1 Tattalin Fanni da Kammalawa da Nau'in Ma'aikataruwar 500kV Dry - type Shunt Reactors

1.1 Tattalin Fanni

Wani 500kV dry - type shunt reactor, wanda ba ta fi kuli, yana daya daga cikin abubuwan da suka fi sani a cikin tattalin fanni masu kammalawa na jirgin gajiya, suna da muhimmanci sosai. Wadannan abubuwa sun hada da kammalawa mai sauƙi, hanyoyi masu sauki, kammalawa masu kimiyya, da kuma kammalawa masu kammalawa. Abubuwan da suka fi sani ne suka haɗa da nau'ukan kammalawa masu kimiyya.

Kammalawa Mai Sauƙi: Ta yi amfani da epoxy resin casting da nanokomposites (da nan - SiO₂ particles wanda ke zama da lada tsari ta epoxy da ~40% da kuma fasaha tsarin kammalawa ta bayan bincike da ~25%), wanda ya zama da ita ce kammalawa da tasiri mai sauƙi. Wannan nasarorin ya ba da damar kafofin kammalawa da kuma hanyoyin kammalawa a nau'in binciken kammalawa.

Hanyoyi Masu Sauƙi: Aikace - aikace (multi - channel forced air cooling + phase - change material - assisted heat dissipation) yana da ita ce hot - spot temperature rise within 60K (wanda ya zama da ita ce IEC limits, verified via finite element analysis and experiments). An buƙata hukumomin hanyoyi masu sauki da kammalawa a nau'in ma'aikataruwa.

Kammalawa Masu Kimiyya: Multi - layer staggered winding and gradient insulation optimize electric field distribution, improving short - circuit resistance. Finite element analysis shows ~20% reduction in maximum electric field strength in windings. Standards should add evaluation methods for electric field distribution and short - circuit resistance.

Kammalawa Masu Kammalawa: Composed of serially connected identical basic units, easing manufacturing, transportation, and on - site installation. Standards need test requirements for inter - module connection reliability and overall performance consistency.

1.2 Nau'in Ma'aikataruwa da Kammalawa

A lokacin da mutanen Brazil suke amfani da 500kV dry - type shunt reactor tech, ma'aikataruwar kammalawa suna da muhimmanci. Wadannan takammanin suka duba ABNT NBR 5356 - 6 Transformer Part 6: Reactors, da kuma international standards like IEC 60076 - 6 Power Transformers - Part 6: Reactors and IEEE Std C57.12.90 - 2021 Standard Test Procedures for Liquid - Immersed Distribution, Power, and Regulating Transformers, don samun 500kV dry - type shunt reactor technical specification fitting Brazil’s context.

Abubuwan da aka duba a lokacin da aka samun specification:

Level of Insulation: Tailored to Brazil’s grid, insulation requirements were raised (lightning impulse withstand voltage: 1550kV; operating impulse withstand voltage: 1175kV – higher than Chinese standards but grid - suitable). Per NBR5356 - 6, switching impulse test Tz ≥ 1000 μs and Td ≥ 200 μs.

Temperature Rise & Heat Dissipation: For Brazil’s high - temp environment, the average temperature rise limit was tightened from 60K to 50K (via innovative cooling design, boosting safety). Added thermal imaging analysis and long - term temperature monitoring for the composite cooling structure.

Loss Requirements & Calculation: Designed per Brazil’s standards with a 0.3% interference loss limit. Using IEEE Std C57.12.90 - 2021 Annex B.2, a 50Hz - 60Hz loss conversion model was built, ensuring accurate and comparable loss calculations across frequencies.

Environmental Adaptability: For Brazil’s hot and humid climate, added anti - salt - fog, anti - pollution - flashover, and anti - UV requirements to enhance long - term reliability. Formulated tests like accelerated aging and humid - heat cycle tests.

2 Yadda Ake Amfani Da 500kV Dry - type Shunt Reactors a Brazil

2.1 Tasowa da Duk'iyar Nau'in Ma'aikataruwa

Amfani da 500kV dry - type shunt reactor technology a Brazil’s power system yana da duk'iyoyi, kuma yana buƙata hukumomin waɗannan abubuwa:

Technical Standard Differences: Brazil’s ABNT NBR 5356 - 6 Transformer Part 6: Reactors and China’s GB/T 1094.6 - 2017 Power Transformers - Part 6: Reactors are structurally similar but differ in specific requirements and implementation details. Both reference IEC 60076 - 6 but are localized to national needs, varying in insulation levels, temperature - rise limits, and loss - calculation methods. These differences demand careful handling during technology adaptation.

Climate Adaptability: Brazil’s tropical climate (e.g., Silvânia region: annual average temperature >25°C, relative humidity ≥80%) imposes higher heat - dissipation and insulation demands. Such a hot, humid environment severely challenges traditional power equipment’s insulation and service life.

Grid - Characteristic Adaptation: Brazil’s 500kV grid has voltage fluctuations ~15% higher than China’s same - level grids, with different harmonic environments. Reactors need stronger voltage adaptability and anti - harmonic performance.

Localized Operation & Maintenance (O&M) Needs: To ensure long - term reliable operation, localized O&M capabilities/habits must be considered, covering technical training, spare - parts supply, and localized services.

2.2 Harsuna da Ingantaccen Nau'in Ma'aikataruwa

Don haɗe waɗannan duk'iyoyi, wadannan takammanin suka yi ingantaccen harsuna, musamman harsuna na ma'aikataruwa masu kammalawa. Wannan ya haɗe duk'iyoyin teknikal da kuma tushen kananan nau'in ma'aikataruwa masu kammalawa.

Ma'aikataruwar kammalawa masu harsuna:

Cancel Partial Discharge Test:External corona interference on dry - type reactors far exceeds their internal partial discharges. With no mature testing methods/criteria for interference partial discharge, and considering NBR 5356 - 11 - 2016 only applies to low - voltage dry - type transformers (no external interference) and IEEE C57.21 exempts dry - type shunt reactors from such tests, the partial discharge test for 500kV dry - type reactors is canceled.

Optimize Insulation & Test Time:Per Brazilian standards, lightning impulse withstand voltage is 1550kV and operating impulse withstand voltage is 1175kV. Due to reactor impedance, switching impulse test time parameters are adjusted to Td ≥ 120 μs and Tz ≥ 500 μs.

Enhance Heat Dissipation:For Brazil’s hot, humid climate, a new composite heat - dissipation structure using Class H (180°C) insulation (boosting heat resistance by 30°C vs traditional designs) is developed. Thermal simulations show hot - spot temperature rise stays within 60K (below design limits).

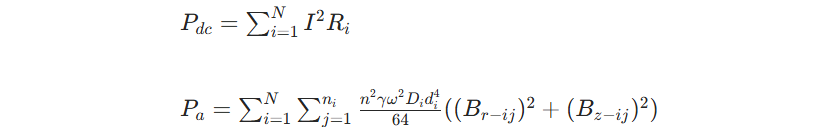

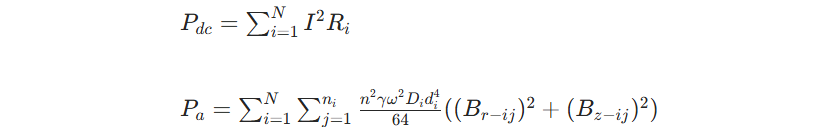

Adjustment of Loss Calculation Method: A reactor’s loss comprises the DC resistance loss of its winding (Pdc) and the winding’s additional loss (Pa). For a given reactor structure, both Pdc and Pa are proportional to the square of the current. Using transposed conductors, and with only a few small conductive metal components (like connectors) at connection points (non - magnetic), the additional loss accounts for a low proportion of the DC loss. Test results show the prototype’s extra loss is ~9%–12%, so the loss calculation formula is as follows:

Enhancing Voltage Adaptability: By optimizing the electromagnetic design, the voltage adaptation range of the equipment was expanded to cope with the large voltage fluctuations in the Brazilian power grid. Meanwhile, the equipment’s anti - harmonic performance was improved, and harmonic modes were reduced through a special winding design.

3 Binciken Yadda Ake Amfani Da Ma'aikataruwa da Kammalawa

3.1 Binciken Yadda Ake Amfani Da Ma'aikataruwa

A lokacin da ake amfani da 500kV dry - type shunt reactor a Silvânia Substation, an samun yawan kammalawa. Idan ake duba CEPRI - EETC03 - 2022 - 0880 (E) test report, abubuwan da suka fi sani:

Loss Level: Measured loss: 58.367kW @ 80°C (below 60kW limit), verifying effective loss calculation/control methods.

Noise Control: Measured noise: 57dB(A) (well under 80dB(A) requirement), thanks to focused noise - control design.

Temperature - Rise Performance: Average temp rise: 22.9K; hot - spot rise: 26.5K (both under design limits), validating new cooling design for Brazil’s climate.

Electrical Performance: Performed well in tests (lightning/operating impulse). Used ABNT NBR 5356 - 4/IEC 60076 - 4 parameters (T1, Td, Tz) for operating impulse, accounting for reactor impedance.

Wadannan suna nuna yawan kammalawa da 500kV dry - type shunt reactor a Brazil’s grid, musamman a hanyoyin energy efficiency/environmental protection, supporting sustainable development. Results also verify scientific, forward - looking technical specs.

3.2 Binciken Yadda Ake Harsuna Ma'aikataruwa

Based on practice/operation, the team proposes optimizations:

Loss Limits: Lower 500kV/20Mvar reactor loss limit from 60kW @ 80°C to 58kW @ 80°C; use 75°C for loss - calculation reference.

Noise Standards: Refine standards (e.g., 75dB(A) for substations near residences); consider noise under varying voltages (e.g., 600kV).

Temperature - Rise Limits: Adjust average temp - rise limit from 60K to 50K; specify Class B insulation (130°C temp index, 60/90°C avg/hot - spot rises).

Insulation Coordination: Raise lightning impulse withstand voltage to 1600kV (for Brazil’s frequent lightning); use 140kV power - frequency dry - withstand for neutral - point insulation. Define test freq (≥48Hz, 80% of rated) and duration (≥60s).

Environmental Adaptability: Add anti - salt - fog reqs (coastal areas); consider EMF impact, set spacing. Use shields, anti - pollution/UV coatings in design.

Wadannan takammanin suna nuna yawan kammalawa da ƙarfi, suna taimakawa da ma'aikataruwa masu kammalawa, da kuma taimakawa da Brazil’s grid zuwa yawan kammalawa, ƙarfi, da kima.