Directiva de Operatione et Maintenance Pro Capacitoribus Electricis

Capacitoribus electricis sunt instrumenta compensationis reactivae staticae, praeclare ad supplendum potentiam reactivam systematibus electricis et meliorandam factorum potentiae. Per applicationem compensationis reactivae localis, reducuntur currentes lineares, minimantur pernicies potentiae lineares et diminutiones voltage, et contribuunt significanter ad meliorem qualitatem potentiae et maiorem utilisationem instrumentorum.

Quae sequuntur delineant aspectus claves operationis et maintenance capacitorum electricorum pro reference.

1. Protectio Capacitorum Electricorum

(1) Oportet ut meas protectionis convenientes ad bancos capacitorum applicentur. Hae possunt includere protectionem relaii aequilibriatae vel differentialis, vel protectionem relaii overcurrent instantaneae. Pro capacitoribus valoratis 3.15 kV et super, recommendatur ut fusus singuli in singulos capacitors installentur. Valorem nominalem fusus oportet secundum characteristica fusorum et inrush currentem durante energizatione, saepe 1.5 vice nominale currentem capacitoris, selectum esse, ut preveniant explosiones oleo receptaculorum.

(2) Praeter ea supra, meas protectionis supplementarias oportet, quando necessarium, applicari:

Si incrementa voltage sunt frequentia et sustinata, oportet ut meas capiantur ut voltage non excedat 1.1 vice valorem nominalem.

Utantur interruptoribus automaticis convenientibus ad protectionem contra overcurrent, limitantes currentem ne plus quam 1.3 vice nominale currentem.

Cum capacitoribus connectuntur ad lineas aereas, oportet ut surge arresters convenientes adhibeantur ad protectionem contra overvoltages atmospherae.

In systematibus altae tensionis ubi currentes short-circuit excedunt 20 A et dispositiva protectionis standard aut fusus non potest securiter eliminare faultas ground, oportet ut protectionem faultarum uniphasalis implementent.

(3) Selectio correcta schematum protectionis est critica ad operationem capacitorum securam et fidelis. Quocunque methodo usus, systema protectionis debet satisfacere sequentibus requisitis:

Sensibilitas sufficientis ut operatio fidelis in casu faultarum internarum in quovis singulari capacitore aut defectus elementorum individualium.

Facultas selective removerendi capacitors defectuosos, aut permittendi facilem identificationem unitatum damnis post complete de-energizationem.

Nihil falsi tripping durante operationibus switching aut faultis systematis sicut faultis ground.

Facile ad instalandum, adjustandum, testandum, et maintenendum.

Consumptio parva potentiae et costus operationis.

(4) Non debet reclosing automaticum in bancis capacitorum installari. In loco, oportet ut device undervoltage release trip utantur. Hoc quia capacitors tempus requirunt ad dischargendum. Si attemptetur reclose immediate post tripping, residua charge cum polaritate opposita ad re-energizing voltage remanere potest, resultans in ingressu currentis extremo qui potest causare bulging casings, spraying olei, aut etiam explosionem.

2. Energizatio et De-energizatio Capacitorum Electricorum

(1) Antequam energizatur banka capacitorum, ut megohmmeter ad circuitum discharge inspectandum.

(2) Considerationes sequentes applicari debent quando switchuntur banci capacitorum:

Banci capacitorum non debent connecti ad grid quando bus voltage excedit 1.1 vice valorem nominalem.

Post disconnectionem ab grid, banka capacitorum non debet re-energizari intra 1 minutum, praeter in applicationibus automaticis repeated switching.

Interruptores ad switchendum utendi non debent producere overvoltages periculosas. Interruptoris rated current debet non minus esse quam 1.3 vice nominale currentem banci capacitorum.

3. Discharge Capacitorum Electricorum

(1) Post disconnectionem ab grid, capacitors debent automaticamente dischargeri. Voltage terminalis celeriter debet diminui ita ut, quodcumque sit valorem nominalem, non excedat 65 V intra 30 secundorum post disconnectionem.

(2) Ut securitas assequatur, oportet ut dispositiva automatica discharges installentur in parte oneris interruptoris circuiti capacitoris et directe in parallelum cum capacitore (nec commutatores, isolatores, aut fusus in serie collocandi). Banci capacitorum equipati dispositivis non-dedicated discharges, sicut transformatores voltage (pro capacitoribus altae tensionis) aut lampades incandescentes (pro capacitoribus parvae tensionis), aut directe connecti ad motrices, non requirunt dispositiva discharges addita. Cum lampadibus, vita servitia potest extendi augmentando numerum lampadarum in serie.

(3) Antequam tangantur partes conductivae capacitoris disconnecti, etiamsi discharges automatica contigerit, oportet ut metallica baculus insulatus ad terminales capacitoris short-circuiting manuale utatur.

4. Maintenance et Cura Durante Operatione

(1) Banci capacitorum debent monitorari ab personis instructis, et recordationes operationis retineri debent.

(2) Inspectio visibilis bancorum capacitorum operantium decet quotidie iuxta regulas. Si observetur bulging receptaculorum, unitas statim debet e service removeri ut preveniatur defectus.

(3) Currentes phase in banco capacitorum potest monitorari per ammeter.

(4) Capacitors non debent energizari quando temperatura ambientalis sub -40 °C. Durante operationem, media temperatura non debet excedere +40 °C ultra 1 horam, +30 °C ultra 2 horas, aut +20 °C annuatim. Si limites exceduntur, refrigeratio artificialis (sicut ventillatores) debet adhiberi aut banka capacitorum disconnecti ab grid.

(5) Inspectiones temperature in loco installationis et in calidissimo puncto casing capacitoris debent perfici per thermometra mercurialia vel equivalentia, cum recordationibus retinentibus (praesertim durante aestate).

(6) Tensiones operationis non debent excedere 1.1 vice tensionem nominalem; currentes operationis non debent excedere 1.3 vice currentem nominalem.

(7) Connectio capacitorum potest tollere tensionem systematis, praesertim sub levi onere. In tali casu, pars aut tota banka capacitorum debet disconnecti.

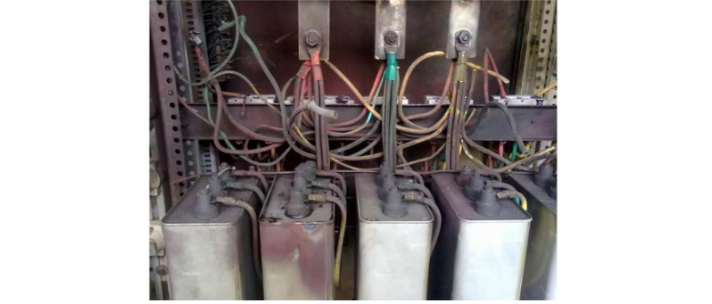

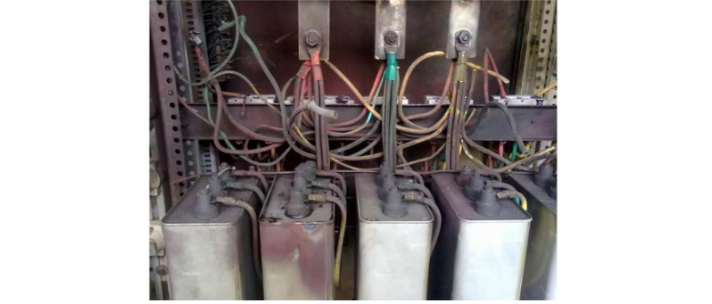

(8) Bushings et support insulators debent esse mundi, integri, et liberi ab signis discharges. Receptaculum capacitoris debet esse mundum, undeformatum, et sine effusione. Nihil pulvis aut detritus debet accumulari in capacitore aut in suo support frame.

(9) Omnes connectiones in circuitu capacitoris (busbars, grounding wires, circuit breakers, fusus, switches, etc.) debent inspectari pro firmitate. Etiam vinctus soluta aut contactus infirmus potest ducere ad defectum praecox capacitoris aut incidentia systematis universali.

(10) Si dielectric withstand test post periodum operationis requiritur, debet fieri ad specificatas tensiones test.

(11) Inspectiones valorum capacitance et fusorum debent fieri saltem semel per mensem. Tangentem loss (tanδ) capacitorum debet mensurari 2-3 vicibus per annum sub tensione nominale vel prope nominale ad aestimationem conditionis insulationis.

(12) Si banka capacitoris trippit propter operationem relaii, non debet re-energizari nisi causa identificata sit.

(13) Si effusio olei invenitur durante operationem aut transportem, potest reparari per brazing cum tin-lead solder.

5. Precautiones Operationis Switching (Isolation)

(1) Sub normalibus conditionibus, durante complete shutdown substationis, interruptor circuiti banci capacitorum debet primum aperiri, dein interruptores outgoing line. Durante re-energizationem, sequentia debet inversari.

(2) In eventu complete power outage, interruptor circuiti banci capacitorum debet aperiri.

(3) Post tripping banci capacitorum, re-energization coacta prohibetur. Si fuse protectiva dissiluit, fuse non debet substitui et re-energizari nisi causa determinata sit.

(4) Capacitors non debent energizari dum charged. Post disconnectionem, re-closing debet differri saltem 3 minutas.

6. Handling Faultarum Durante Operatione

(1) In casu sprays olei, explosionis, aut incendii, statim disconnectio supply potentiae et extinguendo ignis per harenam aut extinguentem dry-type. Tales incidentia sunt saepe causatae per overvoltages internas/externas aut gravis faultas internas. Ut preveniatur repetitio, oportet ut rating fusorum rectus sit, non re-energizari coacte post tripping, et non uti auto-reclosing.

(2) Si interruptor trippit sed branch fuse intacta manet, dischargeo capacitore 3 minutas, dein inspectio interruptoris, current transformer, power cable, et externa conditio capacitoris. Si nulla abnormalia inveniuntur, faulta potest esse causata per disturbia externa aut fluctuationes voltage. Post confirmationem, tentativum re-energization test potest conari. Alioquin, faciat full energized test systematis protectionis. Si causa non invenitur, dismanche bank et teste singulos capacitors. Non conare re-energization nisi causa invenitur.

(3) Quando fuse dissiluit, reporta ad dispatcher duty et obtine approval ante opening interruptoris circuiti capacitoris. Post de-energizing et discharging, fac inspectionem externam (sicut bushing flashover, deformation casings, effusio olei, faultas ground). Deinde mensura inter-terminal et ground resistance insulation per megohmmeter. Si nulla faulta detecta est, substitute fuse et resume operation. Si fuse iterum dissiluit post re-energization, isole capacitoris defectuosum et restituere service to remainder.

7. Precautiones Securitatis Quando Handling Faulty Capacitors

Antequam handling faulty capacitor, disconnect eius interruptor circuiti, aperi disconnect switches on both sides, et discharge the bank through the discharge resistor (e.g., discharge transformer or VT). Propter possible residual charge, manual discharge must still be performed. Primum, secure the grounding end of the grounding rod, then repeatedly discharge the capacitor terminals until no sparks or sounds occur. Finally, secure the ground connection.

Faulty capacitors may have poor internal connections, open circuits, or blown fuses, leaving residual charge. Therefore, maintenance personnel must wear insulating gloves and short-circuit the two terminals of the faulty capacitor with a shorting wire before touching it.

For capacitor banks with double-star connections, the neutral line, and for series-connected capacitor strings, individual discharge must also be performed.

Among substation equipment, power capacitors are relatively vulnerable due to weaker insulation, higher internal heat generation, poor heat dissipation, higher internal failure rates, and combustible internal materials, making them prone to fire. Therefore, favorable low-temperature and well-ventilated operating conditions should be provided whenever possible.

8. Repair of Power Capacitors

(1) The following faults may be repaired on-site:

Oil leakage from the casing can be repaired by soldering with tin-lead alloy.

Oil leakage at bushing welds can also be repaired by soldering, but care must be taken to avoid excessive heat that could damage the silver plating.

(2) Failures such as ground insulation breakdown, significantly increased loss tangent, severe casing bulging, or open circuits require repair at specialized capacitor service facilities equipped with proper tools and testing equipment.