Bi gavên çewitî yên navendî, şûnışê xelektrîkî di navendên baxraçan de dersa pirsgirêkên teknîkî û envîronmentî da. Hîstîna ekstrem, geolojîya taybet, û demên zimistînê meheng, bi barf, kar, û sturm, ser stabîlîya pîçeyên xelektrîk û şûnışê xelektrîkî (pîvan, maliyê, bikarhêner) tevniyek bibin. Substationsên serherî yên tradîsyonel, bi pîvanê derê û kêm adaptasyon, dest nake binivîsin baha xweş û stabîl bike navendên baxraçan.

Substationsên kabînên prefabricated, wekî cihazên modular yên fabrikada, ku pîçeyên sereke integre kirin (swîçanên hêviya bilind, transformatoran, sisteman kontrol), dêşebikeve ji bo serherî şebikekirina rastî. Van dê encamên li ser envîronment hatine, vê nirxên taybet di navendên baxraçan da ku demên derbas û pîvan derbas an de werdigire. Ev çalakat dêşebikeve biguhezîne ser parzûnandina sistemên xelektrîkî yên navendî û çalakatên xelektrîkî yên jîn navendan di navendên din.

Taybetmendiyên Projeyê

Projeyek di navendek baxraçan de ya navendî yên Çînê ya bakûr-garo: - 8°C tempê yeksa salan, - 30°C demên zimistîn, 5+ mihan bi barf-bar, pêwistî yên zemin bi 1m. Bi 3600m altîtûd, van dê 6000m2(1200m2) serparêzînin, bi ¥55 milyon investîsyon toman (¥33 milyon ji bo pîçey, ¥22 milyon ji bo şûnış).

Van divê 2×120MVA transformator sereke (ji bo behterba zimistîn), 8×10kV kabinetên distribûsyon (ji bo distribûsyon xelektrîk), û 3km kabên anti-smoke, anti-freeze (ji bo serdem) hene. Bi pîvanê şebîkekirina-dizaynê 8 mihan, van dêşebikeve stabîl û bexwestî xelektrîk di şertên ekstrem de bidin.

Pêşdestkirina Lîyanê Anti-Frost

Dema baxraçan û pêşdestkirina frost-thaw cycles riske frost ên lîyanê, ku asayî yên substation û kabînan tevniyek bibin. Ji bo vê, GCL (thermal conductivity < 0.5W(m·K), insulation taybet) bikar îne. Rêzikê 0.8m dikare frost heave hate piştî.

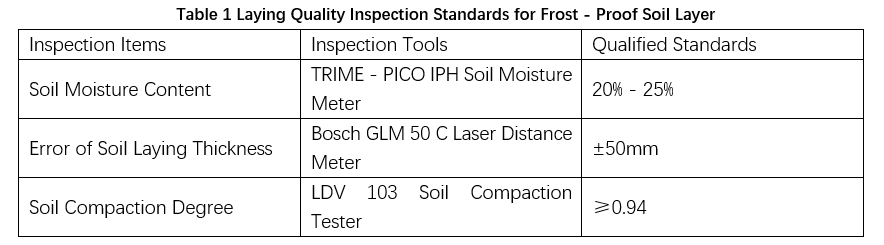

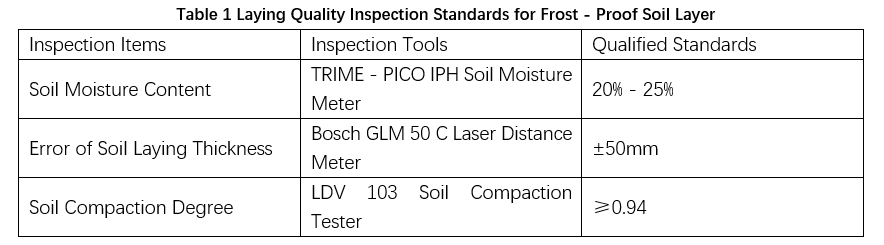

Ji bo dema ekstrem: Yekem, excavator CAT 336E topsoilên frostbexser/kîrkirî digire. Dua, gravel 5-20mm wergirtin (300mm thick) bi bo bixebitina kapasiteyê û drainage. Double-layered GCL 400mm thick (≥200mm lap, ji bo gap check) dibêje. Gravel protection layer 100mm thick, 5-15mm, di ser de dibêje bi bo şermîn GCL di dema bikarhêner de.Demê şebîkekirina, layer bi sectionan 200mm thick rolin, bi ≥6 pass. Standardên kaliteyê di Table 1 de ne.

Noktên Sereka Pêşdestkirina Lîyanê Anti-Frost

Di dema pêşdestkirina lîyanê anti-frost de ji bo substationsên kabîn prefabricated di navendên baxraçan de, noktên berîn dêşebikeve kontrol bikin:

Temperature Control: Dema ambient di dema şebîkekirinan de divê piştî -10°C were barkirin bi bo frost ên lîyanê, ku dê encamên li ser kaliteyê bibin.

Drainage Assurance: Drainage facilities di ser şebîka şebîkekirinan de bixebitîne bi bo frost ên water ên şebîkekirinan lîyanê û danandina rêzikê lîyanê.

Construction Schedule Planning: Şebîkekirina pîvanê şebîkekirina bi bo şebîkekirina zimistînê hatine. Ji bo dema ekstrem ên zimistînê frost ên problemên lîyanê bibin, pîvanê şebîkekirina bi bo şebîkekirina lîyanê anti-frost û stabilîya asayî substation.

Dizaynê Insulation û Kabîn

Di dema ekstrem ên baxraçan de, tempê di navbera kabînan de dikare bi destpiyawêtî -30°C were barkirin, ku pirsgirêk taybet dikare bidin stabîlîya operasyonan pîçeyên substation. Naverok, dizaynê insulation systematic dibe bi bo navbera kabîn stabîl bikin:

Noktên Sereka Pêşdestkirina Lîyanê Anti-Frost

Di dema pêşdestkirina lîyanê anti-frost de ji bo substationsên kabîn prefabricated di navendên baxraçan de, noktên berîn dêşebikeve kontrol bikin:

Temperature Control: Dema ambient di dema şebîkekirinan de divê piştî -10°C were barkirin bi bo frost ên lîyanê, ku dê encamên li ser kaliteyê bibin.

Drainage Assurance: Drainage facilities di ser şebîka şebîkekirinan de bixebitîne bi bo frost ên water ên şebîkekirinan lîyanê û danandina rêzikê lîyanê.

Construction Schedule Planning: Şebîkekirina pîvanê şebîkekirina bi bo şebîkekirina zimistînê hatine. Ji bo dema ekstrem ên zimistînê frost ên problemên lîyanê bibin, pîvanê şebîkekirina bi bo şebîkekirina lîyanê anti-frost û stabilîya asayî substation.

Dizaynê Insulation û Kabîn

Di dema ekstrem ên baxraçan de, tempê di navbera kabînan de dikare bi destpiyawêtî -30°C were barkirin, ku pirsgirêk taybet dikare bidin stabîlîya operasyonan pîçeyên substation. Naverok, dizaynê insulation systematic dibe bi bo navbera kabîn stabîl bikin:

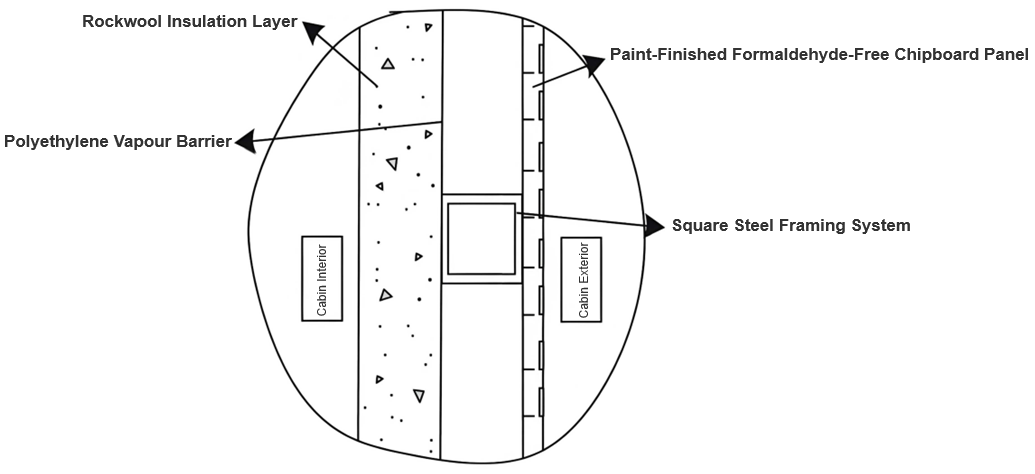

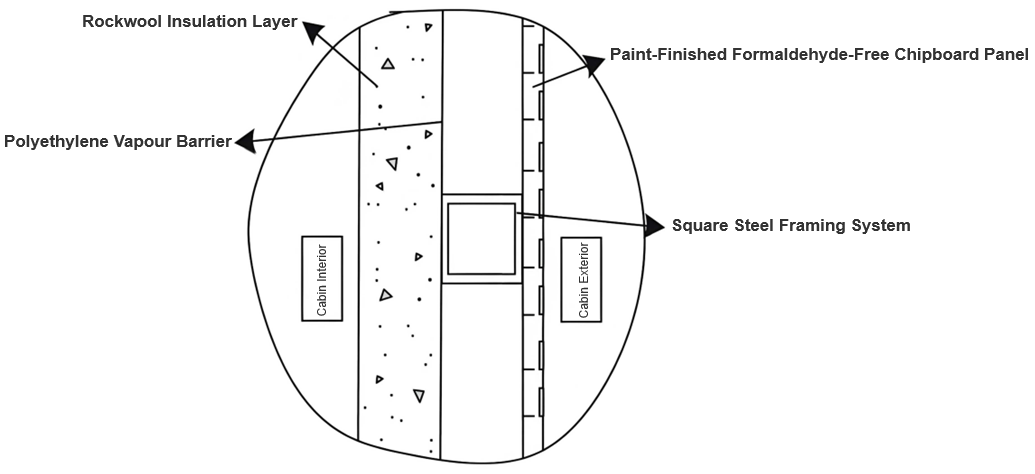

(1) Hilbijartina û Structura Malperên Insulation

Exterior Facade Maintenance: Panel FC 15mm thick hilbijartin, ku her duşmanc û dayîn e û "protective shell" di navbera kabîn de were.

Main Thermal Insulation Layer: Vegera thermal resistance ên rock wool, panel sandwich phenolic rock wool 50mm thick navbera kabîn were şebikekirin bi bo "thermal barrier" form bikin.

Moisture-Proof Enhancement: Polyethylene moisture-proof film di navbera panel FC û panel rock wool de were şebikekirin bi bo penetration path ên external moisture block bikin, navbera kabîn dry bikin, service life ên insulation layer prolong bikin, û structural stability ên kabîn improve bikin.

(2) Optimization of Installation Process

Teknîka purlin-free dry-hanging were bikar în bi bo connect panel exterior wall FC, panel rock wool, û keel square steel. Special hangers û fasteners bikar în bi bo tightly combine insulation layer bi framework structural. This measure seamless continuity ên insulation layer realize bikin, thermal bridge effect (heat loss through heat-conducting parts such as the metal framework) avoid bikin, û overall thermal insulation efficiency improve bikin.

(3) Sealing Detail Treatment

For the tongue-and-groove of the rock wool sandwich panel, foamed polyurethane with a density of ≥30kg/m³ is used for filling and sealing. With its characteristics of plasticity, airtightness, high strength, and non-water absorption, this material forms a highly efficient sealing environment at both ends of the sandwich panel (with a thermal conductivity of ≤0.024W/(m·K) ), greatly reducing heat loss at the joints, ensuring the thermal insulation performance of the cabin in the alpine environment, and laying a solid foundation for the reliable operation of the prefabricated cabin substation in extreme climates.

Heating Cable Installation

When an electric current passes through the heating cable, its electrical resistance converts into heat, thereby warming the surrounding environment. For prefabricated substation cabins in alpine regions, heating cables with a power rating of 20–30W/m are selected. This power level ensures sufficient heat output to maintain the internal temperature within a safe operating range for electrical equipment.

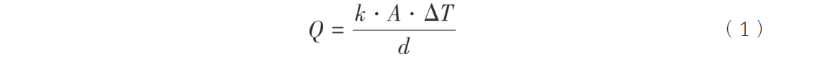

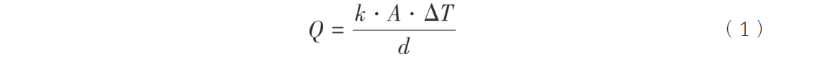

Prior to installation, a detailed thermal assessment is conducted using Fourier's Law of Heat Conduction to calculate the heating requirements for critical components and pipelines. The mathematical formula is as follows:

In heat conduction calculations:

Q: Required heat (unit: W)

k: Thermal conductivity of equipment surface material (unit: W/m·K)

A: Heat conduction area (unit: m2)

ΔT: Required temperature difference (unit: K)

d: Thickness of heat conduction path (unit: m)

For heating cable installation:

Fixing: Use high-strength clamps (e.g., stainless steel clips, plastic straps) to secure cables to equipment surfaces/pipelines, with clamp spacing ≤ 30 cm to prevent displacement and ensure stable heat transfer.

Layout Density: Arrange cables at 10 cm intervals in trenches and on critical equipment to provide sufficient heat and prevent icing.

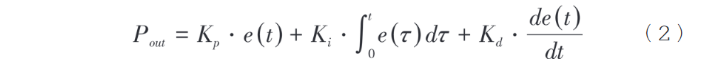

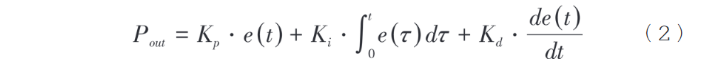

Temperature Control: Use K-type thermocouples to monitor cable operation in real-time. Pair with PID (proportional-integral-derivative) algorithms to auto-adjust power output, maintaining temperature within required ranges. The PID formula is shown in Equation (2).

Ventilation Device Layout

In alpine regions, extremely low winter temperatures can affect substation equipment (e.g., transformers, switchgear) and overall stability. Thus, 4 axial fans (1.5 kW, (2000 m3/h) are symmetrically installed on side walls to ensure uniform air flow and prevent condensation.

For prefabricated cabin substations, a “top intake, bottom exhaust” ventilation design is used. The area ratio of intake to exhaust outlets is 1:1.5 to ensure sufficient air changes. Insulated ducts (50 mm rock wool, 0.035 W/(m·K) thermal conductivity) with 0.5 mm aluminum foil wrapping reduce heat loss and maintain stable indoor temperatures.

Dual-Power Supply

To adapt to alpine climates, two S13-M-100/10 oil-immersed transformers (100 MVA, 10/0.4 kV) are used as main transformers. Connected to independent power sources, they operate in parallel (50% load rate under standard conditions) to reduce losses and extend service life. The SCADA system monitors and balances loads in real-time.

In emergencies (e.g., one transformer fails), the ATS switch completes power transfer within 0.1 s, ensuring seamless load takeover and stable power supply. As per GB 50052-2009, two DKSC-100/10 reactors (100 A, 6% reactance) limit short-circuit current to ≤ 20 kA, preventing overvoltage damage.

Conclusion

Alpine regions' extreme conditions (low temps, wind, snow) demand higher standards for prefabricated cabin substation operation and maintenance. Design and construction must include suitable insulation, heating, moisture-proof measures, and wind-snow-resistant equipment.

Future advancements in technology and practice will further optimize these substations. Intelligent monitoring and dispatching systems will enhance remote management and adaptability to extreme climates, ensuring stable and safe power supply.