Lêên 2009 deravê 2010, Cihazên Elektrîk û Şebeka wek faza pilota pêşkeftina şebeka zekî taybetand, bi tevgeha peyvên xilasê plana şebeka zekî taybet dibe, biguherîne û bidevekirine teknolojî yên herêmî yên keyî, ji bo cihazên destpêka çêrçem u operasyonên projeyên pilota li ser piramên yên din. Di dema 2011 deravê 2015 de, vê dema ya qada tama pêşkeftinê hatiye, di navbera ku sistem ê kontrolê operasyonî û servisên interaktîf li ser şebeka zekî taybet dibû, û guhertoyên keyî yên teknolojî û cihazan piştguh werin kirin û sererast bûn bi kar.

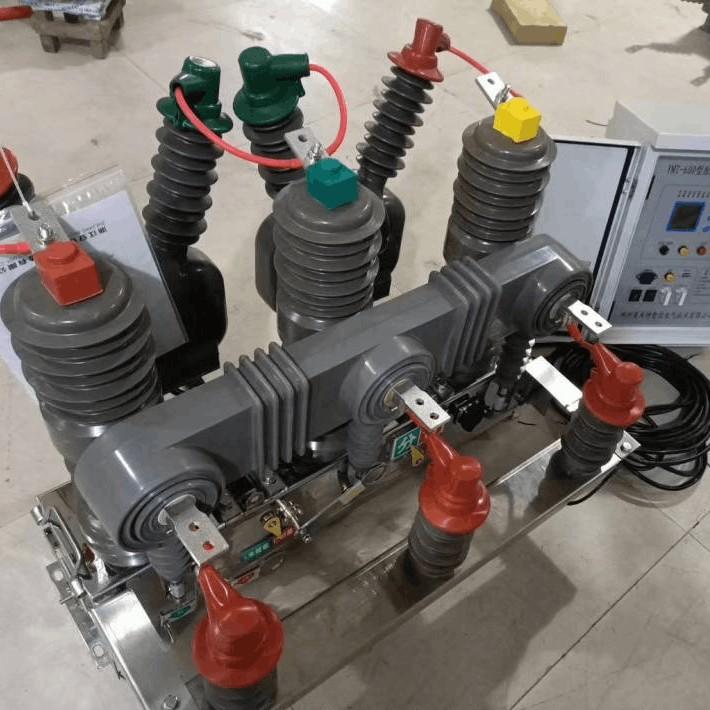

Di dema 2016 deravê 2020 de, vê dema ya rêxistin û nûvekirin hatiye, bi şebeka zekî taybet û yekbûyî tama têkildar dibû, û teknolojî û cihazan berdewam di standardên herêmî yên keyî de werin. Di dema wê de, têkiliya şebeka da jê bikar bû dike hêz dan. Ji bo parzûna hedefên pêşkeftina şebeka zekî ya welat, kesên kurtora vakumî yên ser sütûnê li ser şebeka elektrîkê ya raya wan dê bibin paqij kirin bi himaya zekî yên komputerî yên bi hesabdarîya mezin, ya ku ew dê min bîcûk biryariyên amadeya operasyon a primîtir bêt.

Nimûceyan, ji bo her faza ya tre, divê bi transformatôrên cure yên taybet be, ji bo himaya diferansiyel, kesên kurtora vakumî yên ser sütûnê dê bibin paqij kirin bi transformatôrên cureya qalib bi himaya komputerî yên bi hesabdarîya mezin, bi cema himaya keçeyan komputerê. Transformatôrên cureya qalib yên girtilla mezin ne, ger û çêker, û çetirina hevdik nîşana.

Li ser etîrovanên têkilîya barkirina qalib û lêngîna tirşînan ya deken, dê nikare parzûna hedefên himaya komputerî yên kesên kurtora vakumî yên ser sütûnê. Li dema niha, hemû kesên kurtora ser sütûnê yên ku dê parzûna hedefên şebeka zekî ya welat bibin, ji aliyê wan dê çêkirin, ev ê bi maliyetê mezin re bide. Ji bo parzûna hedefên pêşkeftina şebeka zekî ya welat, dê bibin çêkirin kesên kurtora ser sütûnê yên ku parzûna hedefên şebeka zekî ya welat bibin.

Di dema niha, pirsa teknîkî yên herêmî yên divê biguheztin ewa çêkirina transformatôrên cureya qalib bi himaya komputerî yên bi hesabdarîya mezin, ku bi kesên kurtora vacumî yên ser sütûnê bibin paqij kirin, li ser parzûna barkirina ser têkilîya keçik, himaya keçeyan komputerî yên bi hesabdarîya mezin, û operasyonên sererast, û yekemîn çêkirina lokalizasyonê transformatôrên cureya qalib bi himaya komputerî yên bi hesabdarîya mezin.

Vendiya û Parzûnya Himayê transformatôrên Cureya Qalib Bi Himaya Komputerî

Transformatôrê cureya qalib (transformatôrê cureya sıfırxan) transformatôrê cureya xusûlî ye ku ji bo transformasyona cureya qalib (cureya sıfırxan) tayin kirin. Ev bi himaya încitkirina yek parreya li ser sisteman da ku neutraliyan înserîn. Trî parreya li ser perdesa transformatoran herêmî dibin geşe, wek primîtir transformatoran.

Ji dema ku sistema bi rastî şev bike, phasor sum trî cureyan parreyan sifir e, û tiştên deken transformatoran cureya qalib bêt. Ji dema ku încitkirina yek parreya li ser raya hilbijêre, cureya primîtir transformatoran cureya qalib dike werda ji minimum operating current of the relay or microcomputer protection, triggering the protection device to act.

Di transformatoran cureya qalibên girtilla, tiştên deken bi relay têkildar in. Ji ber ku herêmî primîtir transformatoran çendîjiyên 1 e, çendîjiyên tiştên deken bi lez e. Minimum cureya primîtir transformatoran cureya qalib yên girtilla zêdetir di nav 2.4A deravê 10A de ne, û cureya primîtir transformatoran cureya qalib yên girtilla zêdetir di nav 15A deravê 300A de deweze. Ji bo parzûna standartên sererast, çimkaniya transformatoran bi lez taybetandin, ev ê li ser mezûna mezin, ger, çêker, û tiştên deken keçik.

Ji dema ku cureya încitkirina li ser 2.4A, cureya tiştên deken transformatoran girtilla nikare bi aktivekirina relay, ku "dead zone" bide. Ji ber vê yekê, ji bo parzûna transformatoran da ku himaya sererast komputerê bibin di nav cureyên operasyonî yên çapraz de bêt, dê bibin çêkirin transformatoran cureya qalib yên bi himaya komputerî yên bi hesabdarîya mezin.

Li ser parzûna têkilîya kesên kurtora, transformatoran cureya qalib bi himaya komputerî yên bi hesabdarîya mezin divê wekî ku mezûna keçik, ger, û çêker bibin, û bi output tiştên deken bi sererastî û load tiştên deken mezin. Genel, cureya primîtir transformatoran bi hesabdarîya mezin di nav 0.2A deravê 10A de deweze. Ji dema ku transformatoran bi output load tiştên deken mezin dikare parzûna linearîtiya û hesabdarîya mezin, ev ê parzûna himaya komputerî bibin û "dead zone" bêt.

Rêzikirina Sernasa Transformatoran Cureya Qalib Bi Himaya Komputerî

Hilbijartin Parametrên Load Rated Transformatoran

Kesên kurtora vakumî yên ser sütûnê genel di derbar de çêkirin û derê li ser cihazên automatîkê yên destpêka. Lêmagar, load required by the microcomputer protection itself is very low. When designing the residual current transformer, the rated load mainly considers the load of the secondary lead circuit of the transformer. Since the microcomputer protection device is usually far from the pole - mounted circuit breaker installed outdoors, the rated load of the transformer is generally selected to be relatively large, with the maximum reaching about 200Ω (this load can be determined according to the actual situation of the user).

Hilbijartin Çendîjiyên Primîtir û Tiştên Deken, Şekla û Mala Perdan

Transformatoran cureya qalib bi himaya komputerî yên bi hesabdarîya mezin bi hesabdarîya mezin dibin tayin kirin û dê bi sererastî û çêker bivînin. Hesabdarîya wek kemciyeya tiştên deken transformatoran da ki dike vê bi cureya keçeyan, ku ev dê wek hev bijarte: bi cureya keçeyan, emsaliyê elektromotiv tiştên deken transformatoran yên din bi hesabdarîya mezin, bi hesabdarîya mezin.

Hesabdarîya li ser çendîjiyên primîtir û tiştên deken transformatoran. Çendîjiyên tiştên deken zêde, hesabdarîya zêde. Transformatoran cureya qalib bi kesên primîtir yên trî parreyan paqij kirin, û kable primîtir parrez a, bi çendîjiyên primîtir 1. Zêdetir çendîjiyên primîtir nikanîn.

Emsaliyê elektromotiv tiştên deken, U2=4.44f⋅N2⋅μ⋅I1⋅S, ku:

I1represents the rated primary current.

S is the cross-sectional area of the iron core.

muis the magnetic permeability.

f is the frequency.

N2 is the number of turns of the secondary winding.

As can be seen from the formula, due to the limitations of the installation position of the transformer, the external dimensions of the transformer cannot be very large. Thus, the cross-sectional area of the iron core of the transformer is relatively small. To enhance the sensitivity of the transformer, it is necessary to either increase the number of turns of the secondary winding or improve the magnetic permeability of the iron core of the transformer.

The rated primary current of outdoor circuit breakers is basically 630A or less. Given the small cross-sectional area of the iron core of the transformer, in order to ensure high sensitivity, through experiments, the number of turns of the secondary winding is generally initially set between 1500 and 2000 turns. The specific number of turns can be determined according to the secondary load and the secondary output voltage of the transformer required by the microcomputer.

Once the cross-sectional area of the iron core, the number of turns, and the secondary load are determined, the parameter that affects the secondary induced electromotive force (i.e., sensitivity) of the

transformer is only related to the magnetic permeability of the iron core. Therefore, determining the material of the iron core used in the transformer is of crucial importance. The linearity and residual characteristics of the transformer mentioned later are also closely related to the material of the iron core.

Analyzing the data in Table 1, both nanocrystalline alloy and Metglas have the highest magnetic permeability. However, Metglas has a relatively low saturation induction intensity and is also expensive in the market. Considering comprehensively, we preferentially select nanocrystalline alloy as the material.The sensitivity of the transformer is not only directly proportional to the magnetic permeability of the iron core but also has a direct relationship with the shape of the iron core and the length of the magnetic circuit.

Generally, apart from using high - permeability materials for the iron core to enhance the transformer's sensitivity, we also try to shorten the magnetic circuit of the iron core as much as possible to reduce magnetic leakage and ensure the utilization rate of the iron core. Under normal circumstances, a circular iron core has the shortest magnetic circuit. However, since the three - phase primary conductors of the outdoor pole - mounted circuit breaker are arranged side - by - side in a line, when space permits, the iron core should be designed as an ellipse based on the arrangement shape and spacing of the three - phase primary conductors of the circuit breaker. The shape of the transformer and its positional relationship with the primary conductor are shown in Figure 1.

The residual current transformer should be able to respond quickly to abnormal leakage states in the circuit and provide an actionable voltage signal to the microcomputer protection device. The transformer must have good linearity to truly reflect the operating status of the circuit. Linearity refers to the ratio of the change in the input current to the change in the output voltage of the transformer being a constant, as shown in Figure 2.

transformer is only related to the magnetic permeability of the iron core. Therefore, determining the material of the iron core used in the transformer is of crucial importance. The linearity and residual characteristics of the transformer mentioned later are also closely related to the material of the iron core.

In the circuit, the minimum primary operating current of the circuit breaker is generally required to be below 10A. Therefore, it is generally required that when the primary current of the transformer is below 10A, the better the ratio of the change in the input current to the change in the output voltage of the transformer is linear, the more it can meet the usage requirements. The linearity requirement of the transformer needs repeated testing.

Under the condition of a certain magnetic permeability of the iron core and secondary load, the voltage output of the transformer is ensured to change linearly by adjusting the cross - sectional area of the iron core or the number of secondary turns. However, in actual circuits, there are often other factors that affect the transformer from providing an accurate voltage signal to the microcomputer protection device.

When the transformer is installed, it needs to be sleeved on the three - phase conductors arranged side - by - side in a line. When the primary conductor passes the rated current, the residual current transformer will be interfered by the magnetic fields generated by the three - phase currents simultaneously, and the local magnetic flux density of the iron core will increase. If the local part of the iron core is oversaturated, the linearity of the transformer will deteriorate, seriously affecting the magnitude of the secondary output voltage. As a result, the microcomputer protection may malfunction or fail to operate.

During actual operation, after the residual current transformer is impacted by a large - scale ground - fault current, and after the protection action is completed and power supply is restored for continued operation, if the technical parameters of the transformer cannot return to the state before the impact, that is, there is residual magnetism in the iron core of the transformer, it will seriously affect the accurate action of the leakage protector next time.

When designing this residual current transformer, the following points should be noted:

The iron core should preferably be made of materials with high saturation magnetic flux density and high magnetic permeability. Or, when space permits, the cross - sectional area of the iron core should be increased as much as possible, and the length of the magnetic circuit should be shortened to prevent the local part of the iron core from being saturated prematurely.

The secondary winding should be evenly wound on the iron core. At the same time, a shielding cover should be added outside the iron core or the winding. The shielding cover is usually made of non - magnetic materials to shield the interference of external magnetic fields or magnetic fields from adjacent phases on the residual current transformer.

During the design process, the residual characteristics of the transformer should be controlled with emphasis. According to operating experience, it is generally required that when the primary current within the range of 0 to greater than or equal to the rated primary current is simultaneously applied to the three phases, and the transformer is connected to the specified load, the measured residual voltage on the secondary side should not exceed 15mV, which can meet the usage requirements. (The residual voltage value can also be adjusted according to the special requirements of customers).

The iron core is preferably made of nanocrystalline alloy with high magnetic permeability and low residual magnetism. This material has good overload characteristics and can easily return to the initial magnetic state under over - current impact. The residual voltage of the transformer can be controlled and detected not to be too large by simulating the passage of various ground - fault currents on the primary side. However, the residual voltage of the transformer generally increases with the increase of the rated primary current. But after the iron core reaches magnetic saturation, the residual voltage on the secondary side of the transformer will increase sharply.

When designing the transformer, in order to minimize the influence of the primary current on the residual voltage value of the residual current transformer, when choosing nanocrystalline alloy with high magnetic permeability and low residual magnetism to make the iron core, measures such as appropriately increasing the cross - sectional area of the iron core or reducing the internal resistance of the secondary winding can be taken jointly to reduce the residual voltage of the residual current transformer.