Transformer Bushing Operating Principle

In electrical power systems, a bushing is an insulating device that allows an electrical conductor to pass safely through a grounded conductive barrier, as in the case of transformers or circuit breakers. All transformer windings are connected to high-voltage lines, so special attention must be paid to the terminal connections to prevent flashover between the high-voltage terminals and the transformer body. In low-voltage distribution transformers, cable connections are made within a terminal box on the secondary side.

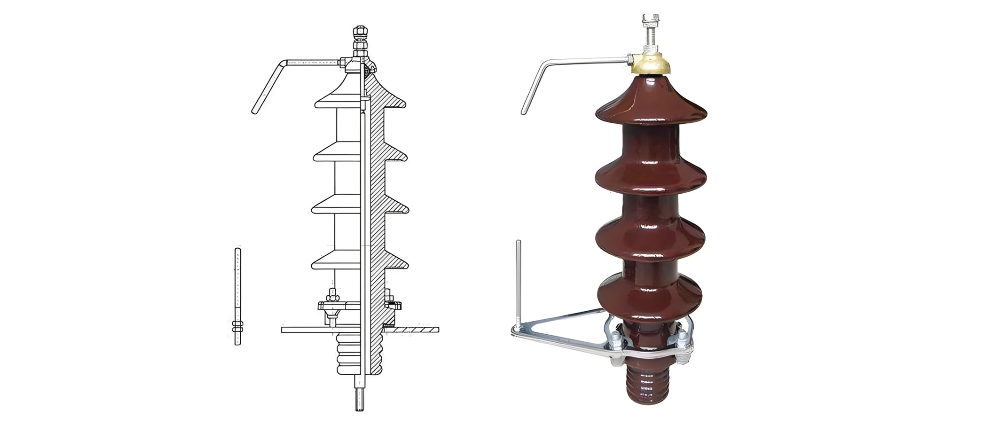

However, in power transformers, both sides operate at high voltage, necessitating specially designed devices known as bushings. A bushing typically consists of a central current-carrying conductor (a rod, busbar, or cable) and a porcelain housing mounted in the opening of the transformer cover, which insulates the live part. The simplest type is a molded high-quality glazed porcelain insulator with a central conductor. This type is used for voltages up to 33 kV and features a smooth or slightly ribbed surface for indoor applications.

For outdoor transformers, the external (upper) part of the bushing includes sheds to protect the lower ribs from water during rain. For transformers operating above 36 kV, oil-filled or capacitor-type bushings are used. An oil-filled bushing consists of a hollow, two-part porcelain cylinder with a conductor passing through its axis. The space between the conductor and the inner surface of the porcelain is filled with oil, which is separate from the oil in the transformer tank. The top of the bushing connects to a small expansion chamber to accommodate volume changes due to oil temperature variations. Provision is made at the lower end for current transformers, allowing the bushing to be removed without disturbing the current transformer.

A capacitor bushing is constructed with layers of synthetic resin-bonded paper interleaved with thin metallic foils impregnated with conductive material. This forms a series of capacitors, where each pair of metal foils and the intervening resin-bonded paper cylinder acts as a capacitor. By varying the length of the metallic foils and the thickness of the resin-bonded paper layers, the dielectric stress is evenly distributed across the radial depth—i.e., along the radius of the bushing.

Hello,I'm Wdwiin. A decade of hands-on experience in electrical engineering, specializing in high-voltage systems, smart grids, and renewable energy technologies. Passionate about technical exchange and knowledge sharing, committed to interpreting industry trends with professional insights to empower peers. Connection creates value—let’s explore the boundless possibilities of the electrical world together!