A cikin yawan karamin harkokin duniya, na'urar gagar da kashi da kasa tana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi. Karamin zafi masu yawa, kimiyya mai zurfi, da kuma lokacin da za ta shiga zafi don wasu rana, da kuma kafin da sautin jiki da kafin da sani, suna haifar da tsarin kashi da kuma bayanai na'urar kashi da kasa (kafin da suka shiga, mali, ingantaccen bayyana). Tsarin substation da ke kan kasa, wadanda suke da kalmomin kafa da kuma ba su iya amfani da yawa, ba su iya tabbatar da buƙata da kashi da kasa a wasu wurare.

Substations masu ofishin baki, wadanda ake kafa a cikin ofishin kasa da kuma ake kara waɗanda ake amfani da su (kashi masu karshe, transformers, tsarin nuna), suna ba su karfin kafa na ƙasa da kuma inganta a kan kasa. Suna haifar da al'amuran da suka shiga, wadanda suna da muhimmanci a wurare da yawa da kasa. Ingantaccen wannan yanayin shine ya faruwa a kan kafar da kashi da kasa a wurare da yawa da kuma kafar da kashi da kasa a wurare masu yawa a duniya.

Bayanai na'ura

An yi na'ura a wurare da yawa a kudu na Najeriya: - 8°C misali na ranar zuwa shekarar, - 30°C misali na ranar zuwa shekarar da ke kasa, 5+ ranar da ke da kafin da sautin jiki, da kuma kafin da sautin jiki mai yawa da kusa. A 3600m kasa, yana da 6000m2(1200m2) kafin da suka shiga, da kuma ₦55 million da suka shiga (₦33 million da suka shiga saboda kashi, ₦22 million da suka shiga saboda kasa).

Yana da 2×120MVA main transformers (wadanda suke da buƙata don kafin da sautin jiki), 8×10kV distribution cabinets (don kafin da kashi), da kuma 3km low-smoke, anti-freeze cables (wadanda suke da buƙata don kafin da sautin jiki). Da kafin da 8-watan kafin da suka shiga, an yi amfani da ita don tabbatar da kashi da kasa a cikin kafin da sautin jiki.

Kafin da suka shiga Frost-proof Soil Layer

Kafin da suka shiga da kasa da kafin da sautin jiki, yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi. Don haka, an yi amfani da GCL (thermal conductivity < 0.5W(m·K), da kuma yawan daidaito) da suka shiga. An yi amfani da layer da 0.8m da suke da yawan daidaito don haifar da frost heave.

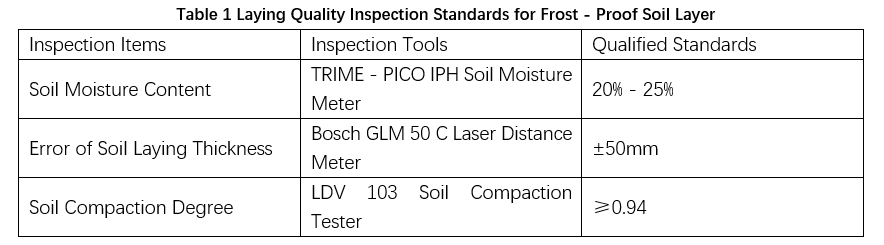

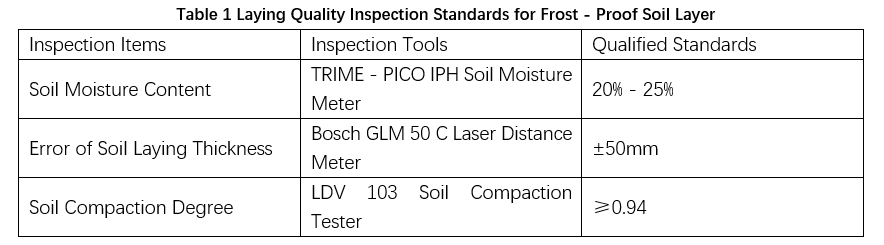

Don kafin da sautin jiki: kafin da suka shiga, an yi amfani da CAT 336E excavator don haifar da topsoil da ke da kafin da sautin jiki. Sannan, an yi amfani da 5–20mm gravel (da 300mm da suke da yawan daidaito) don haifar da yawan daidaito da kuma kafin da suka shiga. An yi amfani da double-layered GCL (da 400mm da suke da yawan daidaito, da kuma ≥200mm lap, da kuma an yi amfani da su don haifar da gaps) don haifar da yawan daidaito. An yi amfani da 100mm-thick, 5–15mm gravel protection layer don haifar da GCL a lokacin da suke amfani da su. A lokacin da suke amfani da su, an yi amfani da su don haifar da yawan daidaito da kuma an yi amfani da su don haifar da yawan daidaito. Standardai da suke da yawan daidaito suna cikin Table 1

Muhimman Abubuwa na Kafin da suka shiga Frost-proof Soil Layer

A lokacin da suke amfani da frost-proof soil layer don prefabricated cabin substations a wurare da yawa, yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi:

Temperature Control: Misali na ranar zuwa shekarar da ke da kafin da suka shiga yana da muhimmanci don haifar da kafin da sautin jiki, wanda yake da iha ga yawan daidaito na kafin da suka shiga.

Drainage Assurance: Yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi a cikin drainage facilities a cikin kafin da suka shiga don haifar da kafin da suka shiga da kuma kafin da suka shiga.

Construction Schedule Planning: Yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi a cikin kafin da suka shiga don haifar da kafin da sautin jiki. Ba a yi amfani da kafin da suka shiga a kafin da sautin jiki, domin kafin da sautin jiki yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi. An yi amfani da su don haifar da yawan daidaito na kafin da suka shiga.

Thermal Insulation Design of Cabin Structure

A cikin kafin da sautin jiki, temperature inside the cabin may drop to below -30°C, posing a severe challenge to the stable operation of the equipment in the substation. Therefore, a systematic thermal insulation design is required to maintain a stable internal environment of the cabin:

Muhimman Abubuwa na Kafin da suka shiga Frost-proof Soil Layer

A lokacin da suke amfani da frost-proof soil layer don prefabricated cabin substations a wurare da yawa, yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi:

Temperature Control: Misali na ranar zuwa shekarar da ke da kafin da suka shiga yana da muhimmanci don haifar da kafin da sautin jiki, wanda yake da iha ga yawan daidaito na kafin da suka shiga.

Drainage Assurance: Yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi a cikin drainage facilities a cikin kafin da suka shiga don haifar da kafin da suka shiga da kuma kafin da suka shiga.

Construction Schedule Planning: Yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi a cikin kafin da suka shiga don haifar da kafin da sautin jiki. Ba a yi amfani da kafin da suka shiga a kafin da sautin jiki, domin kafin da sautin jiki yana da muhimmanci da take da matsaloli da kuma kungiyoyin zafi. An yi amfani da su don haifar da yawan daidaito na kafin da suka shiga.

Thermal Insulation Design of Cabin Structure

A cikin kafin da sautin jiki, temperature inside the cabin may drop to below -30°C, posing a severe challenge to the stable operation of the equipment in the substation. Therefore, a systematic thermal insulation design is required to maintain a stable internal environment of the cabin:

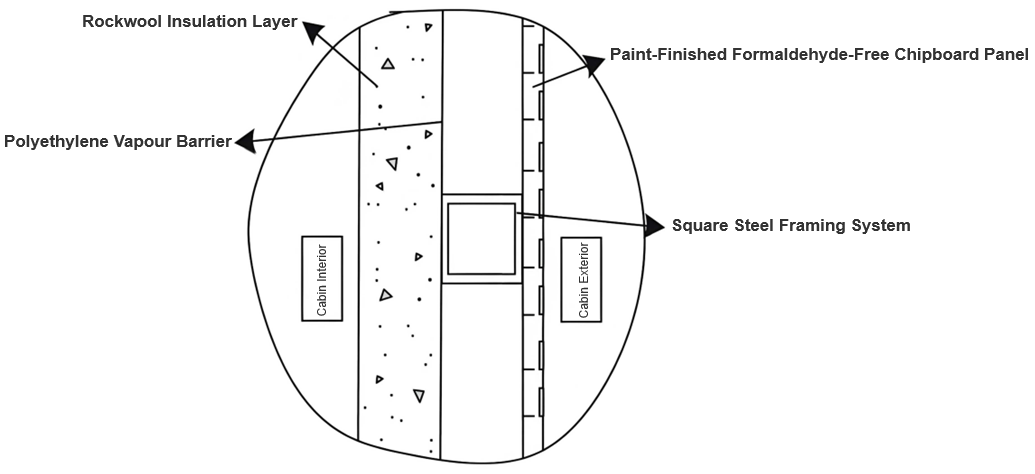

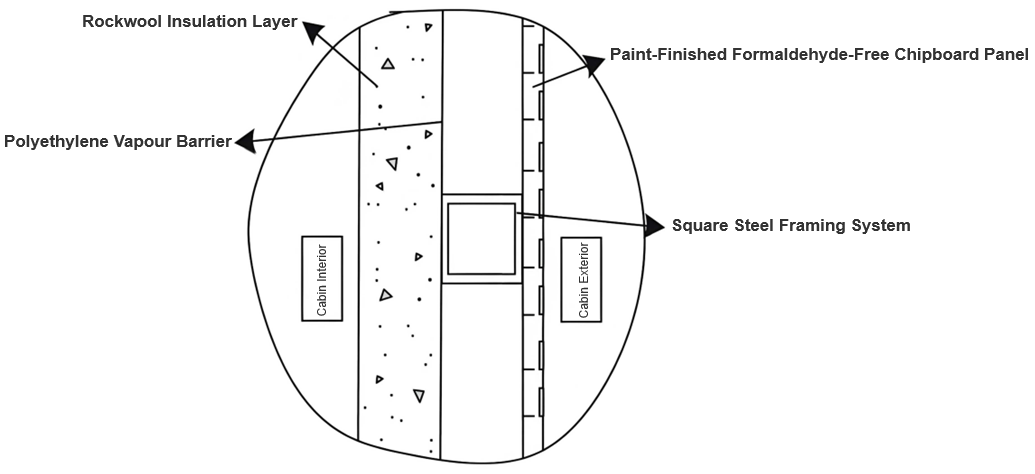

(1) Selection and Structure of Thermal Insulation Materials

Exterior Facade Maintenance: An yi amfani da 15mm-thick FC (Fiber Cement) panel, wanda yana da yawan daidaito da kuma yawan daidaito, da kuma an yi amfani da su don haifar da "protective shell" na'urar kashi da kasa.

Main Thermal Insulation Layer: An yi amfani da advantage na rock wool, wanda yana da yawan daidaito, an yi amfani da 50mm-thick phenolic rock wool sandwich panel a cikin na'urar kashi da kasa don haifar da "thermal barrier".

Moisture-Proof Enhancement: An yi amfani da polyethylene moisture-proof film a cikin FC panel da rock wool panel don haifar da penetration path na external moisture, don haifar da interior na'urar kashi da kasa, don haifar da yawan daidaito na thermal insulation layer, da kuma don haifar da yawan daidaito na structure na'urar kashi da kasa.

(2) Optimization of Installation Process

An yi amfani da purlin-free dry-hanging technology don connect FC external wall panel, rock wool panel, da square steel keel. An yi amfani da special hangers da fasteners don tightly combine thermal insulation layer with structural framework. Wannan measure yana haifar da seamless continuity na thermal insulation layer, yana haifar da thermal bridge effect (heat loss through heat-conducting parts such as the metal framework), da kuma yana haifar da overall thermal insulation efficiency.

(3) Sealing Detail Treatment

For the tongue-and-groove of the rock wool sandwich panel, foamed polyurethane with a density of ≥30kg/m³ is used for filling and sealing. With its characteristics of plasticity, airtightness, high strength, and non-water absorption, this material forms a highly efficient sealing environment at both ends of the sandwich panel (with a thermal conductivity of ≤0.024W/(m·K)), greatly reducing heat loss at the joints, ensuring the thermal insulation performance of the cabin in the alpine environment, and laying a solid foundation for the reliable operation of the prefabricated cabin substation in extreme climates.

Heating Cable Installation

When an electric current passes through the heating cable, its electrical resistance converts into heat, thereby warming the surrounding environment. For prefabricated substation cabins in alpine regions, heating cables with a power rating of 20–30W/m are selected. This power level ensures sufficient heat output to maintain the internal temperature within a safe operating range for electrical equipment.

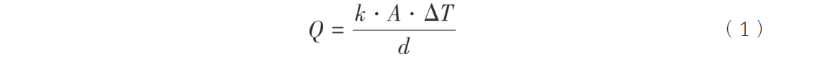

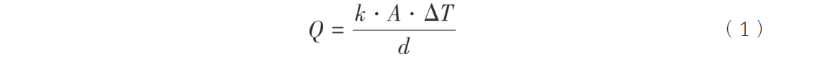

Prior to installation, a detailed thermal assessment is conducted using Fourier's Law of Heat Conduction to calculate the heating requirements for critical components and pipelines. The mathematical formula is as follows:

In heat conduction calculations:

Q: Required heat (unit: W)

k: Thermal conductivity of equipment surface material (unit: W/m·K)

A: Heat conduction area (unit: m2)

ΔT: Required temperature difference (unit: K)

d: Thickness of heat conduction path (unit: m)

For heating cable installation:

Fixing: Use high-strength clamps (e.g., stainless steel clips, plastic straps) to secure cables to equipment surfaces/pipelines, with clamp spacing ≤ 30 cm to prevent displacement and ensure stable heat transfer.

Layout Density: Arrange cables at 10 cm intervals in trenches and on critical equipment to provide sufficient heat and prevent icing.

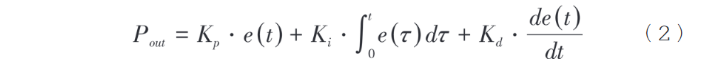

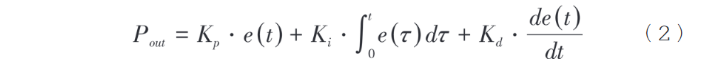

Temperature Control: Use K-type thermocouples to monitor cable operation in real-time. Pair with PID (proportional-integral-derivative) algorithms to auto-adjust power output, maintaining temperature within required ranges. The PID formula is shown in Equation (2).

Ventilation Device Layout

A cikin wurare da yawa, kafin da sautin jiki na ranar zuwa shekarar yana da iha ga yawan daidaito na kashi da kasa (misali, transformers, switchgear) da kuma yawan daidaito na kashi da kasa. Saboda haka, an yi amfani da 4 axial fans (1.5 kW, (2000 m3/h) symmetrically installed on side walls to ensure uniform air flow and prevent condensation.

For prefabricated cabin substations, a “top intake, bottom exhaust” ventilation design is used. The area ratio of intake to exhaust outlets is 1:1.5 to ensure sufficient air changes. Insulated ducts (50 mm rock wool, 0.035 W/(m·K) thermal conductivity) with 0.5 mm aluminum foil wrapping reduce heat loss and maintain stable indoor temperatures.

Dual-Power Supply

To adapt to alpine climates, two S13-M-100/10 oil-immersed transformers (100 MVA, 10/0.4 kV) are used as main transformers. Connected to independent power sources, they operate in parallel (50% load rate under standard conditions) to reduce losses and extend service life. The SCADA system monitors and balances loads in real-time.

In emergencies (e.g., one transformer fails), the ATS switch completes power transfer within 0.1 s, ensuring seamless load takeover and stable power supply. As per GB 50052-2009, two DKSC-100/10 reactors (100 A, 6% reactance) limit short-circuit current to ≤ 20 kA, preventing overvoltage damage.

Conclusion

Alpine regions' extreme conditions (low temps, wind, snow) demand higher standards for prefabricated cabin substation operation and maintenance. Design and construction must include suitable insulation, heating, moisture-proof measures, and wind-snow-resistant equipment.

Future advancements in technology and practice will further optimize these substations. Intelligent monitoring and dispatching systems will enhance remote management and adaptability to extreme climates, ensuring stable and safe power supply.