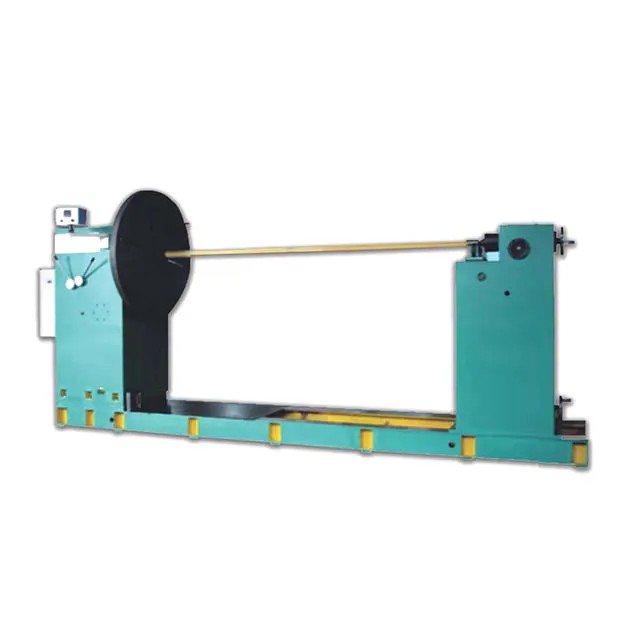

| Brand | Wone |

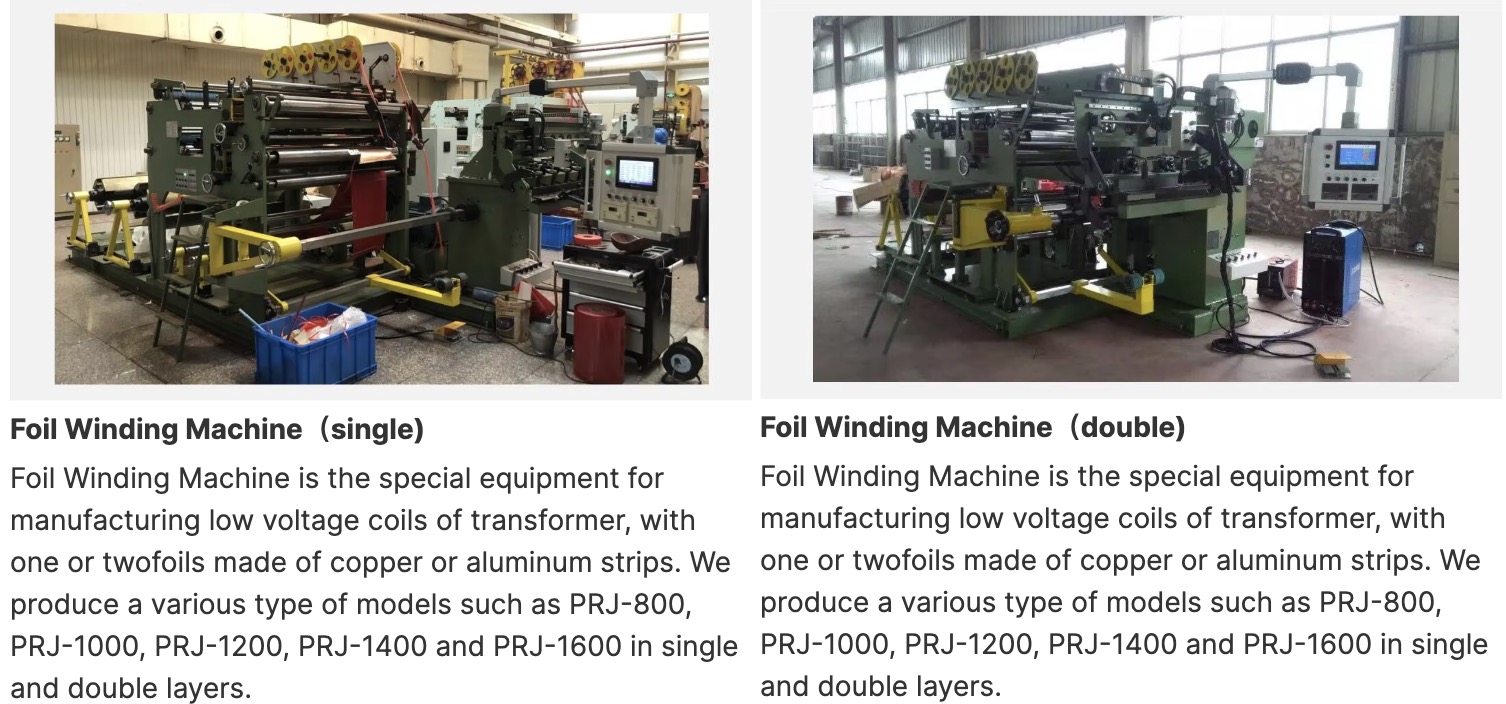

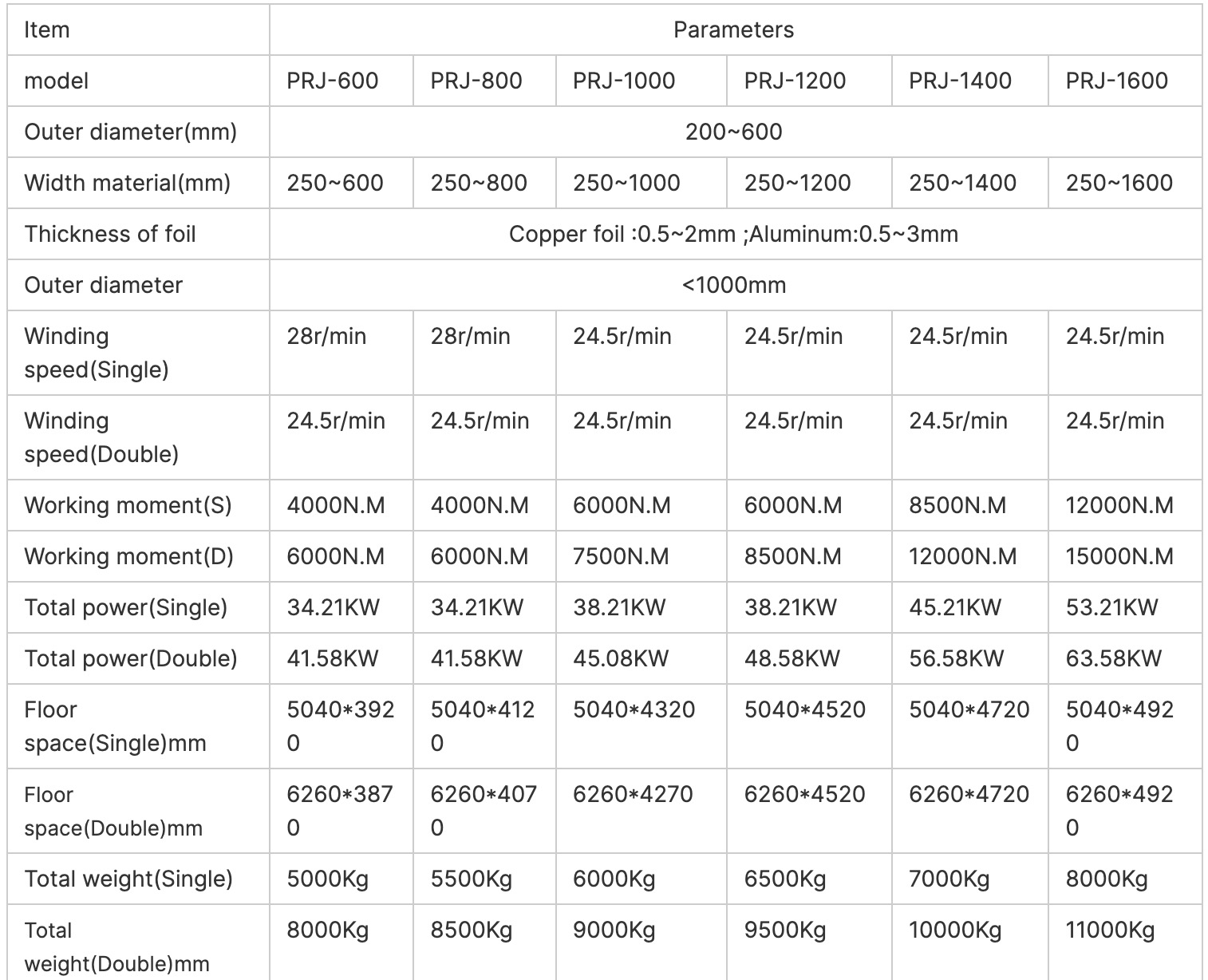

| Model NO. | PRJ double winding Copper Strip Foil Winding Machine for machinery industry |

| Outer diameter(mm) | 200~600mm |

| Width material(mm) | 250~1600mm |

| Thickness of foil | 0.5-3mm |

| Winding speed | 24.5r/min |

| Working moment | 15000N.M |

| Total power | 63.58KW |

| Volume Number | Double |

| Series | PRJ |

Description

The PRJ Foil Winding Machine is a foil coil winding system which is applicable for transformer and electrical industry. Foil coil is made of copper or aluminum foil of different thickness as conductor, with wide-band insulating material as layer insulation, and narrow-band insulating material as end insulation. The winding is completed by the foil winding machine and the coil is formed. Meanwhile, the welding of the inner and outer leads of the coil and binding of outer surface are completed. Double layer foil winding machine can be used to foil with narrow strips and winding into a wide foil coil or can support a thin foil strip with two layers of thick foil coil. It can provide enough support to produce foil coil conforming to the requirements of the specification with the functions of the equipment. This machine is a necessary equipment for production of such electrical products.

Composition

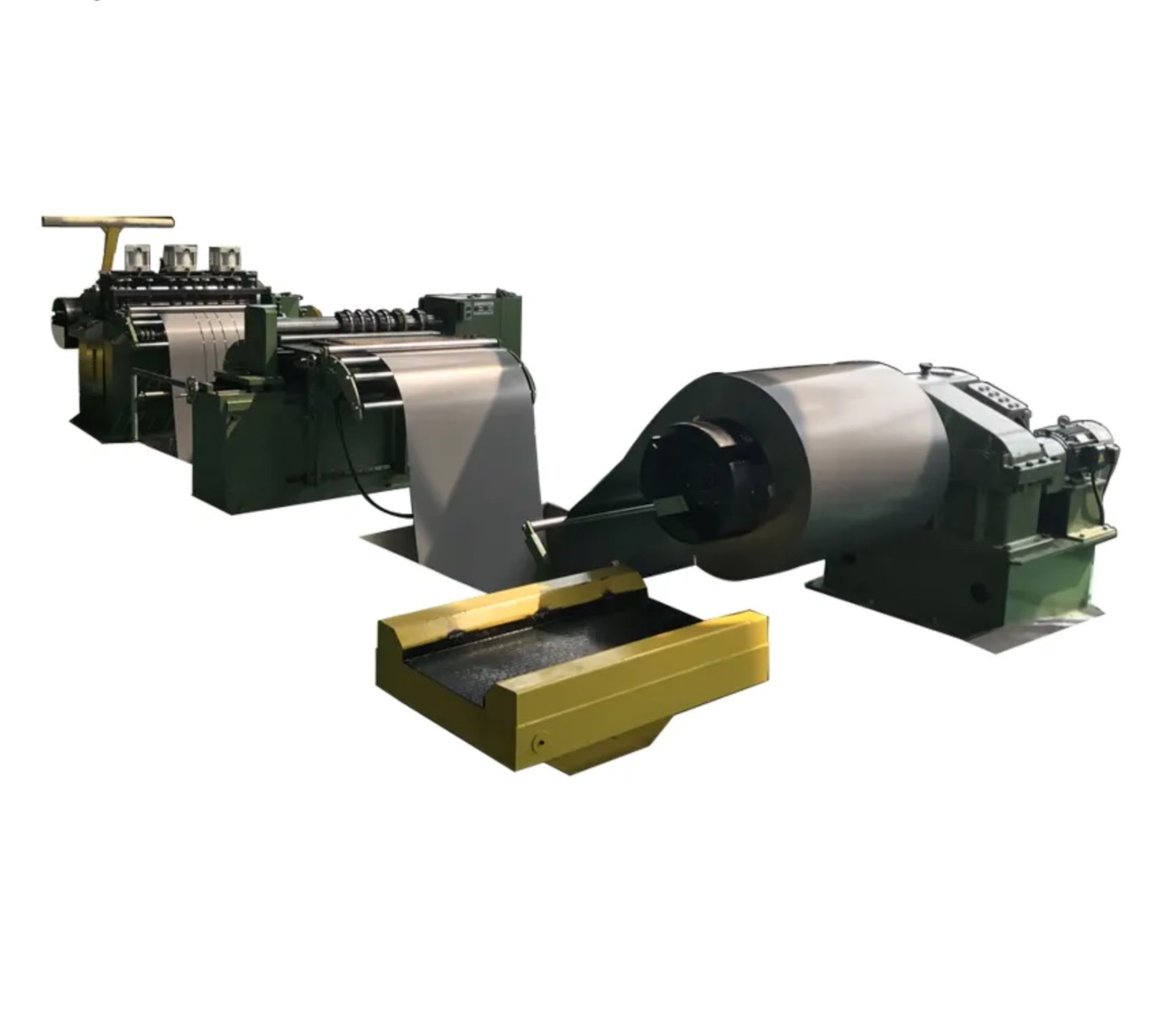

l● De-coiler of foil coil and foil offset regulating system

l● Foil edge burr remover and clean device

l● Foil feeding mechanism

l● Foil offset regulating sensing system

l● Electrical tensioning device

l● Foil sheet shearing unit

l● De-coiler for layer insulation

l● Layer insulation edge cutting mechanism

l● Welding unit

l● Foil winding system

l● End insulation strip wrapping system

l● Discharge trolley

l● Wound coil pressing device

l● Electrical control system

Specifications