| Brand | ROCKWILL |

| Model NO. | 6/10kV Three - phase dry - type grounding/earthing transformer |

| Rated voltage | 10kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 1000kVA |

| Series | DKSC |

Description

Designed for grounding protection in medium-voltage power grids, the 6/10kV three-phase dry-type grounding transformer adopts epoxy resin vacuum casting thin-insulation technology. Both high and low-voltage windings are wound with copper foils, ensuring partial discharge values below 10pC. Thanks to the foil winding structure, it features large interlayer capacitance and linear initial voltage distribution, delivering outstanding lightning impulse withstand capability. The windings have consistent reactance heights and balanced ampere-turns, with near-zero axial short-circuit force, ensuring excellent short-circuit resistance.

With insulation classes F/H, the transformer operates safely at 155℃/180℃ long-term. Its core uses mineral oxide-insulated cold-rolled silicon steel sheets, achieving low no-load loss and noise. Moisture-proof, flame-retardant, and self-extinguishing, it suits urban distribution networks, industrial facilities, etc. Covering capacities up to 10,000kVA, it establishes a stable neutral grounding system for ≤35kV systems.

Feature

High Lightning Impulse Withstand Capability:Due to the high - and low - voltage windings all being wound with copper strips (foils), the interlayer voltage is low, the capacitance is large, and the initial voltage distribution of the foil - type winding is close to linear. Therefore, its lightning impulse withstand capability is strong.

High Short - Circuit Withstand Capability:Because the reactance heights of the high - and low - voltage windings are the same, there is no helix angle phenomenon, and the ampere - turn balance between the coils is achieved. The axial force on the high - and low - voltage windings caused by short - circuit is almost zero. Therefore, its short - circuit withstand capability is strong.

Good Anti - Cracking Performance:The dry - type transformer adopts the epoxy resin “thin insulation (1 - 3mm) technology”, which meets the requirements of occasions with low temperature, high temperature, and a large temperature variation range, and meets the anti - cracking requirements after long - term operation. It solves the cracking problem that is difficult to solve with the “thick insulation (6mm) technology”, providing reliable technical guarantee for dry - type transformers.

Strong Overload Capacity:If the load losses of transformers with the same capacity are equal, the area of the copper foil will be increased correspondingly compared with the copper conductor. After the volume is increased, the dosage of the filling resin is increased correspondingly. Therefore, the heat capacity of the winding is large, and the short - term overload capacity of the transformer is strong.

Good Flame - Retardant Performance:The epoxy resin vacuum casting process is adopted without environmental pollution, which is beneficial to environmental protection. The transformer has the characteristics of maintenance - free, moisture - proof, resistance to damp - heat, flame - retardant, and self - extinguishing, and is suitable for various environments and harsh conditions.

Low Loss and Low Noise:The iron core usually adopts high - quality cold - rolled silicon steel sheets insulated with mineral oxides. Through advanced processing technology, the loss level and no - load current are reduced to the minimum, and a very low noise level is achieved. At the same time, the assembled iron core is coated with class F resin paint on its surface to prevent dust, corrosion, smoke, and rust.

High Temperature Resistance Grade:The epoxy resin dry - type transformer belongs to class F or class H insulation, and can operate safely at a high temperature of 155℃ or 180℃ for a long time. With the same capacity, it has a small volume and light weight, which can save installation costs, etc.

Relevant Technical Specifications:Capacity ≤ 10000kVA; Voltage ≤ 35kV; Insulation grade: class F or H

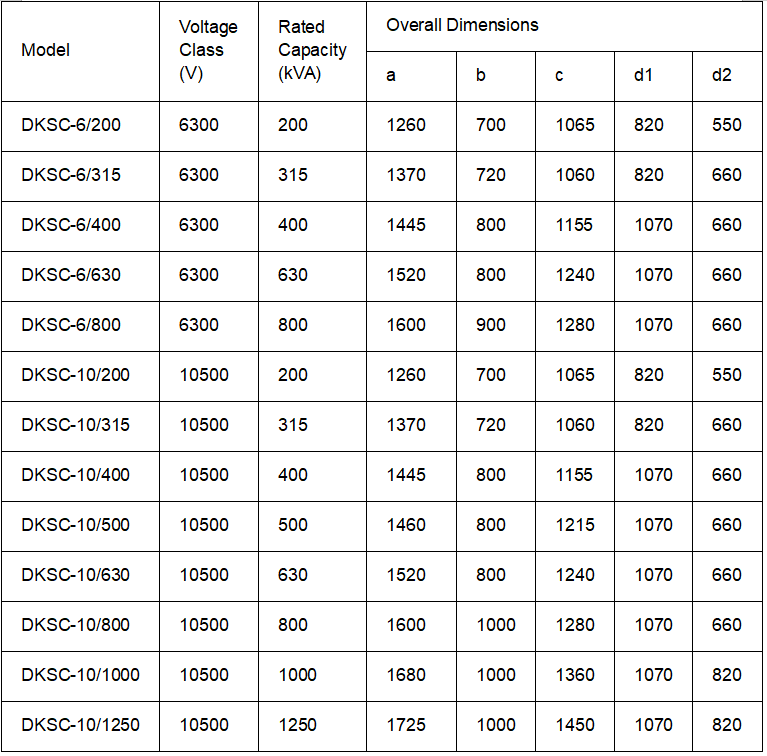

Main technical parameter

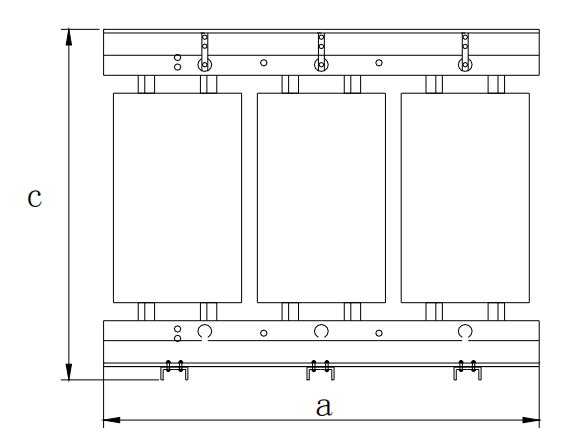

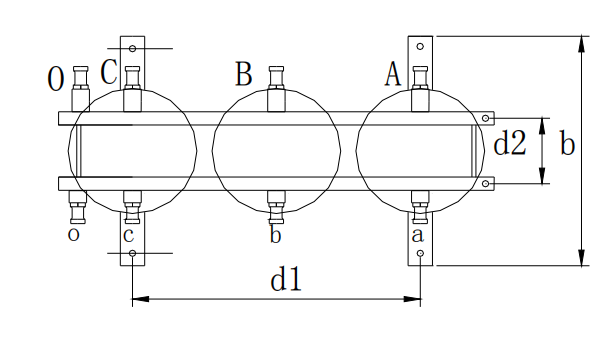

Outline Dimensions Diagram