Interruptores de alto voltaje SF₆ sunt apparati switchgear maxime usitati in substationibus. Inspectio et conservatio regularis eorum essenti sunt ad stabilitatem operationis systematis electrici assecurandam. Tamen, in campo conservationis substationum, praesertim in conservatione interruptorum SF₆ de alto voltatu, sunt multa pericula (sicut intoxicatio, commotio electrica, etc.), quae graviter personale salutem operariorum minantur. Ex hoc, huiusmodi scriptum analysat ex perspectiva locationis et technologiarum controlis securitatis, ad securitatem operationum conservationis substationum meliorem faciendam et accidentia minuenda.

1 Analyse principiorum operativorum et characteristicarum

1.1 Proprietates physicae et chemicae gasis SF₆

Molecula SF₆ constat ex uno atomo sulfuris et sex atomis fluoris, cum pondere atomico 146.06, quinque virgula trece quinquies gravior quam aer. Sub 150°C, gas SF₆ exhibet bonam inertiam chemica et non reagitat cum metallis communibus, plasticis, et aliis materialibus in interruptoribus. Itaque, est colorless, sine odore, non toxicus, et transparent non combustibilis gas, qui generaliter difficile decomponitur (insolubilis in oleo transformatoris et parum solubilis in aqua). Tamen, per operationes apertionis et clausurae switcharum, gas SF₆ partialiter decomponitur sub actione discharges et arcuum, formans producta decompositionis in forma gaseosa vel pulverulenta, sicut fluorides metallici, SOF₂, SO₂F₄, etc., quae valde nocivae sunt corpori humano. Inter haec, gas SF₆ decomponitur et dissociatur sub actione arcuum (moleculae polyatomicae decomponuntur in atomos singulos vel particulas charged), et mutationes internae augmentant eius conductivitatem thermicam et electricam.

1.2 Principium operativum interruptorum SF₆ de alto voltatu

Interruptor SF₆ constat ex tribus unitatibus insulatorum porcellanearum verticalibus, uniuscuiusque cum camera arc-extinguendi gas-blast. Hoc designatum facit interruptorem compactum, cum bonis proprietatibus insulationis et arc-extinguendi. Camera arc-extinguendi gas-blast est pars core componentis interruptoris SF₆ de alto voltatu, et impletur gas SF₆ per canales coniunctos ad tres camaras arc-extinguendi. Quando interruptor aperitur, contactus controllabilis separatur a contactu fixo, generans arcum. Tunc, gas SF₆ in camera arc-extinguendi celeriter fluit versus arcum per canales, utendo proprietatibus insulationis et arc-extinguendi gas ad celeriter extinguendum arcum. Praeterea, mechanismus operationis spring et sua equipment controlis unibox sunt partes claves ad motum contactuum interruptoris SF₆ de alto voltatu dirigendi et controlandi. Usualiter constat ex spring, connective rods, transmission mechanisms, microprocessors, aut programmable logic controllers. Quando interruptor oportet aperi aut claudere, equipment controlis edicit mandatum ut mechanismus operationis spring actuet et moveat contactum mobile convenienter.

1.3 Characteristica performance interruptorum SF₆ de alto voltatu

Comparatis cum aere et oleo transformatoris, gas SF₆ habet characteristica fortis insulationis, excellentis performance arc-extinguendi, et parvi voluminis, et habet amplas prospectivas applicationis in campo electrico de alto voltatu.

- Effectus obstructivus: Ad plenum utitur effectu arc-blowing fluxus gas. Camera arc-extinguendi est parva, structura simplex, magnus currentus breaking, brevis tempus arcing, nullus reignition quando breaking currentus capacitive vel inductive, et parvus over-voltage.

- Longa vita electrica: Potest continue rumpere 19 vicibus ad full capacity 50kA, cum currentu breaking cumulativo 4200kA, longa periodus maintenance, et idonea pro scenariis saepe operatis.

- Fortis insulationis: Gas SF₆ potest transire varios testes insulationis cum margine magno sub 0.3MPa. Postquam currentus breaking cumulativus attingit 3000kA, quisque portus breaking potest sustinere voltage power-frequency 250kV intra 1 minutum sub 0.3MPa, et adhuc potest sustinere voltage power-frequency 166.4kV quando pressio gas SF₆ reducitur ad zero gauge pressure.

- Bona performance sealing: Contentus aquae gas SF₆ est comparativus parvus. Camera arc-extinguendi, resistors, et supports possunt dividi in compartimenta gas independentia ad impediendo dirt et humiditatem ab intrando interior interruptoris.

- Parvus power operativus et smooth buffering: Ratio transmissionis inter working cylinder mechanismi et contactum arc-extinguendi est 1∶1, et mechanismus habet characteristica stabilia. Stabilitas characteristica mechanismi potest attingere 3000 vicibus (10000 vicibus in environment test), et noise operativus est minor quam 90dB.

2 Analyse punctorum periculi in locis conservationis substationum

2.1 Typi et characteristica punctorum periculi

Puncta periculi in locis conservationis substationum praecipue includunt quattuor typi: pericula electrica, mechanica, chimica, et factores environmental. Haec puncta periculi possunt directe vel indirecte personalem salutem personarum conservationis minari.

- Pericula electrica: Causata ab damage insulationis equipmenti vel erroribus operationalibus, praecipue manifesta ut alta voltage et arcs. Quoniam interruptor portat altam voltatum in operatione et habet effectus capacitivi et inductivi, residua charges adhuc esse possunt etiam quando est in state open-circuit, ducens ad injuries electricas. Arcs possunt generare altas temperatures et causare incendia.

- Pericula mechanica: Pericula praecipue veniunt ex partibus mechanicis equipmenti. Si non recte operantur et conservantur, unus potest pellere aut impingere a partibus rotantis vel movendis.

- Pericula chimica: Gas SF₆ est stabilis ad temperaturam ambientem, sed coepit decomponi sub actione arcuum, coronae, etc. Inhaling gas generatus potest causare vertigines, pulmonem edema, vel etiam mortem.

- Pericula environmental: Faciendo conservationem in weather sicut tempestates et venti fortes non solum augent difficultatem laboris conservationis sed etiam affert pericula incontrolabiles personarum conservationis. Praeterea, problemata sicut mala ventilatio et parvus spatium in environment conservationis possunt etiam augere periculum in situ conservationis.

2.2 Analyse causarum punctorum periculi

Causae punctorum periculi in locis conservationis substationum praecipue includunt factores equipmenti, humani, et environmental. Cum incremento numeri operationum conservationis, gradus usurae equipmenti crescit, ducens ad declinationem performance electricae et maiorem periculum accidentium.

Propter inaequalitatem qualitatis personarum conservationis, quidam eorum non sufficientem intellectum de structura et principiis operativis equipmenti habent, et potest negligentia esse in actualibus operationibus. Exempli gratia, propter insufficiens vigilantiam, personae posse tactu casu partes vivas tangere aut tools inappropriate uti, quod directe accidents safety posset trigger.

Pro interruptoribus SF₆, pericula praecipue oriuntur ex suis proprietatibus chemicis. Toxic substances generatae sub conditionibus specificis probabile est accumulentur indoor propter limitationes environmental, ulterius augmentantes gradum periculi.

3 Location punctorum periculi et technologiae controlis securitatis

3.1 Methodi locationis punctorum periculi

- Fiber optic sensing technology: Fiber optic sensing technology habet excellentes proprietates insulationis et anti-electromagnetic interference. Potest efficaciter monitorare sanitate structurale et parametri electrici interruptorum SF₆, collecta et analyza data in real-time, et detecta prompte potential faults et pericula securitatis.

- Wireless sensor network: Wireless sensor network constat ex multis nodis sensorum. Suus finis principalis est monitorare parametri environmental, status equipmenti, et informationem locationis personarum conservationis in real-time. Rete habet characteristica self-organization, self-adaptation, et anti-interference, et potest adaptari ad complexa et variabilia conditiones environmental in situ, realizando monitoring et locationem punctorum periculi in real-time.

- Machine vision et infrared thermal imaging technology: Machine vision technology potest identificare et locare potential hazard points, sicut cables exposti et equipment damaged, captando et analyzando imagines in situ; while infrared thermal imaging technology potest monitorare distributionem temperature equipmenti in real-time et accurate locare puncta fault et potential risk points.

3.2 Model predictivus punctorum periculi basatus super analysis data

Nunc, intelligentia, digitalization, automation, et integration sunt principales tendentiae grid electrici China, et applicatio technologiarum artificial intelligence et big data acceleravit processum huius development. Durante conservationem interruptorum SF₆, model predictivus punctorum periculi basatus super analysis data constituitur, qui praecipue includit quattuor passus: data collection, data preprocessing, feature engineering, et model training.

- Data collection: Obtained per varios sensors, operation records of monitoring equipment, etc. To improve the accuracy of the model, a large amount of comprehensive data should be collected as much as possible.

- Data preprocessing: Preprocess the original data (outlier detection and processing, data transformation, etc.) to improve data quality and lay the foundation for subsequent feature engineering and model training.

- Feature engineering: After preprocessing is completed, useful features for hazard point prediction need to be selected from a large amount of data. These features should have good discrimination and predictive ability to improve the accuracy of the model.

- Model training: SVM (Support Vector Machine) is a commonly used classification and regression analysis method. It separates different categories of data by finding the optimal hyperplane, maximizing the classification interval between the two types of data.

3.3 Strategiae technologiae controlis securitatis

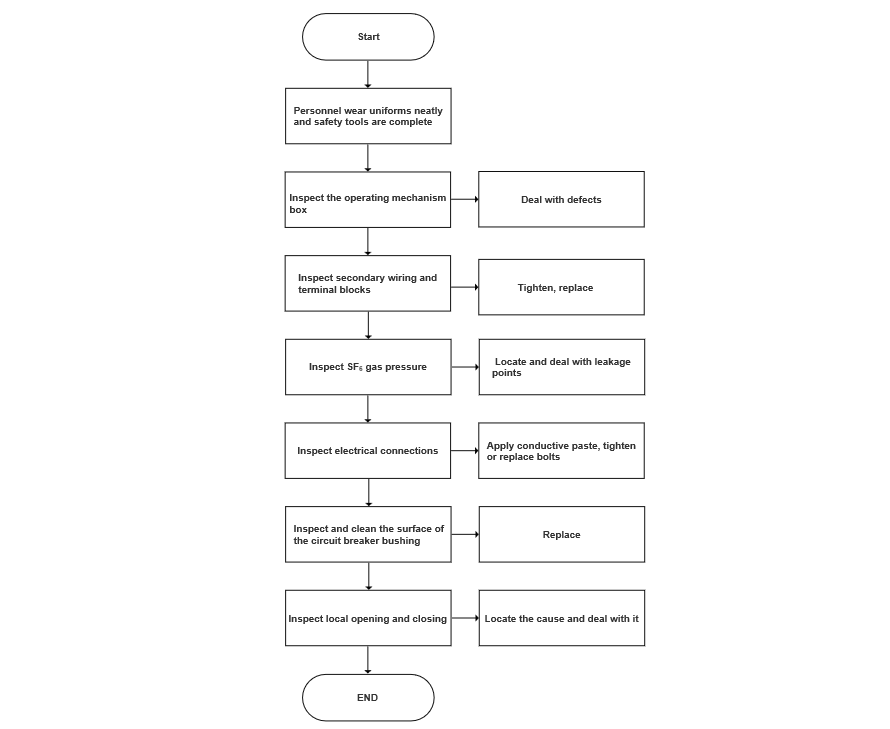

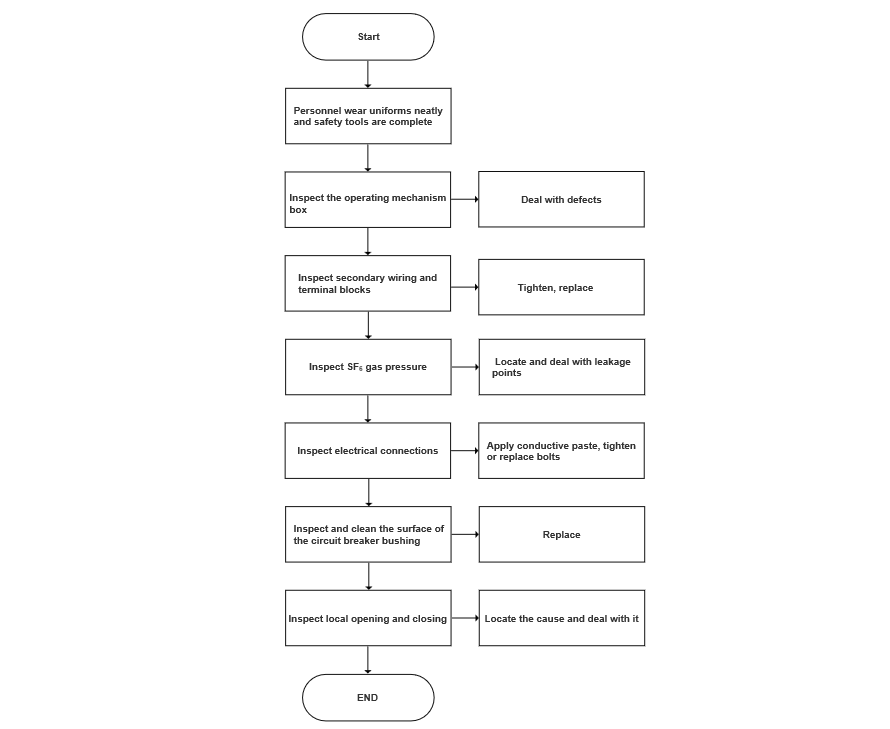

To improve the accuracy and practicality of location technologies, big data and artificial intelligence technologies should be utilized, and machine learning algorithms should be applied to intelligently identify and predict hazard points in substation maintenance sites, providing more accurate location information for maintenance personnel and reducing the risk of accidents. In substation maintenance sites, data from various sensors should be fused to improve the accuracy of location and the accuracy of the model. Applying augmented reality (AR) technology, which integrates virtual information with the real world, can enable maintenance personnel to better understand the equipment structure and thus solve the problem of operational errors. Relevant parties should strengthen the management of on-site maintenance work and strictly follow the operation procedures for maintenance (see Figure 1). At the same time, develop intelligent wearable devices for maintenance personnel to obtain their location information in real-time and monitor them in real-time to ensure safety.

4 Conclusio

In locis conservationis substationum, accurate identificare et locare puncta periculi est clavis ad securitatem locorum conservationis interruptorum SF₆ assecurandam. Per profundam studia de principiis operativis et characteristicis interruptorum SF₆, inventum est quod factores chimici sunt principale punctum periculi non negligibile in eorum processu conservationis. Ut efficaciter tractentur pericula, novae technologiae, conceptus, et methodi debent uti pro preventione ante eventum, praedicens pericula potentia et providens informationem early-warning personis conservationis ad operationes conservationis suaves progressuras.