| Brand | Schneider |

| Model NO. | FlexSeT Switchboards (cULus Listed) |

| Rated normal current | 2000A |

| Series | FlexSeT |

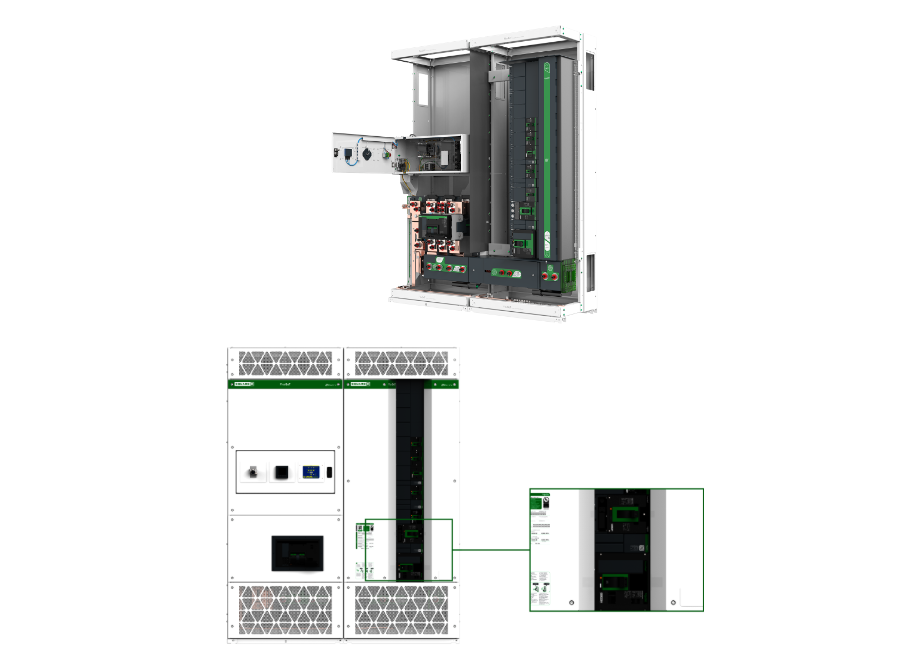

FlexSeT is a complete low voltage Switchboard offer and service model that enables new methods of assembly, installation, and maintenance, while delivering unprecedented availability, reliability, and modularity. FlexSeT customers will benefit from dramatically reduced lead times with design flexibility through a modern and innovative switchboard system, offering an end-to-end digital experience. Designed with the entire product lifecycle experience in mind, FlexSeT is a product developed with a fully customer centric approach, making everything simpler and faster from ordering to maintenance without compromising quality or safety, all while ensuring compliance to UL Standards. FlexSeT is delivered on-time with the shortest lead time in the market! The complete offer can shorten delivery to days instead of weeks. Even with configuration changes at virtually any part of the ordering process. The product modularity allows for adaptations without risks to your project timelines as features are added or removed in the lineup.

Years of leadership in the switchboard market have provided Schneider Electric with the expertise to drive innovation. FlexSeT switchboards are designed to take solutions to a whole new level, making the best switchboards in the market even better.

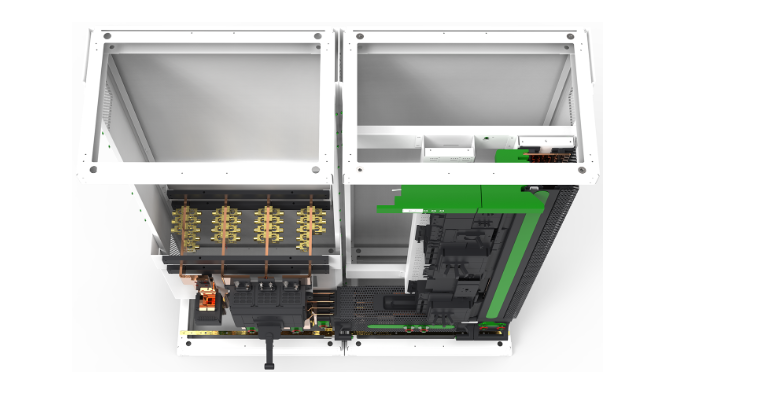

Designed to be assembled anywhere without the need of heavy machinery or complex tools, FlexSeT is structured to be simple and intuitive, not only for assembly but also for operation and maintenance.

FlexSeT modularity comes in the form of kits and design features that allow for quick and easy installation, removal, or replacement. This makes installation and operation more intuitive and faster with the benefit of improved efficiency.

Just like all Schneider Electric products, FlexSeT is always evolving to bring the best features to market with the latest technology, and will continue to develop and enhance customer solutions, constantly improving the offer!

Here are the latest features for FlexSeT Switchboards:

NEMA 1 enclosure

All front and side covers use captive hardware

Front and rear accessible

Swingable main breaker mounting assembly

Main breaker ampacities—100% rated up to 65 kA

Backfed: 400 A, 600 A, 800 A, 1000 A, 1200 A, 1600 A

Individually mounted: 400 A to 2000 A

All copper system bussing rated for 2000 A, including neutrals

Plug-on neutral for group mounted devices

2000 A I-Line™ feeder section with neutral bar within the stack—feeders from 15 A up to 1200 A

Splice bridge with extending bussing

Visi-Tite™ bolts on all torque-required bussing connections

Swingable instrument compartment—separated and modularized

Available devices:

PowerLogic™ power meter PM5563

Surge protective device—rated up to 240 kA

Maintenance mode setting (MMS) switch—compliant with NEC 240.87 Arc Energy Reduction requirements

SmartCell™ compatible!

Digital Asset Lifecycle Management—all drawings, test reports, and instruction/installation manuals are cyber-secured and available online