| Brand | Schneider |

| Model NO. | CBGS-0 Gas-Insulated Switchgear |

| Rated voltage | 38kV |

| Series | CBGS-0 |

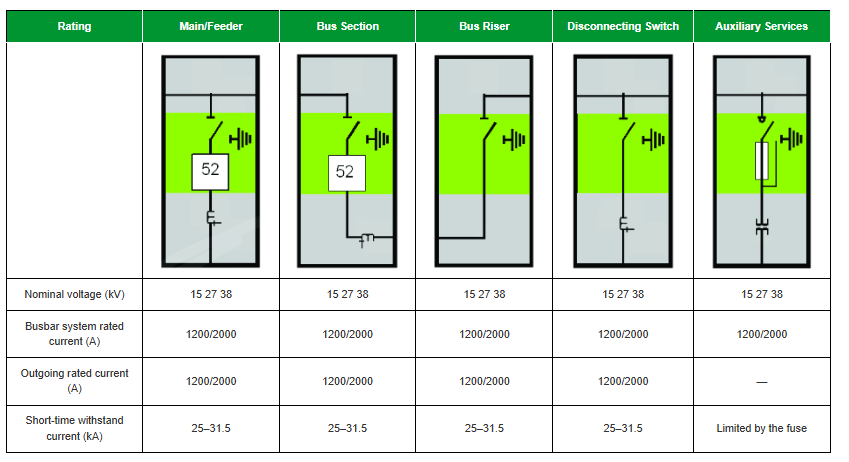

CBGS-0 Medium Voltage (MV) switchgear is compact and easy to install and operate. Due to the insulating gas as well as the solidly insulated busbar and cable connections the medium voltage circuit is protected from environmental influences reducing the risk of arc flash events.

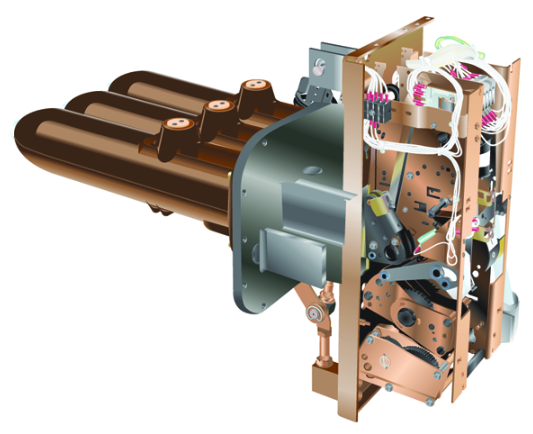

Each section consists of a sealed-for-life SF6 tank which contains the fixed SF range circuit breaker and disconnect switch. By design there is no gas handling throughout the service life of the equipment from installation until recycling at the end of life of the switchgear.

Front accessible and ideal for a variety of applications from transformer substations to primary power distribution in markets ranging from mining and metals renewable installations container substations and heavy industry where space is at a premium.

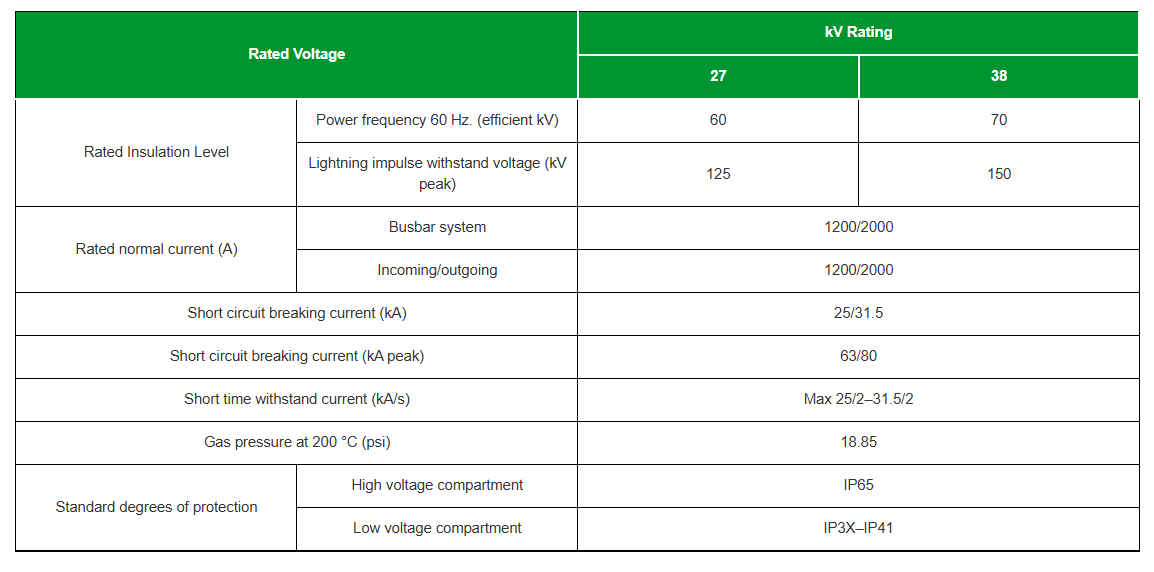

General Electrical Characteristics