Thermal power remains vital in the global energy mix, yet traditional systems face challenges of high energy consumption and emissions, requiring innovation for greener operations. High-voltage inverters, by regulating motor speed, offer an effective solution for energy efficiency and emission reduction in power plants.

1 Overview of High-Voltage Inverters

High-voltage inverters control high-voltage motors and transformers by adjusting frequency, enabling energy savings, improved efficiency, and extended equipment life. The system, comprising inverters, circuit breakers, disconnect switches, and transistors, operates cohesively for stable performance. The inverter, as the core, dynamically adjusts voltage and frequency to match load demands, optimizing operation. This reduces energy use and minimizes damage from frequent starts or overloads, prolonging equipment life.

Circuit breakers protect against overloads and short circuits; disconnect switches ensure safety during maintenance. Transistors enable precise current control, enhancing operational accuracy. These reliable components support the widespread use of high-voltage inverters in power, oil, chemical, and metallurgy industries for driving fans, pumps, and compressors efficiently.

2 Application Value in Thermal Power Generation

2.1 Improving Boiler Efficiency

Boilers, central to energy conversion, directly impact plant efficiency and emissions. High-voltage inverters enhance boiler performance by enabling stepless speed control of feedwater pumps, forced draft, and induced draft fans. This allows dynamic adjustment based on load and combustion needs, maintaining optimal water, air, and flue gas flow. Precise control reduces energy waste from over-supply and prevents incomplete combustion due to insufficient air, boosting thermal efficiency and stability. It also reduces mechanical wear and vibration, extending equipment life and lowering maintenance costs.

2.2 Reducing Turbine Thermal Losses

Steam turbines are crucial for power conversion, but thermal losses reduce efficiency and increase costs. High-voltage inverters mitigate this by precisely managing steam intake and speed regulation. Unlike fixed valve control, inverters adjust steam flow in real time to match load demands, keeping turbines in peak efficiency zones. They also smooth speed transitions during startup, shutdown, and load changes, reducing energy waste and mechanical stress, thereby improving reliability and economic performance.

2.3 Reducing Plant Power Consumption

Auxiliary equipment like pumps and fans consume significant plant power, affecting net output and economics. High-voltage inverters reduce this by enabling stepless motor speed control, adjusting power to actual load needs. This avoids the "oversized motor" issue, cutting energy use. For example, inverters on cooling pumps and fans adjust flow based on demand, minimizing waste. They also enhance auxiliary equipment efficiency, reduce wear from fluctuations, extend life, and lower maintenance and downtime costs.

3 Specific Applications in Thermal Power

3.1 In Boiler Systems

Beyond basic speed control, high-voltage inverters support advanced boiler optimization. Integrated with sensors and data analytics, they enable intelligent combustion control by monitoring flame temperature, flue gas, and oxygen levels, adjusting fuel and air for peak efficiency and low emissions of NOx and SOx.

They also improve load-following capability. Using predictive algorithms, inverters adjust boiler output in anticipation of grid demand, enhancing flexibility and reducing losses from load swings. Deep integration with DCS and SIS enables coordinated control with turbines and generators, optimizing overall plant efficiency and response through data sharing and unified scheduling, supporting intelligent and efficient plant transformation.

3.2 In Condensate Pump Systems

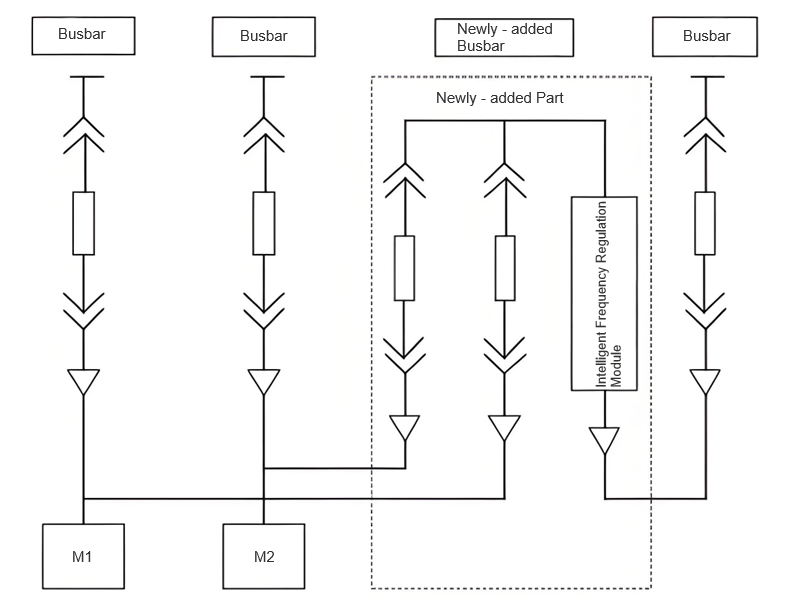

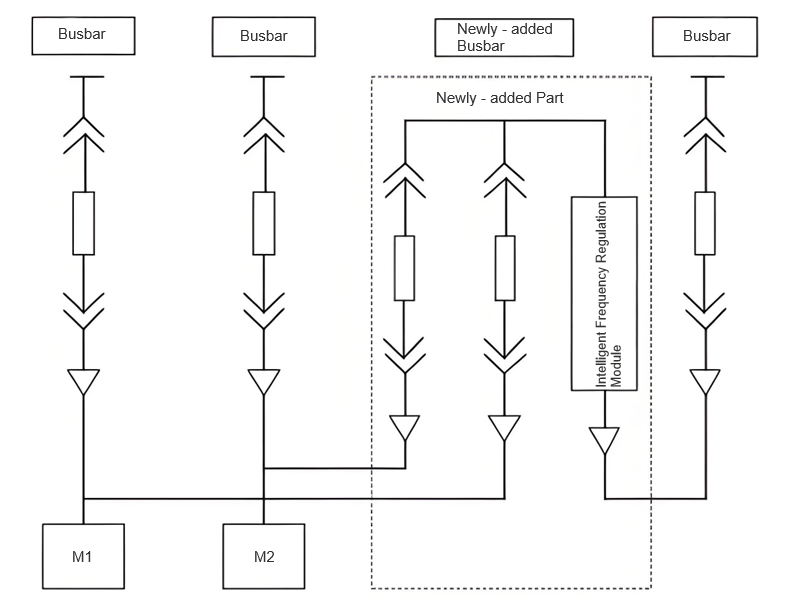

Traditional condensate pumps run at fixed speeds, wasting energy. High-voltage inverters solve this by enabling precise speed control based on condensate flow (Fig. 1). Pumps slow down at low loads to save energy and speed up at high loads to maintain supply, ensuring stability.

The system monitors motor temperature, current, and voltage in real time, using built-in protection to prevent overloads and faults, extending equipment life. Integration with boiler and turbine controls optimizes the steam-water cycle, maximizing efficiency. Remote monitoring and fault diagnostics allow early detection of issues, preventing unplanned outages. Data analysis further optimizes operations, uncovering additional energy savings and improving economic performance.

3.3 Application of High-Voltage Inverters in Dust Removal Systems

The application of high-voltage inverters in dust removal systems offers a new solution for improving environmental performance and energy efficiency in thermal power plants. With flexible speed control, intelligent coordination, and significant environmental benefits, high-voltage inverters are becoming a key choice for upgrading and optimizing dust removal systems.

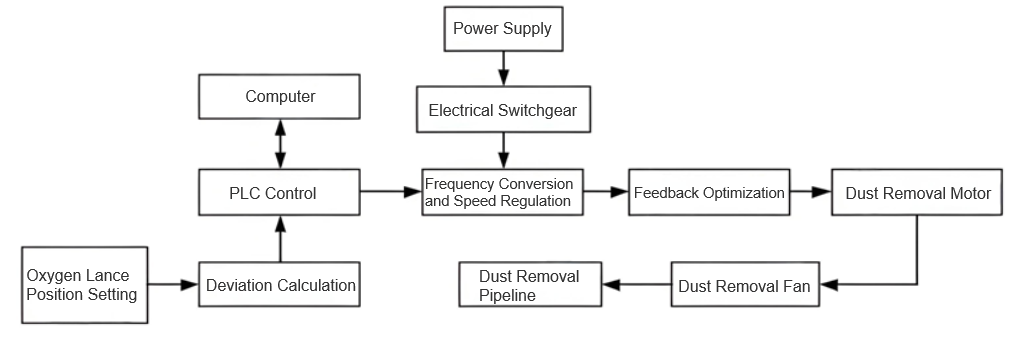

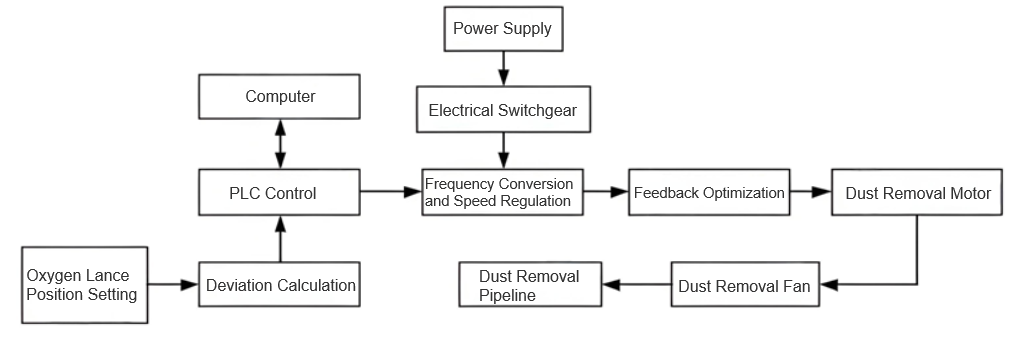

Specifically, the high-voltage inverter control process in a power plant’s dust removal system includes key steps such as lance position setting, deviation calculation, PLC control, variable frequency speed regulation, and feedback optimization, as shown in Figure 2. The position of the oxygen lance is critical to dust removal efficiency. Traditional methods use fixed settings, unable to adjust in real time based on flue gas composition and dust removal performance. In contrast, high-voltage inverters integrate high-precision sensors to monitor dust concentration and oxygen content in flue gas in real time, dynamically calculating the optimal lance position using preset algorithms. In this process, the inverter not only drives motor speed control but also participates in closed-loop feedback for position adjustment, ensuring precise and rapid response to positioning commands.

The programmable logic controller (PLC), as the core control unit, coordinates the operation of all system components. The tight integration between the high-voltage inverter and the PLC enables fine-grained control of each part of the dust removal system. By receiving control signals from the PLC, the inverter precisely adjusts the speed of the dust removal fan to match the current flue gas flow and dust concentration. This real-time data-driven speed control strategy improves dust removal efficiency while avoiding energy waste and equipment wear caused by excessive blowing.

The application of high-voltage inverters extends beyond simple speed control, enabling continuous optimization of control strategies through feedback mechanisms. By monitoring key indicators such as dust emission concentration and flue gas transparency in real time, the inverter automatically adjusts control parameters based on feedback data, achieving adaptive regulation. This ongoing optimization significantly enhances system stability and reliability while reducing operational and maintenance costs.

4 Conclusion

In summary, the widespread application of high-voltage inverters in thermal power generation—spanning intelligent boiler management, efficient condensate pump control, and environmentally optimized dust removal—demonstrates their significant potential and value. Through precise speed regulation, intelligent system optimization, and real-time feedback control, high-voltage inverters not only substantially improve energy efficiency and environmental performance but also enhance system flexibility and stability, providing solid technical support for the continuous, efficient, and safe operation of power plants.