The solid insulated ring main unit (RMU) is a novel distribution equipment that integrates external solid encapsulation, insulated busbar, and compact combined unit technology. Its switches and high-voltage live components are entirely embedded in epoxy resin, which serves as the primary insulation between live parts and ground, and between phases. As an environmentally friendly alternative to SF₆ gas-insulated equipment, the 12kV solid insulated RMU offers advantages but inherently suffers from poor heat dissipation characteristics.

In the studied 12kV solid insulated RMU, the main conductive loops are encased in epoxy and silicone rubber materials. While the disconnecting switch utilizes air insulation, it resides within an extremely confined, sealed space with poor heat dissipation conditions. This makes it highly prone to exceeding temperature rise limits. Prolonged exposure to high temperatures can cause the equipment's manufacturing materials to deform and undergo thermal aging. This degradation reduces the product's insulation performance, leading to a decline in overall product quality and reliability. In severe cases, it can trigger electrical accidents, disrupting normal operation.

Given the critical importance and inherent difficulty of addressing the temperature rise issue, it became the focus of intense research. Structural optimizations were continuously implemented to increase the temperature rise margin, ensuring the product's long-term stable operation. The insulation of the solid insulated RMU primarily employs a combination of air and solid insulation. A prototype based on the initial design underwent temperature rise research testing. Key test point data is shown in Table 1.

|

No.

|

Measurement Point Location

|

Standard (K)

|

Equilibrium Temp. (°C)

|

Temp. Rise (K)

|

Margin from Std. (K)

|

Remark

|

|

1

|

A-phase Disconnect Knife Pivot

|

65.0

|

86.1

|

73.0

|

-8.0

|

Exceeded

|

|

2

|

A-phase Disconnect Knife Tip

|

65.0

|

78.2

|

65.1

|

-1.1

|

Exceeded

|

|

3

|

B-phase Disconnect Knife Pivot

|

65.0

|

86.4

|

73.3

|

-8.3

|

Exceeded

|

|

4

|

B-phase Disconnect Knife Tip

|

65.0

|

88.0

|

74.9

|

-9.9

|

Exceeded

|

|

5

|

C-phase Disconnect Knife Pivot

|

65.0

|

80.6

|

67.5

|

-2.5

|

Exceeded

|

|

6

|

C-phase Disconnect Knife Tip

|

65.0

|

81.6

|

68.5

|

-3.5

|

Exceeded

|

As indicated in Table 1, temperature rise testing on the prototype based on the initial design revealed severe exceedances of limits at both the disconnecting knife pivots and tips. To resolve this issue, optimization efforts focused on the following two aspects:

- Magnetothermal Coupling Simulation (Using ANSOFT): Perform magnetothermal coupling simulation to optimize conductor contact methods, the shape of irregular conductors, and the conductive cross-sectional area. This reduces internal heating by minimizing joule heat generation at the source.

- Cabinet-Level Thermal Simulation (Using ICEPAK): Conduct cabinet-level thermal simulation to establish effective heat dissipation pathways, increase the heat dissipation coefficient of the conductors themselves, and efficiently dissipate the generated heat. This approach aims to lower the temperature of the conductive loops through a dual approach of blocking and dissipating heat.

Magnetothermal Coupling Simulation

Since the applied current was less than 1000A, this simulation solely modeled the joule heating generated by the loop resistance in the conductive path. The simulated temperature distribution directly reflects joule heating effects, excluding scenarios involving heat dissipation through radiation or convection. This makes the results suitable for analyzing the impact of conductor structure on temperature distribution. Key product technical parameters are listed in Table 2.

|

No.

|

Parameter Name

|

Value

|

|

1

|

Rated Voltage (kV)

|

12

|

|

2

|

Rated Current (A)

|

700

|

|

3

|

A-phase Loop Resistance (μΩ)

|

190 (Assumed)

|

|

4

|

B-phase Loop Resistance (μΩ)

|

190 (Assumed)

|

|

5

|

C-phase Loop Resistance (μΩ)

|

190 (Assumed)

|

Simulation Results

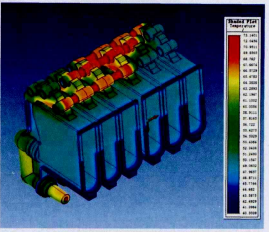

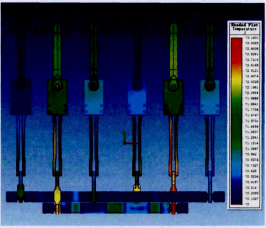

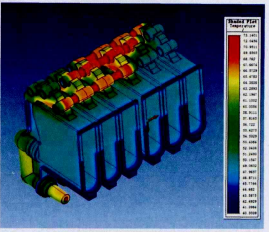

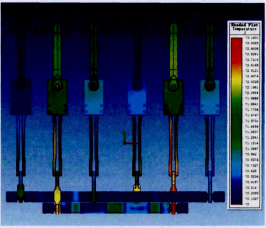

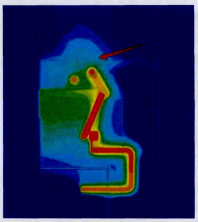

Figure 1 shows the magnetothermal coupling temperature distribution of the insulation module. Figure 2 shows the overall magnetothermal coupling temperature distribution of the internal conductive path. Magnetothermal coupling simulation using ANSOFT software revealed that the primary locations of elevated heat generation were the tips of the disconnecting knives and the contact points with the stationary contacts. The B-phase disconnecting knife, in particular, exhibited consistently higher temperatures. Structural optimization is required to reduce constriction resistance and homogenize the conductive cross-sectional area.

Cabinet-Level Thermal Simulation

Cabinet-level thermal simulation using ICEPAK software examined the distribution and forms of heat dissipation from the conductive paths after current flow, as well as the impact of the enclosure on heat transfer.

Technical Requirements

The temperature rise standard follows GB/T 11022-2011 "Common specifications for high-voltage switchgear and controlgear standards." As stipulated by the relevant standards:

- Maximum temperature for touchable enclosures: 70°C (max. temp. rise 30 K above ambient).

- Maximum temperature for non-touchable enclosures: 80°C (max. temp. rise 40 K above ambient).

- Maximum conductor temperature: 115°C (max. temp. rise 75 K above ambient).

- Maximum contact temperature: 105°C (max. temp. rise 65 K above ambient).

For temperature rise tests, a test current of 1.1 times the rated current is typically used to account for solar radiation effects.

Software Settings

Initial Temperature: 20°C; Three-phase current phase angles: 0°, 120°, -120°.

Simulation Results

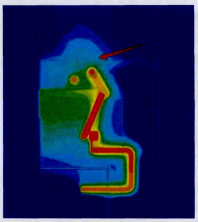

The cabinet-level thermal simulation results (Figure 4) showed that due to the small clearance between the top plate of the sealed enclosure and the upper part of the insulation module, the effective heat dissipation area on the upper part of the cabinet is very limited. Consequently, heat concentrates at the top, making it difficult to dissipate, leading to persistently high busbar temperature rise. To provide more heat dissipation space within the sealed cabinet, the cabinet height was increased and a heat-dissipating coating was applied to its inner surfaces.

Temperature Rise Test After Structural Optimization

Following the simulation studies and initial temperature rise test findings, modifications were made to the cabinet and certain components. A subsequent temperature rise test was conducted (refer to Table 4).

|

No.

|

Measurement Point Location

|

Standard (K)

|

Equilibrium Temp. (°C)

|

Temp. Rise (K)

|

Margin from Std. (K)

|

Remark

|

|

1

|

A-phase Disconnect Knife Pivot

|

65.0

|

72.4

|

55.2

|

+9.8

|

Compliant

|

|

2

|

A-phase Disconnect Knife Tip

|

65.0

|

73.7

|

56.5

|

+8.5

|

Compliant

|

|

3

|

B-phase Disconnect Knife Pivot

|

65.0

|

73.6

|

56.4

|

+8.6

|

Compliant

|

|

4

|

B-phase Disconnect Knife Tip

|

65.0

|

73.6

|

56.4

|

+8.6

|

Compliant

|

|

5

|

C-phase Disconnect Knife Pivot

|

65.0

|

69.6

|

52.4

|

+12.6

|

Compliant

|

|

6

|

C-phase Disconnect Knife Tip

|

65.0

|

70.7

|

53.5

|

+11.5

|

Compliant

|

As shown in Table 4, the temperature rise values for the prototype retested are now compliant with requirements. Furthermore, a design margin of at least 8.5 K has been achieved.

Subsequent Optimization and Rectification

Given the critical importance of temperature rise and the potential consequences of non-compliance, further optimization is warranted to enhance prototype performance, even after meeting the standard. The goal is to achieve a controlled temperature rise margin between 12 K and 15 K. For instance, specific modifications on the insulation module require testing (Original Table 5 was incomplete; logically incorporated). Simulation results suggest that optimizing the structure of the main insulation module creates a more reasonable internal heat dissipation pathway, offering significant potential for further reducing the overall internal conductive loop temperature rise. This potential requires further experimental validation.

Conclusion

A combined design approach utilizing computer simulation technology and temperature rise testing enabled structural optimization of the solid insulated ring main unit. The optimized product complies with the temperature rise requirements stipulated in GB/T 11022-2011 "Common specifications for high-voltage switchgear and controlgear standards" and achieves a significant safety margin.