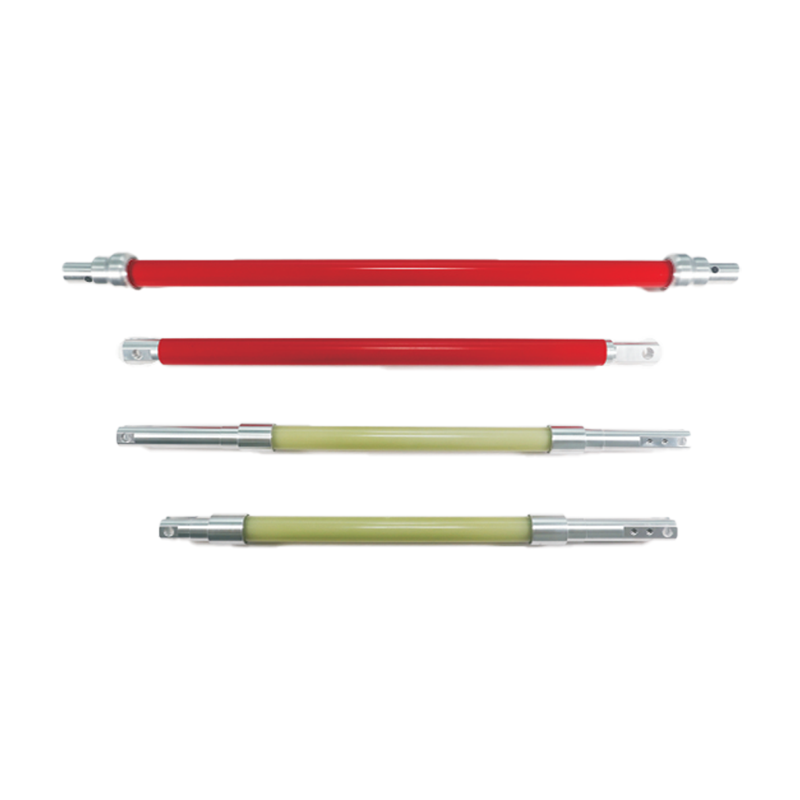

The 126kV GIS (gas insulated metal enclosed switchgear) tubular insulation rod is a key component in GIS circuit breakers, playing an important role in electrical insulation and mechanical operation. The following is a detailed introduction for you:

Structure and Materials

Structure: It usually adopts a tubular structure design, consisting of metal joints at both ends and an insulating tube in the middle. Metal joints are used to connect the operating mechanism and the moving contacts of circuit breakers, achieving force transmission; The insulation tube body undertakes the function of electrical insulation, ensuring the insulation performance between the operating mechanism and the live parts.

Material: The insulation tube body is generally made of glass fiber reinforced epoxy resin composite material. Glass fiber endows it with high mechanical strength, enabling it to withstand mechanical stresses such as tension and compression during operation; Epoxy resin provides excellent electrical insulation performance and chemical corrosion resistance. Metal joints are often made of materials such as copper alloys or stainless steel to ensure good conductivity and mechanical connection strength.

working principle

During the opening and closing operation of GIS circuit breakers, the operating mechanism applies tension or pressure to the insulation tube through the metal joint of the insulation rod, causing mechanical displacement of the insulation rod and driving the movement of the moving contact to achieve the opening or closing action of the circuit breaker. At the same time, the insulation tube of the insulation rod isolates the mechanical movement of the operating mechanism from the high-voltage conductive parts, preventing electric shock to the operators and ensuring the safe and reliable operation of the equipment.

Performance Requirements

Electrical performance: It needs to have excellent insulation performance and be able to withstand the rated voltage, power frequency withstand voltage, lightning impulse withstand voltage and other electrical test requirements of the 126kV system. It is usually required to have no flashover or breakdown phenomenon under the specified test voltage, and the partial discharge should also be controlled at an extremely low level, such as not exceeding a few picoku (pC).

Mechanical performance: It has high mechanical strength and good fatigue resistance to withstand the mechanical stress caused by frequent operation. For example, its tensile strength generally needs to reach several hundred megapascals, able to withstand tens of kilonewtons or even higher tensile forces, and its mechanical properties will not show significant decline after long-term operation cycles.

Environmental resistance: It can adapt to different environmental conditions, such as high temperature, low temperature, humidity, pollution, etc. In harsh environments, its insulation and mechanical properties remain stable and reliable.

Production and Testing

Production process: The insulation tube body is generally formed by extrusion molding. After impregnating the glass fiber with epoxy resin, it is extruded and cured through a mold to ensure dimensional accuracy and material uniformity; The connection between metal joints and insulation pipes is often achieved through processes such as adhesive bonding or mechanical crimping to ensure a firm connection and good contact.

Testing: During the production process and after the finished product, strict testing is required, including appearance inspection, size measurement, electrical performance testing (such as power frequency withstand voltage test, partial discharge test, etc.), mechanical performance testing (such as tensile test, fatigue test, etc.). Only insulation rods that meet the standard requirements in all indicators can be put into use.

Note: Customization with drawings is available

Online store

On-time delivery rate

Response time

100.0%

≤4h

Company overview

Workplace: 1000m²

Total staff:

Highest Annual Export(usD): 300000000

Workplace: 1000m²

Total staff:

Highest Annual Export(usD): 300000000

Services

Business Type: Sales

Main Categories: Electrical fittings/Equipment Parts/Low Voltage Electrical Apparatus

Whole life care manager

Full lifecycle management services for equipment procurement, use, maintenance, and after-sales,

ensuring safe operation of electrical equipment, continuous control, and worry-free electricity

consumption.

The equipment supplier has passed platform qualification certification and technical evaluation,

ensuring compliance, professionalism, and reliability from the source.