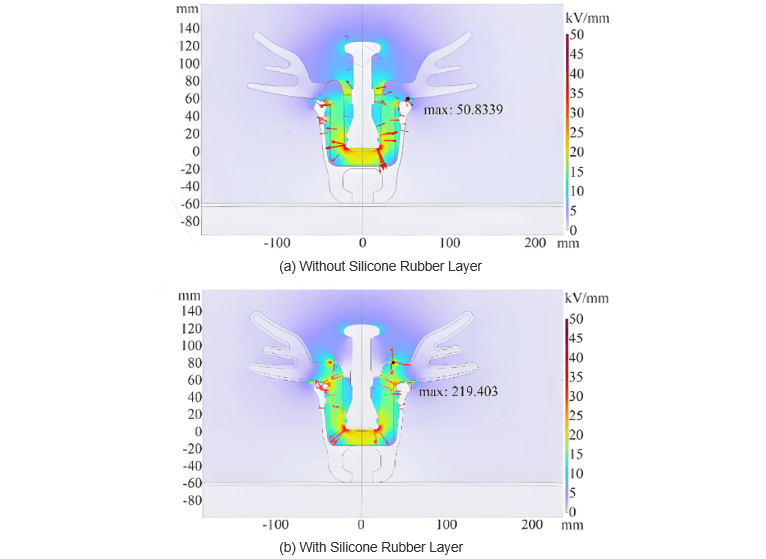

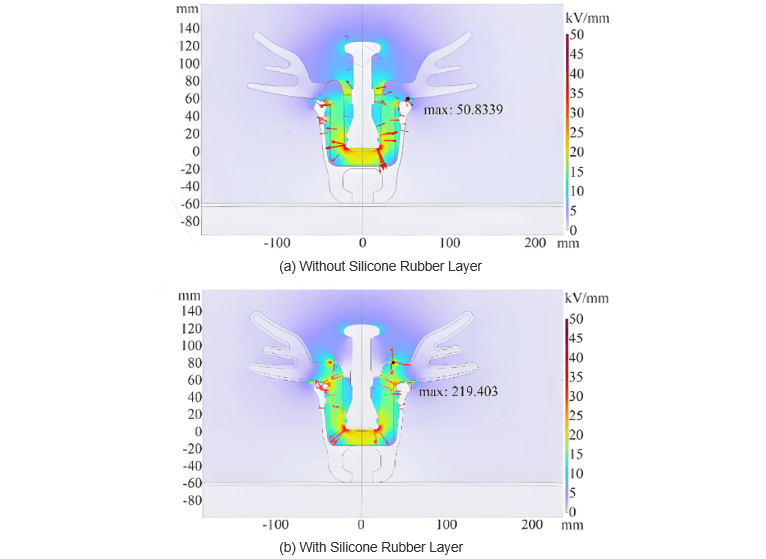

In the model without a silicone rubber coating, the electric field distribution of the porcelain insulator at the peak of the steep-front impulse voltage is shown in Figure 6(a). As seen in Figure 6, the electric field intensity is mainly concentrated at the insulator's head, reaching up to 50 kV/mm, indicating a high likelihood of head flashover—consistent with field experience and related studies.

To comparatively analyze the effect of the silicone rubber coating, the electric field distribution of the composite insulator model with one-time injection-molded silicone rubber was calculated, with results shown in Figure 6(b). It can be observed from Figure 6(b) that the maximum electric field occurs at the end of the arc on the lower surface of the insulating body, approximately 219.4 kV/mm; the field strength at the arc end on the upper surface is lower, at 41.21 kV/mm; and significant field concentration also exists at the pin head, with a maximum of 50.68 kV/mm.

Thus, under the influence of the silicone rubber coating, the surface resistivity of the insulator increases, significantly raising the ratio of volume capacitive current to surface resistive current in the sheds. This leads to a substantial increase in the electric field component perpendicular to the insulator surface, causing the arc to closely follow the surface after initiation.

Under the influence of the HTV coating, surface arcs propagate along the insulator surface when subjected to steep-front voltage, resulting in a sharp rise in local field strength—far exceeding that at the pin head—making breakdown more likely at the arc tip and leading to shed flashover. This indicates that the steep-wave withstand performance is affected by the HTV coating on the shed surface. Additionally, the simulation shows a relatively high electric field at the insulator head, which correlates with the observed head flashovers in tests.

3 Conclusion

Air impulse breakdown tests were conducted on composite insulators to analyze their steep-wave breakdown characteristics, and electric field distribution simulations were performed at the peak of the steep-front voltage. The following conclusions were drawn:

Under 2.8 p.u. steep-front impulse voltage, 15 out of 20 composite insulator specimens experienced breakdown, with 80% occurring within the first four impulses, indicating that the presence of HTV silicone rubber significantly reduces the steep-wave withstand performance of composite insulators.

Among the 15 breakdown events, in addition to flashovers at the pin head, six occurred at the sheds, indicating a clear change in the overall breakdown path compared to conventional porcelain insulators.

Simulation results show that the surface arc propagation in composite insulators causes a significant increase in shed electric field intensity at the voltage peak, reaching 217.64 kV/mm, making shed flashover more likely. In contrast, for insulators without a silicone rubber layer, the maximum field during arc development is located at the pin head, reaching 49.55 kV/mm, where breakdown primarily occurs.