| Brand | ROCKWILL |

| Model NO. | PQflexC Series Hybrid capacitor bank |

| Rated voltage | 400V |

| Mounting type | rackmounting |

| Rated capacity | 100kVA |

| Series | PQflexC Series |

Overview

Reactive power compensation

Stepless reactive power compensation for both inductive and capacitive loads, to meet a desired power factor PQflexC can perform precise stepless reactive power compensation of both inductive and capacitive loads. The target power factor is programmable from 0.6 (inductive) to 0.6 (capacitive) which makes PQflexC a superior alternative to a conventional capacitor bank. This also allows compensation of loads fed by generators without the risk of overcompensation.

Hybrid capacitor bank

An economic way of stepless power factor control Customers can set-up a capacitor bank with 1 PQflexC module and several capacitor steps1. This way, any capacitor bank with

steps can be converted into one that has ‘stepless behavior’ as the active part will smoothen out the step changes, when the rating of that PQflexC module (active part) is at least equal or bigger than the size of a single capacitor step (passive part).

Enhanced communication features

Wi-Fi enabled modules allow users to monitor and set parameters via smartphone or computer

The optional 7-inch user-friendly HMI interface offers direct access to the equipment control for parameters setting and system monitoring.

Comprehensive portfolio

The unique modularity feature of the PQflexC allows several combinations depending on the type of application. The modular units are available at 30 kvar, 75 kvar and 100 kvar in module, wall-mounted solution or a standalone cabinet.

PQflexC - M - Module

● Modular design: Suitable for OEMs, LV switchgear and drive manufacturers

● Very compact: Can be integrated into a small cubicle, either vertically or horizontally

● Low losses: Reduced losses and in-built forced air cooling

PQflexC - WM - Wall-mounted

● Distributed solution: For building applications where space restrictions exist

● Easy to install thanks to wall-mounting kit

● Silent solution: <65dBA, perfect solution for installing on office floors

PQflexC - C - Standalone cabinet

● Complete solution: Factory made fully functional tested panel

● A bank with several PQflexC modules, but without any capacitor steps

● A hybrid bank with 1 PQflexC module and several capacitor steps, where PQflexC will play the role of power factor controller to switch the steps of capacitor units

● Flexibility: Rating can be extended in modular way up to 300 kvar in single cabinet

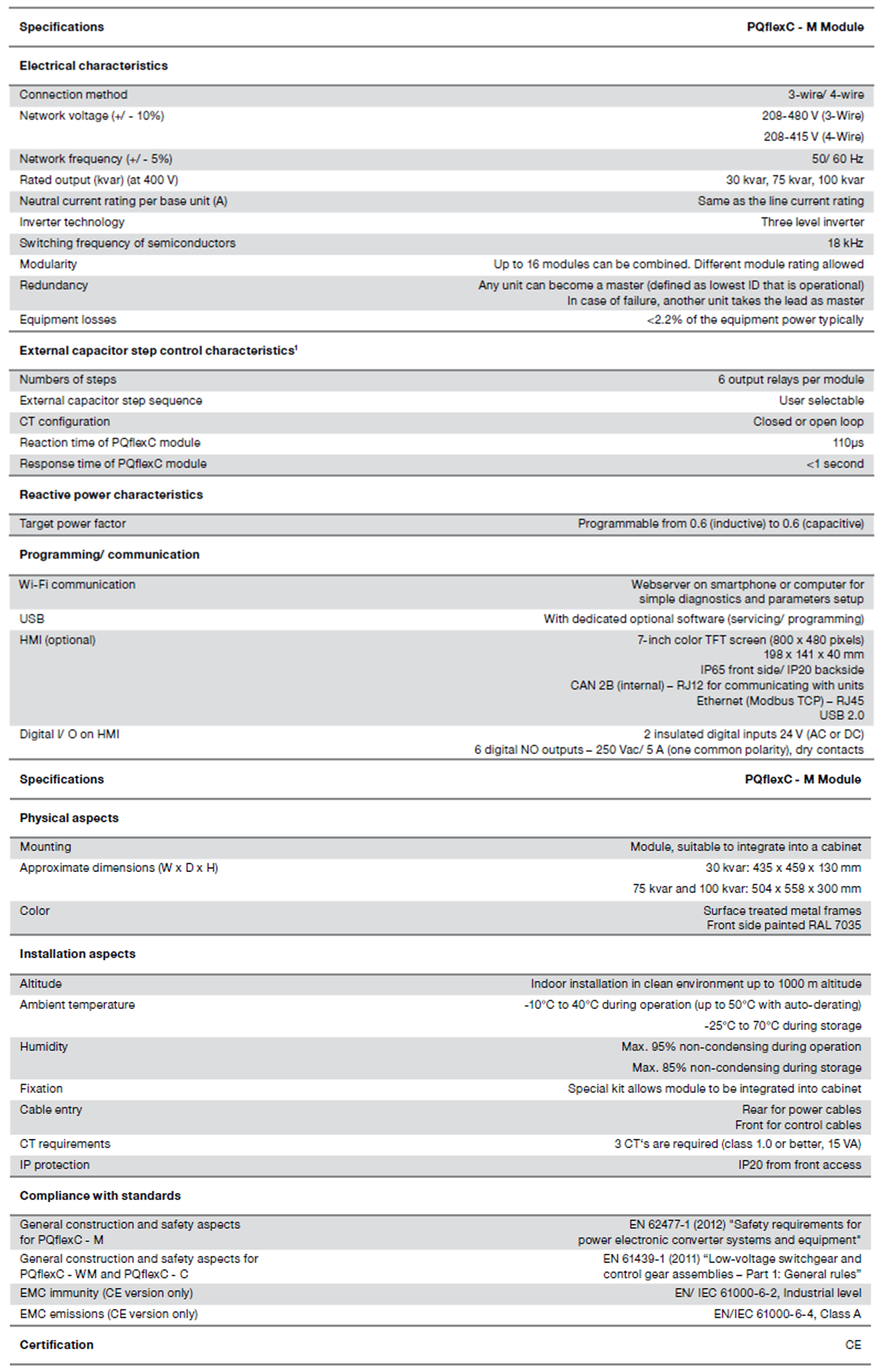

Technology parameters