Porcelain and glass insulators exhibit excellent insulation performance and mechanical strength, but are prone to pollution flashover under severe contamination, threatening the stable operation of power grids. To enhance the pollution flashover resistance of external insulation, manufacturers commonly apply room-temperature vulcanized silicone rubber (RTV) coatings with superior hydrophobicity and hydrophobicity transfer properties onto insulator surfaces, thereby reducing flashover risks. Initially, RTV coatings in China were applied on-site, a method characterized by high construction difficulty and inconsistent quality control.

Subsequently, factory-based dipping or spraying processes were developed, enabling RTV-coated insulators to be delivered as complete products subject to supervision and acceptance, significantly improving product quality and promoting widespread adoption in power grids. However, RTV coatings suffer from low mechanical strength and weak interfacial adhesion to the insulating body, making them susceptible to damage from external forces during transportation, construction, installation, and long-term operation. Operational aging phenomena such as peeling, cracking, and delamination are common, necessitating disassembly and recoating, resulting in high maintenance costs.

Disc suspension composite porcelain insulators utilize a complete porcelain insulator as the core, with a high-temperature vulcanized silicone rubber (HTV) sheath—minimum thickness of 3 mm—formed in a single molding process via high-temperature injection. Compared to RTV, HTV demonstrates superior mechanical strength, as well as enhanced performance in tracking and erosion resistance, flame retardancy, electrical properties, aging resistance, and high-temperature endurance.

Furthermore, by modifying the glaze layer on the porcelain surface and employing specialized coupling agents, the interfacial bonding strength between the porcelain and HTV silicone rubber is significantly improved, promoting integration and uniformity of the component. Consequently, disc suspension composite porcelain insulators offer superior mechanical and anti-pollution flashover performance with low operational and maintenance requirements, opening a new path for external insulation applications in transmission lines.

Field experience indicates that when overhead lines are struck by lightning, the resulting overvoltage contains steep-fronted impulses with extremely short duration, high steepness, and very high peak voltages, posing significant threats to line insulators. Such steep impulses can cause puncture or even explosion of disc insulators, and in severe cases, lead to string breakage and line drop. Steep-front impulse withstand capability is a critical indicator of insulator quality.

Although extensive research has been conducted on the steep-wave performance of porcelain and glass insulators both domestically and internationally, studies on disc suspension composite porcelain insulators remain scarce, and their underlying mechanisms are not well understood. Therefore, this paper conducts impulse breakdown tests in air on disc suspension composite porcelain insulators to investigate their steep-wave breakdown characteristics.

Air impulse breakdown tests effectively evaluate the steep-wave withstand performance of electrical equipment, ensuring safety and reliability under extreme conditions, and hold significant value in insulator quality assessment. This study first performs impulse breakdown tests to analyze the steep-wave performance, then establishes an electric field distribution simulation at the peak of the steep-wave voltage based on test results to explore the mechanism of performance variation, aiming to provide guidance for insulation coordination of composite porcelain insulators in transmission lines.

1 Air Impulse Breakdown Test Setup

1.1 Specimen

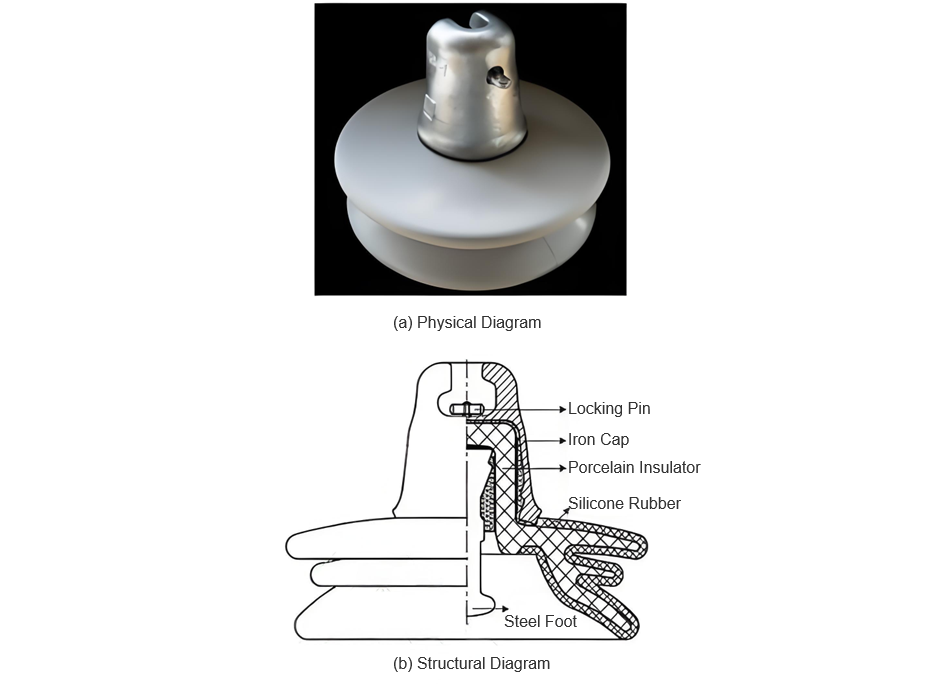

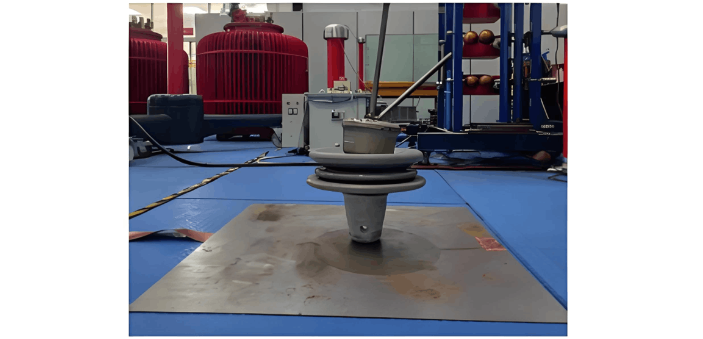

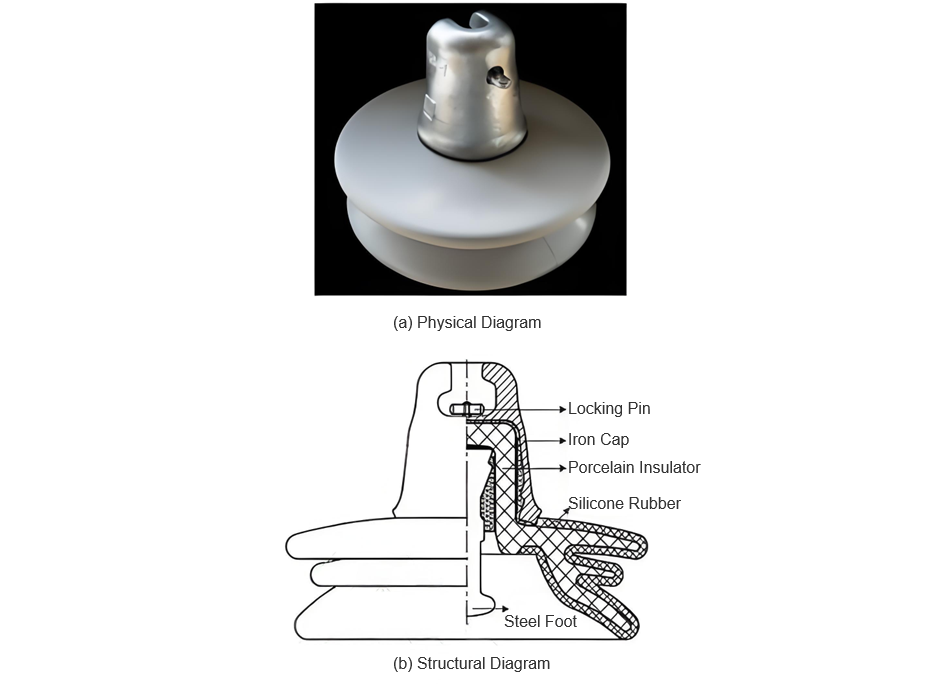

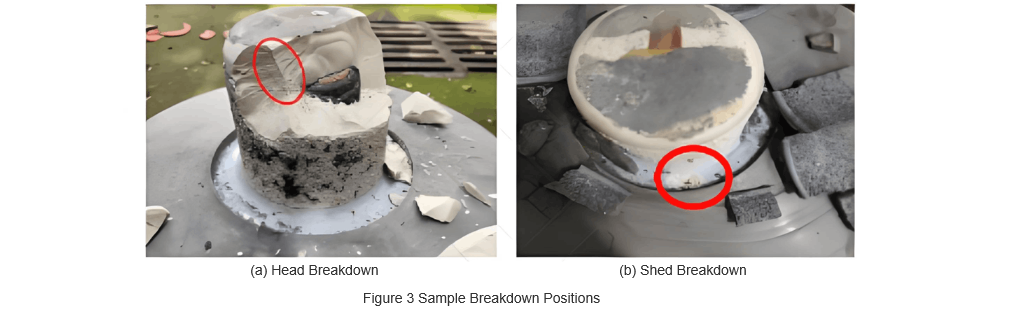

The HU550B240/650T AC disc suspension composite porcelain insulator produced by a manufacturer was selected as the test specimen. The insulator has a triple-umbrella structure, as shown in Figure 1. Its main performance parameters are listed in Table 1.

1.2 Test Platform and Scheme

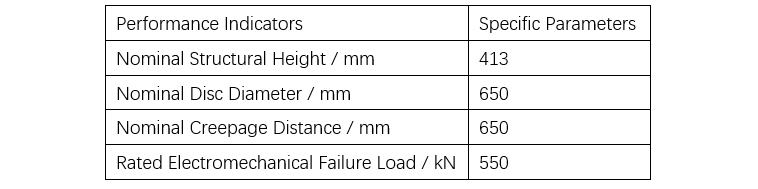

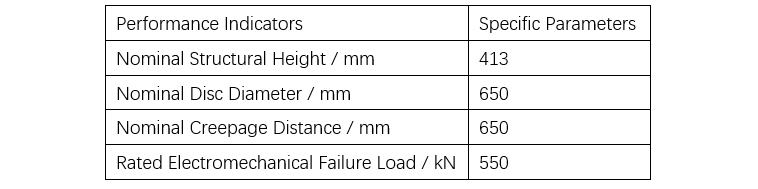

A 2400 kV impulse voltage generator was used for the test. The insulator cap was placed downward on a grounded metal plate, and a standard ball socket was installed at the pin end to prevent excessive electric field concentration in the cemented area around the pin. The insulator setup is illustrated in Figure 2.

Impulse breakdown tests in air were conducted on a total of 20 insulator specimens. The test methods for air impulse breakdown are categorized into the steepness method and the amplitude method, with the amplitude method primarily used for disc insulators.

This study employed the amplitude method, which does not require linearity of the impulse front but uses only the amplitude of the breakdown voltage as the criterion, with the front time controlled between 100 and 200 ns and amplitude deviation within ±10%. During the test, each insulator was subjected to five positive-polarity impulse voltages followed by five negative-polarity impulses, and this sequence was repeated once. The interval between consecutive impulses was maintained between 1 and 2 minutes.

Research from both domestic and international sources indicates that coating insulator surfaces with silicone rubber alters the propagation rate of surface streamers on porcelain insulators, leading to reduced steep-front impulse withstand performance. However, the insulation performance at the insulator's head remains unaffected in actual operation.

This phenomenon has been confirmed by over ten domestic disc insulator manufacturers: regardless of whether the shed profile is deep-rib or alternating-umbrella type, or whether the head structure is cylindrical or conical, all insulators exhibit some degree of reduced steep-wave breakdown performance after silicone rubber coating.

As a result, relevant standards have been revised, reducing the impulse breakdown test amplitude in air for RTV-coated disc insulators from 2.8 p.u. to 2.2 p.u. Preliminary test results show that breakdown rarely occurs at 2.2 p.u. Therefore, this study selected porcelain insulators without RTV coating and conducted air impulse breakdown tests at the standard test voltage of 2.8 p.u., with the voltage front time controlled within the 100–200 ns range.

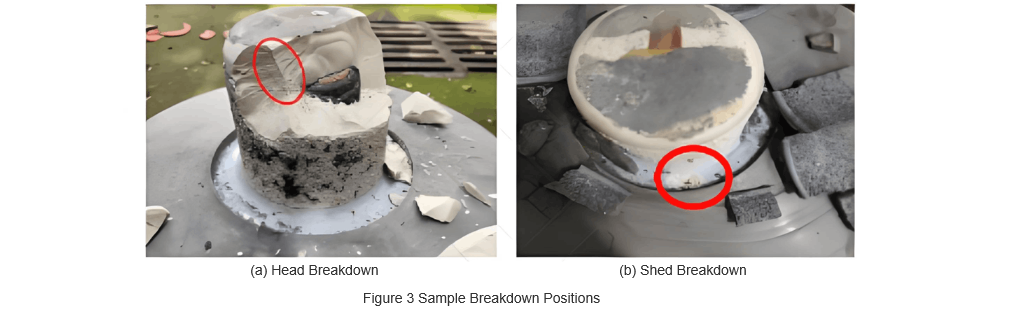

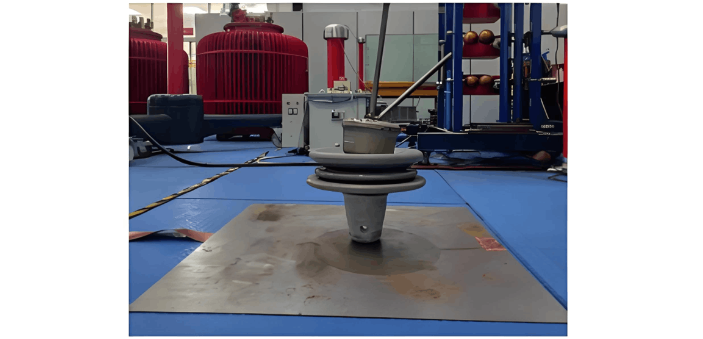

Further statistical analysis of the voltage polarity and breakdown location revealed that out of 15 breakdown events, 14 occurred under positive polarity and only one under negative polarity. Among the positive-polarity breakdowns, 8 occurred at the head and 6 at the sheds; the single negative-polarity breakdown occurred at the head. Additionally, arcing was observed on the insulator surface prior to shed breakdowns, whereas no such arcing was observed during head breakdowns.

However, in reference, all steep-front breakdowns of porcelain insulators occurred at the head, and in reference, porcelain insulators broke down at the head both before and after RTV coating. In contrast, this test shows that without the one-time injection-molded HTV overcoat, steep-wave breakdowns in the same batch of porcelain insulators occurred exclusively at the head. After HTV overmolding, breakdowns in the composite porcelain insulators occurred not only at the head but also at the neck, indicating that the HTV silicone rubber coating alters the breakdown path.

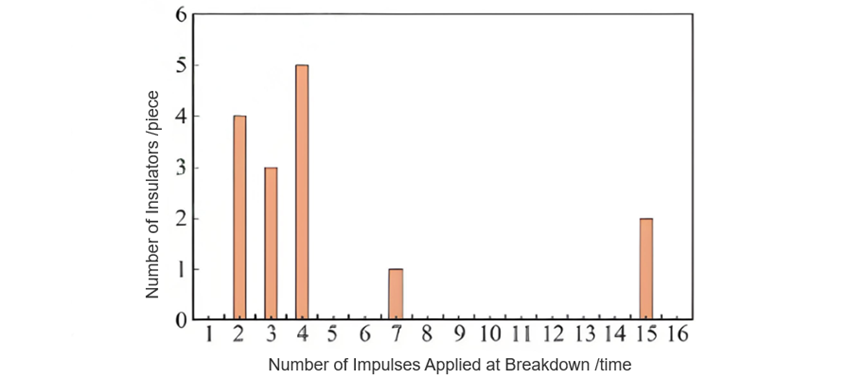

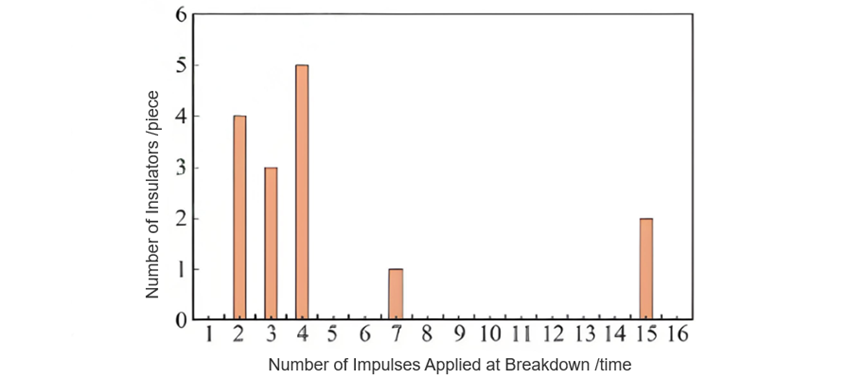

The number of impulse applications before breakdown was recorded, with results shown in Figure 4. As illustrated, 12 insulators broke down within the first five impulses, one broke down on the 7th impulse, and two broke down on the 15th impulse. Reference indicates that porcelain insulators coated with RTV exhibit a significant reduction in steep-wave withstand performance, with higher breakdown probability for larger-tonnage insulators, suggesting that silicone rubber coating degrades steep-wave resistance. In this test, 80% of the HTV overmolded composite insulators broke down within the first four impulses, further demonstrating that the presence of HTV silicone rubber significantly reduces the insulator's ability to withstand steep-front impulses.

3 Electric Field Distribution Simulation at Steep-Wave Voltage Peak

Analysis of the test results in Section 2 reveals that, compared to porcelain insulators, the breakdown path of composite insulators has changed and their steep-wave withstand performance has significantly decreased. This section employs simulation to calculate the electric field distribution of the composite insulator at the peak of the impulse voltage, aiming to investigate the causes of the altered breakdown path and reduced steep-wave performance.

2.1 Simulation Model

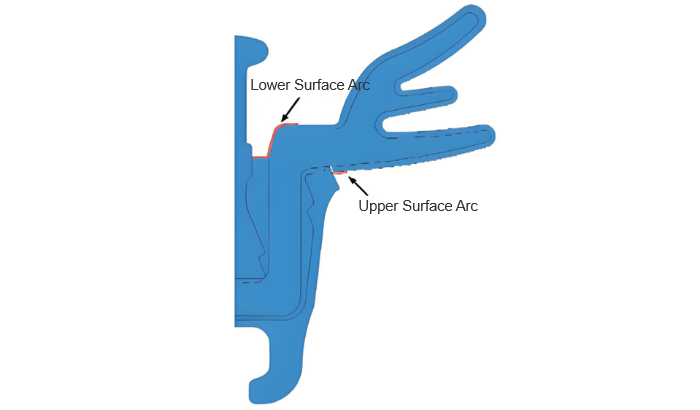

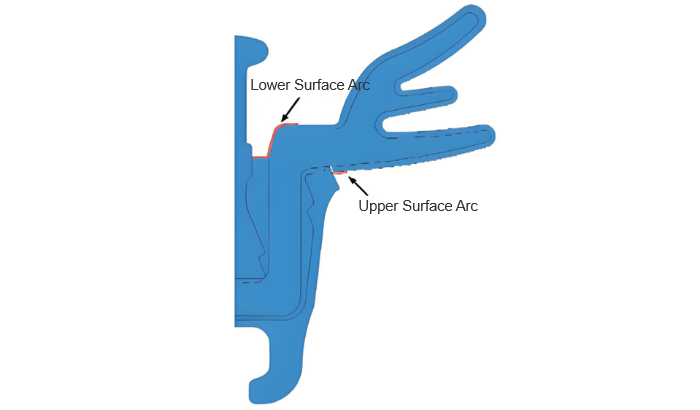

Observations from the air impulse breakdown tests indicate that when shed flashover occurs in composite insulators, arcs develop along the insulator surface to the breakdown location. The presence of arcs influences the electric field distribution and must be considered in the model. However, due to the irregular shape of arcs, establishing a 3D model for computation would be challenging, especially because the silicone rubber layer is thin and much smaller in dimension compared to the overall insulator, making 3D meshing difficult. Therefore, to qualitatively analyze the impact of the silicone rubber layer and arcs on the electric field distribution, a two-dimensional axisymmetric model is adopted for simplification in this section. The simulation model is shown in Figure 5.

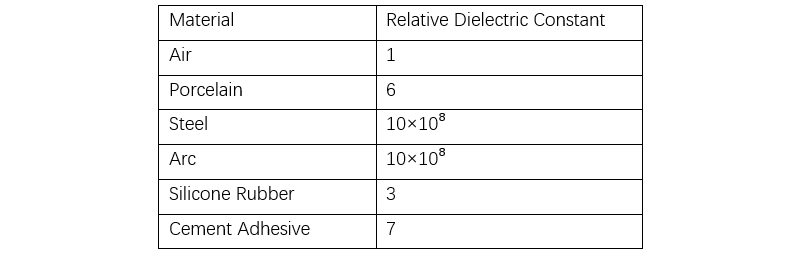

2.2 Materials and Boundary Conditions

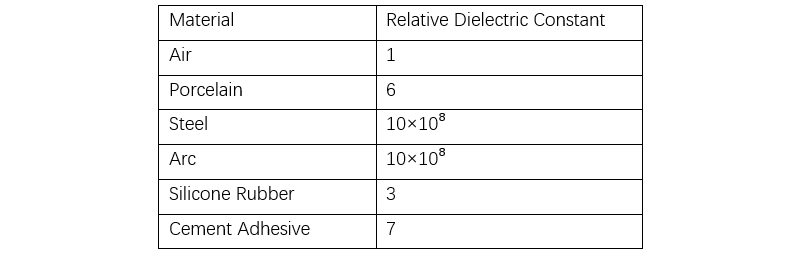

The 50% lightning impulse flashover voltage of the insulator is 145 kV, and the peak value of the 2.8 p.u. steep-front impulse voltage is 406 kV. Since most of the test specimens experienced positive-polarity breakdown, in the simulation, the pin (steel pin) is set as the high potential (406 kV) and the cap (steel cap) as zero potential. The relative permittivity values of the materials are listed in Table 2.

2.3 Simulation Results and Analysis

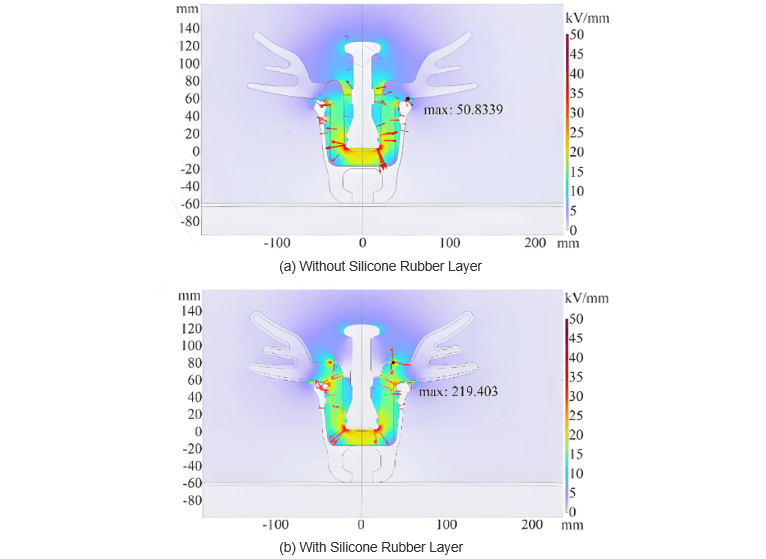

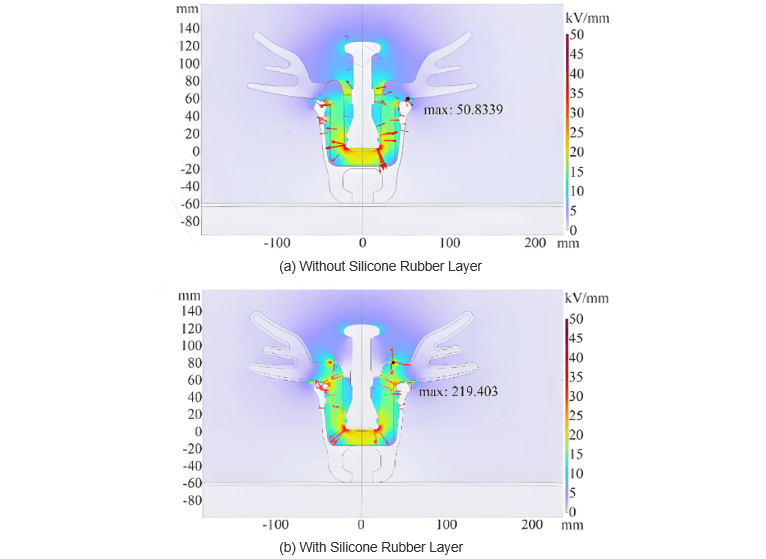

In the model without a silicone rubber coating, the electric field distribution of the porcelain insulator at the peak of the steep-front impulse voltage is shown in Figure 6(a). As seen in Figure 6, the electric field intensity is mainly concentrated at the insulator's head, reaching up to 50 kV/mm, indicating a high likelihood of head flashover—consistent with field experience and related studies.

To comparatively analyze the effect of the silicone rubber coating, the electric field distribution of the composite insulator model with one-time injection-molded silicone rubber was calculated, with results shown in Figure 6(b). It can be observed from Figure 6(b) that the maximum electric field occurs at the end of the arc on the lower surface of the insulating body, approximately 219.4 kV/mm; the field strength at the arc end on the upper surface is lower, at 41.21 kV/mm; and significant field concentration also exists at the pin head, with a maximum of 50.68 kV/mm.

Thus, under the influence of the silicone rubber coating, the surface resistivity of the insulator increases, significantly raising the ratio of volume capacitive current to surface resistive current in the sheds. This leads to a substantial increase in the electric field component perpendicular to the insulator surface, causing the arc to closely follow the surface after initiation.

Under the influence of the HTV coating, surface arcs propagate along the insulator surface when subjected to steep-front voltage, resulting in a sharp rise in local field strength—far exceeding that at the pin head—making breakdown more likely at the arc tip and leading to shed flashover. This indicates that the steep-wave withstand performance is affected by the HTV coating on the shed surface. Additionally, the simulation shows a relatively high electric field at the insulator head, which correlates with the observed head flashovers in tests.

3 Conclusion

Air impulse breakdown tests were conducted on composite insulators to analyze their steep-wave breakdown characteristics, and electric field distribution simulations were performed at the peak of the steep-front voltage. The following conclusions were drawn:

Under 2.8 p.u. steep-front impulse voltage, 15 out of 20 composite insulator specimens experienced breakdown, with 80% occurring within the first four impulses, indicating that the presence of HTV silicone rubber significantly reduces the steep-wave withstand performance of composite insulators.

Among the 15 breakdown events, in addition to flashovers at the pin head, six occurred at the sheds, indicating a clear change in the overall breakdown path compared to conventional porcelain insulators.

Simulation results show that the surface arc propagation in composite insulators causes a significant increase in shed electric field intensity at the voltage peak, reaching 217.64 kV/mm, making shed flashover more likely. In contrast, for insulators without a silicone rubber layer, the maximum field during arc development is located at the pin head, reaching 49.55 kV/mm, where breakdown primarily occurs.