Sê-deha biniyên din, bi pêşketina çewtî yên serorê ya transî şahîn û nûrî yên metro, beşa vê yek ji bo transî şahîn û nûr ê zêde kir. Li vir dibeke malpera wekheviya enerjî û parzûna cihê, transformatorên amorfik alloy core, ku amorfik alloy strips bi mizazeyê mezin yên magnetîk hatîne bikar anîn, wêne biguherînin da ku heta dihêl û xebitên navbêtî yên jêrnavîn ne. Li vir dibeke împekanî yên wekheviya enerjî û parzûna cihê, transformatorên amorfik alloy core yên tîkî (li miran "amorfik dry-type transformers") werin jî tiştî yên pêşbarwariyê yên transformatorên wekheviya enerjî. Li vir rêzikê Beijing Metro Line 14, belgeya ku dihat dekirin dihêle vê belge dihêl bi princîp, struktur û xusiyetên teknîk a transformatorên amorfik alloy core yên tîkî (li miran "amorfik dry-type transformers"), li gelek dihêl bi efektên operasyonê rengî ve li vir dihêl û pirsgirêkên ji bo operasyona dirêj bikerin, bi aimê ku referans û agahdarî bidin berdest bikin ji bo hilbijartina û bikaranîna transformatorên distribûsyon di metro'yan de.

Struktur û Princîpê Operasyonî a Transformatorên Amorfik Dry-Type

Struktur a Transformatorên Amorfik Dry-Type

Transformatorên distribûsyon amorfik alloy dikarin amorfik alloy bi mizazeyê magnetîk hatîne bikar anîn. Wêne girîngîna magnetîk ê bi sathî mezin, xebitên ultra-jêr, xebitên navbêtî jêr, û coercivity jêr, û transformatorên wekheviya enerjî û parzûna cihê bi stabilitêta mezin. Transformatorên amorfik dry-type dikarin xusiyetên transformatorên epoxy-cast dry-type yên tîkî, wêneyek halîgên jêr, fire retardancy, smoke generation jêr, û properties self-extinguishing, bi avantajên xebitên jêr amorfik alloy strips, ku ji bo wêne destniha yekdeme bihişkên amade yên publik yên wek metro'yan.

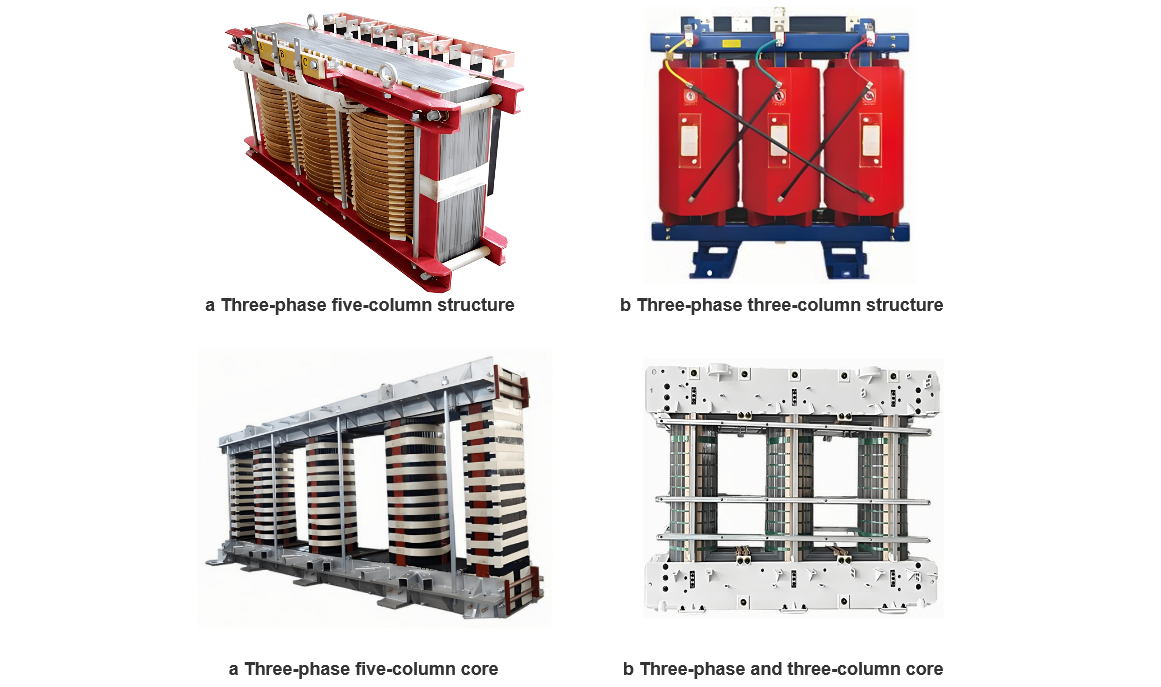

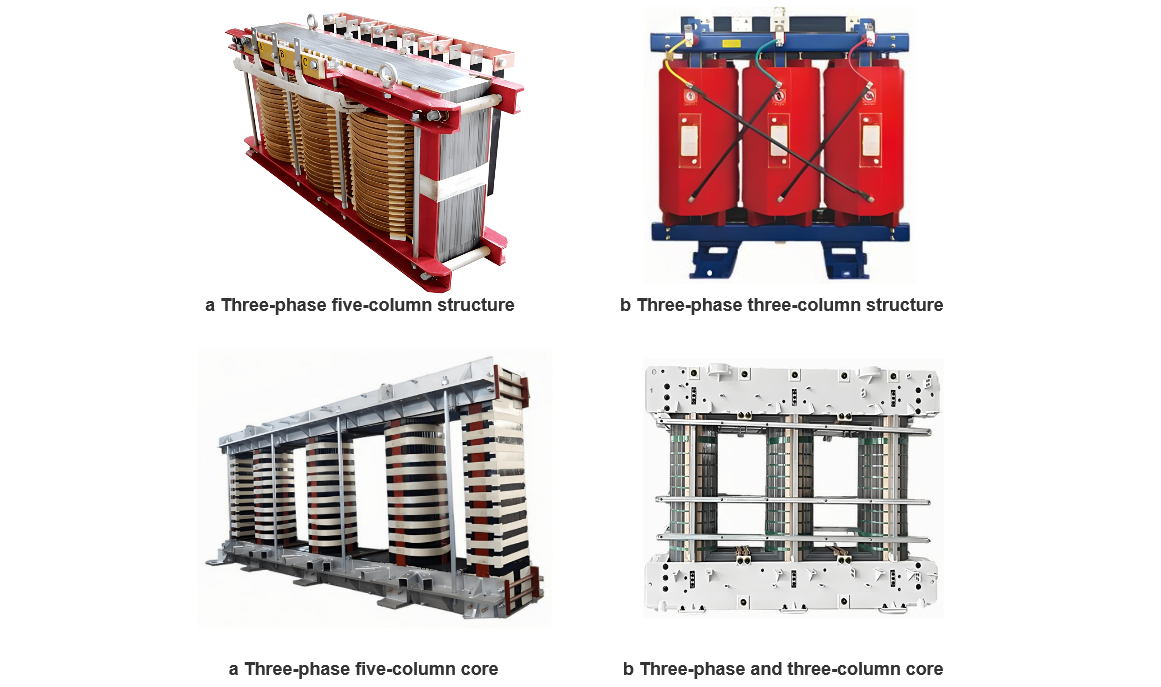

Amorfik alloy strips niha materyalên magnetîkên ten (bi girîngîna derengî yên 0.03 mm) û kevîn. Ji ber vê yekê, li vir dibeke disegnîn ji bo strukturên wound core. Niha, strukturên transformatorên amorfik dry-type yên epoxy-cast divê veşteha div yekan dikin, yekan ji wan heye strukturên three-phase three-limb û three-phase five-limb, wêneyek li Şekil 1. Struktur a core a three-phase five-limb form dihat bi kombinasyon a four frames, wêneyek li Şekil 2 a; struktur a core a three-phase three-limb form dihat bi kombinasyon a three frames, wêneyek li Şekil 2 b. Ji ber vê yekê ku section a core a transformatorên amorfik alloy rectangular e, coils a high- û low-voltage dizayn kirin bi strukturên rectangular yên bi rounded corners. Ji ber vê yekê ku magnetic flux density û lamination factor a core a amorfik alloy jêr in silicium steel sheets, volume a core a amorfik alloy zêdetir in ji core a silicium steel sheet yên same capacity. Transformatorên amorfik dry-type yên li vir raya metro yekem jî dikarin bi disegn a core a three-phase five-limb, ku wêne avantajên heat dissipation ê mezin, struktur a compact, û volume a jêr.

Princîpê Operasyonî a Transformatorên Amorfik Dry-Type

Kriştalên material a core a amorfik alloy, silicium steel, bi struktur û xusiyetên wan hatine destniha bêtir ji bo magnetization û demagnetization. Amorfik alloy typîkî dikare 80% iron, bi components bêtir yên materialan yên wek silicium û boron. Agahdarî yên testên mezbur û hatekîn ku crystallization temperature a amorfik alloy 550°C e, û Curie temperature about 415°C e. Sê dibeke temperatures bêtir ji bo processing a amorfik alloy, annealing after core forming, normal operating temperature, û thermal-stable temperature during short-circuits, ji ber vê yekê çi probleman ne di application a transformatorên amorfik dry-type de.

Li vir rêzikê three-phase, four-frame, five-limb amorfik alloy distribution transformer, ji ber vê yekê ku har winding li du frames bi independent magnetic circuits hatîne kafas kirin, magnetic flux a har frame dikare fundamental-wave magnetic flux û some third-harmonic magnetic flux. Ratio a third-harmonic to fundamental-wave depends on rated magnetic flux density. Lakin, third-harmonic magnetic fluxes li du core frames a one winding opposite in phase û equal in value. Ji ber vê yekê, third-harmonic magnetic flux vector li har winding zero ye. Ji ber vê yekê ku high-voltage coil connected in a delta (D) configuration, there is a path for the third-harmonic current in the coil. Ji ber vê yekê, generally no third-harmonic voltage component induced secondary-side voltage waveform. Lakin, no-load loss li har frame still affected by the third-harmonic current within that frame. The two side yokes of this structure can provide a path for the zero-sequence component or higher-order harmonics in the magnetic flux.

Main Technical Characteristics of Amorphous Dry-Type Transformers

Characteristics of Amorphous Dry-Type Transformers

Amorfik alloy strips extremely sensitive to pressure. Once damaged, they cannot be restored. Therefore, during the manufacturing process, the following two points must be ensured: First, the core only bears its own weight, and the weight of the high- and low-voltage coils is supported by steel-structure components such as the base, upper and lower clamping pieces. Second, the short-circuit withstand capability is improved through optimized design structure.

The rectangular-structured windings of amorphous dry-type transformers are not as uniformly stressed as circular windings. When the transformer withstands short-circuit current, the long-axis direction is more prone to deformation. In actual production, the high-voltage windings are rigid-structured wires cast with epoxy resin and fixed in the resin layer. Dynamic and thermal stability calculations and practical simulations have proven that the high-voltage coils can withstand the electrodynamic force during short-circuits.

The low-voltage windings are mostly wound with copper foils and have a thermally cured epoxy-resin end-sealing structure, with slightly lower rigidity. They are prone to deformation during short-circuits, subjecting the amorphous alloy strips to stress. Therefore, during the design process, a large ratio between the long and short axes of the low-voltage coil windings should be avoided. Moreover, during the assembly process, supporting spacers must be placed between the core and the low-voltage coils to enhance the short-circuit withstand capability.

The noise of a transformer mainly comes from the magnetostriction of the core. The magnetostriction of amorphous alloy is approximately 10% higher than that of silicon steel sheets. By comparing the national standards "JB/T 10088 - 2004 Sound Levels for 6 kV - 500 kV Power Transformers" and "GB/T 22072 - 2008 Technical Parameters and Requirements for Dry-type Amorphous Alloy Core Distribution Transformers", it can be seen that the noise requirements for dry-type amorphous alloy core distribution transformers in the national standards are the same as those for silicon steel sheet core distribution transformers.

This increases the difficulty of manufacturing amorphous dry-type transformers. However, through the rational design of the structure of amorphous dry-type transformers, the noise can still be controlled within the national standard range. The magnetic flux density is an important factor affecting the noise of amorphous dry-type transformers.

For every 0.05 T increase in magnetic flux density, the no-load noise increases by approximately 2 dB(A), and the transformer noise increases by 5 dB(A)[1]. Therefore, the magnetic flux density of amorphous dry-type transformers should be reasonably selected to achieve noise reduction. Under normal circumstances, a magnetic flux density of less than 1.25 T is sufficient for amorphous dry-type transformers.

However, considering the special situation of high passenger flow density in subways, the noise level should be controlled even lower, and the magnetic flux density is generally selected to be less than 1.2 T. In addition, the noise of amorphous dry-type transformers needs to be suppressed by optimizing the structure. For example, appropriate space should be left in the frame composed of the core and clamping pieces to avoid excessive stress on the core and control the increase in core vibration. Sound-absorbing materials should also be padded between the core and the frame to effectively reduce noise.

During transportation and installation, amorphous dry-type transformers should be strictly operated in accordance with the operation specifications and procedures to avoid situations such as the core being stressed or knocked.

Economic Performance Analysis of Amorphous Dry-Type Transformers

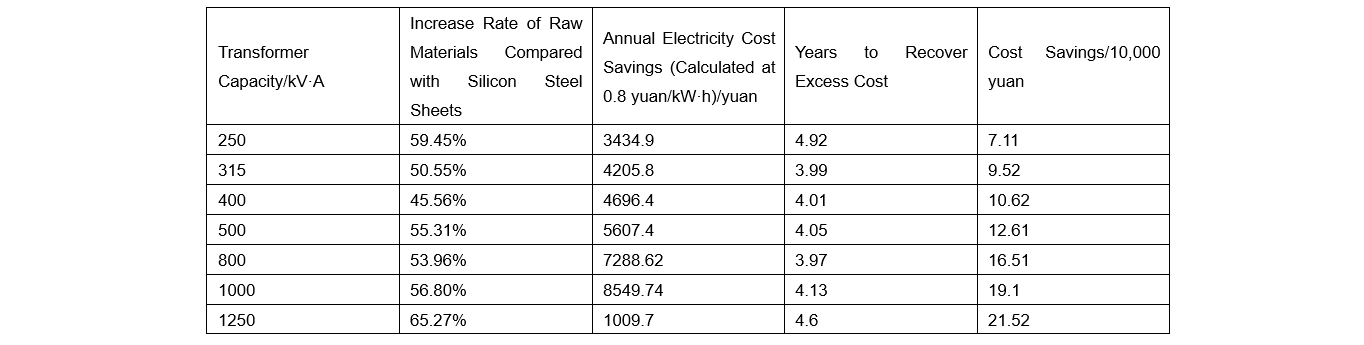

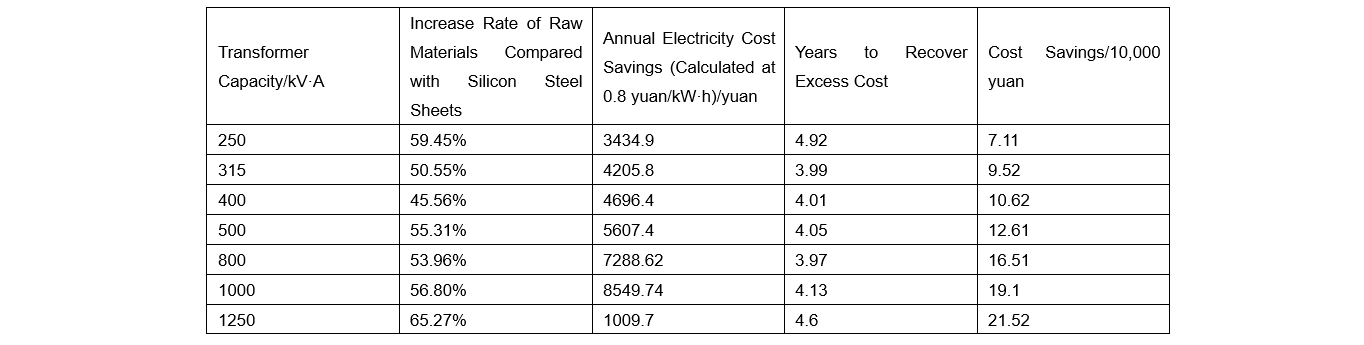

Amorphous dry-type transformers have obvious energy-saving effects. The following conducts an economic analysis of SCBH15-type amorphous dry-type transformers and SCB10-type silicon steel sheet distribution transformers with different capacities. The comparison is made in terms of the value of amorphous materials and silicon steel sheet materials, annual electricity cost savings, the number of years to recover the additional cost, and cost savings, as shown in Table 1.

It can be seen from Table 1 that amorphous dry-type transformers have more advantages in energy-saving compared to traditional silicon steel sheet transformers. Translated into operating costs, it is quite remarkable. The maximum number of years to recover the additional cost is only 5 years, showing great application prospects.

Application and Effect of Amorphous Dry-Type Transformers in Subways

Application of Amorphous Dry-Type Transformers in Subways

Through the elaboration of the structure and principle of amorphous dry-type transformers and the economic performance analysis, combined with the engineering situation of Line 14 of the Beijing Subway, for the application scheme of amorphous dry-type transformers, key research should be carried out on technical aspects such as the short-circuit withstand capability, noise control, loss index, and installation scheme of amorphous dry-type transformers, so as to give full play to the good energy-saving performance of amorphous dry-type transformers and improve the energy-saving level of subways.

On-site Implementation Effect

Taking the SCBH15-800/10/0.4 amorphous dry-type transformer that has been put into operation on Line 14 of the subway as an example, compared with the SCB10-800/10.0.4 dry-type transformer, ΔP0 = 1.05 kW; ΔPk = 0. The annual reduction in power consumption of one unit can be calculated as follows:

ΔWk = 8 760×(1.05 + 0.62×0) = 9 198 kW·h

Through calculation, it can be seen that the energy-saving effect of amorphous dry-type transformers is relatively obvious.

Relevant Suggestions for Long-term Online Operation

For the long-term operation of amorphous dry-type transformers on subway lines, their design, production, maintenance, and overhaul should be meticulously carried out in accordance with their unique characteristics. The author puts forward the following suggestions:

Given that the magnetic saturation density of amorphous alloy materials is relatively low and their magnetostriction is relatively large, during product design, the rated magnetic flux density should not be set excessively high. Generally speaking, it is preferable to select a value below 1.2 T.

Throughout the design and production processes, due attention must be paid to the short-circuit withstand capability of amorphous dry-type transformers. This capability should be enhanced through means such as process refinement and structural optimization.

Amorphous alloys exhibit extreme sensitivity to mechanical stress. Therefore, in structural design, it is necessary to avoid the traditional design approach that uses the core as the main load-bearing component.

To achieve excellent low-loss characteristics, annealing of the amorphous alloy core is an indispensable process.

Regular maintenance and repair of amorphous dry-type transformers are essential. This helps to eliminate potential safety hazards and prolong the service life of the transformers.

Conclusion

Against the backdrop of the country's vigorous promotion of energy conservation and emission reduction, all industries are making strenuous efforts to cut down energy consumption. As a significant electricity consumer within urban power grids, the widespread adoption of amorphous dry-type transformers in subways is in line with national industrial policies and holds broad prospects for application.

It should be noted that the cost of amorphous alloy distribution transformers is higher than that of traditional silicon steel sheet transformers, and their installation also has certain unique features. Therefore, a rational transformer selection scheme should be formulated based on a comprehensive analysis of regional and line-specific conditions.

Since amorphous alloy distribution transformers demand a high standard of design and production processes, when choosing suppliers, it is advisable to opt for enterprises that have a track record of successful applications and possess advanced technical capabilities.