1 Pagsulay sa mga Key Components sa AC Contactor

Ang AC contactor usa ka automatikong electromagnetic switch nga gamiton alang sa dugay ug kahayag nga pag-saklo ug pag-abli sa AC main circuits ug control circuits. Iya rason ang automatic operation, under-voltage ug no-voltage protection, high-capacity operation, matigas nga estabilidad, ug gamay nga panginahanglan sa maintenance. Sa electrical control circuits sa machine tools, ang AC contactors gamiton sa pag-control sa electric motors ug uban pang loads.

Ang key components sa AC contactor kasamtangan sa electromagnetic system, contact system, ug arc-extinguishing device, etc. Ia gihimo sa mga structural parts sama sa main contacts, moving iron core, coil, static iron core, ug auxiliary contacts.

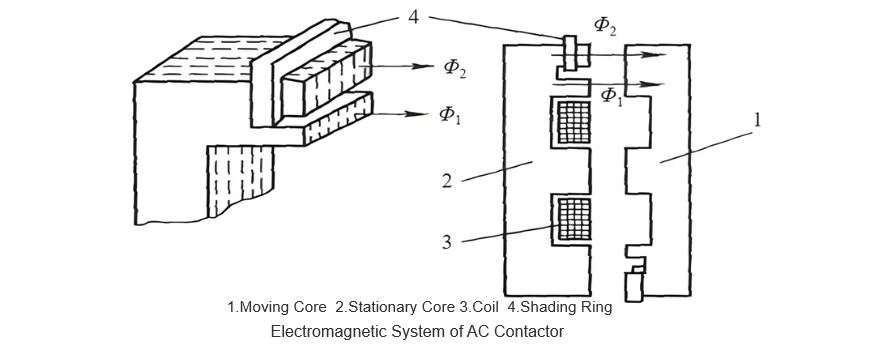

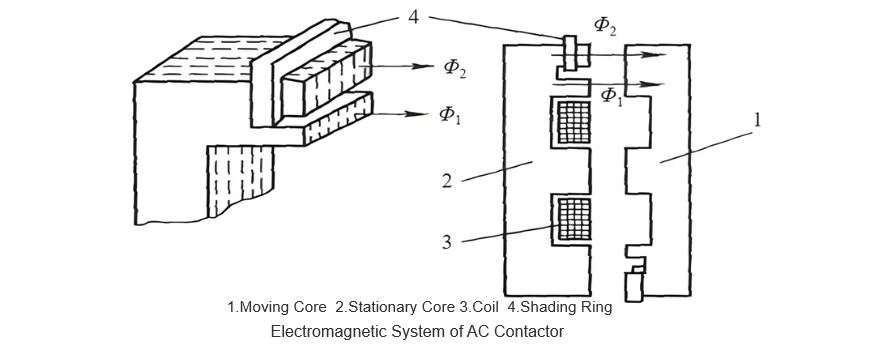

1.1 Electromagnetic System

Ang electromagnetic system sa AC contactor kasamtangan sa coil, moving iron core, static iron core, ug short-circuit ring. Kung ang control coil energized o de-energized, ia mahimo ang pulling-in o releasing action, ang makapahimulos sa moving contacts ug static contacts sa open o closed state, aron mapatuman ang layo sa pag-saklo sa circuit.

Arong mabawasan ang eddy current ug hysteresis losses, ang iron core ug armature sa AC contactor gihimo pinaagi sa laminating E-shaped silicon steel sheets. Aron madaghan ang heat dissipation area ug iwas sa burning out, ang coil gihimo og thick ug small cylinder wound sa insulating frame, may distance sa iron core aron dili mog-overlap. Ang E-shaped iron core nag-reserve og air gap sa 0.1 - 0.2 mm sa end face sa middle cylinder aron mabawasan ang effect sa residual magnetic field ug iwas sa jamming sa armature.

Kung ang AC contactor nagtrabaho, ang alternating current sa coil naghimo og alternating magnetic field sa iron core, nag-cause sa armature og oscillate ug generate noise. May groove sa bawhong end sa iron core ug armature, ug short-circuit ring gikan sa copper o nickel-chromium alloy giparag sa groove aron masolv-an ang problema. Pag-install sa short-circuit ring, kung alternating current nag-flow sa winding, magnetic fluxes Φ₁ ug Φ₂ sa different phases mag-form, aron sigurado nga adunay attractive force sa iron core ug armature, nag-bawas sa vibration ug noise.

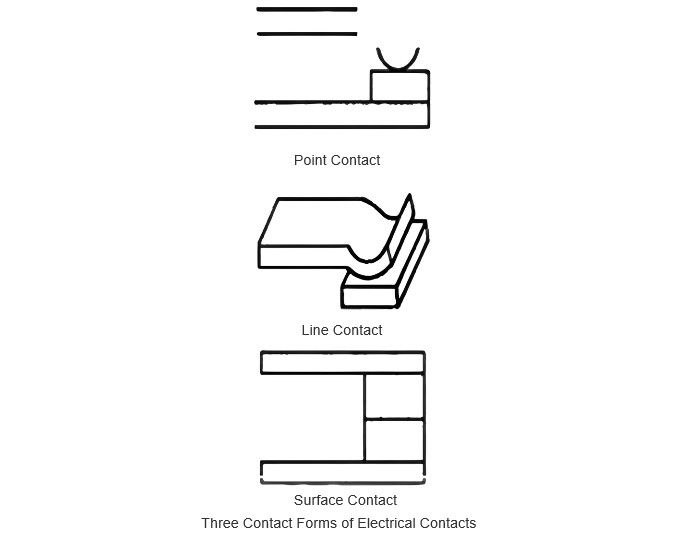

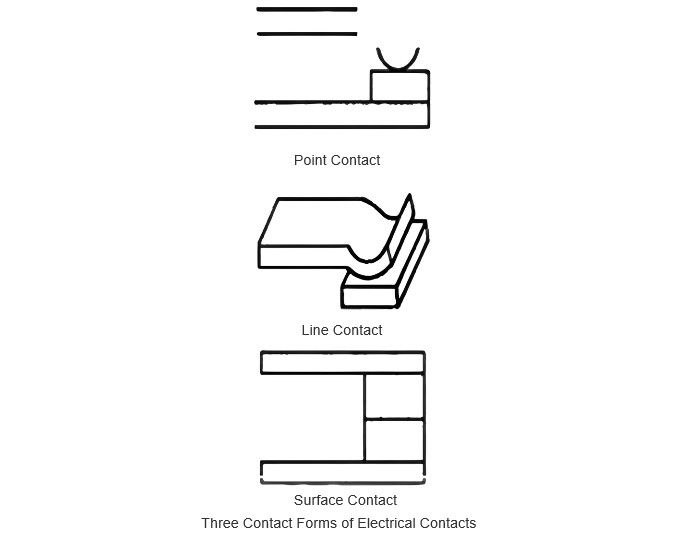

1.2 Contact System

Tres tipos ang AC contactor contacts, point contact type, line contact type, ug surface contact type, sama sa figure. Pinaagi sa structural form, ma-classify sila og bridge contacts ug finger contacts. Bridge contacts kasamtangan sa point-contact bridge type ug surface-contact bridge type, suitable sa different current occasions. Finger contacts labi na sa line contact mode, ug ilang contact area usa ka straight line, suitable sa frequent ug large-current occasions. Pinaagi sa making-and-breaking capacity, ma-divide sila og main contacts ug auxiliary contacts. Main contacts suitable sa large-current main circuits, ug adunay 3 pairs sa normally open contacts. Auxiliary contacts suitable sa small-current control circuits, ug adunay 2 pairs sa normally open contacts ug 2 pairs sa normally closed contacts.

1.3 Arc-Extinguishing Device

Sa high-current o high-voltage circuits, arcs siguradong mog-occur kung ang AC contactors mag-open, nag-cause sa contact burning, damage sa device, affect sa service life, ug interfere sa circuit breaking time; sa severe cases, mao ni maka-lead sa fire. Sa safety reasons, tanang contactors nga adunay capacity nga over 10 A kinahanglan adunay arc-extinguishing device. Ang common arc-extinguishing methods sa AC contactors kasamtangan sa double-break electric force arc extinguishing, longitudinal slot arc extinguishing, ug grid arc extinguishing.

Ang double-break electric force arc-extinguishing device nag-divide sa arc sa duha ka bahin, ug stretch sa arc pinaagi sa electric force sa contact circuit mismo, aron makapatuman ang heat dissipation ug cooling sa arc ug achieve ang purpose sa pag-extinguish. Ang longitudinal slot arc-extinguishing device gihimo gikan sa arc-resistant clay, asbestos cement, ug uban pa, may one o more longitudinal slots sa iyang inner side, nag-expand sa contact area sa arc ug wall sa arc-extinguishing chamber, ug achieve ang effect sa pag-extinguish sa arc pinaagi sa compressing. Kung ang contacts sa separated state, ang arc ipasa sa slots pinaagi sa external magnetic field o electric force, ug transfer sa heat energy sa wall sa arc-extinguishing chamber, aron quick na mapatay ang arc.

Sulod niini, proposed ang new type sa grid arc extinguisher structure. Ang metal grid adopt herringbone copper-plated o galvanized iron sheets ug inserted sa arc-extinguishing cover. Ang arc gikan sa contact breaking generate strong magnetic field, ug ang existence sa magnetic resistance nag-make sa electric field intensity uneven, aron pull sa arc sa gaps sa grid aron mag-form og short arcs. Each grid act as an electrode, dividing the entire arc voltage drop into several sections, and the arc voltage between each section is less than the arc ignition voltage. At the same time, the grid dissipates heat to eliminate the arc quickly, achieving the effect of extinguishing [3-5].

1.4 Auxiliary Components

Ang auxiliary components sa AC contactor kasamtangan sa reaction spring, buffer spring, contact pressure spring, transmission mechanism, base, etc. Ang reaction spring push sa armature aron release energy pagkatapos power failure, aron ang contacts return sa original state. Ang buffer spring mitumong sa impact force. Ang contact pressure spring madaghan ang contact pressure ug bawasan ang contact resistance. Ang operating contacts driven sa armature o reaction spring aron kontrol sa connect o disconnect.

2 Proper Use of AC Contactors

2.1 Selection Principles of AC Contactors

Ang rated voltage sa main contacts dili dapat lower sa rated voltage sa control circuit. Ang rated current sa main contacts kinahanglan molabay sa load requirements: para sa resistive loads, equal sa rated current; para sa motor loads, slightly greater sa rated current. Ang voltage sa attraction coil selected pinaagi sa complexity sa control circuit: 380 V o 220 V para sa simple circuits, ug 36 V o 110 V para sa complex circuits. Ang number ug type sa contacts kinahanglan molabay sa basic standards sa control circuit.

2.2 Installation and Maintenance of AC Contactors

Para sa pre-installation inspection, kinahanglan confirm kung ang technical data sa contactor (sama sa rated voltage, current, operating frequency, etc.) compliant sa standards, check kung ang appearance damaged o flexible movement, ug measure ang DC resistance value ug insulation resistance value sa coil. Ang installation position vertical, ang inclination dili dapat over 5°, ug ang side sa heat dissipation holes face sa vertical direction. Durante sa installation ug wiring, i-prevent ang parts sama sa screws, washers, ug terminals mula mobato, mao ni mabati ang AC contactor stuck o short-circuited.

Pasabot sa installation, kinahanglan check kung ang wiring correct. Without energizing the main contacts, energize and de-energize the contactor several times to check the movement of the main contacts and whether there is noise after the iron core is pulled in. It can be put into use only if there is no error. It is not allowed to connect the AC contactor to a DC power supply, otherwise the coil will be burned out.

3 Common Faults and Maintenance Methods of AC Contactors

3.1 Main Contact Faults

3.1.1 Severe Sparking at the Moment of Connection and Disconnection of Moving and Static Main Contacts

Kung ang load normal nga nagtrabaho, sparking occur sa moment ang contacts connect ug disconnect. Ang contact surface form irregular small pits tungod sa high temperature sa arc, result sa reduced contact area, increased current, ug severe sparking. Para repair ang damaged contacts, kinahanglan check ang degree sa damage sa contact surface; ang contact repairable lang kung ang thickness over 2/3 sa original thickness. Sa repair sa contacts, unang place fine sandpaper sa horizontal surface, grind ang damaged contacts flat sa sandpaper, check ang repair situation hangtud tanang damaged points ground off, ug finally deal sa burrs.

3.1.2 Melting, Burning and Adhesion of Moving and Static Main Contacts

Ang main causes sa melting, burning, ug adhesion sa moving ug static main contacts kasamtangan sa short circuit sa load, short circuit sa main circuit, o reduction sa load impedance. Among them, ang simultaneous occurrence sa short circuit ug main circuit short circuit ang key factor. Tungod sa work needs, ang operating frequency sa AC contactor ranges from low to high; during the frequent connection and disconnection of the contacts, the surface temperature rises, and under the action of the arc, the moving and static main contacts will eventually melt, burn and adhere.

Adunay generally duha ka treatment methods: first, replace the AC contactor with one with a higher voltage and current rating; second, repair the AC contactor: replace the contacts with the same specification, clean the carbon deposits around the moving and static contacts, etc., and connect Resistor-Capacitance (RC) arc-extinguishing devices in parallel with each of the 3 pairs of main contacts.

3.2 Auxiliary Contact Faults

3.2.1 Excessively High Contact Resistance of Moving and Static Auxiliary Contacts

Excessively high contact resistance of moving and static auxiliary contacts will lead to an increase in the loop impedance of the control circuit and a decrease in voltage. There are two main reasons for this phenomenon: first, a large amount of oil stains and dust are deposited on the contacts; second, an oxide layer is formed on the contact surface. Based on the under-voltage protection mechanism of the AC contactor, when the voltage across the AC contactor coil is lower than 85% of the rated voltage, the control circuit will stop working. The solution is to take out the contacts, wipe them dry with clean gauze, and then gently treat the contact surface with fine sandpaper.

3.2.2 Severe Sparking at the Moment of Connection and Disconnection of Moving and Static Auxiliary Contacts

The main reasons for this fault may be that the controlled circuit has experienced a short circuit, or the impedance value of the energy-consuming components in the control circuit has decreased, etc.

3.3 Coil Faults

3.3.1 Coil Open Circuit

An open circuit of the AC contactor coil will cause the control circuit to fail to work. This phenomenon is relatively rare, and it is generally caused by quality problems of the contactor or improper installation during assembly.

3.3.2 Coil Short Circuit

A short circuit of the AC contactor coil will cause the fuse of the short-circuit protection in the control circuit to blow. A common situation of coil short circuit is that the AC voltage applied across the coil is not 0.85-1.05 times the rated voltage; long-term operation of the coil under low or high voltage may cause a short circuit. A damaged AC contactor coil must be replaced; when replacing the coil, attention should be paid to the coil size, rated voltage, and the specification of the AC contactor.

3.4 Faults of Moving and Static Iron Core Contact Surfaces

3.4.1 Adhesion of Moving and Static Iron Core Contact Surfaces

The main reason for this fault is the presence of oil stains on the contact surfaces of the moving and static iron cores. After pressing the start button, the motor runs normally, but when pressing the stop button, the AC contactor coil loses power, the contacts do not return to their original state, and the motor continues to run. After the hand leaves the stop button, the coil remains energized, and the motor continues to run. The treatment method is to clean the contact surfaces of the moving and static iron cores.

3.4.2 Loud Noise from the Iron Core

The main reasons for loud noise from the iron core are the breakage of the short-circuit ring, or a large amount of rust on the contact surfaces of the moving and static iron cores. For the case of a large amount of rust, fine sandpaper can be used to treat the contact surface. If the short-circuit ring is damaged, the iron core is generally replaced to repair the fault.

4 Conclusion

The proper use, fault diagnosis and maintenance skills of AC contactors are crucial to the stable operation of electrical control systems. In order to improve the service efficiency of AC contactors and extend their service life, common faults should be repaired in a timely manner to reduce the failure rate during production.