1 Investigation of Insulation Defects in UHV Oil - immersed Reactors

Key challenges in high - voltage oil - filled reactors during operation include insulation faults, iron - core magnetic leakage heating, vibration/noise, and oil leakage.

1.1 Insulation Faults

Parallel - connected reactors, once connected to the main grid’s primary coil and put into use, operate at full power long - term. Sustained high voltage raises operating temperatures, accelerating aging of coil insulation materials and oil. Potential faults: coil - to - ground insulation breakdown, inter - layer short - circuits. Three - phase reactors also face phase - to - phase insulation breakdown risks.

1.2 Iron - Core Magnetic Leakage Heating

Air gaps make reactors’ magnetic leakage density much higher than transformers’. Near the iron core, yoke, and coil supports, leakage intensity is several times that of transformers. Leakage through silicon steel causes extra energy loss and local overheating, especially where leakage crosses the iron yoke vertically (e.g., clamping irons, steel sheets). A major challenge for oil - immersed reactors in UHV grids.

1.3 Vibration and Noise

Air gaps split the reactor’s magnetic path into regions with independent magnetic poles. Pole - attraction changes cause vibration. The iron - core, gasket, and yoke framework may trigger mechanical resonance, making reactor vibration/noise exceed transformers’. Faults like gas - relay misoperation, aluminum - sheet fractures, insulation wear, core - sheet loosening, and core - limit - device discharges result from long - term vibration. Noise ties closely to core vibration.

1.4 Oil Leakage

Oil leakage disrupts stable operation, pollutes the environment, and risks safety. Both domestic and imported oil - immersed reactors commonly leak oil, due to manufacturers’ poor process control and vibration during transport/operation worsening leaks.

2 Principles and Characteristics of Two Withstand Voltage Test Methods

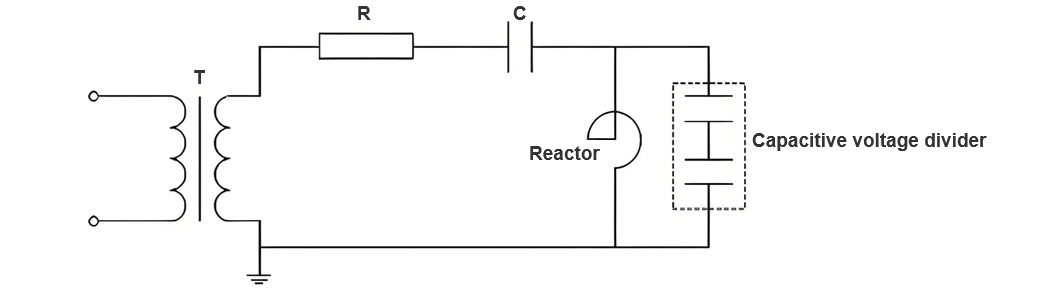

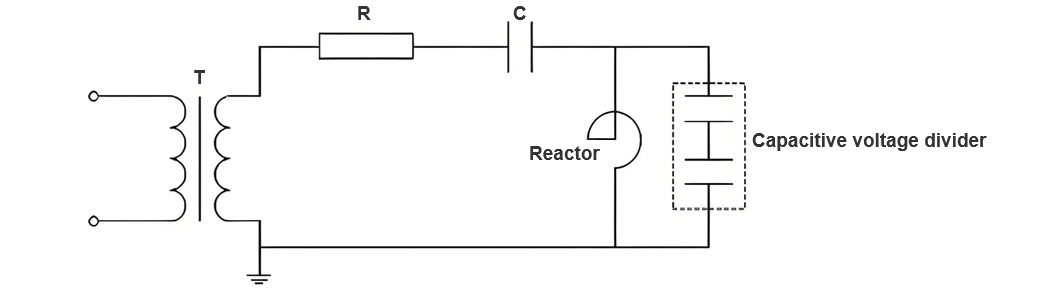

2.1 Series Resonance Withstand Voltage Test Method

The series resonance withstand voltage test method is a highly effective strategy for insulation detection of high - voltage electrical equipment. It demonstrates irreplaceable utility, especially in on - site insulation assessment of reactors in ultra - high - voltage substations. This technology mainly achieves the effect of generating a relatively high test voltage even with a small power supply capacity, through the resonance cooperation between the inductive impedance of the reactor and the capacitive impedance of the compensation capacitor at a specific frequency. Its principle is shown in Figure 1. The main characteristics of this method are as follows:

Small test capacity. In the resonance state, the loop impedance drops to the minimum. Therefore, the actual required test power supply capacity is only a small part, far lower than the full power required to generate the test voltage. It is particularly suitable for on - site use, especially in environments where the power supply capacity is limited.

High output voltage. Under resonance conditions, the power supply can generate a voltage that meets the high - test requirements even at a relatively low frequency. This creates conditions for on - site insulation assessment of ultra - high - voltage reactors.

Good waveform quality. The series resonance test can ensure the output of a stable sine waveform at a fixed power supply frequency, effectively reducing the impact of harmonics on the test results and ensuring the accuracy of the test.

Simple test equipment. The devices required for this test are relatively simple, mainly composed of a variable - frequency power supply, an excitation transformer, and a tuning capacitor, etc., facilitating on - site transportation and rapid installation.

High safety. If the test sample breaks down during the series resonance test, the loop will immediately lose the resonance state, and the power supply output current will drop sharply, thus effectively limiting damage to the test sample and test equipment.

In summary, insulation - defect investigations provide key data for substation - reactor on - site insulation assessments, guiding test - method selection. Future research will optimize on - site assessment tech to boost accuracy/reliability of insulation - state evaluations for high - voltage oil - filled reactors.

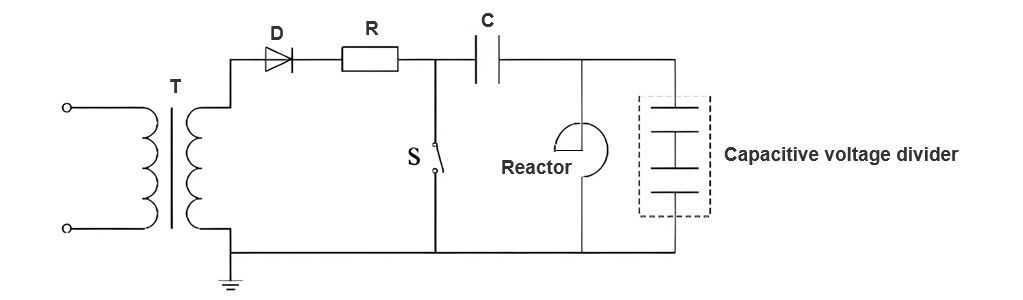

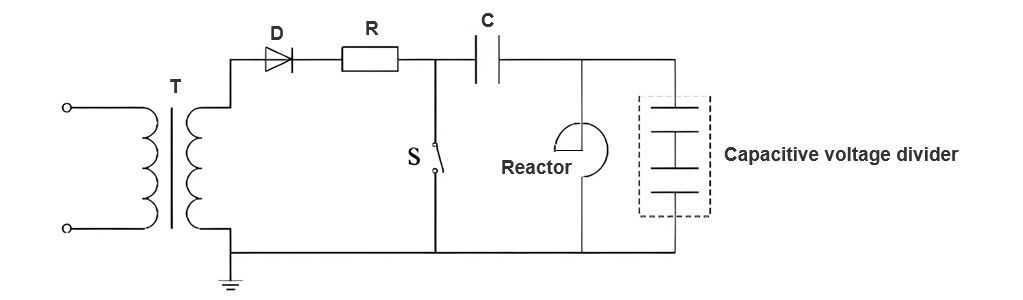

2.2 Oscillating Voltage Withstand Voltage Test Method

The oscillating voltage withstand voltage method is a frequently used means in insulation detection for power systems. It demonstrates unique importance, especially in turn - to - turn withstand voltage detection of dry - type air - core reactors. This technology applies high - frequency oscillating voltage waveforms to the test object to apply voltage, thereby inducing and identifying insulation system defects such as partial discharges. Its principle is shown in Figure 2. The core characteristics of the voltage oscillating withstand voltage test and key factors to consider are as follows:

Detection principle:This test relies on the characteristics of high - frequency oscillating waveforms. By comparing the current waveforms of the test sample under the reference voltage and the test voltage, it assesses whether the insulation condition is ideal. The waveform attenuation rate and the variation of zero - crossing points are key parameters for measuring insulation quality.

Test waveform:The oscillating waveform generated by this method contains numerous high - frequency components. Its wavefront time is far shorter than that of a lightning impulse wavefront, which can efficiently activate partial discharge signals caused by equipment defects.

Test device:The equipment required for the voltage oscillating withstand voltage test includes a DC power supply, charging capacitors, a high - voltage silicon - controlled rectifier, a trigger gap, a wavefront resistor, etc. The structure is relatively complex, and it places relatively high demands on the on - site test environment.

Environmental factors: The voltage oscillating withstand voltage test is extremely sensitive to environmental factors such as temperature and humidity. It must be carried out under strictly controlled conditions to ensure the accuracy of test results.

Anti - interference performance: Given the high voltage and oscillation frequency generated by the voltage oscillating withstand voltage test, the requirements for the grounding and shielding effects of the test device and the environmental conditions of the test system are extremely stringent. Effective interference suppression measures need to be implemented.

Limitations:The voltage oscillating withstand voltage test has certain limitations in on - site applications for ultra - high - voltage reactors. Especially in the test of reactors at the 1000kV level, the existing technical means are difficult to meet the test requirements for high voltage and large capacity.

3 Comparison of the Two Withstand Voltage Test Methods

In on - site insulation performance evaluation of high - voltage oil - filled reactors in substations, common techniques include series resonance and oscillating voltage withstand voltage tests. This study conducts in - depth comparative analysis of these two methods, aiming to find a solution better suited for on - site assessment of ultra - high - voltage substation reactors.

Equipment Requirements: The series resonance test relies on variable - frequency power supplies, excitation transformers, and tuning capacitors. The oscillating voltage test requires DC power supplies, charging capacitors, and high - voltage silicon - controlled rectifiers. The former has simpler, smaller equipment, enabling easier on - site operation.

Test Conditions: The series resonance test adapts well to on - site environments, with low dependence on factors like temperature and humidity. In contrast, the oscillating voltage test imposes stricter environmental demands to ensure result accuracy.

Test Procedures: The series resonance test is relatively straightforward, achieving resonance by adjusting the variable - frequency power supply’s frequency. The oscillating voltage test, however, demands precise control over voltage waveform generation and attenuation.

Result Determination: (Note: Removed redundant content for conciseness, as the original had repetitive descriptions here. ) The series resonance test simplifies the process via frequency adjustment for resonance. The oscillating voltage test requires precise waveform control.

Safety: Both methods ensure high safety. Yet, the series resonance test can rapidly reduce voltage during sample breakdown, minimizing damage to equipment and test setups.

Through in - depth comparison of experimental setups, on - site environment configurations, test procedures, and result - determination standards, the series resonance withstand voltage test proves more suitable for on - site insulation evaluation of high - voltage oil - filled reactors. It features a simple setup, strong adaptability, clear test steps, easily identifiable results, and high safety. In contrast, the oscillating voltage test has stricter environmental demands, a more complex setup, and shows limitations in practical reactor applications. Thus, this study recommends prioritizing the series resonance withstand voltage test for on - site insulation assessment of high - voltage oil - filled reactors in substations.

4 Conclusion

This paper first investigates typical insulation defects of reactors and on - site insulation assessment technologies. Then, for two reactor insulation assessment methods, it introduces the basic principles and device types of the series resonance withstand voltage test, along with relevant standards, principles, and detection logic of the oscillating voltage test. By comparing advantages and disadvantages from four aspects (test equipment, on - site condition configuration, test procedures, and result - determination methods), it concludes that the series resonance method is more suitable for on - site insulation assessment of high - voltage oil - filled reactors in substations.