Tibu 2009 hangtod 2010, ang State Grid naghimo og pilot phase sa pagplano sa smart grid, pokusado sa pagbuhat og strong smart grid development plan, pagdulog ug pagbuhat sa mga key technologies, paggama sa equipment, ug pagpahibalo og mga pilot projects sa iba't ibang sektor. Ang panahon gikan 2011 hangtod 2015 nagmarka sa full-scale construction phase, kung diin ang operational control ug interactive service system para sa smart grid naka-form na sa unang panahon, ug napakita ang significant breakthroughs sa key technologies ug equipment, resulta niana ang kanilang extensive application.

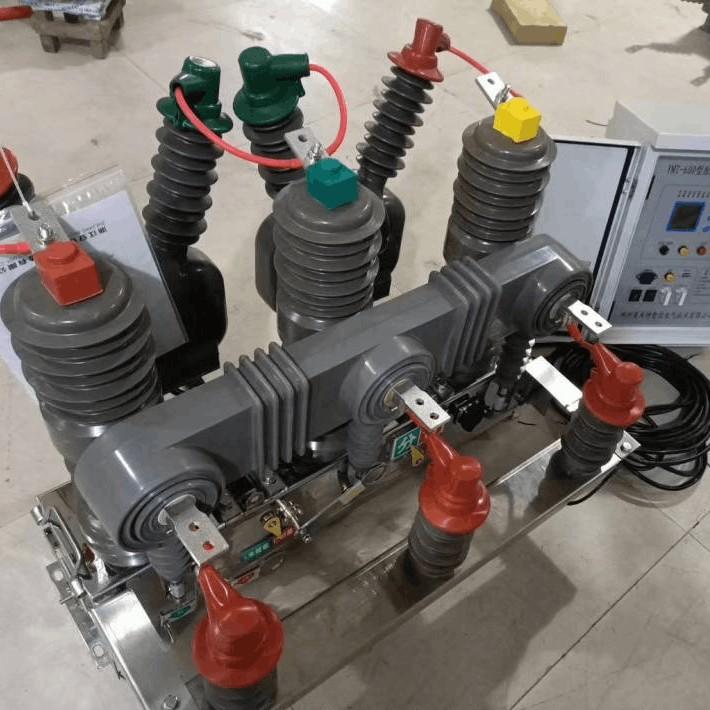

Gikan 2016 hangtod 2020, nagsugyot sa leading and upgrading stage, uban ang unified ug strong smart grid naka-establish na, ug ang technologies ug equipment nakaabot sa international advanced levels. Sa panahon na, ang kakayahan sa grid nga optimize ang resource allocation mapataas pa kaayo. Aron masagop ang development goals sa national smart grid, ang outdoor pole-mounted vacuum circuit breakers nga gisulod sa major power grids gigimana nga mag-achieve og microcomputer-based intelligent protection nga may high sensitivity, mao nga low minimum primary operating current value.

Dili lang niini, ang tanang tatlo ka phases gipagbutangan usab og separate current transformer para sa differential protection, ang outdoor pole-mounted vacuum circuit breakers gigimana nga mag-angay og residual current transformers para sa microcomputer protection aron ma-provide ang precise leakage protection alang sa microcomputer. Ang traditional residual current transformers dako kaayo, berde sa timbang, ug low sa accuracy.

Ang mga factors sama sa limited installation space ug long secondary lead circuits, sila dili makapag-satisfy sa application requirements sa microcomputer protection alang sa outdoor pole-mounted vacuum circuit breakers. Karon, ang tanang outdoor circuit breakers nga makapag-satisfy sa requirements sa national smart grid giproduktso sa foreign-funded enterprises, resulta niana ang mataas nga cost. Aron masagop ang development requirements sa national smart grid, kinahanglan nga mag-develop og outdoor circuit breakers nga makapag-satisfy sa needs sa national smart grid.

Karon, ang primary technical challenge nga kinahanglan namataasan mao ang pag-develop og residual current transformers para sa microcomputer protection nga mahimong gamiton kasama sa mga circuit breakers, satisfying the requirements of small space installation, high-sensitivity leakage microcomputer protection, ug accurate operation, ug unang ma-achieve ang localization sa residual current transformers para sa microcomputer protection.

Applications and Performance Requirements of Residual Current Transformers for Microcomputer Protection

Ang residual current transformer (zero-sequence current transformer) usa ka specialized current transformer nga gihimo aron molihok sa residual current (zero-sequence current). Gigamit kini para sa single-phase grounding protection sa neutral-insulated systems. Ang three-phase conductors musulod sa core window sa transformer parehas, serving as the primary winding of the transformer.

Kon ang sistema molihok normal, ang phasor sum sa three-phase currents zero, ug walay output sa secondary side sa residual current transformer. Kon adunay single-phase grounding fault sa certain line, ang primary current sa residual current transformer madungog sa minimum operating current sa relay o microcomputer protection, triggering the protection device to act.

Owero, it remains inactive. Sa traditional residual current transformers, ang secondary side direkta gi-connect sa relay. Kon ang number of turns sa primary winding sa transformer kay 1, ang number of turns sa secondary winding kaayo ka gamay. Ang minimum primary operating current sa traditional residual current transformers adunay range gikan 2.4A hangtod 10A, ug ang rated primary current sa traditional residual current transformers gikuya sa range gikan 15A hangtod 300A. Aron masagop ang accuracy requirements, ang core cross-sectional area sa transformer gidesign nga relatively large, resulta niana ang dako kaayo, berde sa timbang, ug low sa accuracy, ug gamay sa secondary load.

Kon ang fault current less than 2.4A, ang current output sa traditional transformer dili enough aron mobati ang relay, creating a "dead zone." Therefore, aron makapahimo ang transformer og accurate protection for the microcomputer within a wide range of operating currents without a dead zone, kinahanglan nga mag-design og special residual current transformer nga mahimong gamiton kasama sa microcomputer protection.

Restricted by the installation space of the circuit breaker, the special residual current transformer used with microcomputer protection not only needs to be small in size and light in weight but also requires high-precision secondary output and a large secondary load. Generally, the primary operating current of the transformer is required to be between 0.2A and 10A. If the transformer can ensure good linearity and sensitivity under the condition of a large secondary load output, it can meet the requirements of microcomputer protection and avoid the occurrence of a "dead zone."

Structural Design of Residual Current Transformers for Microcomputer Protection

Selection of Rated Load Parameters of the Transformer

Ang outdoor pole-mounted vacuum circuit breakers karanihan gisulod sa labaw ug layo gikan sa supporting automation devices. Opon sa rili, ang load required by the microcomputer protection itself kaayo ka gamay. Sa panahon sa pagdesign sa residual current transformer, ang rated load mainly considers the load of the secondary lead circuit of the transformer. Since the microcomputer protection device is usually far from the pole-mounted circuit breaker installed outdoors, the rated load of the transformer is generally selected to be relatively large, with the maximum reaching about 200Ω (this load can be determined according to the actual situation of the user).

Selection of the Number of Turns of the Primary and Secondary Windings, Core Shape, and Material

Residual current transformers for microcomputer protection require extremely high sensitivity and must respond promptly and accurately. Sensitivity refers to the ability of the secondary winding of the transformer to respond to leakage current, which can be described as follows: under a certain amount of leakage current, the higher the induced electromotive force of different transformers, the higher their sensitivity.

Sensitivity is related to the number of turns of the primary and secondary windings of the transformer. The more turns in the secondary winding, the higher the sensitivity. The residual current transformer is directly installed on the three-phase primary conductors, and the primary wire is the protected line, with the number of primary turns being 1. Increasing the number of primary turns is not practical.

The induced electromotive force of the secondary winding, U2=4.44f⋅N2⋅μ⋅I1⋅S, where:

I1represents the rated primary current.

S is the cross-sectional area of the iron core.

muis the magnetic permeability.

f is the frequency.

N2 is the number of turns of the secondary winding.

As can be seen from the formula, due to the limitations of the installation position of the transformer, the external dimensions of the transformer cannot be very large. Thus, the cross-sectional area of the iron core of the transformer is relatively small. To enhance the sensitivity of the transformer, it is necessary to either increase the number of turns of the secondary winding or improve the magnetic permeability of the iron core of the transformer.

The rated primary current of outdoor circuit breakers is basically 630A or less. Given the small cross-sectional area of the iron core of the transformer, in order to ensure high sensitivity, through experiments, the number of turns of the secondary winding is generally initially set between 1500 and 2000 turns. The specific number of turns can be determined according to the secondary load and the secondary output voltage of the transformer required by the microcomputer.

Once the cross-sectional area of the iron core, the number of turns, and the secondary load are determined, the parameter that affects the secondary induced electromotive force (i.e., sensitivity) of the

transformer is only related to the magnetic permeability of the iron core. Therefore, determining the material of the iron core used in the transformer is of crucial importance. The linearity and residual characteristics of the transformer mentioned later are also closely related to the material of the iron core.

Analyzing the data in Table 1, both nanocrystalline alloy and Metglas have the highest magnetic permeability. However, Metglas has a relatively low saturation induction intensity and is also expensive in the market. Considering comprehensively, we preferentially select nanocrystalline alloy as the material.The sensitivity of the transformer is not only directly proportional to the magnetic permeability of the iron core but also has a direct relationship with the shape of the iron core and the length of the magnetic circuit.

Generally, apart from using high-permeability materials for the iron core to enhance the transformer's sensitivity, we also try to shorten the magnetic circuit of the iron core as much as possible to reduce magnetic leakage and ensure the utilization rate of the iron core. Under normal circumstances, a circular iron core has the shortest magnetic circuit. However, since the three-phase primary conductors of the outdoor pole-mounted circuit breaker are arranged side-by-side in a line, when space permits, the iron core should be designed as an ellipse based on the arrangement shape and spacing of the three-phase primary conductors of the circuit breaker. The shape of the transformer and its positional relationship with the primary conductor are shown in Figure 1.

The residual current transformer should be able to respond quickly to abnormal leakage states in the circuit and provide an actionable voltage signal to the microcomputer protection device. The transformer must have good linearity to truly reflect the operating status of the circuit. Linearity refers to the ratio of the change in the input current to the change in the output voltage of the transformer being a constant, as shown in Figure 2.

transformer is only related to the magnetic permeability of the iron core. Therefore, determining the material of the iron core used in the transformer is of crucial importance. The linearity and residual characteristics of the transformer mentioned later are also closely related to the material of the iron core.

In the circuit, the minimum primary operating current of the circuit breaker is generally required to be below 10A. Therefore, it is generally required that when the primary current of the transformer is below 10A, the better the ratio of the change in the input current to the change in the output voltage of the transformer is linear, the more it can meet the usage requirements. The linearity requirement of the transformer needs repeated testing.

Under the condition of a certain magnetic permeability of the iron core and secondary load, the voltage output of the transformer is ensured to change linearly by adjusting the cross-sectional area of the iron core or the number of secondary turns. However, in actual circuits, there are often other factors that affect the transformer from providing an accurate voltage signal to the microcomputer protection device.

When the transformer is installed, it needs to be sleeved on the three-phase conductors arranged side-by-side in a line. When the primary conductor passes the rated current, the residual current transformer will be interfered by the magnetic fields generated by the three-phase currents simultaneously, and the local magnetic flux density of the iron core will increase. If the local part of the iron core is oversaturated, the linearity of the transformer will deteriorate, seriously affecting the magnitude of the secondary output voltage. As a result, the microcomputer protection may malfunction or fail to operate.

During actual operation, after the residual current transformer is impacted by a large-scale ground-fault current, and after the protection action is completed and power supply is restored for continued operation, if the technical parameters of the transformer cannot return to the state before the impact, that is, there is residual magnetism in the iron core of the transformer, it will seriously affect the accurate action of the leakage protector next time.

When designing this residual current transformer, the following points should be noted:

The iron core should preferably be made of materials with high saturation magnetic flux density and high magnetic permeability. Or, when space permits, the cross-sectional area of the iron core should be increased as much as possible, and the length of the magnetic circuit should be shortened to prevent the local part of the iron core from being saturated prematurely.

The secondary winding should be evenly wound on the iron core. At the same time, a shielding cover should be added outside the iron core or the winding. The shielding cover is usually made of non-magnetic materials to shield the interference of external magnetic fields or magnetic fields from adjacent phases on the residual current transformer.

During the design process, the residual characteristics of the transformer should be controlled with emphasis. According to operating experience, it is generally required that when the primary current within the range of 0 to greater than or equal to the rated primary current is simultaneously applied to the three phases, and the transformer is connected to the specified load, the measured residual voltage on the secondary side should not exceed 15mV, which can meet the usage requirements. (The residual voltage value can also be adjusted according to the special requirements of customers).

The iron core is preferably made of nanocrystalline alloy with high magnetic permeability and low residual magnetism. This material has good overload characteristics and can easily return to the initial magnetic state under over-current impact. The residual voltage of the transformer can be controlled and detected not to be too large by simulating the passage of various ground-fault currents on the primary side. However, the residual voltage of the transformer generally increases with the increase of the rated primary current. But after the iron core reaches magnetic saturation, the residual voltage on the secondary side of the transformer will increase sharply.

When designing the transformer, in order to minimize the influence of the primary current on the residual voltage value of the residual current transformer, when choosing nanocrystalline alloy with high magnetic permeability and low residual magnetism to make the iron core, measures such as appropriately increasing the cross-sectional area of the iron core or reducing the internal resistance of the secondary winding can be taken jointly to reduce the residual voltage of the residual current transformer.