1. Koyar da Wuraren Winding Don Turancin 10 kV-Class High-Voltage High-Frequency Transformers

1.1 Koyar da Zoned da Partially Potted Ventilated Structure

Anka biyu U-shaped ferrite cores suna gano don samun magnetic core unit ko kuma za su iya samun series/series-parallel core modules. Primary da secondary bobbins suna gano a hagu da yau da kullum na core, ciki har zuwa hagu da ace, tare da core mating plane ta zama boundary layer. Windings of the same type suna gano a fadin daɗi. Litz wire ita ce mai karfi a zaba don wata material don kawo zafi a matsayin high-frequency losses.

High-voltage winding (ko primary) ne ke kula potting da epoxy resin. Anka PTFE sheet ya zama a gano bayan primary da core/secondary don haɓaka insulation daidai. Surface na secondary ya zama mai kafa da insulating paper ko tape.

Daga bambanta ventilation channels (gaps bayan windings da kuma bayan secondary windings a hagu da yau da kullum) da gaps bayan magnetic cores, wannan design ya zama da muhimmanci a kawo zafi a matsayin lokacin da ya kawo tsari da cost, duk da ya yi tasiri ga dielectric strength—wanda yana ba da shiga ≥10 kV isolation applications.

1.2 Modular Design da Grounded Litz Wire Electric Field Shielding

High-voltage da low-voltage winding modules suna potting da kuma za su gano a cikin core unit. Air gaps suna dace bayan modules don taimaka assembly da kuma zafi, da kuma anka modules masu lafiya suke da iya kofin da maɗa saboda faults, wanda yake da muhimmanci a kawo maintainability.

Grounded Litz wire-based electric field shielding layers suna gano a fadin daɗin da kuma waje na high-voltage winding. Wannan yana kasa high-frequency electric field domin yana zama daidai a cikin high-dielectric-strength epoxy-potted region, wanda yana kawo zafi a matsayin partial discharge (PD) risk bila da buƙatun spacing da take amsa da electric field suppression.

Litz wire shielding layer zai iya kasance open-circuited da single-point grounding, wanda yana ba da electric field shaping tare da kawo zafi a matsayin eddy current losses. Ventilation channels suna dace bayan windings da core, wanda yana ba da semi-ventilated cooling da miniaturization daidai.

1.3 Segmented Winding da Electric Field Shaping

Coaxial sleeves da segmentation ribs suna gano a insulating bobbin, wanda yake da iya gano primary da secondary windings a “segment groups.” Wannan yana kawo zafi a matsayin inter-layer voltage gradients da equivalent parasitic capacitance, wanda yana kawo zafi a matsayin conducted EMI da kuma kafin uniformity da voltage distribution.

Number of segments n da layer count suna samun via analytical ko empirical formulas (e.g., n = −15.38·lg k₁ − 18.77, idan k₁ shine minimum value among primary/secondary self-capacitance da mutual capacitance ratios), wanda yake da iya samun optimal trade-off among volume, leakage inductance, da parasitic capacitance—ideal for high-power, high-voltage, high-frequency operation.

1.4 Composite Windings da Integrated Water Cooling

Core an zama da biyu winding zones. A composite winding approach ita ce: first composite winding (e.g., primary) ita ce mai winding daga fadin daɗin zuwa waje da leads reserved; sannan a zone na biyu, second composite winding (e.g., secondary) ita ce mai winding a reverse using the reserved leads. Wannan yana kafin inter-layer gaps da kuma kawo zafi a matsayin residual charge, wanda yana kawo zafi a matsayin high-voltage reliability da lifespan.

Relief slots suna gano a outer core wall don integrate non-contact water-cooling channels, wanda yana kawo zafi a matsayin thermal performance bila da buƙatun mechanical damage a lokacin assembly. Composite insulation suna amfani da PI/PTFE laminates arranged in a stepped configuration don haɓaka adequate creepage distance da high-quality potting fill.

1.5 Novel Winding Techniques da Loss Control Pathways

PDQB (Power Differential Quadrature Bridge) winding technology ita ce mai gano: through optimized winding topology da layout, skin da proximity effects—and thus high-frequency losses—are significantly suppressed. Wannan yana samun coupling efficiency >99.5% a reported cases, da kuma 10 kV isolation capability, controllable leakage inductance, da low distributed capacitance—wanda yana ba da shiga customized 30–400 kW, 4–50 kHz high-voltage high-frequency applications.

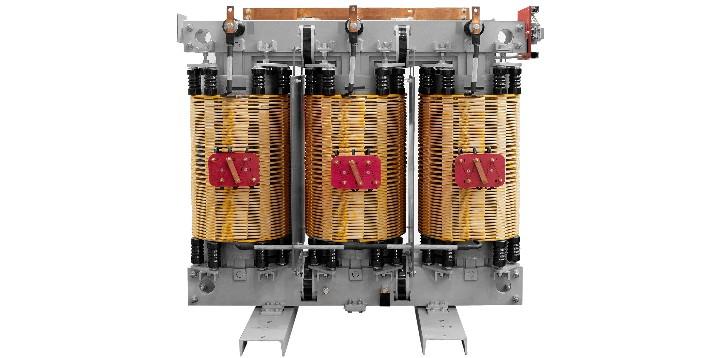

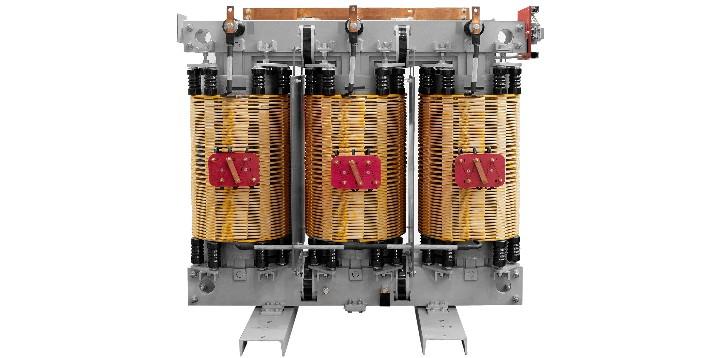

2. Common Winding Structures for 10 kV-Class High-Voltage High-Frequency Transformers

2.1 Basic Winding Configurations da Application Scenarios

Multi-layer cylindrical: Mature manufacturing process; easy to insert inter-layer insulation da cooling channels; suitable for medium-to-high voltage continuous windings.

Multi-segment layered: Multiple axial segments separated by insulating paper rings; effectively reduces inter-layer voltage gradient da field concentration; commonly used in HV windings to mitigate partial discharge.

Continuous (disc-type): Composed of multiple disc sections stacked axially; offers good mechanical strength da thermal performance; suitable for high-capacity/higher-voltage applications.

Double-disc: Two discs per group, connected in series/parallel; ideal for high-current or special-purpose HV windings.

Helical: Single/double/quadruple helix; simple structure; suitable for high-current LV windings or on-load tap-changing windings; limited in turn count.

Aluminium foil cylindrical: One turn per layer using aluminium foil; high space utilization and automation-friendly; suitable for small-to-medium HV windings.

These are standard HV winding structures in power transformers and are often adapted or improved for 10 kV-class high-voltage high-frequency transformers to enhance insulation and thermal performance.

2.2 Typical Winding Layouts and Processes for High-Voltage High-Frequency Applications

Concentric cylindrical (layered) arrangement: HV winding inside, LV outside (or vice versa); multi-layer design with inter-layer insulation to distribute high potential differences; segmented layout may be used to optimize electric field distribution and PD performance.

Segmentation and interleaving: HV winding divided into multiple coils and arranged in staggered/segmented fashion to reduce inter-layer voltage gradient and parasitic capacitance, suppress conducted EMI, and improve voltage uniformity.

Faraday and electrostatic shielding: Copper foil or conductive layers placed between primary/secondary or around windings, grounded at a single point, to reduce common-mode capacitance and coupling noise; shielding must match winding width and avoid sharp edges that could puncture insulation.

Conductor and current density optimization: Litz wire, stranded conductors, or copper foil are preferred for HV/high-current secondaries to suppress skin/proximity effects, reduce AC resistance (Rac) and copper loss; current density (J) and temperature rise are controlled within window and safety regulation limits.

Insulation and creepage design: Use of barriers, end margins, sleeved terminals, and combined inter-layer/inter-winding insulation; creepage distance and clearance are designed according to pollution degree and voltage class; vacuum impregnation/potting may be applied to enhance dielectric strength and thermal conductivity.

These layout and process considerations are closely tied to balancing insulation level, parasitic parameters, and power rating—key to achieving reliable 10 kV isolation in engineering practice.

2.3 Implementation Methods for High-Voltage Secondary Output (Strongly Dependent on Winding Structure)

Voltage multiplier rectification: Multi-stage voltage doubling on the rectifier side significantly reduces voltage stress and parasitic capacitance per winding stage, easing insulation design. However, it is sensitive to load transients/short circuits and prone to surge currents. In practice, no more than two stages are typically used, requiring current-limiting and protection strategies.

Series/parallel combination: The secondary is split into multiple coil packs, which are internally or post-rectifier connected in series/parallel to achieve desired voltage/power. All packs share the same magnetic circuit, facilitating modular design and voltage balancing—ideal for high-power output.

Both methods require integrated design with winding segmentation, shielding, and insulation windows to balance voltage stress, efficiency, EMI, and thermal performance.

2.4 Structural Selection Guidelines (Quick Engineering Reference)

Prioritizing electric field uniformity and PD control: Prefer segmented or continuous (disc-type) HV windings, combined with Faraday shielding, end margins, and barriers; vacuum impregnation/potting recommended when necessary.

Prioritizing high current and low copper loss: Use Litz wire or copper foil for secondary; employ interleaved or sandwich winding internally to minimize leakage inductance and Rac; reinforce outer shielding and insulation.

Prioritizing assembly and maintainability: Adopt modular secondary coil packs with series/parallel connections for easy voltage balancing, testing, and fault isolation; select voltage multiplier rectification (≤2 stages) or series/parallel combination on the rectifier side based on power and transient requirements.