| Brand | Rockwell |

| Model NO. | IMB Series HV outdoor current transformers |

| Rated voltage | 800kV |

| Series | IMB Series |

Overview

Main features

● The unique ‘filling’ composition of oil and quartz results in a compact design

● No oil change or filtration required as the expansion chamber / cooler is filled with Nitrogen (N2) / Metal bellows

● All external iron parts are MS painted for protection against detrimental effects of atmosphere and chemicals

● High seismic withstand capability in both vertical and horizontal directions

● Flexible design to meet special customer requirements such as low currents, high burden, creepage and high altitude

● All gaskets are below oil level ensuring positive oil sealing

Primary winding

The hairpin shaped conductor with graded insulation ensures uniform voltage distribution. The winding is insulated with special paper which has high mechanical and dielectric strength as well as low dielectric losses and good resistance to ageing.

Ratio selection is generally achieved through suitable secondary tapping in the secondary winding.

For ratios in multiples up to and including 1500 A (e.g. 1500-750, 1400-700, 1000-500-250, etc.) selection can also be achieved by a reconnectable primary winding. The primary winding is divided into equal parts, which can be connected in series or parallel by means of external links on the connection head.

The Short Time Current (STC) rating is as per series connection of primary winding (i.e. minimum cross section). With a parallel connection, the STC rating is therefore doubled.

The primary winding consists of a tube open at both ends allowing the oil to circulate. The heat losses are dissipated in the expansion chamber/cooler.

Tan Delta measuring terminal (D3/F terminal)

The outer shield of primary insulation is connected to a bushing in the secondary terminal box and earthed. This is designated as D3/F terminal.

This Tan Delta (D3/F) terminal must be earthed before the CT is charged.

Core

The Current Transformers can normally accommodate up to five cores. However more cores can also be provided on request. High-grade-silicon-steel CRGO is used for manufacture of cores. Stringent accuracy requirements of metering cores are achieved by using special cores made from nickel-iron alloy.

High grade enameled wires are used for winding secondary turns on the cores. They are evenly distributed across the periphery of the core, reducing leakage reactance to a minimum.

Tank & insulator

The lower portion of the CT consists of a aluminium or MS painted tank in which the cores are positioned around the straight limb primary winding. The upper portion of the transformer consists of high-grade brown glazed insulator made from porcelain or polymer. The gaskets are made of oil-proof material.

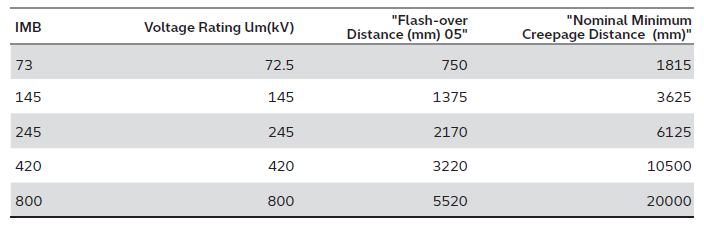

Technology paramete