In modernis systematibus electricitatis, interruptores alta tensio clavem ludunt. Hi securitatem isolationis apparatorum vel lineae electricae durante manutenctione et fiduciam in operatione normali garantiant. Defectus mechanicus interruptorum alta tensio, sicut contactus infirmus, deficere actuatoris, vel fessura componentium structuralium, graviter stabilitatem et securitatem totius systematis electrici possunt impingere.Methodi traditionales detectionis defectus in regulari manutenctione et inspectionibus manualibus constant.

Hae methodi non solum tempus consumunt et laboris multum requirunt, sed etiam periculum praetermittere optimi tempus interventionis in initiis defectus habent. Cum progressu technologico continuo, technicae diagnosticarum intelligentiae emergunt, quae solutionem efficientiorem et accuratiorem pro monitoring defectus et diagnosis offerunt.

Methodi diagnosticarum intelligentiae, sicut collectio datarum sensor-based, processus et analysis datarum, analysis signali currentis motoris drive, et mensura strain resistivus, comportamenta anormalia interruptorum alta tensio in real-time identificare, defectus potentialis praedire, et decisiones manutenctionis dirigere possunt. Hoc significantissime fiduciam et efficaciam operationalis systematis electrici augit.

1 Communes Typi Defectuum Mechanicorum in Interruptoribus Alta Tensio

1.1 Defectus Contactus Infirmi

Contactus infirmus principaliter ab oxidatione superficiei contactus, pressione contactus insufficiens, aut area contactus diminuta causatur. Huiusmodi defectus solent ad augmentum resistentiae, affectantem conductivitatem interruptoris alta tensio, ducere. Propter contactum infirmum, plus calor generatur quando currentis per puncta contactus transit. Hoc non solum usuram puncta contactus accelerat, sed etiam problemata graviora effectus thermicus, sicut defectus welding aut overheat localis, causat.

Contactus infirmus potest etiam instabilitatem tensionis, affectantem qualitatem tensionis systematis electrici, causare. Problemata persistens contactus infirmi facile ad declinum performance insulationis interruptoris alta tensio, incrementumque periculi operativi systematis, ducere possunt. Itaque, prompta detectio et recta tractatio problematum contactus infirmi in interruptoribus alta tensio essenti sunt ad securitatem et stabilitatem operationis systematis electrici garantendam.

1.2 Defectus Actuatoris

Defectus actuatoris est quaestio significans perficientiam interruptorum alta tensio affectans. Huiusmodi defectus comprehendunt usuram mechanicam, lubricationem insufficiens, et senectutem componentium. Usura mechanicam generaliter ad damnum componentium motricium, sicut cymbalorum et rotarum, sub longo repetitivo operatione referunt. Lubricatio insufficiens frictionem auget, velocitatem usurae partium mechanicarum acendens et efficaciam operationalis actuatoris minuens.

Cum tempore servitii crescente, diversa componentia actuatoris proprietates suas originalis amittunt aut deformantur propter senescens materiale, ita perficientiam et securitatem totius operationis interruptoris alta tensio affectantes. Si haec defectus non tempestive deteguntur et tractantur, ad operationem incorrectam interruptoris alta tensio, et in casibus severis, ad periculum stabilis operationis totius systematis electrici, ducere possunt.

1.3 Fessura et Damnum Componentium Structuralium

Fessura et damnum componentium structuralium solent sub influentia stress mechanicus longi temporis et factorum environmentalium occurrere. Componentia structurales, sicut columnae, bacula coniunctiva, et cymbala, gradualiter fatigant materialiter sub actione stress mechanicus longi temporis, praesertim durante frequenti apertura et clausura. Tempore, hae stress intra materiale accumulantur, ad generationem et propagationem microcracks ducentes, qui tandem in significantia damage mechanicus evolvuntur.

Praeterea, factorum environmentalium, sicut mutationes temperature, humiditas, et ambientes corrosivi, fatigam componentium structuralium accelerare, affectantes proprietates mechanicorum et vitam utilem eorum, possunt. Fessura et damnum componentium structuralium non solum functionem normalem interruptorum alta tensio, sed etiam stabilitatem totius systematis electrici, periclitantur.

2 Methodi Diagnosticarum Intelligentiae pro Defectibus Mechanicis Interruptorum Alta Tensio

2.1 Sensoria et Collectio Datarum

Sensoria in diagnostica mechanicis defectuum interruptorum alta tensio partem vitalis ludunt. Principale officium earum est captare parametras physicos key durante operatione apparatorum, sicut vibrationem, sonum, temperaturam, et currentem. Ad interruptores alta tensio, principale sensoria utuntur includunt vibration sensors, acoustic emission sensors, et current and voltage sensors.

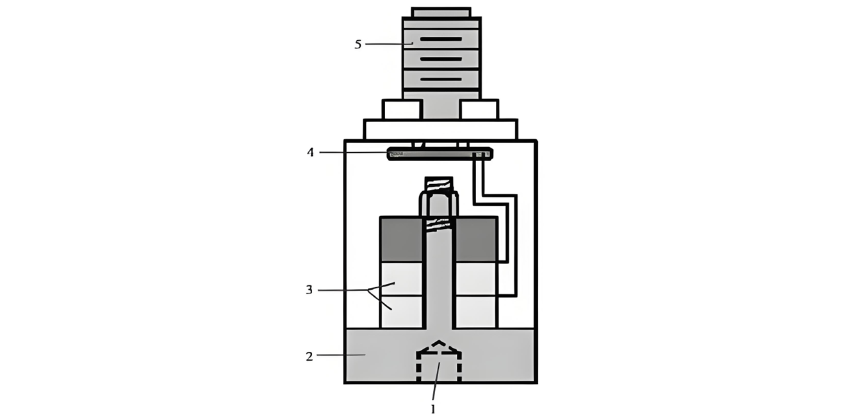

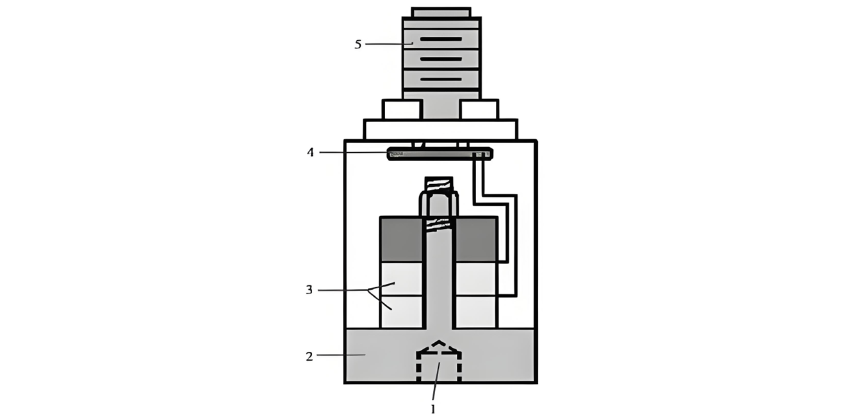

Sensory vibrationis ad detectandum vibrationem frequenciam et amplitudinem generatam a componentibus apparatorum durante operatione utuntur. Per analysin datarum vibrationis, possibile est praedire usuram apparatorum et defectus existentes. Generaliter, frequencia vibrationis interruptoris alta tensio normaliter operantis debet in range standard (saepe, threshold ponitur ultra decem times frequenciam operationis). Si hoc range excedit, indicium anomalitatis esse potest. Schematicum diagramma vibration sensoris in Figura 1 ostenditur.

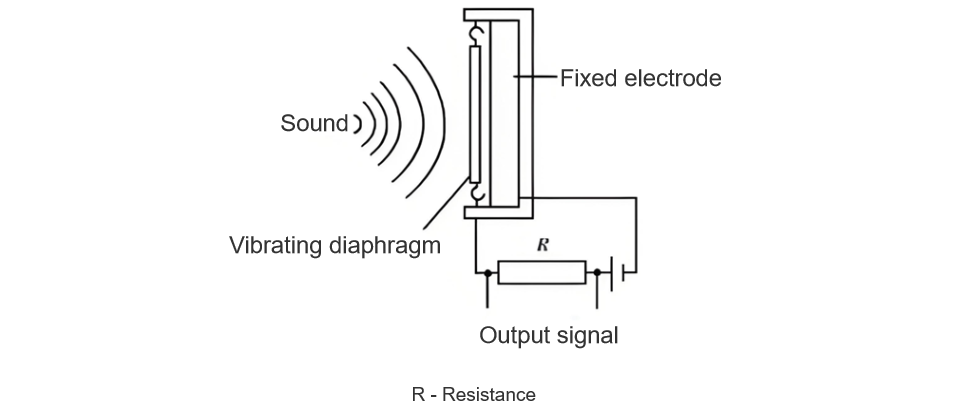

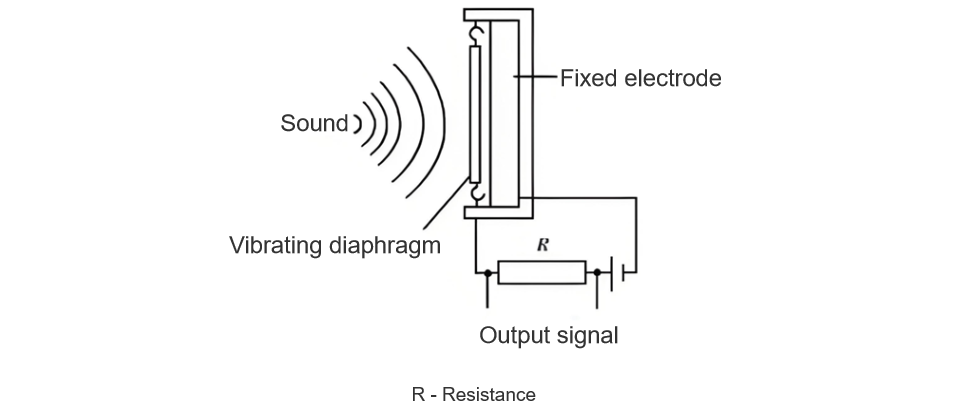

Acoustic emission sensors capiunt sonum basatum in high-frequency sound waves generatis a defectibus materialis aut structuralis. Durante operatione interruptoris alta tensio, si sint fissurae aut laxitudo, acoustic emission sensors posse prompte capere fluctuationes soni causatas his minor deformationibus aut rupturis. Principium acoustic emission sensoris in Figura 2 ostenditur.

Current and voltage sensors principale officium habent monitorare mutationes in currente et voltage levels transiens interruptorem alta tensio. Lecturas abnormalis currentis aut voltage ex his sensoribus solent indicare problemata cum connectionibus electricis aut functionibus.

1 - Foramina bolta; 2 - Fundamentum; 3 - Crystalla piezoelectrica; 4 - Amplificator electronicus; 5 - Connector terminalis

In re collectio datarum, principale officium est convertendi data collecta a sensoribus in informationem utilisabilem. Systema collectio datarum solitum consistit in tribus aspectibus sequentibus:

Data Acquisition Unit (DAU). DAU principale officium habet recipere signales analogos a variis sensoribus et convertendo hos signales analogos in digitales. DAU certificat ut data collecta ad ratem convenientem (saepe cum tempore responsionis in millisecond range) et cum quadam accurate (saepe attingente 16 bits aut superiore) ad satisfaciendum requisitionibus subsequentibus processus.

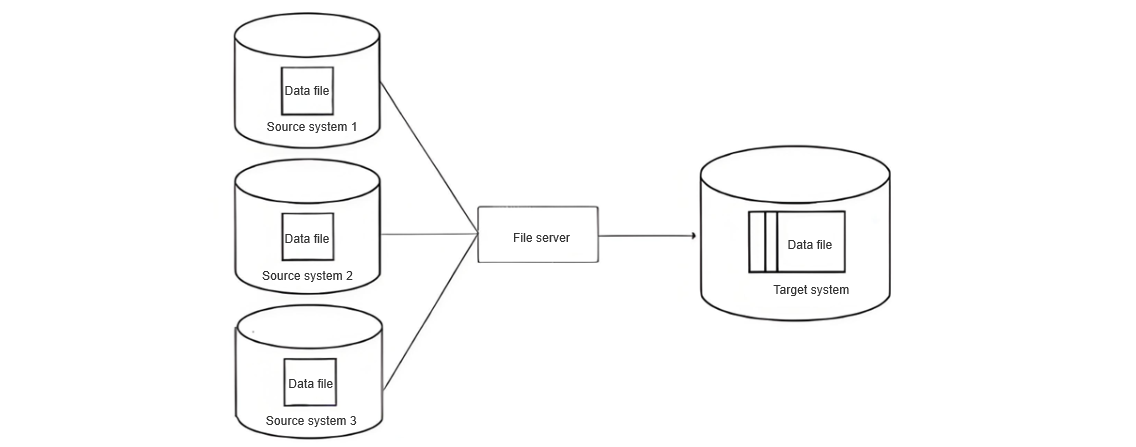

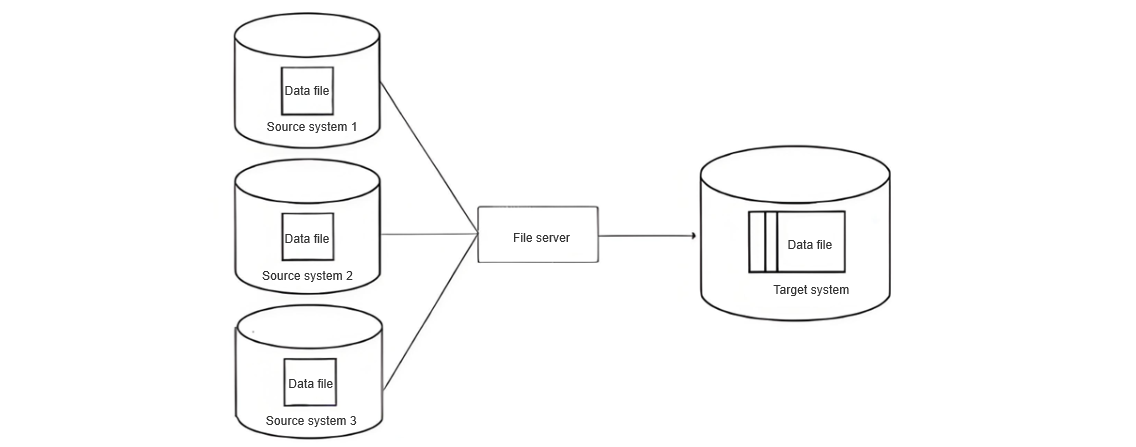

Transmissio Datae. Data collecta transmittitur ad serverum central processing per stabilem network communication. Hoc step saepe in communi dependet technologiae communicationis wireless, sicut Wi-Fi aut 4G/5G networks, quae possunt celeritatem et efficaciam transmissio datae augere et complexitatem et costum cabling reducere.

Storage et Management Datae. Post successful transmissionem datae, necessarium est efficacem storage et management datae in servero aut in nube facere ad database completioris establishment. Storage datae supportum accessus celeris et magnae scalae datae analysis oportet, itaque databases high-performance requiruntur ad data query et retrieval. Schematicum diagramma database establishment in Figura 3 ostenditur.

Per sensoria et collectio datarum, monitoratio real-time status operationis et indicatorum performance apparatorum potest prompte detectare defectus potentialis, praebens fundamentum necessarium pro diagnosi intelligenti defectuum mechanicorum, praeventando occurrence defectus et securitatem operationis systematis electrici garantiendo.

2.2 Processus et Analysis Datae

2.2.1 Analysis Time-Frequency

Analysis time-frequency est methodus efficientis processus datae, quae transformare signales a domino temporis ad dominum frequency, ita revelans internas characteristica et mutationes trend signales. Methodi communiter usitatae analysis time-frequency includunt Short-Time Fourier Transform (STFT), wavelet transform, et Wigner-Ville distribution.

STFT performat transformationem Fourier local in signal per fenestram fixae magnitudinis, id aptum faciens ad analysin signales cuius frequences lentissime mutantur in tempore. Exempli gratia, quando monitoratur actuator, STFT potest efficaciter identificare drifts frequents causatos a frictione aut structurali laxitudo.

Wavelet transform potest fenestras variabilis magnitudinis praebere, id aptum faciens ad processus signales cum characteribus mutationis instantanea. Per adjustmentem functionis mother wavelet, identificationem exactam vibrationum abnormalium in specifico band frequency potest assequi.

Ut instrumentum advanced time-frequency analysis, Wigner-Ville distribution, licet cross-term interference generet, offerre potest analysis finiorem temporis et frequency signali, id particulariter aptum faciens ad detectionem defectus in complexis ambientibus signali.

In applicationibus practicis, combinando methodos supra dictos analysis time-frequency cum datis originalibus mensuratis a sensoribus, accurate monitorari et diagnosticari conditiones operationis interruptorum alta tensio possunt. Sub conditionibus normalibus operationis, range frequency interruptorum alta tensio generaliter mantineri potest inter 50-100 Hz; dum in casibus contactus infirmi, fessurae componentium structuralium, et defectus damni, frequency interruptorum alta tensio significanter mutabitur aut novae componentes frequency apparebunt.

2.2.2 Machine Learning et Pattern Recognition

Primo, post collectio datae, per stage pre-processing sicut elimination noise et extraction feature, data input preparatur pro algorithmis machine-learning. Data includit componentes frequency signali vibrationis, characteres waveform parameterum electricorum, etc.

Secundo, algoritmos supervised learning sicut Support Vector Machines (SVM) et Random Forest uti possunt ad classificandum data obtinenda a sensoribus. Hi algoritmi trainantur ut differentes types fault patterns identificant, sicut unica signa signal causa poor contact aut defectus actuatoris. In applicationibus practicis, mille data points input in algoritmos pro training, ut accurate identificare possint status defectus.

Denique, techniques deep-learning, praesertim Convolutional Neural Networks (CNN), uti possunt ad recognitionem pattern complexa. Techniques deep-learning potest extract useful information from large-scale multi-dimensional data through their automatic feature-learning capabilities, improving the accuracy of diagnosis. Exempli gratia, in specifico modello CNN, several convolutional layers et pooling layers designantur ad processing collected video image data to identify typical fault features.

2.3 Analysis Signali Currentis Motoris Drive

Monitoratio real-time et analysis signali currentis generati durante operationem motoris drive potest praedire et diagnosticare defectus mechanicorum potentialis. Analysis signali currentis motoris drive generaliter focus habet in detectione parvarum mutationum in signali currentis ad determinandum anomalies aut usura componentium mechanicorum.

Si sint defectus in componentibus mechanicis interruptoris alta tensio, sicut damnum cymbalorum, usura rotarum, aut imbalance, indirecte affectabunt onus motoris drive, ita causantes specificas variationes in suo signali currentis.

In re analysis datae, sensor currentis utitur ad recording waveform currentis sub conditionibus normalibus operationis circa coil power-supply motoris. Frequencia sampling generaliter supra 20 kHz ponitur ad capturing detailed information and ensuring high-precision data parsing.

In re extraction feature, Fourier transform utitur ad converting time-domain current signal into a frequency-domain signal, which helps to identify harmonic anomalies caused by mechanical failures. Exempli gratia, under fault-free conditions, the drive motor current signal mainly contains the fundamental frequency and its integer-multiple harmonics. If there is a fault, such as bearing failure, new peaks will be observed at specific frequencies.

In subsequent data processing, statistical methods can be used to analyze the extracted frequencies. For example, calculate the amplitude changes of each frequency point, and train a fault-identification model using a machine-learning algorithm. The input of the algorithm is the frequency characteristics of the current signal, and the output is the prediction of the fault type and severity.

By analyzing the current signal, the deviation of the current signal can be quantified. For example, in the initial stage of bearing failure, the amplitude of the current harmonic can increase by 5-10 A, while in the case of gear wear, the amplitude of the relevant harmonic can increase by 3-8 A. This enables the maintenance team to accurately determine the equipment status and plan maintenance work, thereby avoiding large-scale power outages caused by failures.

2.4 Application of Resistance Strain Measurement Technology

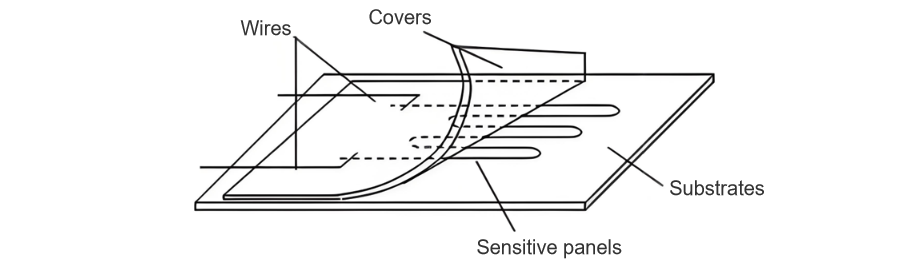

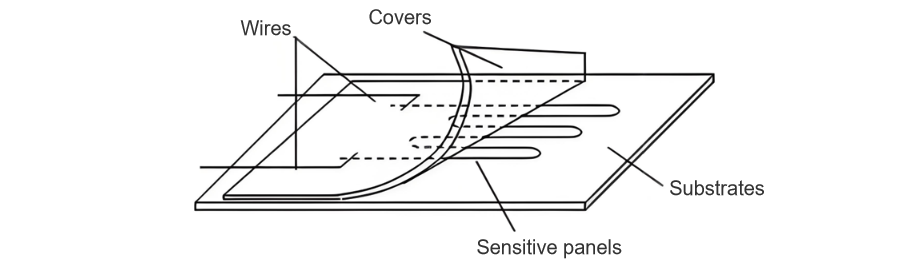

Resistance strain measurement technology can be used to monitor the structural stress and deformation of high-voltage disconnect switches. This technology is realized through resistance strain gauges installed on key components.

A resistance strain gauge is a sensor that converts mechanical deformation into an electrical signal. Its working principle is based on the property that the resistance value of a metal conductor changes when it is deformed under force. A schematic diagram of the resistance strain gauge structure is shown in Figure 4.

When selecting resistance strain gauges, high-precision metal foil resistance strain gauges can be chosen. These gauges have good linear characteristics and stable temperature response, and are usually installed at the positions where the high-voltage disconnect switch is most stressed and most prone to fatigue, such as the contact arm and the rotating shaft.

After the selection and installation of the resistance strain gauges are completed, the gauges are required to be connected to the data collection system through wires. The data collection system is responsible for recording the resistance changes transmitted from the resistance strain gauges and converting them into voltage signals for reading. The data collection system needs to have a high-speed sampling rate and high resolution to ensure that it can capture the rapid strain changes generated during the operation of the high-voltage disconnect switch. The sampling rate used is usually in the kilohertz range, and the resolution reaches the millivolt level.

Appropriate software is used to process the collected voltage signals. First, filtering is performed to remove possible noise interference, and then mathematical algorithms such as the Fast Fourier Transform (FFT) are used to analyze the signal spectrum and extract strain data. The strain data can be converted to obtain the actual stress state of the corresponding component.

The measured strain data is compared with the pre-established stress model of the high-voltage disconnect switch to evaluate the current health status of the equipment. When the monitored stress exceeds the design threshold, the data collection system will automatically issue a warning signal to remind the operation and maintenance personnel to conduct inspections or maintenance.

3 Conclusion

This article has in-depth explored the common types of mechanical failures of high-voltage disconnect switches and their intelligent diagnosis methods. Using intelligent diagnosis methods for mechanical failures of high-voltage disconnect switches can not only improve the reliability of equipment operation but also significantly reduce maintenance costs and optimize the maintenance decision-making process.

With the progress of science and technology and the increasing maturity of data analysis technology, relevant personnel need to increase research investment to improve the intelligent diagnosis level of mechanical failures of high-voltage disconnect switches, providing strong support for the stable operation of the power system.