| Brand | Wone |

| Model NO. | 40.5(72.5)kV Hybrid GIS |

| Rated voltage | 72.5kV |

| Rated normal current | 4000A |

| Rated frequency | 50/60Hz |

| Rated short circuit breaking current | 40kA |

| Series | ZHW58A-40.5(72.5) |

Product introduction:

ZHW58A series was originally designed to meet the needs of power construction and hybrid product development, and its main application scenario is to meet the needs of 35-500KV substation expansion; At present, ZHW58A-40.5/72.5 products have reached the leading level at home and abroad in terms of technical advancement and quality reliability.

Main characteristic:

Current transformers, isolation, grounding switch combination, compact, lightweight design, which can realize the whole transportation, save area, relative AlS station save covers an area of 70%, suitable for power plant and substation construction, expansion or reconstruction project and railway electrification construction, especially suitable for old substation upgrading, reduce the construction difficulty and investment scale.

CT is arranged on two sides of the circuit breaker (different from the structure of mainstream manufacturer’s' similar products, complying with the requirement "blind area of main protection shall be avoided in the configuration of protective current transformer and the allocation of secondary winding" as specified in the Technical specifications of Relay Protection and Safety Automatic Device, improving the reliability of power supply.

The product also adopts straight-through CT, completely solving problems such as excess moisture and low insulation margin and promoting the insulation resistance and reliability of the product.

The product is configured with a grounding switch on equipment side and line side in a built-in way, with reliable earthing that prevents safety hazards in maintenance.

The circuit breaker adopts light-spring operating mechanism and aluminum frame of integral casting. It’s closing-opening springs adopt spiral dual-pressure spring, with a compact and indefatigable structure, realizing a mechanical life of 10000compressions.

Aviation plugs are used to connect CB, DES & ES mechanism cases and control cabinet, facilitating field installation and commissioning.

The structure of three-position disconnecting/grounding switch is stable and reliable.

The inlet and outlet lines are connected to the equipment through bushings. Composite insulation bushings and porcelain bushings can be selected., Compared with GlS equipment, the enclosed bushings are omitted, and theSF6 gas consumption is less (less than 50% of GiS consumption), which is green and economical.

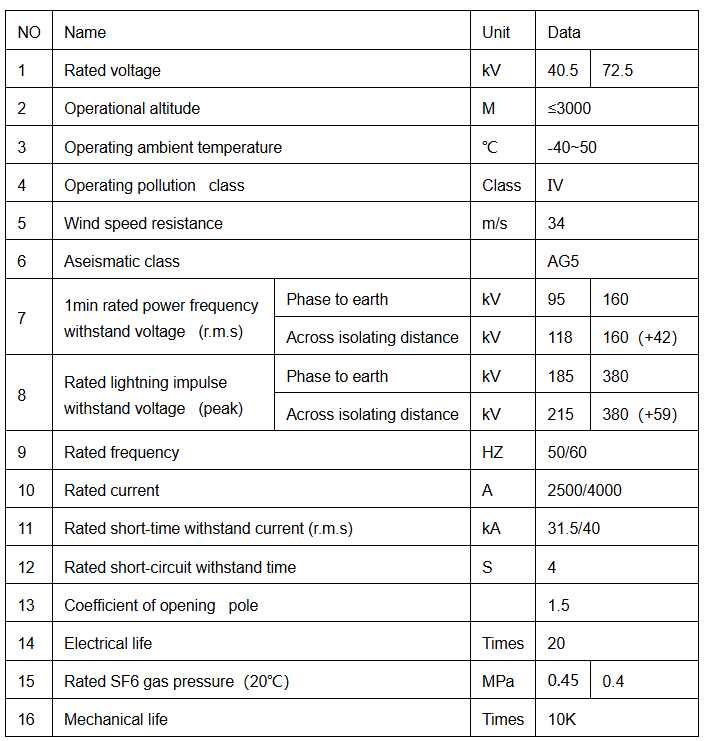

Main technical parameters:

Order Notice:

Application working condition (incoming/outgoing line, main transformer or PT interval);

Rated electrical parameters (voltage, current, breaking current and so on);

Conditions of use environment (ambient temperature, altitude and class of environmental pollution);

Control voltage of operating mechanism and motor voltage;

Quantity. current ratio, grade combination and secondary load of current transformer;

Name and quantity of spare products, spare parts & special tools and equipment (to be ordered separately).

What are the structural characteristics of hybrid high-voltage gas-insulated switchgear?

Hybrid Gas Insulation System:

Typically, a mixture of SF₆ and other gases (such as N₂, CF₄, etc.) is used as the insulating medium. This design aims to combine the properties of different gases. For example, SF₆ has excellent insulating and arc-quenching properties but poses environmental concerns due to its greenhouse effect. By mixing it with other gases, the amount of SF₆ can be reduced while maintaining good insulation performance. The insulation system consists of sealed gas compartments that enclose the high-voltage conductive parts, preventing contact with the external environment and ensuring reliable electrical insulation.

Compact Design Layout:

To fully utilize the insulating properties of the hybrid gas, the internal structure of the equipment is designed to be compact. Various components of the switchgear, such as circuit breakers, disconnect switches, earthing switches, and busbars, are carefully arranged to minimize the overall size of the equipment. For example, compact circuit breaker designs and optimized busbar layouts enable efficient electrical connections and functional integration within a limited space.

Reliable Sealing Structure:

To ensure good insulation performance, the hybrid gas must be maintained at specific pressure and purity levels. Therefore, the equipment features highly reliable sealing structures. High-quality sealing materials (such as rubber O-rings, metal gaskets, etc.) and sealing techniques are used to ensure the airtightness of the gas compartments and prevent gas leakage. Additionally, the sealing structure must withstand temperature changes, mechanical vibrations, and other factors, maintaining stable sealing performance over the long term.