1. Air-insulated and SF₆ Gas-insulated Ring Main Units

Air-insulated ring main units primarily integrate load break switches, disconnectors, or a combination of both with grounding capabilities, operated either manually or electrically. These units may also incorporate fuses to control cable input and output lines. Conversely, SF₆ gas-insulated ring main units, commonly referred to as gas-insulated switchgear, utilize SF₆ gas for insulation and arc quenching due to its high dielectric strength, powerful arc extinguishing capability, non-toxicity, and chemical stability, making it an excellent medium for both purposes.

2. Reasons for Replacing SF₆ Gas with Dry Air

Despite its advantages, SF₆ gas has an extremely high global warming potential (GWP), ranking it among the six greenhouse gases regulated by the Kyoto Protocol. As a signatory committed to reducing emissions, China had reduced its carbon intensity by 48.1% from 2005 levels by the end of 2019, achieving its 2020 target ahead of schedule. With the national goal of peaking carbon emissions before 2030 and achieving carbon neutrality before 2060, decreasing carbon emissions is now a critical focus in future power planning. In this context, replacing SF₆ gas with dry air in medium voltage switchgear serves five key reasons:

2.1 Zero GWP of Dry Air

The GWP index measures how much a given mass of a greenhouse gas contributes to global warming compared to the same mass of carbon dioxide over a specific period. SF₆'s GWP is 23,900 times that of CO₂, marking it as one of the six gases targeted by the Kyoto Protocol and European Directive 2003/87 due to its environmental impact. An average load switch or circuit breaker compartment contains about 1 kg of SF₆; if leaked, this would equate to driving a car approximately 200,000 km in terms of environmental damage.

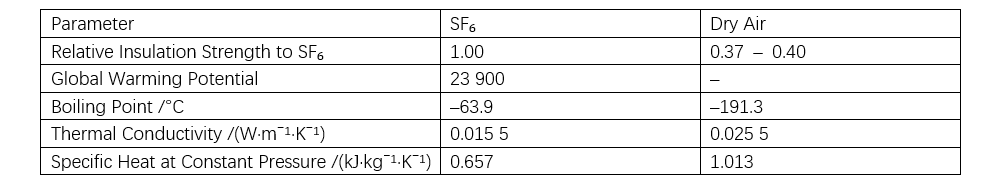

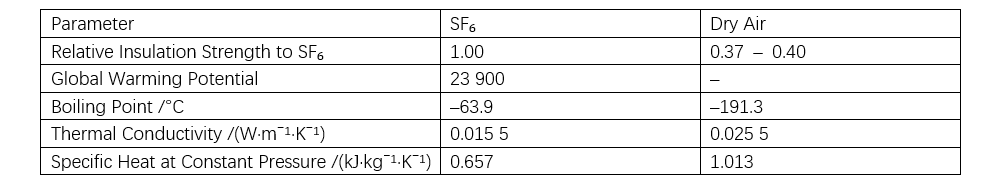

Considering there are roughly 30 million switchgear units globally, the necessity to find an alternative to SF₆ becomes evident. With a GWP of zero, dry air—comprising naturally 21% oxygen and 79% nitrogen—offers a solution that eliminates concerns over global warming contributions, positioning it as the ideal substitute for SF₆ due to its clear environmental safety and benefits. A comparison between SF₆ and dry air properties is summarized in Table 1.

2.2 Dry Air Requires No Recovery or Disposal

Environmentally friendly gas-insulated metal-enclosed switchgear does not use SF₆ gas during production and assembly, eliminating the need for gas recovery and protection systems. It is easy to fill, and its decomposition products contain no harmful substances, making it compliant with environmental standards. Such equipment causes no environmental pollution during long-term operation, is suitable for humid and harsh environments, and is maintenance-free. In contrast, SF₆ gas switchgear must keep the SF₆ gas sealed in a closed system throughout its entire lifecycle to minimize leakage and reduce environmental impact.

When maintenance is required, gas recovery units are used to collect the gas on-site. After purification to remove impurities, the gas is reused. However, under switching operations, SF₆ can produce toxic by-products, classifying used SF₆ gas as hazardous waste. The cost of disposing of SF₆ gas is substantial, approximately 20% of the equipment's original price. Using dry air completely eliminates the need for SF₆, significantly reducing the environmental impact of switchgear and avoiding the costs and procedures associated with disposal and recovery.

2.3 Dry Air Offers Additional Advantages for Operators

New SF₆-free switchgear using dry air provides numerous benefits for operators: ① It retains the compact size that traditional SF₆ equipment is valued for, and the operation method remains unchanged, so technicians require no additional training; ② The three-position load switch in environmentally friendly gas-insulated switchgear uses parallel vacuum interruption technology, maintaining the original three-position operation habits while enabling combined appliance solutions, offering customers economical and reliable transformer protection.

2.4 Dry Air Protects Personnel Health and Safety

Medium-voltage switchgear is often used in public areas, so health and safety are primary considerations when selecting an SF₆ alternative. Dry air, as a safe substitute, protects the public from potential health and safety risks. It is completely non-toxic, so even in the event of a leak, it poses no harm to people or the environment. It does not present health risks to personnel responsible for installation and decommissioning, and there is no need to establish strict equipment handling regulations for personnel safety. In contrast, unverified proprietary gases may pose health and safety risks.

2.5 Dry Air Alleviates Regulatory Concerns

Many companies are taking significant steps to drastically reduce greenhouse gas emissions. These strategic efforts are driven not only by a desire for greater sustainability but also by strong regulatory pressures. In Europe, the use, handling, decommissioning, monitoring, and inventory record-keeping of SF₆ gas are strictly regulated. In China, relevant policies and measures have been introduced since 2012 to regulate the use and recovery of SF₆ gas. According to standards issued by the Standardization Administration of China, SF₆ gas emissions generated during the maintenance and decommissioning of SF₆ equipment have been included in the greenhouse gas accounting and reporting scope for Chinese power grid enterprises.

Given the expectation of increasingly stringent future regulations, adopting environmentally friendly alternative products that are not subject to future regulatory constraints is a prudent choice to ensure operational continuity. Dry air medium-voltage switchgear provides reliable insulation and interruption performance without being affected by environmental regulations or carbon taxes. As the world's second-largest economy and largest energy consumer, China plays a pivotal role in the global energy transition. Recently, the Fifth Plenary Session of the 19th Central Committee proposed key socio-economic development goals for China's 14th Five-Year Plan period, explicitly stating that "energy resource allocation should become more rational, utilization efficiency should significantly improve, and total emissions of major pollutants should continue to decrease."

In summary, dry air as an insulating medium offers the following advantages: ① environmentally friendly and green; ② good thermal conductivity; ③ no need for ventilation or protective equipment during equipment production and maintenance; ④ metal particles generated during production or use pose minimal hazard to dry air-insulated switchgear.

3 Conclusion

The new type of ring main unit uses dry air as an insulating medium, replacing the environmentally harmful SF₆ gas, thereby reducing greenhouse gas emissions. At the end of its life cycle, over 90% of the materials can be recycled. Employing a slight positive pressure gas insulation method reduces the possibility of gas leakage, enhancing safety and reliability. High-voltage components are completely sealed within a metal enclosure, ensuring safe operation in harsh environments such as high altitudes, severe cold, humidity, and pollution. Vacuum switches and three-position isolation/grounding switches support both manual and electric operation, and the switchgear features intelligent capabilities.

Although environmentally friendly ring main units have made progress in intelligence, greenness, and environmental protection, the insulating performance of nitrogen and dry air under the same pressure is only about one-third that of SF₆, particularly in high-voltage GIS products, where no viable replacement for SF₆ has yet been found. Therefore, further efforts are needed in the development of environmentally friendly gases.