1 Technical Features and Standard References of 500kV Dry - type Shunt Reactors

1.1 Technical Features

The 500kV dry - type shunt reactor, an oil - free power device for ultra - high - voltage transmission systems, boasts core features like advanced insulation, innovative heat dissipation, optimized electromagnetic design, and modular structure. These advantages, outperforming traditional oil - immersed reactors, also drive new technical standard demands.

Advanced Insulation: Using epoxy resin casting and nanocomposites (with nano - SiO₂ particles boosting epoxy breakdown strength by ~40% and partial discharge initial voltage by 25%), it enhances insulation and partial discharge resistance. This breakthrough calls for redefining insulation levels and partial discharge test methods in standards.

Innovative Heat Dissipation: A composite structure (multi - channel forced air cooling + phase - change material - assisted heat dissipation) keeps hot - spot temperature rise within 60K (well below IEC limits, verified via finite element analysis and experiments). New temperature - rise test methods/limits are needed in standards.

Optimized Electromagnetic Design: Multi - layer staggered winding and gradient insulation optimize electric field distribution, improving short - circuit resistance. Finite element analysis shows ~20% reduction in maximum electric field strength in windings. Standards should add evaluation methods for electric field distribution and short - circuit resistance.

Modular Structure: Composed of serially connected identical basic units, easing manufacturing, transportation, and on - site installation. Standards need test requirements for inter - module connection reliability and overall performance consistency.

1.2 Reference and Formulation of Technical Standards

In applying 500kV dry - type shunt reactor tech in Brazil, technical standards played a key role. The research team delved into Brazil’s electrical standard ABNT NBR 5356 - 6 Transformer Part 6: Reactors, and combined international standards like IEC 60076 - 6 Power Transformers - Part 6: Reactors and IEEE Std C57.12.90 - 2021 Standard Test Procedures for Liquid - Immersed Distribution, Power, and Regulating Transformers, to develop a 500kV dry - type shunt reactor technical specification fitting Brazil’s context.

Key focuses during specification formulation:

Insulation Level: Tailored to Brazil’s grid, insulation requirements were raised (lightning impulse withstand voltage: 1550kV; operating impulse withstand voltage: 1175kV – higher than Chinese standards but grid - suitable). Per NBR5356 - 6, switching impulse test Tz ≥ 1000 μs and Td ≥ 200 μs.

Temperature Rise & Heat Dissipation: For Brazil’s high - temp environment, the average temperature rise limit was tightened from 60K to 50K (via innovative cooling design, boosting safety). Added thermal imaging analysis and long - term temperature monitoring for the composite cooling structure.

Loss Requirements & Calculation: Designed per Brazil’s standards with a 0.3% interference loss limit. Using IEEE Std C57.12.90 - 2021 Annex B.2, a 50Hz - 60Hz loss conversion model was built, ensuring accurate and comparable loss calculations across frequencies.

Environmental Adaptability: For Brazil’s hot and humid climate, added anti - salt - fog, anti - pollution - flashover, and anti - UV requirements to enhance long - term reliability. Formulated tests like accelerated aging and humid - heat cycle tests.

2 Application Practice of 500kV Dry - type Shunt Reactors in Brazil

2.1 Challenges in Technology Introduction and Standard Adaptation

Applying 500kV dry - type shunt reactor technology in Brazil’s power system poses multiple challenges, requiring solutions to these key issues:

Technical Standard Differences: Brazil’s ABNT NBR 5356 - 6 Transformer Part 6: Reactors and China’s GB/T 1094.6 - 2017 Power Transformers - Part 6: Reactors are structurally similar but differ in specific requirements and implementation details. Both reference IEC 60076 - 6 but are localized to national needs, varying in insulation levels, temperature - rise limits, and loss - calculation methods. These differences demand careful handling during technology adaptation.

Climate Adaptability: Brazil’s tropical climate (e.g., Silvânia region: annual average temperature >25°C, relative humidity ≥80%) imposes higher heat - dissipation and insulation demands. Such a hot, humid environment severely challenges traditional power equipment’s insulation and service life.

Grid - Characteristic Adaptation: Brazil’s 500kV grid has voltage fluctuations ~15% higher than China’s same - level grids, with different harmonic environments. Reactors need stronger voltage adaptability and anti - harmonic performance.

Localized Operation & Maintenance (O&M) Needs: To ensure long - term reliable operation, localized O&M capabilities/habits must be considered, covering technical training, spare - parts supply, and localized services.

2.2 Adjustment and Innovation of Technical Standards

To address the above challenges, this research took innovative measures, most crucially adjusting pre - project technical standards and specifications based on the actual use and testing of the new dry - type reactor. This resolved technical adaptation issues and provided a key reference for similar projects.

Key technical standard modifications:

Cancel Partial Discharge Test:External corona interference on dry - type reactors far exceeds their internal partial discharges. With no mature testing methods/criteria for interference partial discharge, and considering NBR 5356 - 11 - 2016 only applies to low - voltage dry - type transformers (no external interference) and IEEE C57.21 exempts dry - type shunt reactors from such tests, the partial discharge test for 500kV dry - type reactors is canceled.

Optimize Insulation & Test Time:Per Brazilian standards, lightning impulse withstand voltage is 1550kV and operating impulse withstand voltage is 1175kV. Due to reactor impedance, switching impulse test time parameters are adjusted to Td ≥ 120 μs and Tz ≥ 500 μs.

Enhance Heat Dissipation:For Brazil’s hot, humid climate, a new composite heat - dissipation structure using Class H (180°C) insulation (boosting heat resistance by 30°C vs traditional designs) is developed. Thermal simulations show hot - spot temperature rise stays within 60K (below design limits).

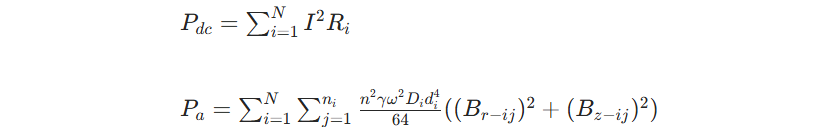

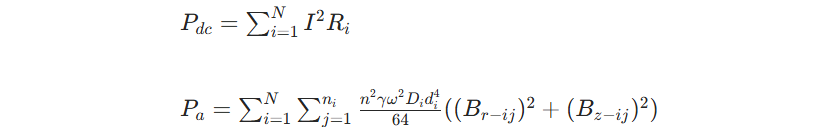

Adjustment of Loss Calculation Method: A reactor’s loss comprises the DC resistance loss of its winding (Pdc) and the winding’s additional loss (Pa). For a given reactor structure, both Pdc and Pa are proportional to the square of the current. Using transposed conductors, and with only a few small conductive metal components (like connectors) at connection points (non - magnetic), the additional loss accounts for a low proportion of the DC loss. Test results show the prototype’s extra loss is ~9%–12%, so the loss calculation formula is as follows:

Enhancing Voltage Adaptability: By optimizing the electromagnetic design, the voltage adaptation range of the equipment was expanded to cope with the large voltage fluctuations in the Brazilian power grid. Meanwhile, the equipment’s anti - harmonic performance was improved, and harmonic modes were reduced through a special winding design.

3 Evaluation of Practical Effects and Technical Standards

3.1 Analysis of Practical Effects

Through application at Silvânia Substation, the 500kV dry - type shunt reactor showed excellent performance. Per CEPRI - EETC03 - 2022 - 0880 (E) test report, key indicators:

Loss Level: Measured loss: 58.367kW @ 80°C (below 60kW limit), verifying effective loss calculation/control methods.

Noise Control: Measured noise: 57dB(A) (well under 80dB(A) requirement), thanks to focused noise - control design.

Temperature - Rise Performance: Average temp rise: 22.9K; hot - spot rise: 26.5K (both under design limits), validating new cooling design for Brazil’s climate.

Electrical Performance: Performed well in tests (lightning/operating impulse). Used ABNT NBR 5356 - 4/IEC 60076 - 4 parameters (T1, Td, Tz) for operating impulse, accounting for reactor impedance.

These prove the reactor’s applicability/superiority in Brazil’s grid, especially in energy efficiency/environmental protection, supporting sustainable development. Results also verify scientific, forward - looking technical specs.

3.2 Technical Standard Optimization Evaluation

Based on practice/operation, the team proposes optimizations:

Loss Limits: Lower 500kV/20Mvar reactor loss limit from 60kW @ 80°C to 58kW @ 80°C; use 75°C for loss - calculation reference.

Noise Standards: Refine standards (e.g., 75dB(A) for substations near residences); consider noise under varying voltages (e.g., 600kV).

Temperature - Rise Limits: Adjust average temp - rise limit from 60K to 50K; specify Class B insulation (130°C temp index, 60/90°C avg/hot - spot rises).

Insulation Coordination: Raise lightning impulse withstand voltage to 1600kV (for Brazil’s frequent lightning); use 140kV power - frequency dry - withstand for neutral - point insulation. Define test freq (≥48Hz, 80% of rated) and duration (≥60s).

Environmental Adaptability: Add anti - salt - fog reqs (coastal areas); consider EMF impact, set spacing. Use shields, anti - pollution/UV coatings in design.

These suggestions boost reactor performance/reliability, guide future standards, and help Brazil’s grid develop efficiently, reliably, and sustainably.